Patents

Literature

51results about How to "Risk of injury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

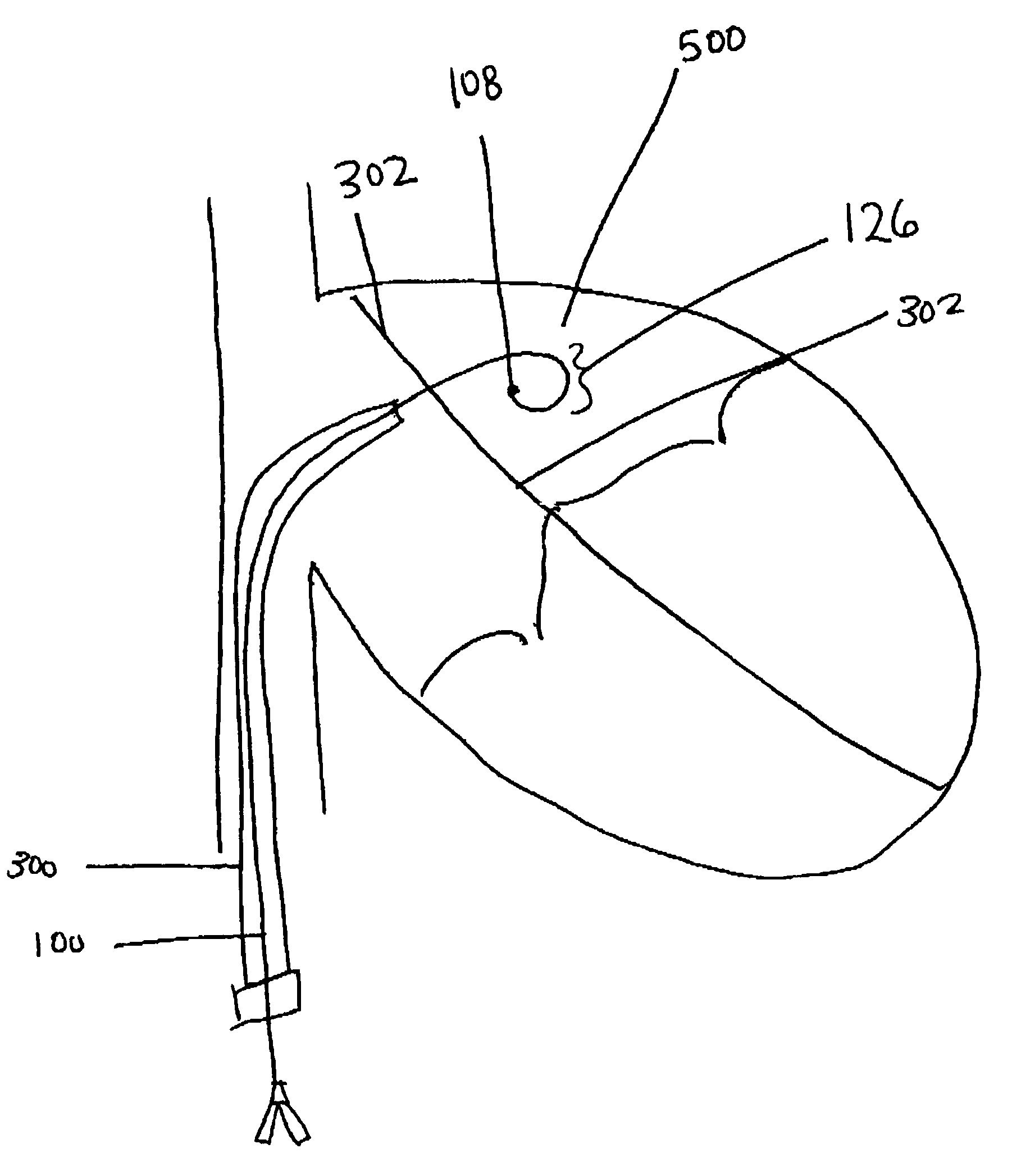

Surgical perforation device with curve

Owner:BOSTON SCI MEDICAL DEVICE LTD

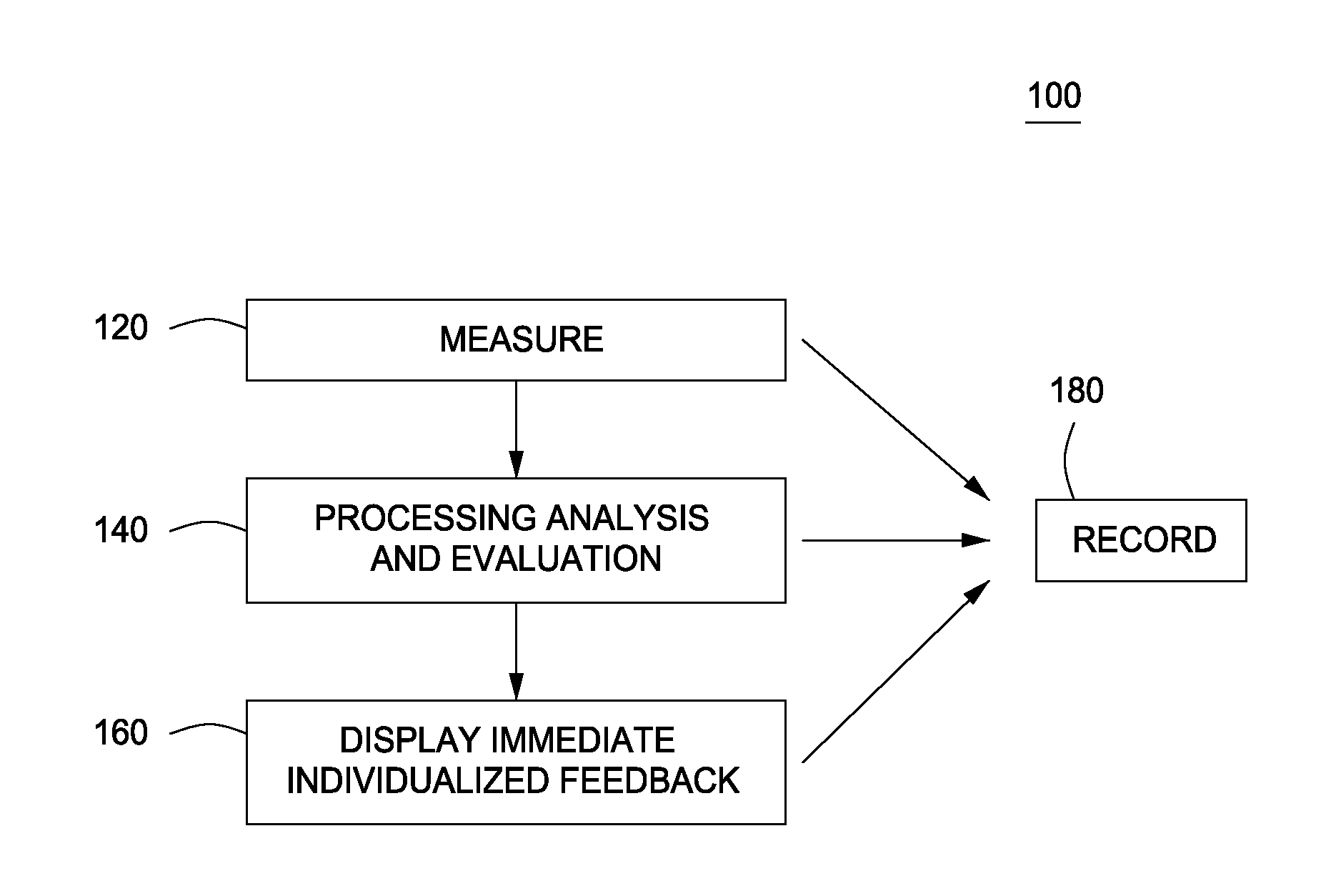

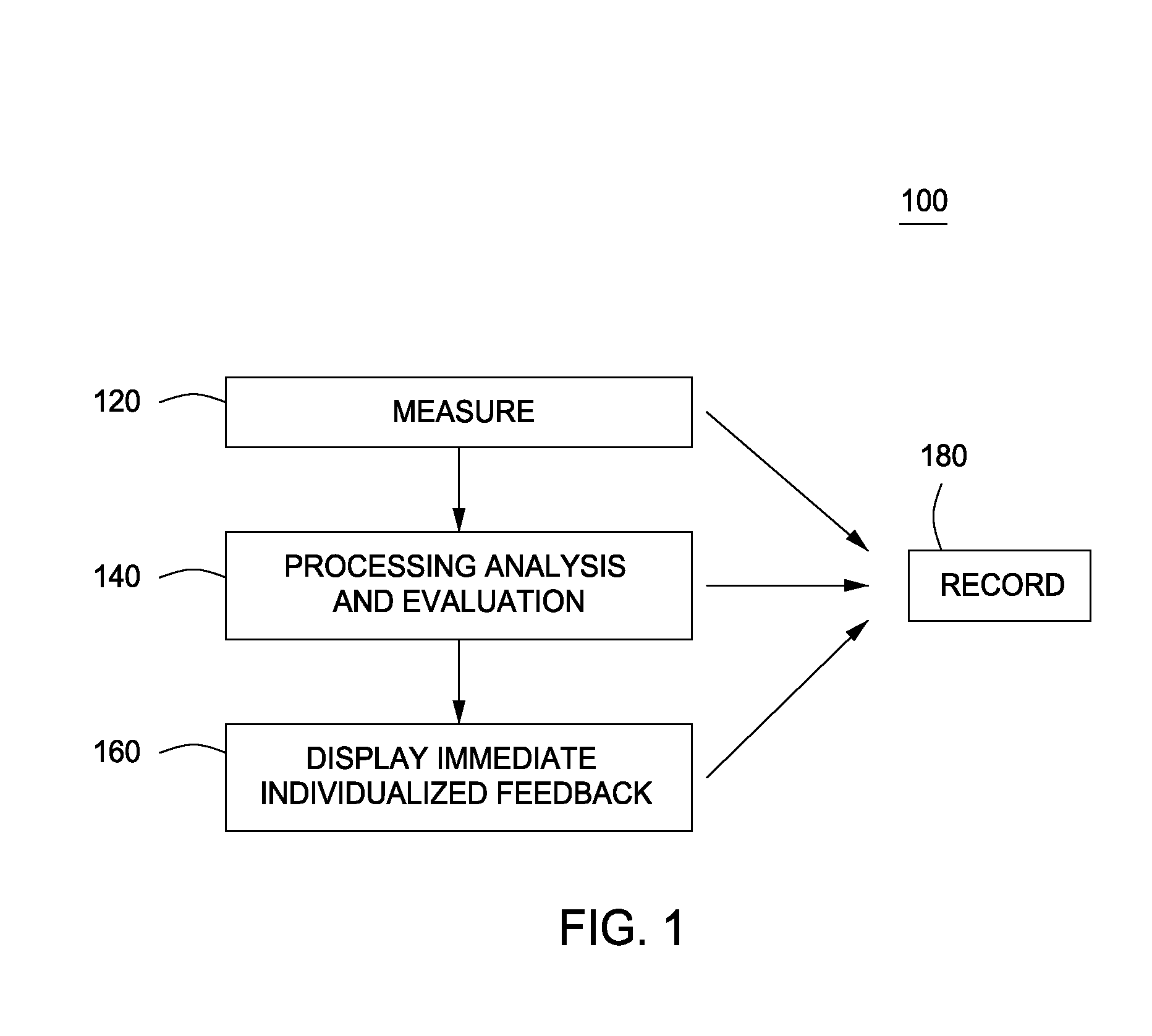

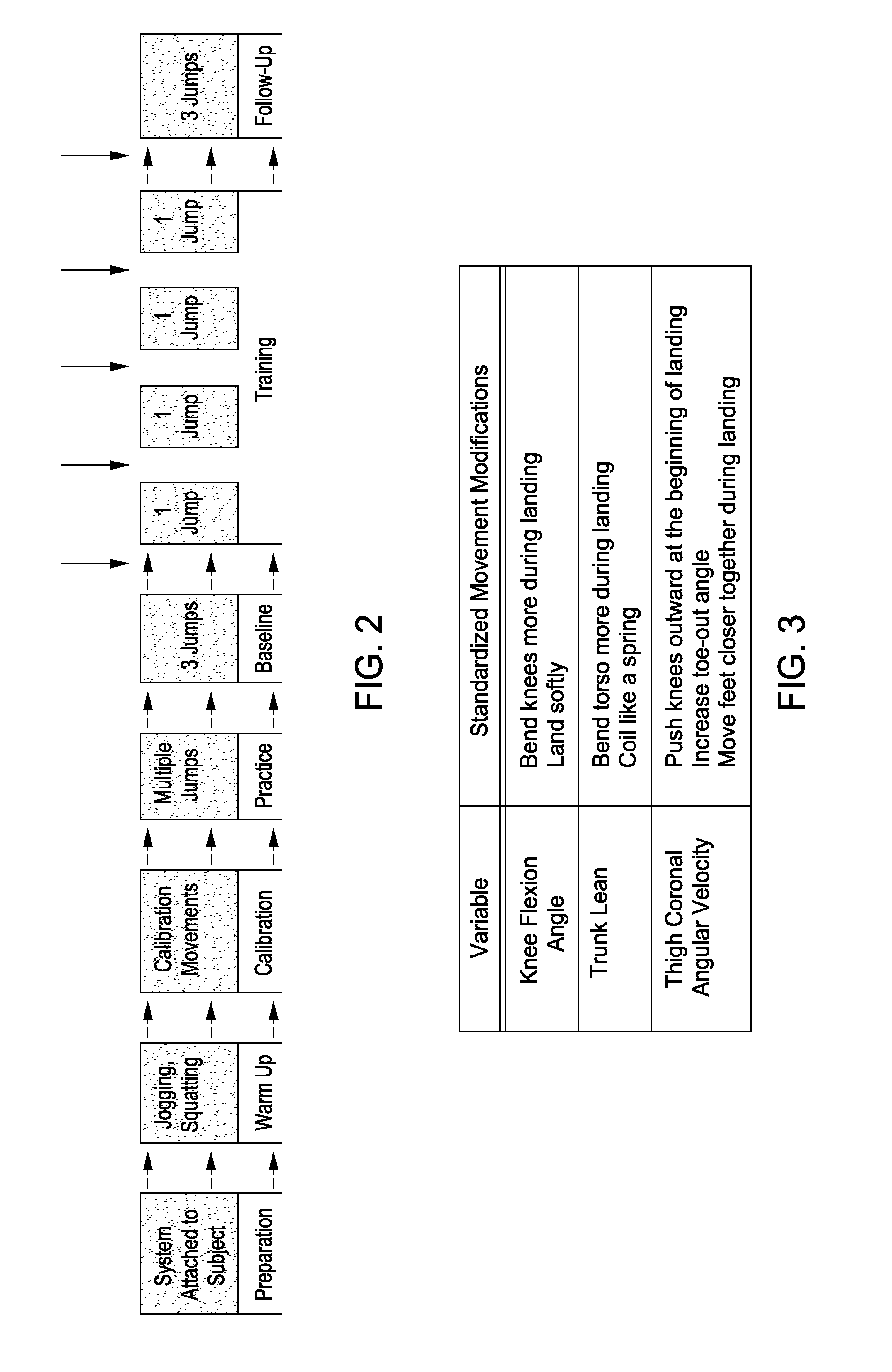

Systems and methods for measuring, analyzing, and providing feedback for movement in multidimensional space

InactiveUS20130244211A1Reduce harmImprove performancePhysical therapies and activitiesCosmonautic condition simulationsMultidimensional scalingMultidimensional space

The present invention provides systems and methods that measure and analyze a user's movement during a specific activity, then provide immediate, focused feedback as to how the user can modify the movement.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

