Large-size sapphire substrate multi-spectral hard antireflection film and preparation method thereof

A sapphire substrate and anti-reflection coating technology, which is applied in optics, optical components, ion implantation plating, etc., can solve problems such as failure of the sapphire window film layer, improve the optical performance and mechanical and physical properties of the film layer, and minimize the overall stress , Ease of transplantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A hard anti-reflection coating for large-scale sapphire window visible light / laser / infrared three-band:

[0045] Size 350mm×310mm×7mm; technical requirements are as follows:

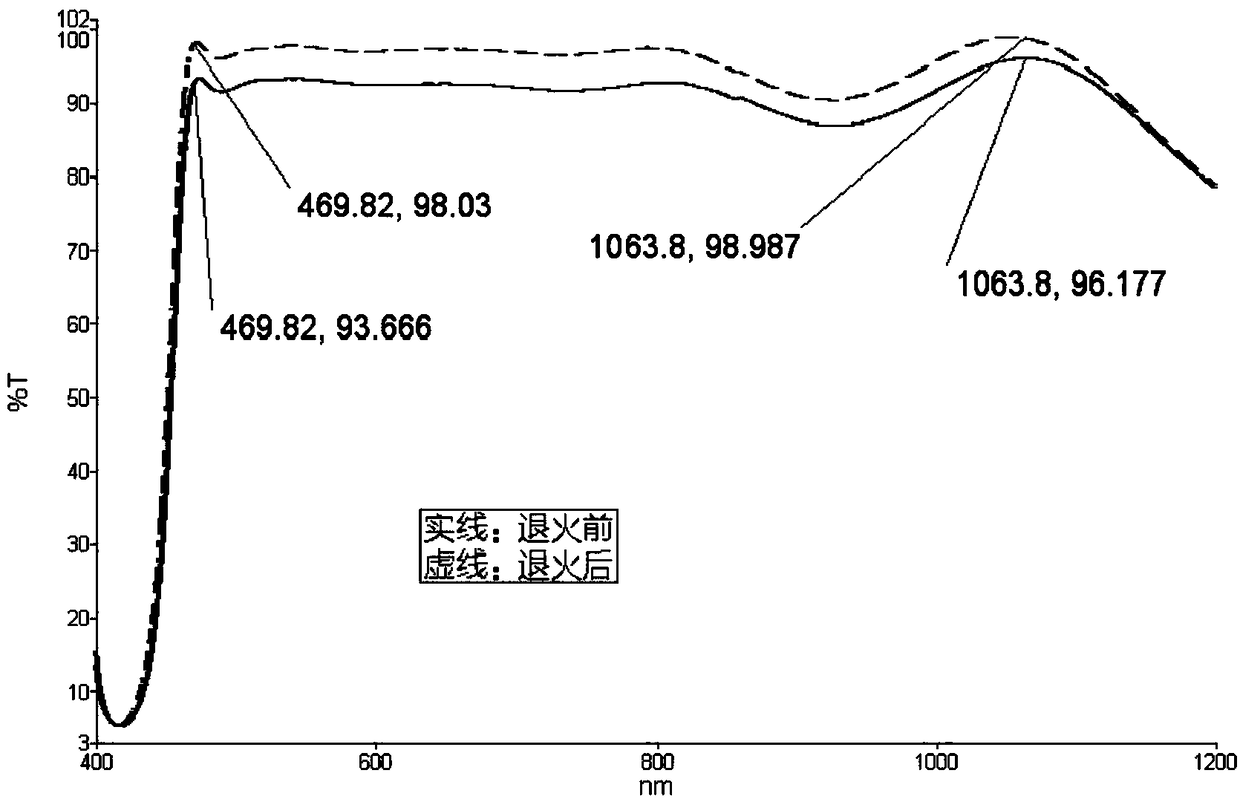

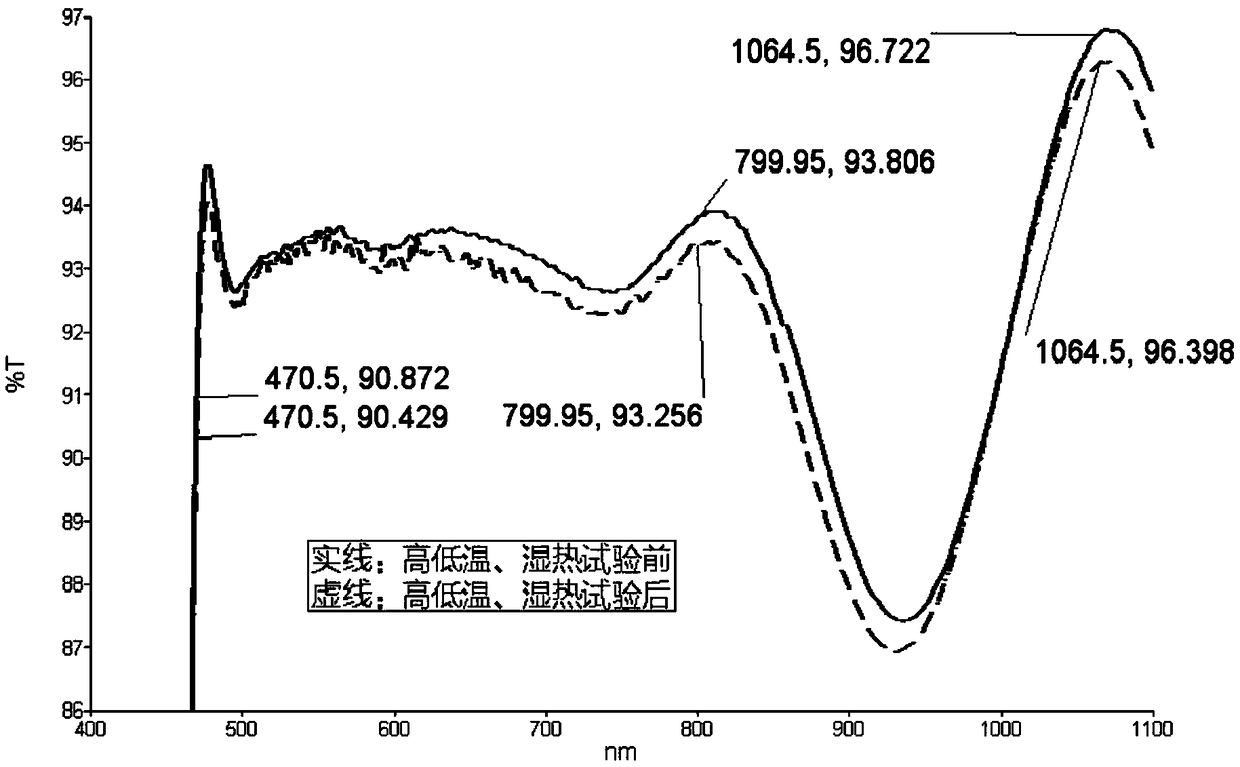

[0046] T avg ≥95%@470nm-800nm, AOI=0-150 (the same below);

[0047] T≥98.5%@1064nm±20nm;

