Heat exchanger made of aluminum alloy and method of producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0126]An aluminum alloy having a composition shown in Table 1 was cast from molten alloy for constituting tubes, and aluminum alloy having a composition shown in Table 2 was cast from a molten alloy for constituting fins. For constituting header pipes, an aluminum alloy for core material, an aluminum alloy for sacrificial corrosion protection material, and an aluminum alloy for brazing material, each having a composition as shown in Table 3 were cast from molten alloys.

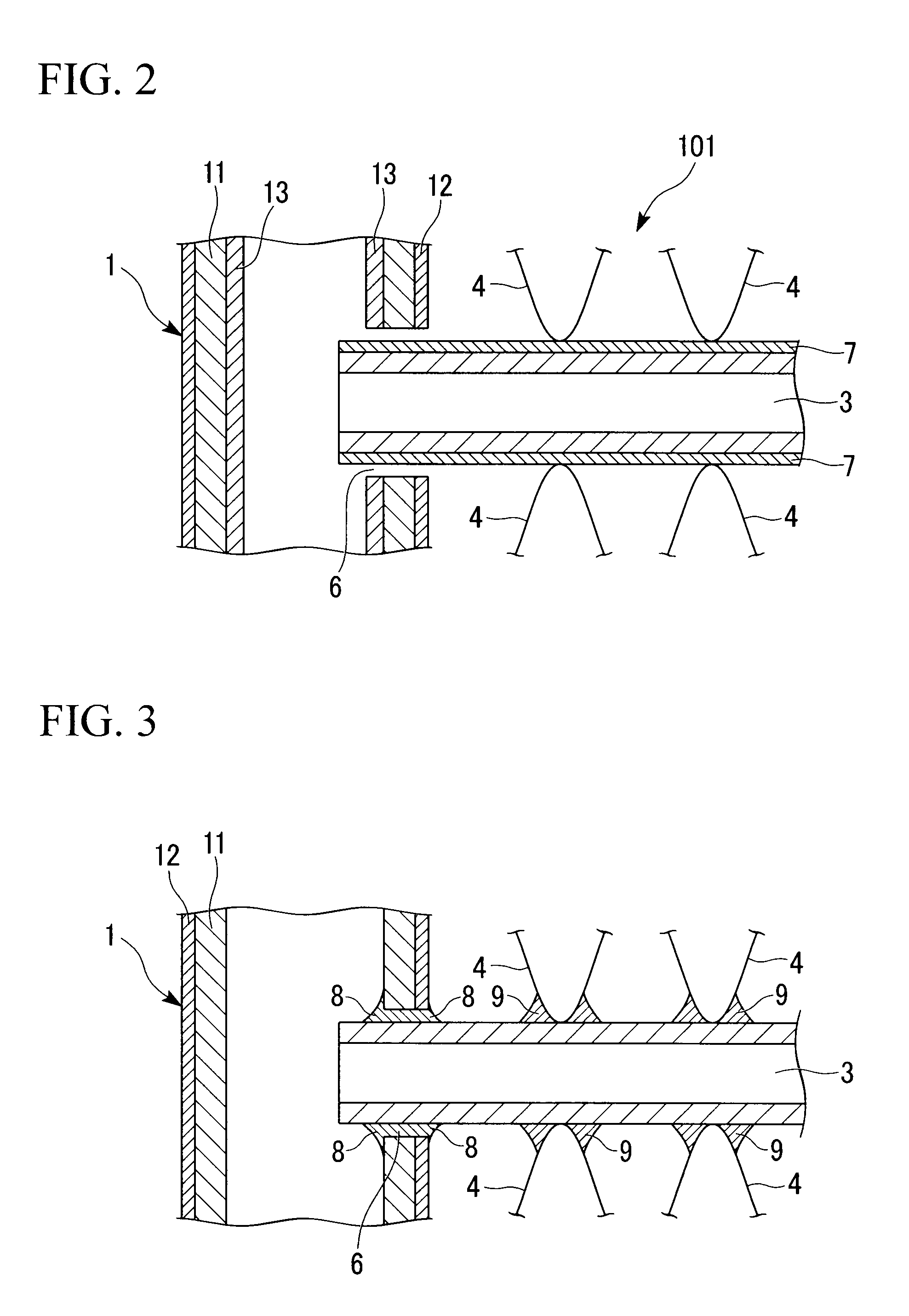

[0127]The aluminum alloy for a tube was subjected to heat treatment for homogenization, and was subsequently subjected to hot extrusion so as to have a shapes as shown in transversal cross section in FIG. 4 and FIG. 6A. In the tube shown in FIG. 4, the wall thickness was 0.30 mm, the width was 18.0 mm, the total thickness was 1.5 mm, the height of flat face of the side surface was 0.6 mm, and the curvature radius of the corner portion was 0.45 mm. In the tube shown in FIG. 6A, the wall thickness was 0.30 mm, the width...