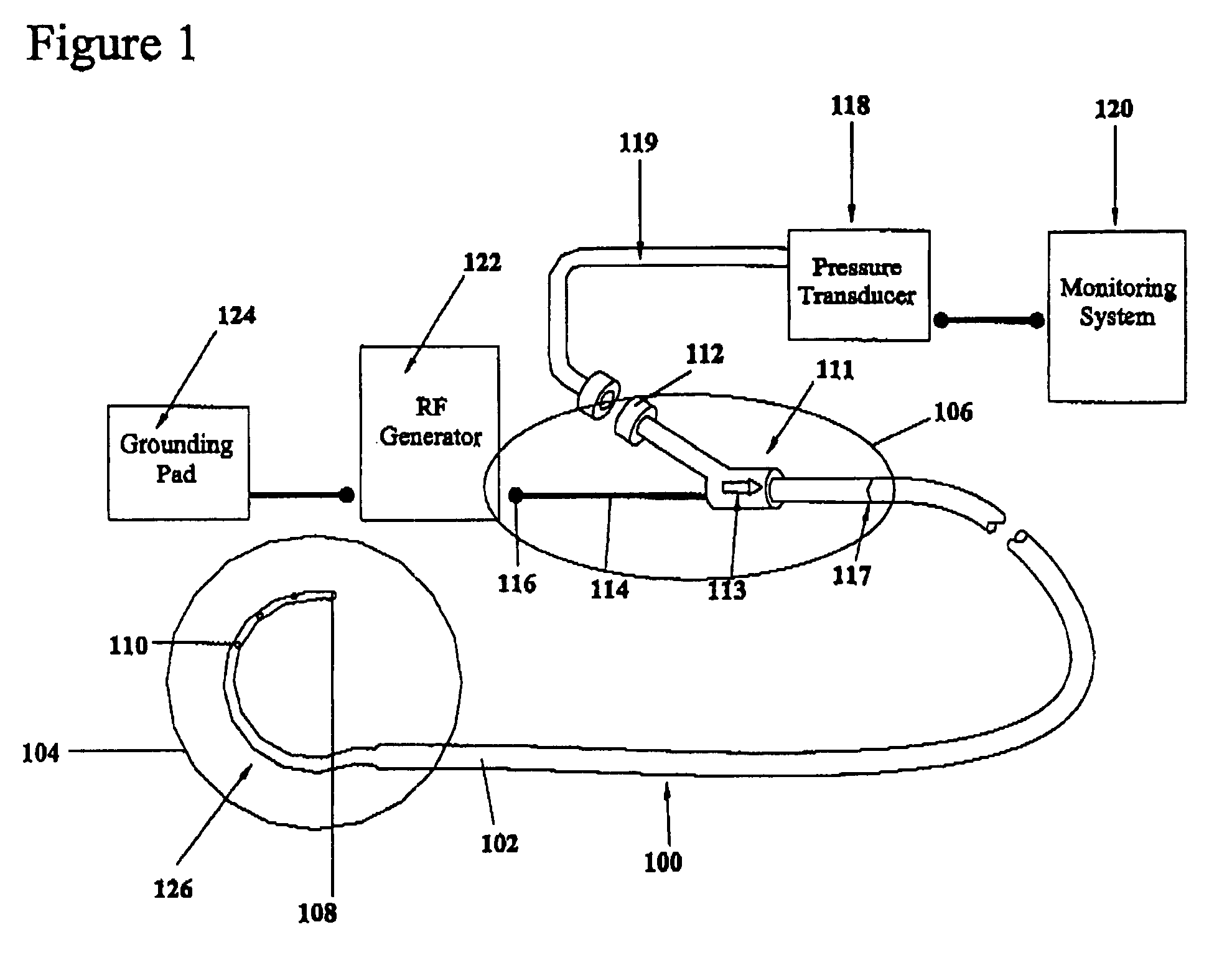

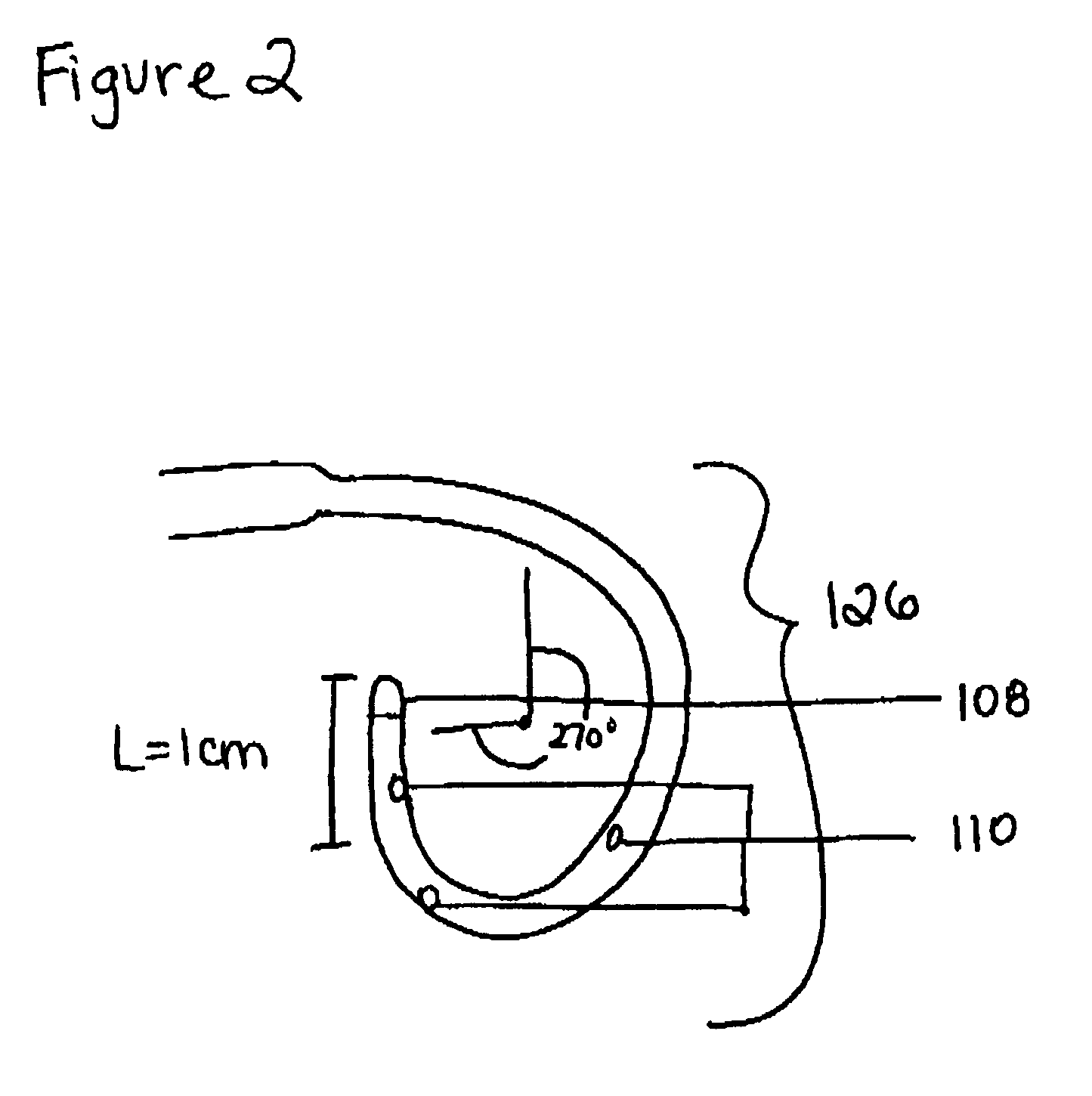

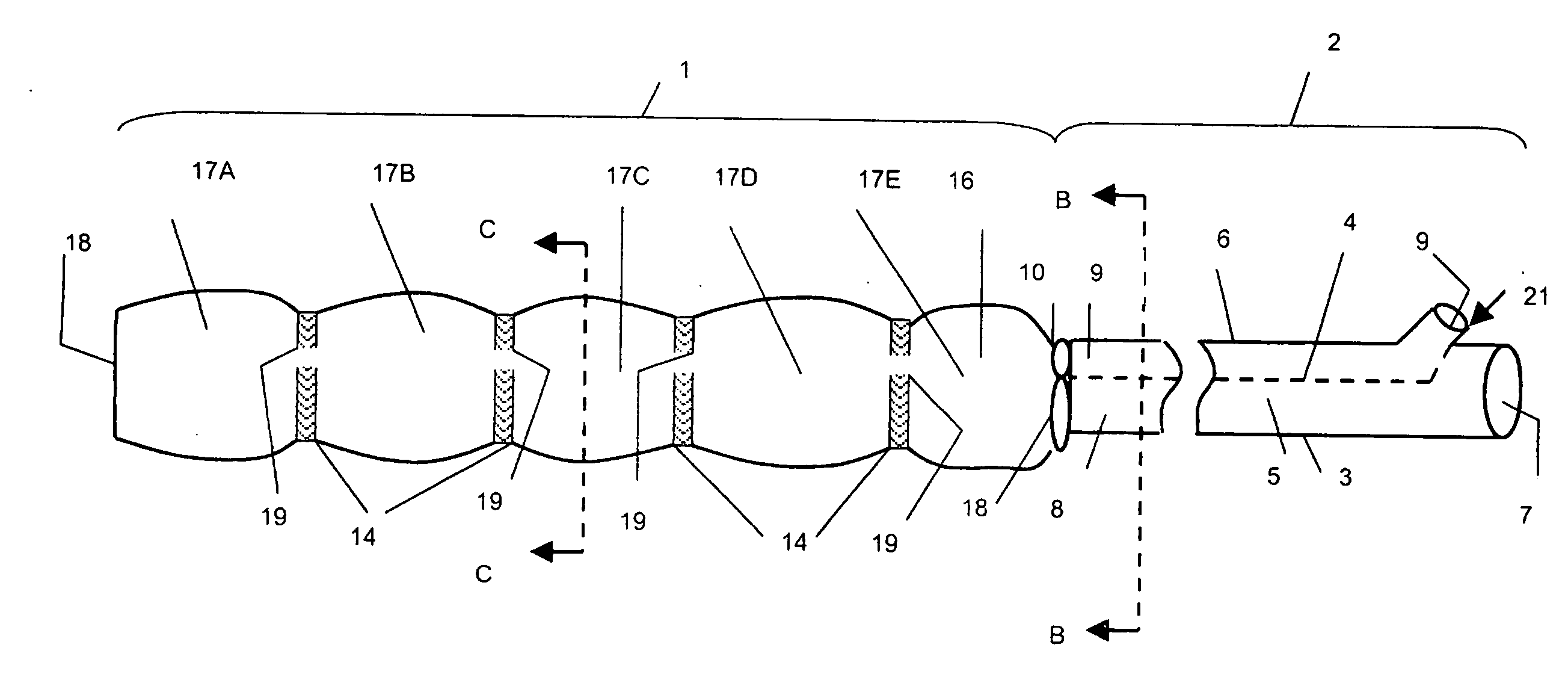

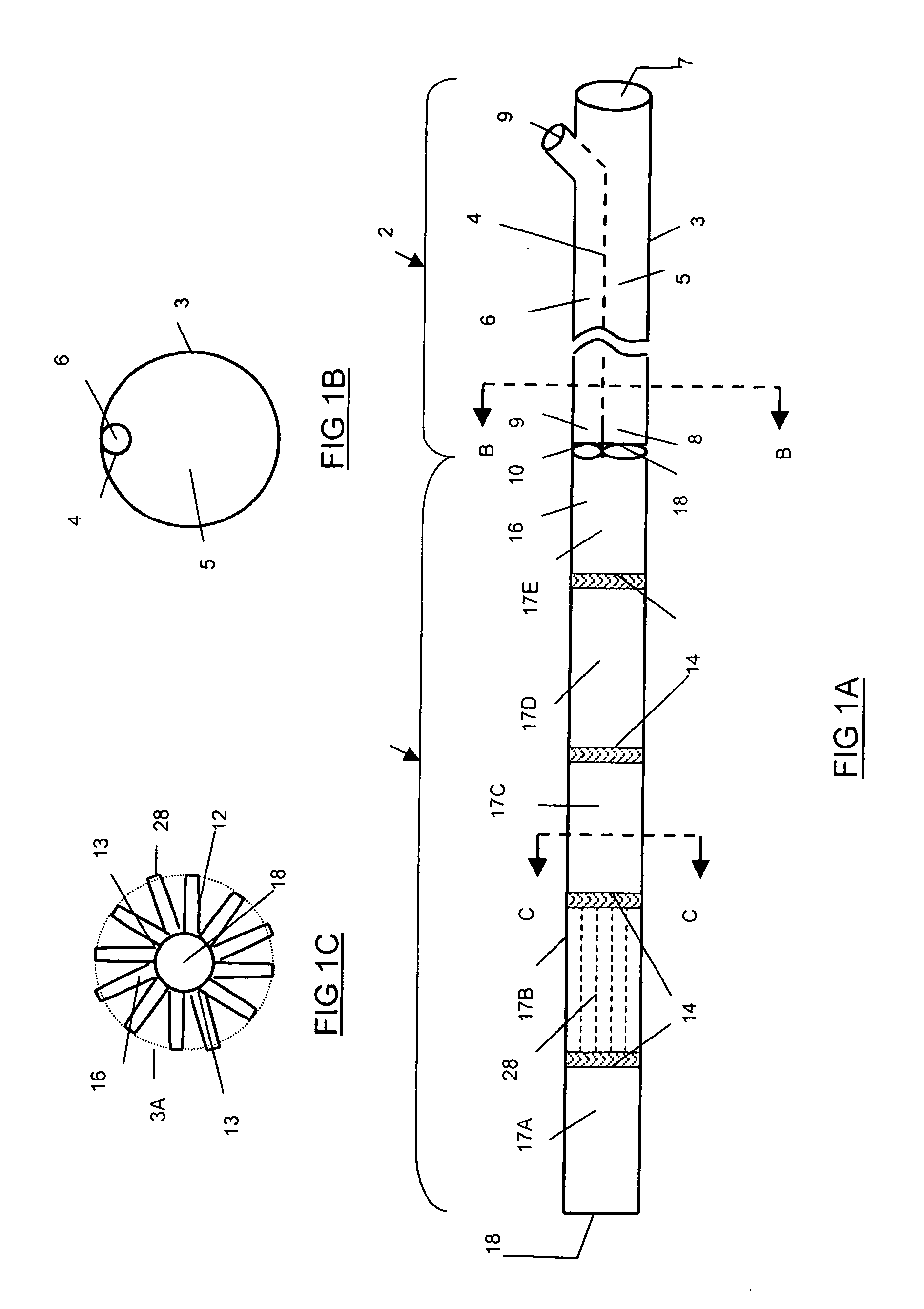

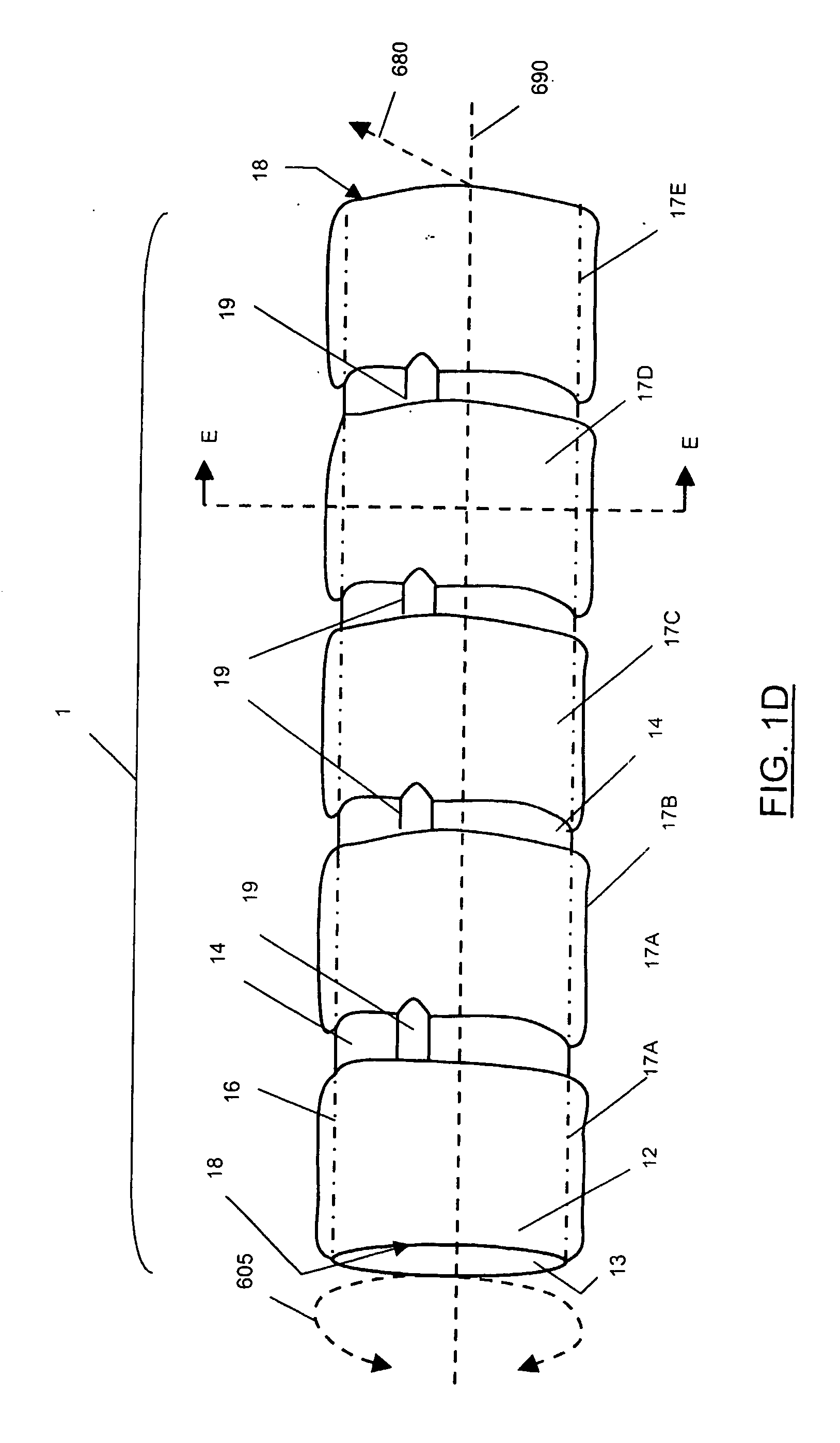

