Vacuum brazing solder and process of Mo-Cu alloy and stainless steel

A molybdenum-copper alloy and brazing technology, applied in metal processing equipment, welding/cutting medium/material, welding equipment, etc., can solve the problems of long holding time, wide melting temperature range, unfavorable welding production efficiency, etc. Density, short melting time, and the effect of expanding the solid solution limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

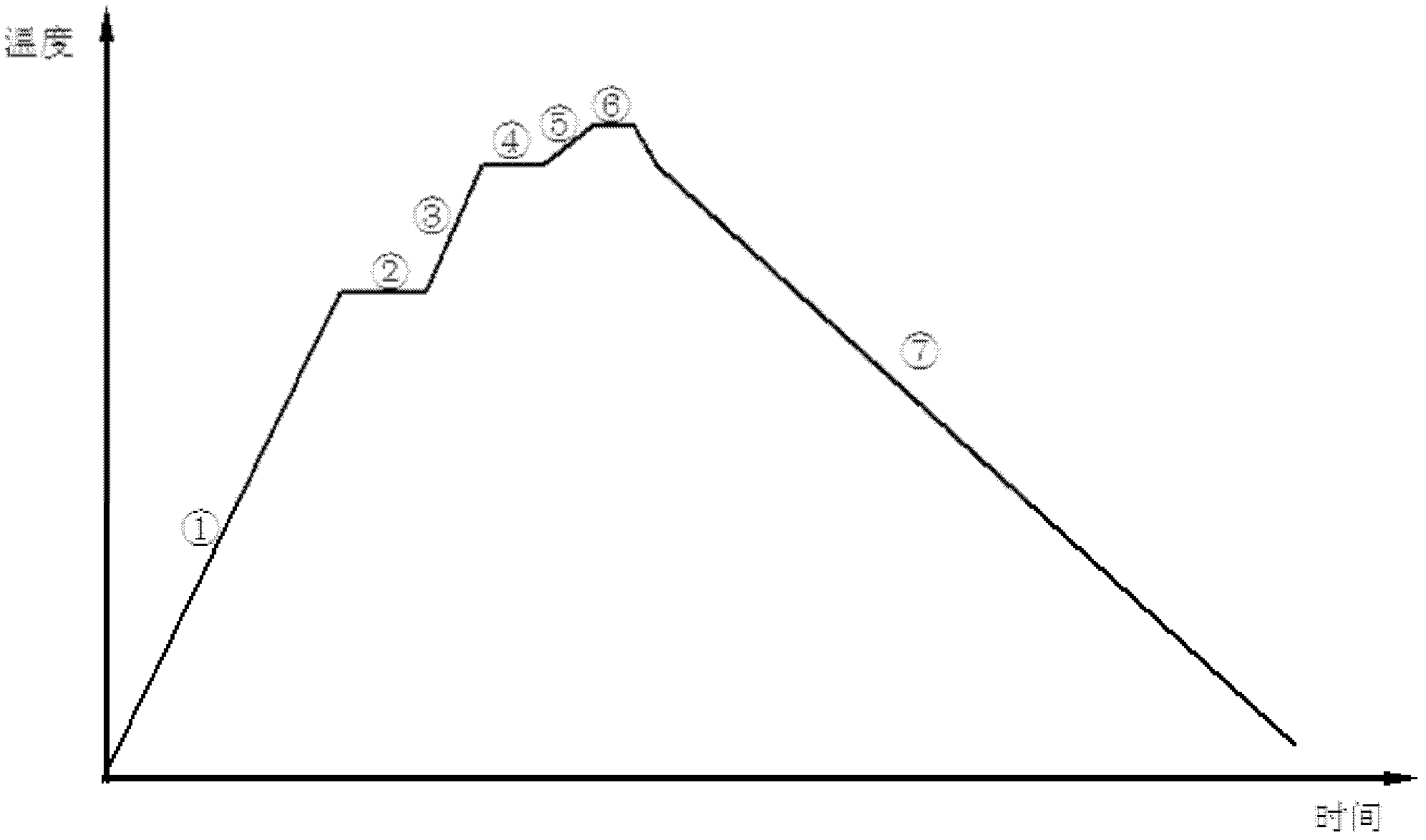

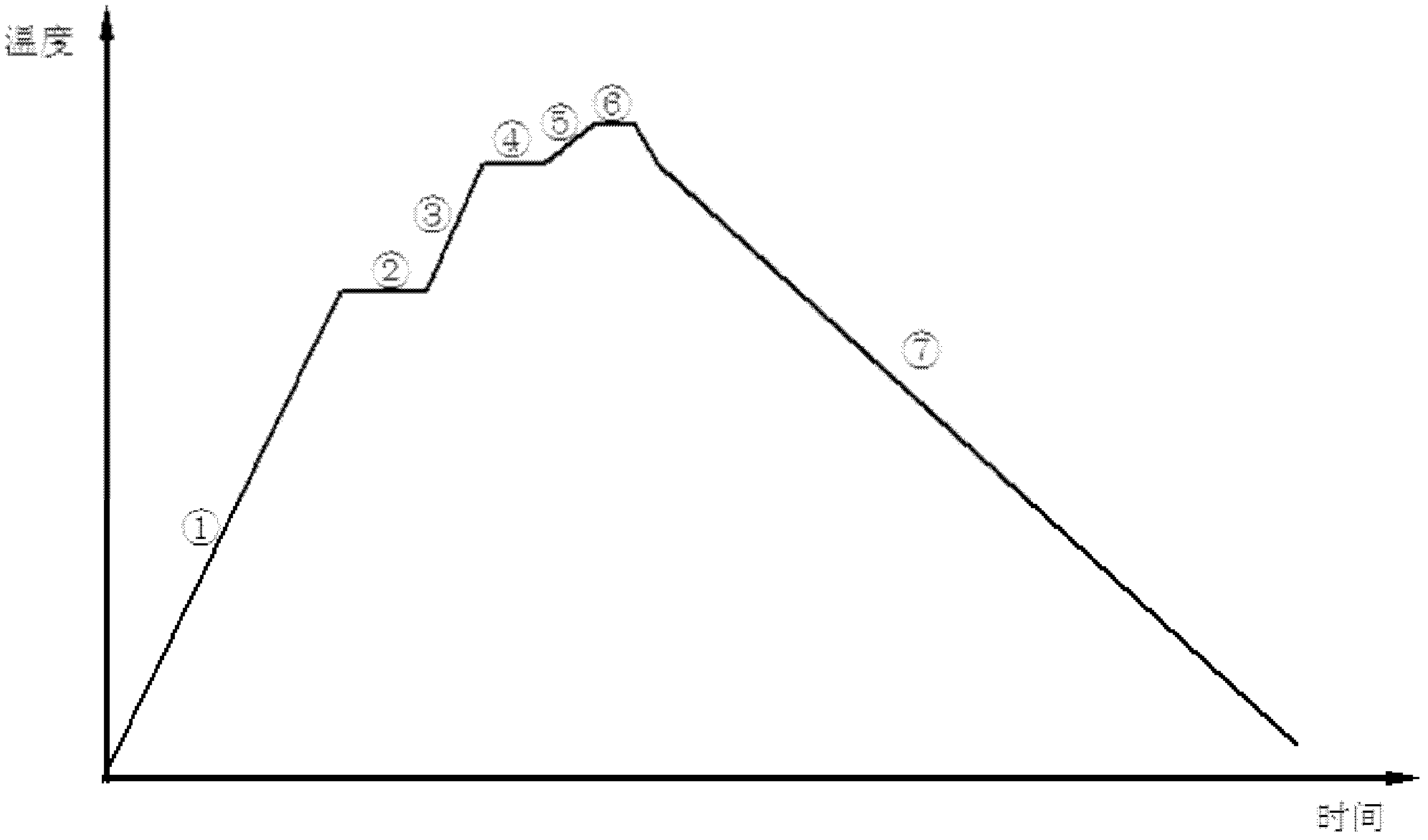

Method used

Image

Examples

Embodiment 1

[0029] Vacuum brazing of molybdenum-copper alloy plate and 1Cr8Ni9Ti austenitic stainless steel butt joint, molybdenum-copper alloy composition is Mo60%-Cu40% (mass fraction), size is 30mm×8mm, thickness is 2.5mm; austenitic stainless steel is 1Cr8Ni9Ti stainless steel , with a size of 30mm×10mm and a thickness of 3.0mm.

[0030] The first step, surface treatment of molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel:

[0031] First, polish the surface of molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel with 800# SiC sandpaper to remove the oxide film on the surface;

[0032] Then put it into acetone, ultrasonically clean it for 30 minutes, take it out and dry it for later use.

[0033] The second step, the assembly of molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel:

[0034] Foil-shaped BNi2 amorphous alloy solder (chemical composition is: Cr 6.5%, Si 5.0%, B 2.7%, Fe 3.5%, C≤0.02%, Ni balance, in mass percent) with a thickness of 50 μm It is placed between th...

Embodiment 2