example 2

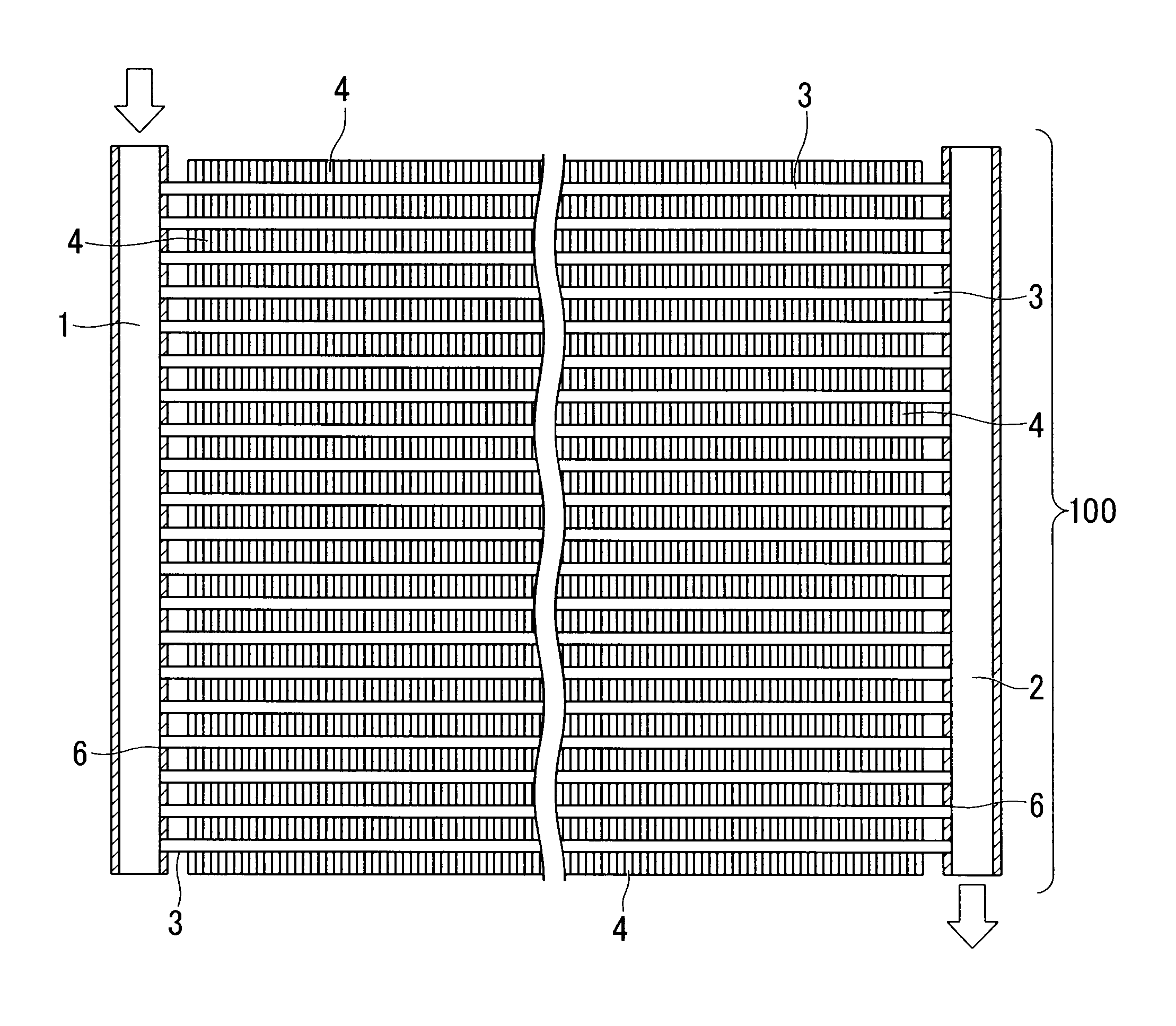

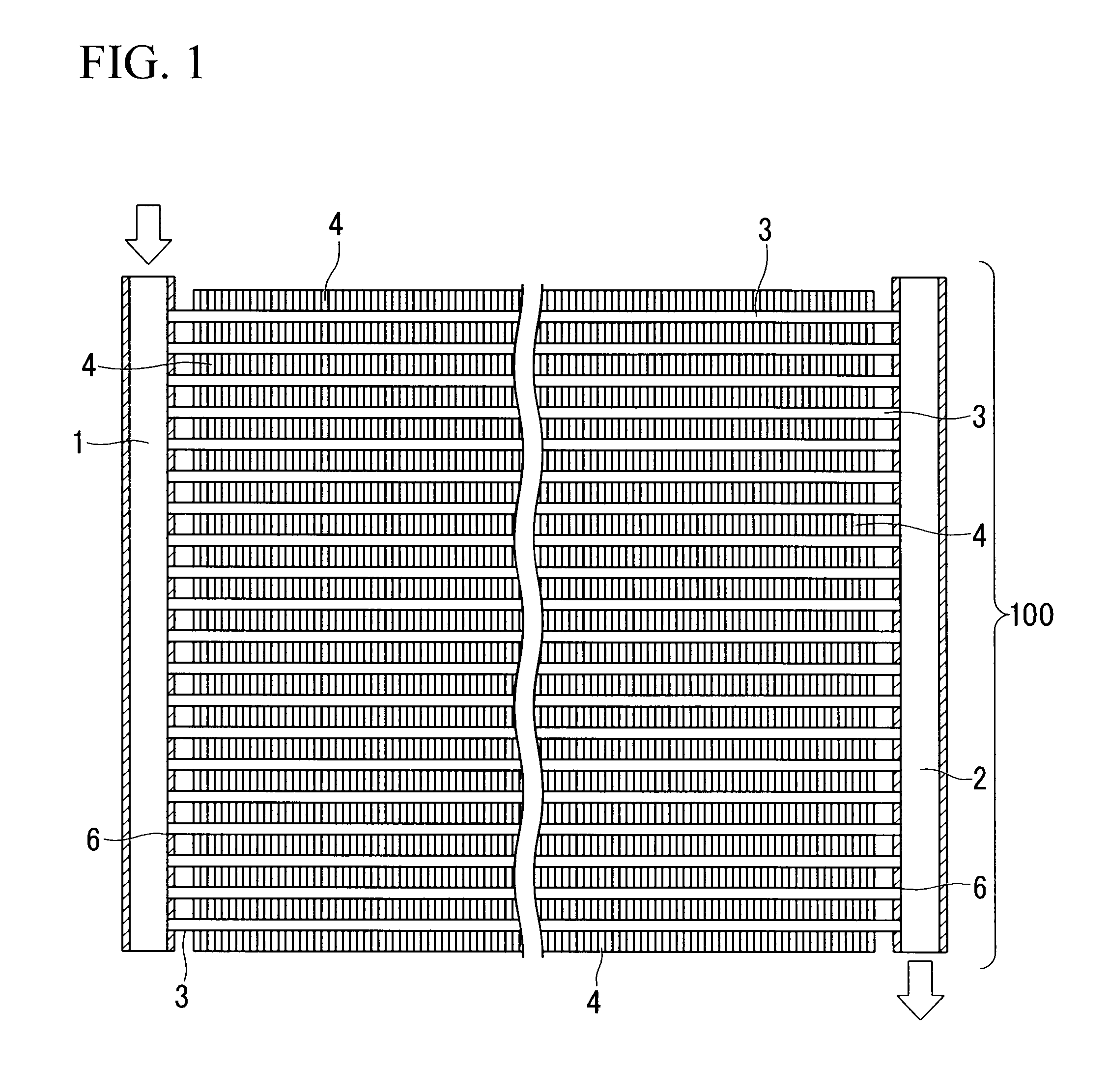

[0148]Heat exchangers 100 were produced in the same manner as in Example 1, while the tubes were made of aluminum alloy having a composition shown in Table 5. The depth of corrosion in the tube 3 and the residual ratio of fins 4 were examined in the same manner as in Example 1. The results are shown in Table 5. In this case, brazing composition of No. 4 shown in Table 4 was applied as a coating composition.

TABLE 5Fin-tubeCorrosionResidualMnSijoint ratiodepth of tuberatio of finsTube(mass %)(mass %)Al(%)(μm)(%)Remark240.130.35balance9511580250.210.35balance967578260.300.35balance947276270.390.35balance957072280.470.35balance957273Excessive Mn,ReducedExtrudability290.300.15balance9610278300.300.26balance967275310.300.44balance957570320.300.52balance957572Excessive silicon,ReducedExtrudability

[0149]As shown in Table 5, the corrosion resistance of the tube 3 and the residual ratio of fins 4 vary depending on the Mn content and the Si content of the tube 3. Therefore, preferable contents...

example 3

[0150]Heat exchangers 100 were produced in a same manner as in Example 1, while the fins were made of aluminum alloy having a composition shown in Table 6. The depth of corrosion in the tube 3 and the residual ratio of fins 4 were examined in the same manner as in Example 1. The results are shown in Table 6. In this case, a brazing composition of No. 4 shown in Table 4 was applied as the coating composition.

TABLE 6Fin-tubeCorrosionResidualjointdepth ofration ofZnSiFeMnZrVCrratiotubefinsFin(mass %)(mass %)(mass %)(mass %)(mass %)(mass %)(mass %)(%)(μm)(%)Remark331.10.950.51.20.130.050.059510592341.30.950.51.20.13—0.05967574351.50.950.51.20.130.05—947078361.70.950.51.2—0.050.05957176372.00.950.51.20.13——959260381.50.60.51.20.13——9611361391.50.80.51.20.130.050.05967575401.51.10.51.20.130.050.05957378411.51.250.51.20.13——959060421.50.950.251.20.13——9410760431.50.950.411.20.130.050.05957280441.50.950.691.20.130.050.05967581451.50.950.851.20.13——948560461.50.950.50.850.130.050.05951057247...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com