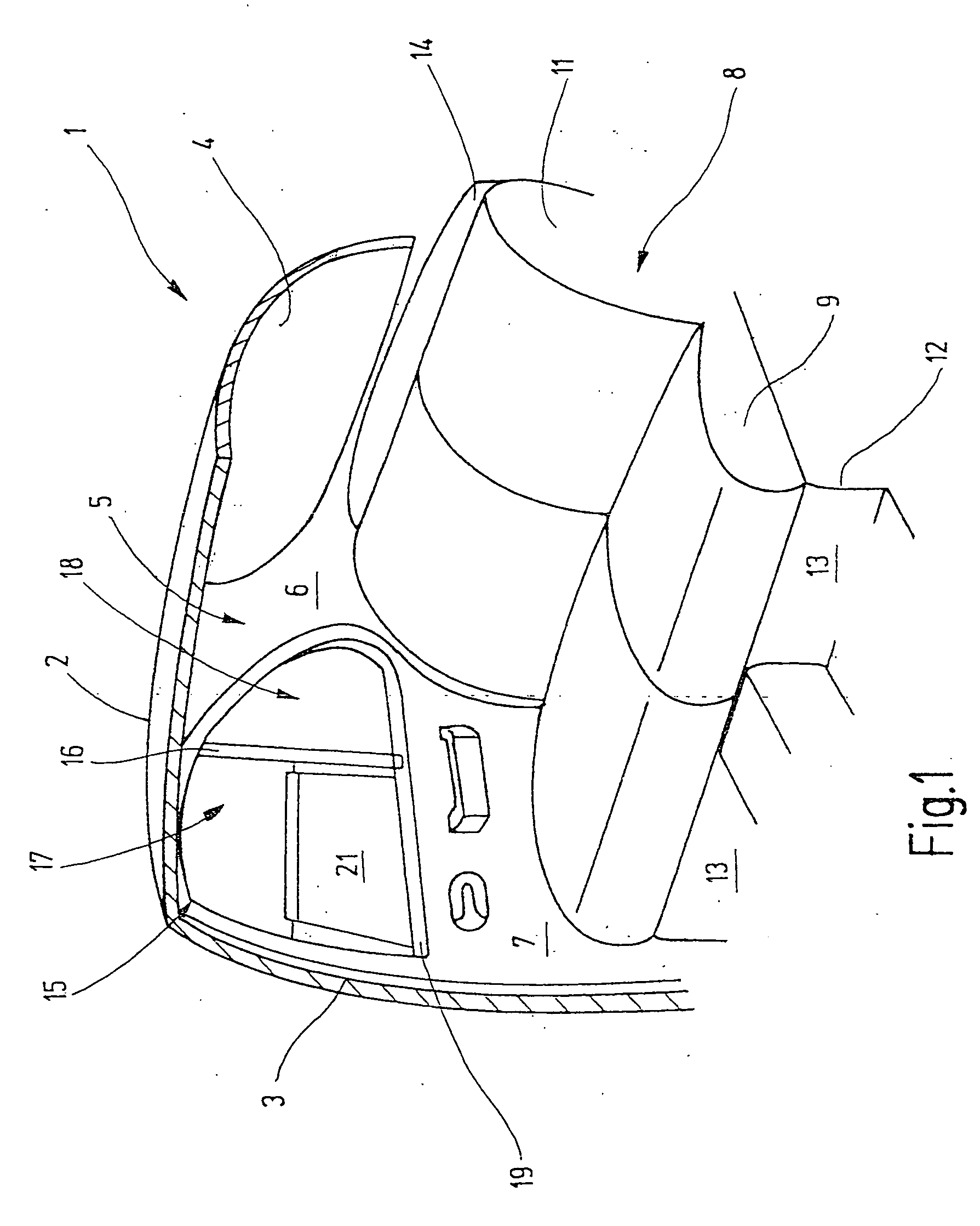

Endovascular balloon graft

InactiveUS20060206197A1Risk of injuryPlace safeStentsBlood vesselsUltimate tensile strengthBlood vessel