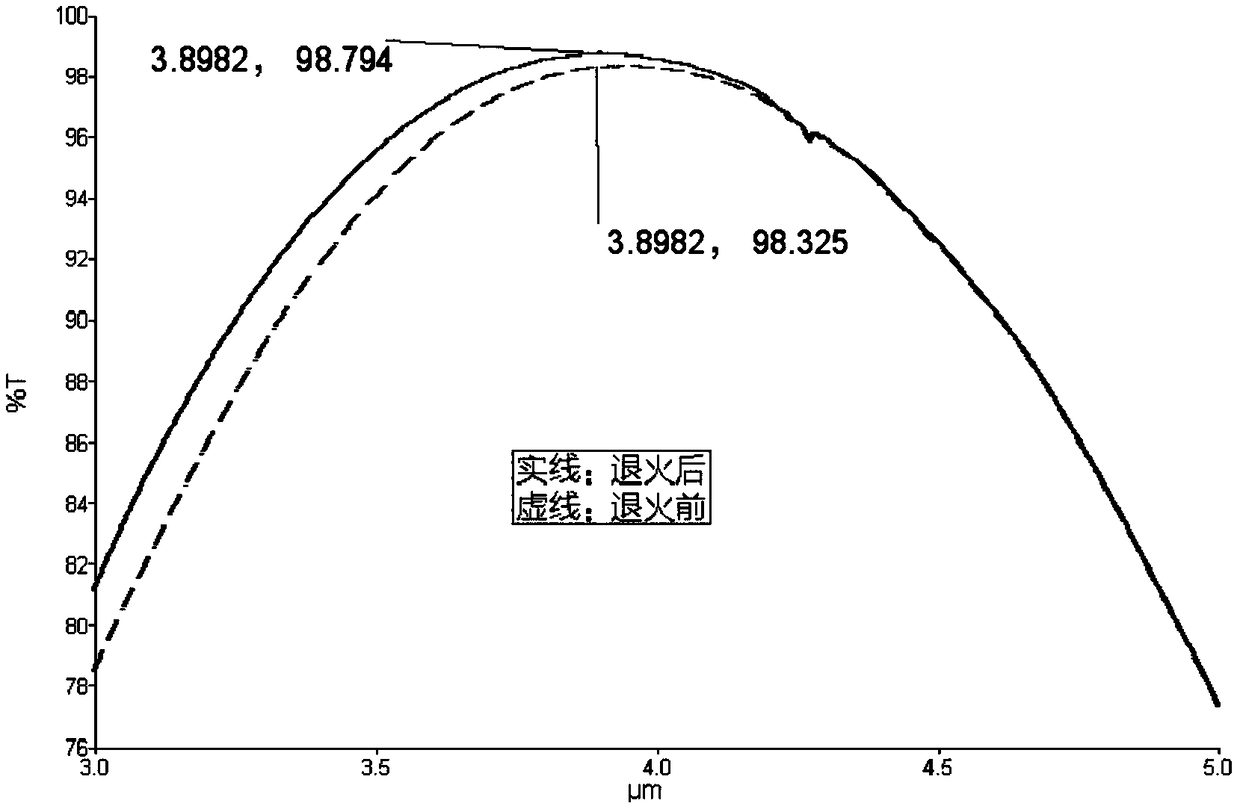

[0048] T avg ≥95%@3.5um-4.4um, T avg ≥92%@3.5um-4.8um;

[0049] Uniformity of optical properties of large-area film formation: within ±2%;

[0050] The coating samples passed the high / low temperature, constant humidity and heat, salt spray, adhesion test and severe friction test specified in GJB2485-95 at one time, and the optical performance before and after the environmental test can still meet the requirements of optical technical indicators.

[0051] First of all, according to the above technical requirements, the optimal design of the film structure is carried out, and the results are as follows:

[0052] Sub|aM / bH / cL / dH / eL / fH / gL / hH / iL / jH / kL / lH / mL / nP / Air

[0053] Among them, M is the stress matc...

Embodiment 2

[0068] Oxide film layer stress test method and result

[0069] G.G.Stoney et al first carried out quantitative research on film stress, and formed the Stoney formula for calculating film stress. On this basis, other researchers have successively proposed calculation methods such as four-step phase shift method, ZYGO interferometer method, step meter method, Moiré fringe method and Newton ring method. Among them, the ZYGO interferometer method has the advantages of high measurement accuracy, simple and convenient operation, etc., and has been widely used in the study of thin film stress in recent years. The testing method of film stress in the present invention is the ZYGO interferometer method adopted. The Stoney formula for membrane stress is as follows:

[0070]

[0071] Among them, E s is the Young's modulus of elasticity of the substrate, υ s is the Poisson’s ratio of the substrate, t s is the substrate thickness, t f is the film thickness; R 0 and R are the curv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Physical thickness | aaaaa | aaaaa |

| Physical thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com