[0047] Vacuum brazing of lap joints between molybdenum-copper alloy plates and stainless steel plates, the molybdenum-copper alloy composition is Mo50%-Cu50% (mass fraction), the size is 30mm×8mm, and the thickness is 2.5mm; the austenitic stainless steel is 1Cr8Ni9Ti stainless steel, the size It is 30mm×10mm and the thickness is 3.0mm.

[0048] The first step, surface treatment of molybdenum copper alloy and stainless steel:

[0049] First, polish the surface of molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel with 800# SiC sandpaper to remove the oxide film on the surface;

[0050] Then put it in acetone and ultrasonically clean it for 25 minutes, and dry it with hot air.

[0051] The second step, the assembly of molybdenum copper alloy and stainless steel:

[0052] Foil-shaped BNi2 amorphous alloy solder (chemical composition is: Cr 7.5%, Si 3.0%, B 3.5%, Fe 2.5%, C≤0.02%, Ni balance, in mass percent) with a thickness of 70 μm It is placed between the pretreated mol...

Embodiment 3

[0065] The steps are the same as in Example 1, except that the mass percentage of the BNi2 amorphous alloy solder is composed of: Cr 6.8%, Si 3.8%, B 2.9%, Fe 3.1%, C≤0.02%, Ni balance.

[0066] The obtained molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel butt brazing joints have beautiful appearance, and the solder has good wettability to the surface of the molybdenum-copper alloy and 1Cr8Ni9Ti stainless steel. No defects such as microscopic cracks and inclusions were found through metallographic microscope observation. The interface of the brazing zone is well bonded, and the shear strength of the joint reaches 225MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com