A method and apparatus for repair of stenotic and aneurysmic vessels utilizing in situ deployment of an inflatable tubular shaped device (1) having a longitudinally oriented annulus (17). When inflated, the size and rigidity of the device (1) is increased, thereby providing supplemental strength to the vessel wall and a lumen (8) for the passage of fluid.

Owner:MORSI HESHAM

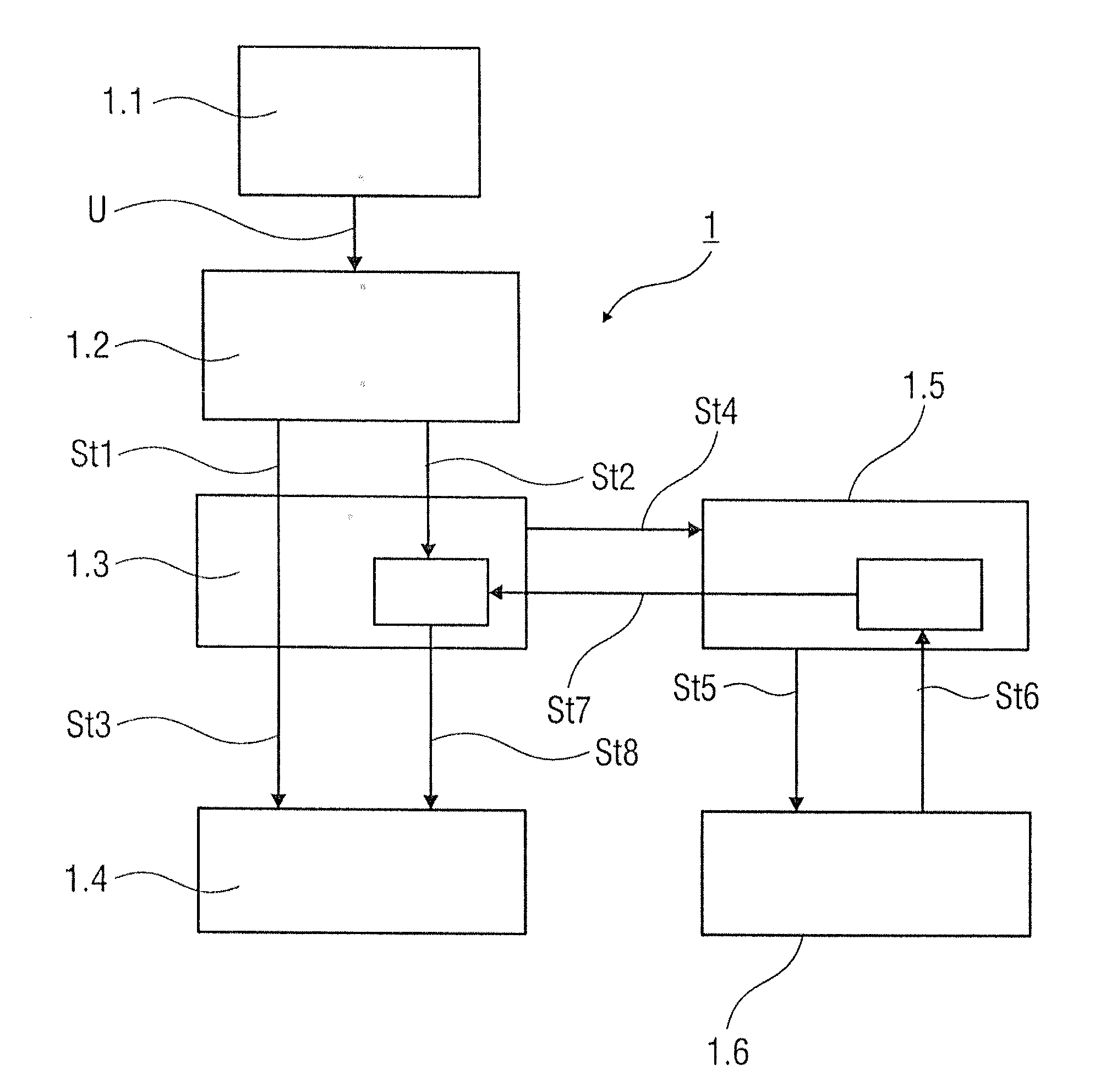

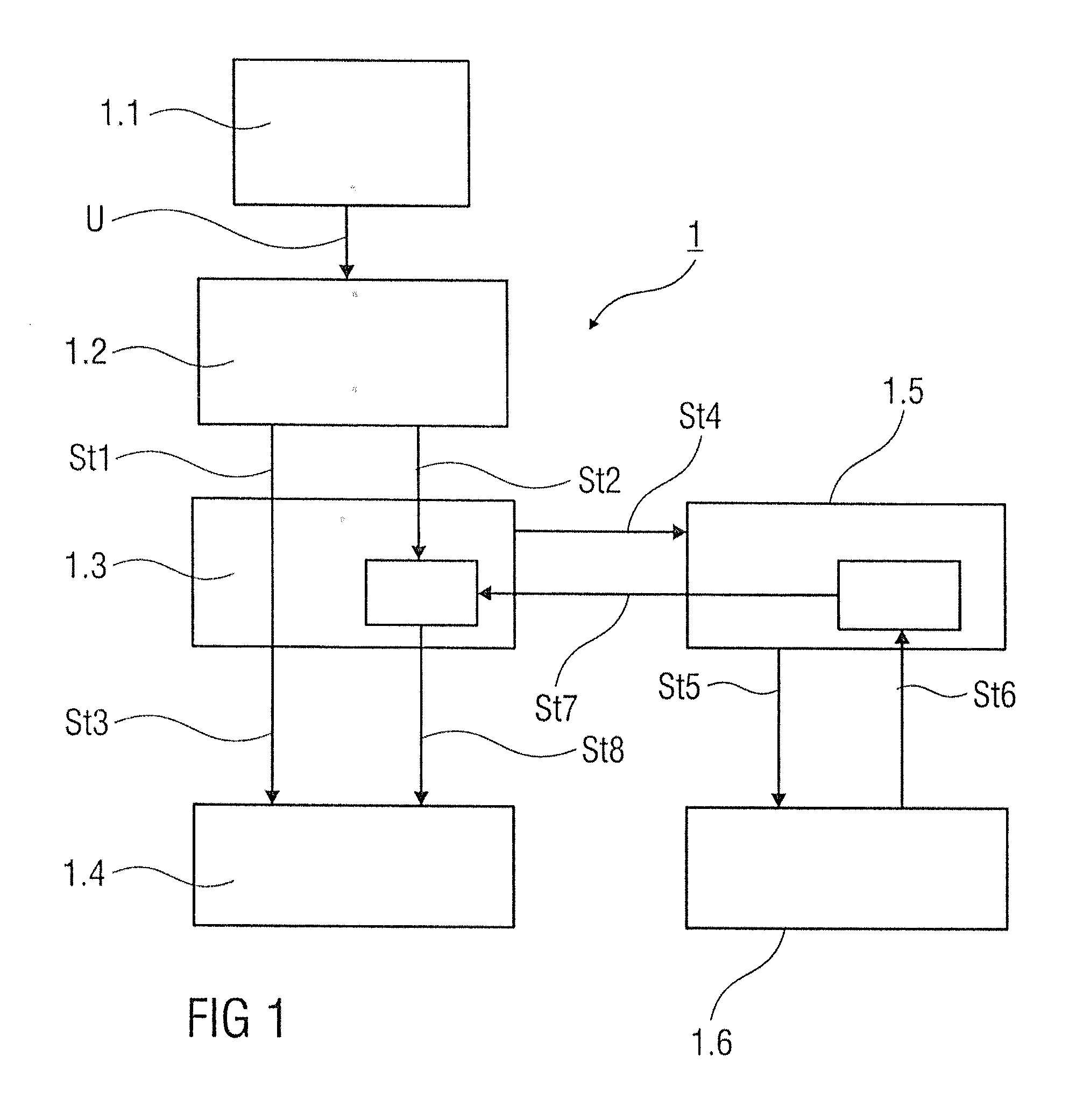

Motor Vehicle Having a Driver Assistance Unit

ActiveUS20140142830A1Increased risk of injuryReduce riskAnalogue computers for trafficAnti-collision systemsMobile vehicleMotorized vehicle

A motor vehicle has a driver assistance unit that includes a braking unit and at least one detection unit to detect an environmental parameter. The driver assistance unit can control performance of an autonomous deceleration of the motor vehicle in the case of a risk of collision, which is recognized using the environmental parameter. The driver assistance unit is formed in such a way that an autonomous emergency stop is only then able to be carried out if the motor vehicle has at least one reversible seat belt pre-tensioner.

Owner:DAIMLER AG

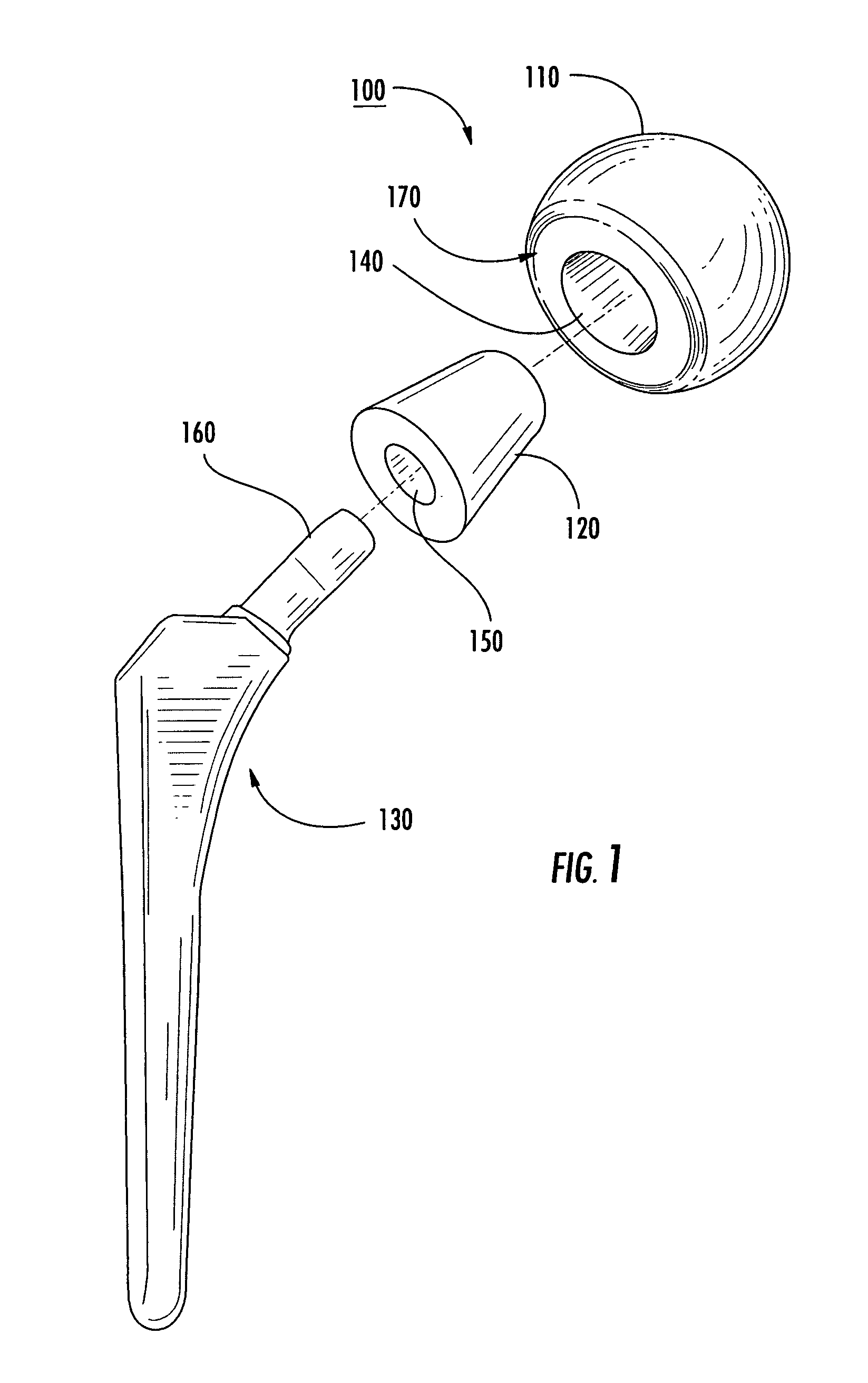

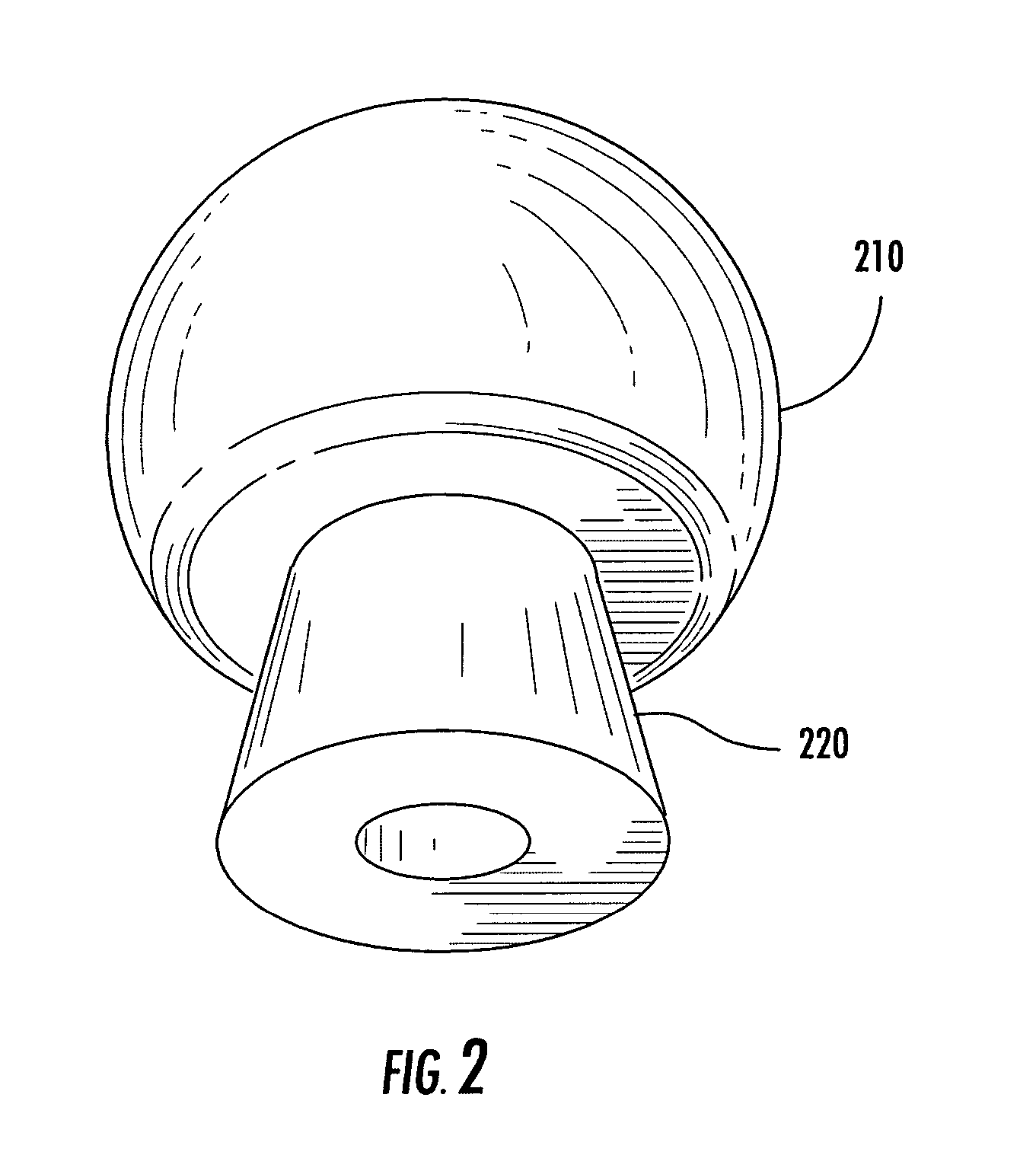

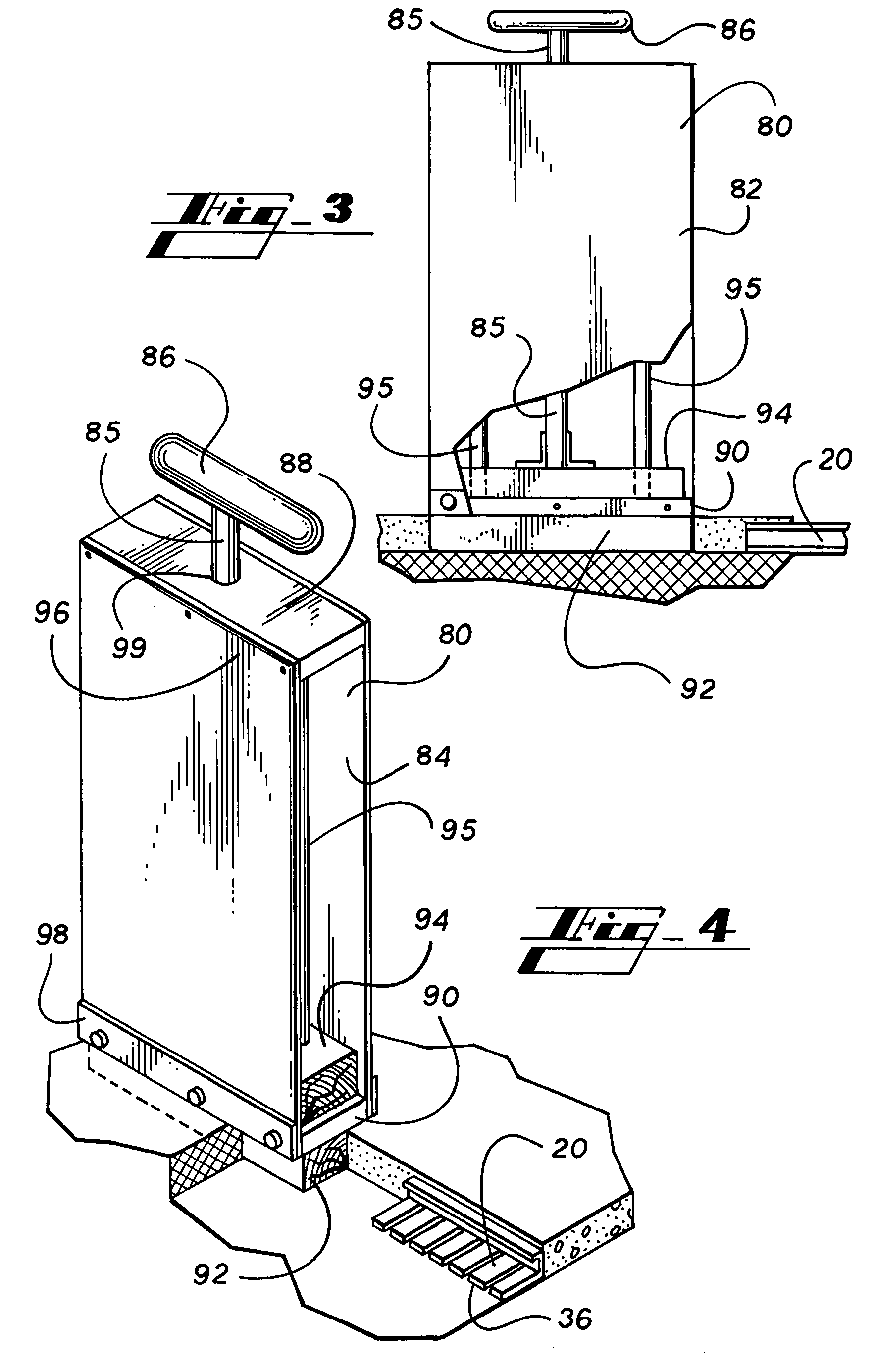

Intraoperative joint force measuring device, system and method

ActiveUS7458989B2Reduce sizeRisk of injurySurgical furniturePerson identificationMeasurement deviceEngineering

A surgical device for joint replacement surgery includes an intraoperative joint head having a stem attachment structure where the stem attachment structure may be removably attachable to a stem and a force sensor housed by the joint head for measuring in vivo forces during surgery. The in vivo forces may be generated by one or more of tension provided by soft tissue, load application during surgery, limb movement during surgery, and a combination thereof. Also, the joint head may provide a cavity where the stem attachment structure houses the force sensor and may be removably insertable in the joint head cavity. A method of performing joint replacement surgery includes installing an intraoperative joint head having a force sensor housed by the joint head and a stem attachment structure, the stem attachment structure being removably attachable to a stem, measuring joint forces, and adjusting an implant parameter based on the measured joint forces.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

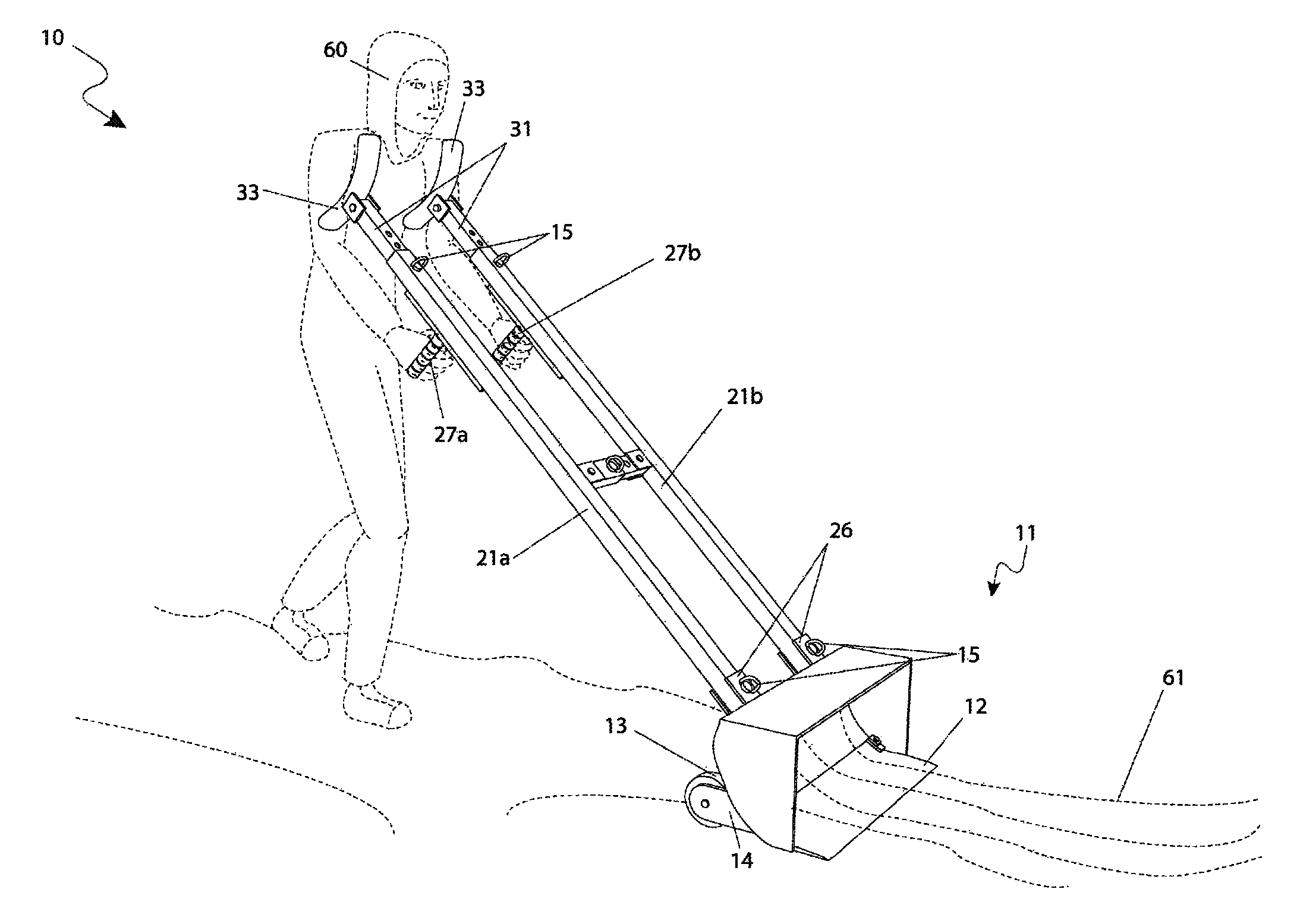

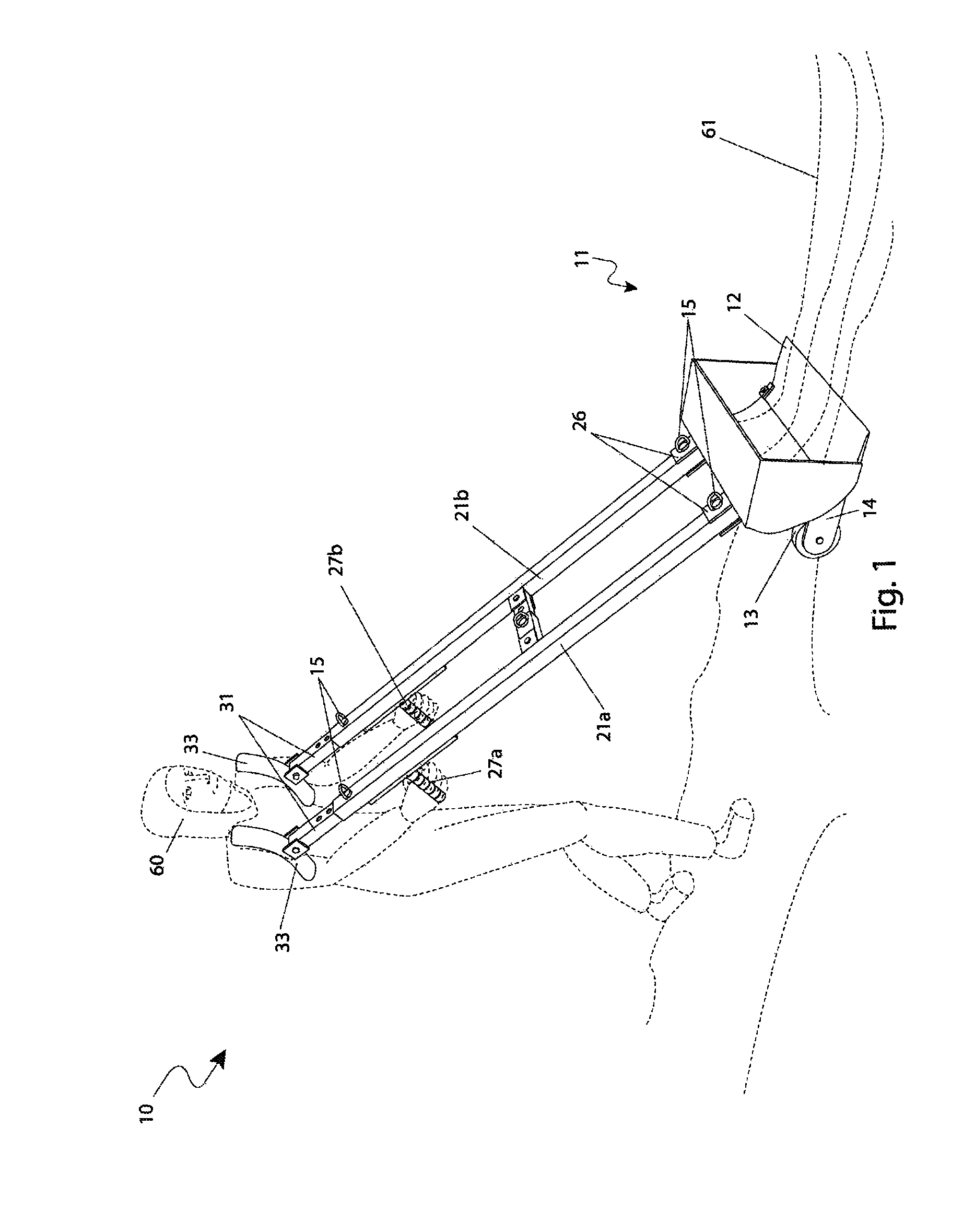

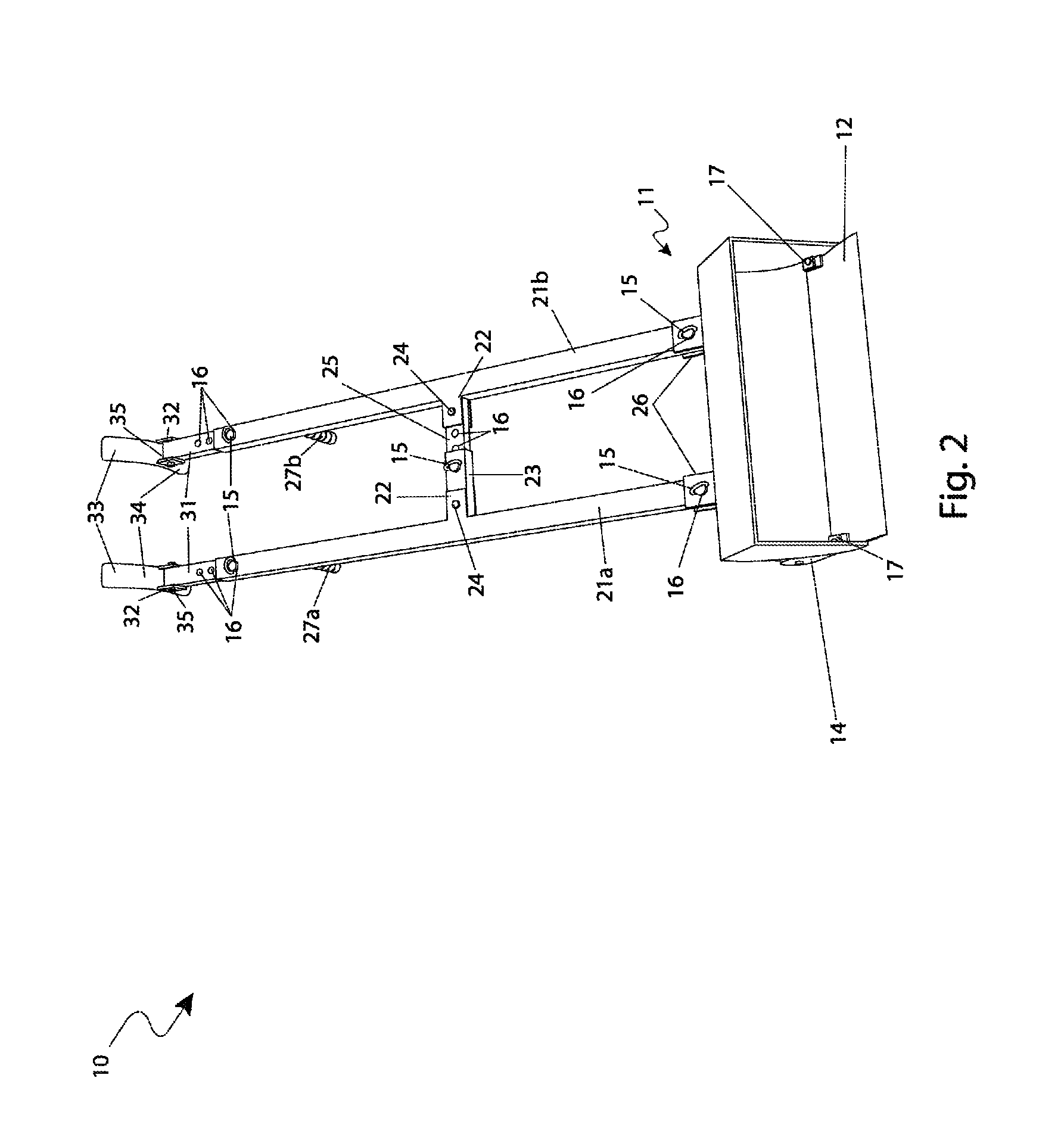

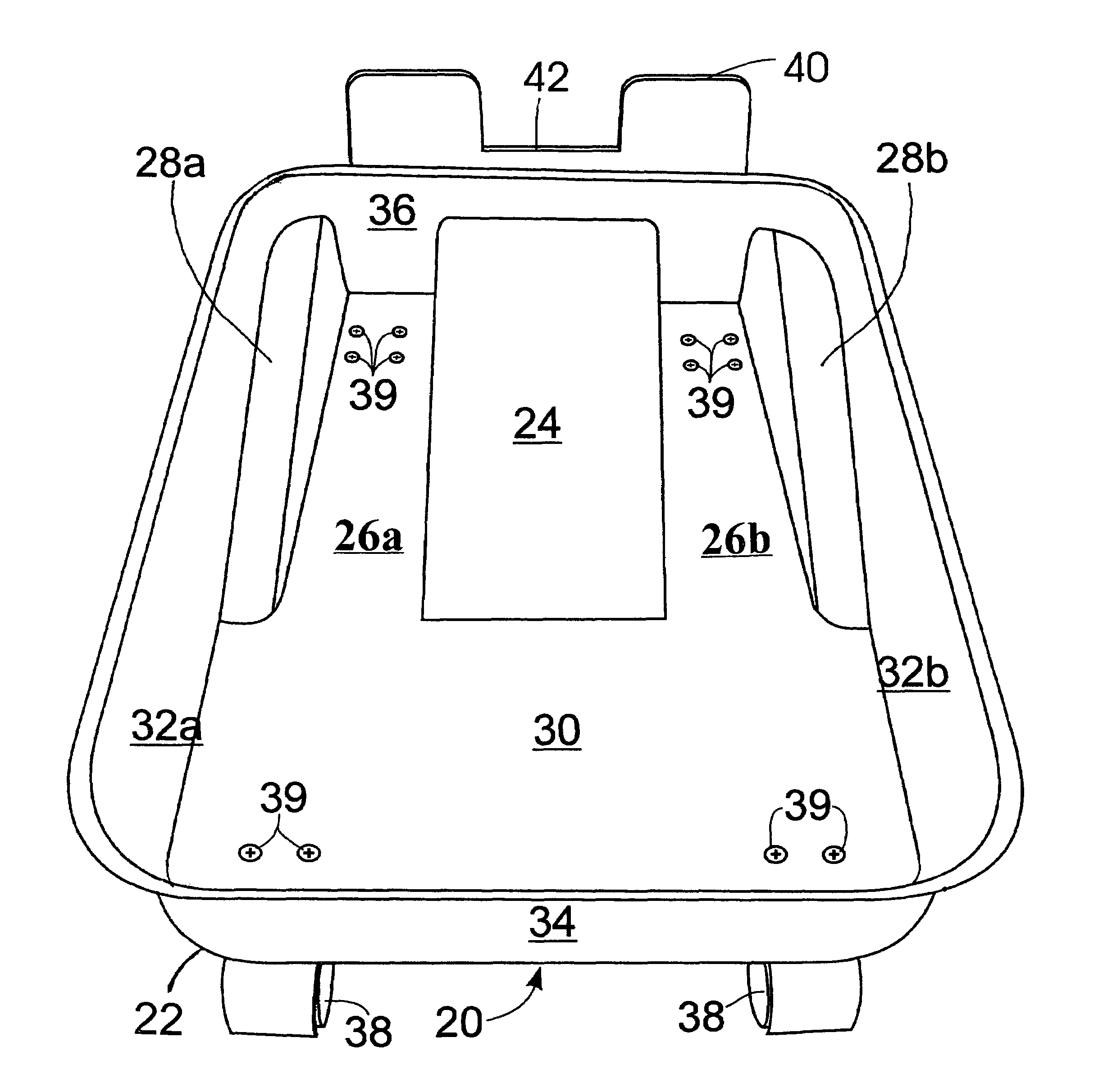

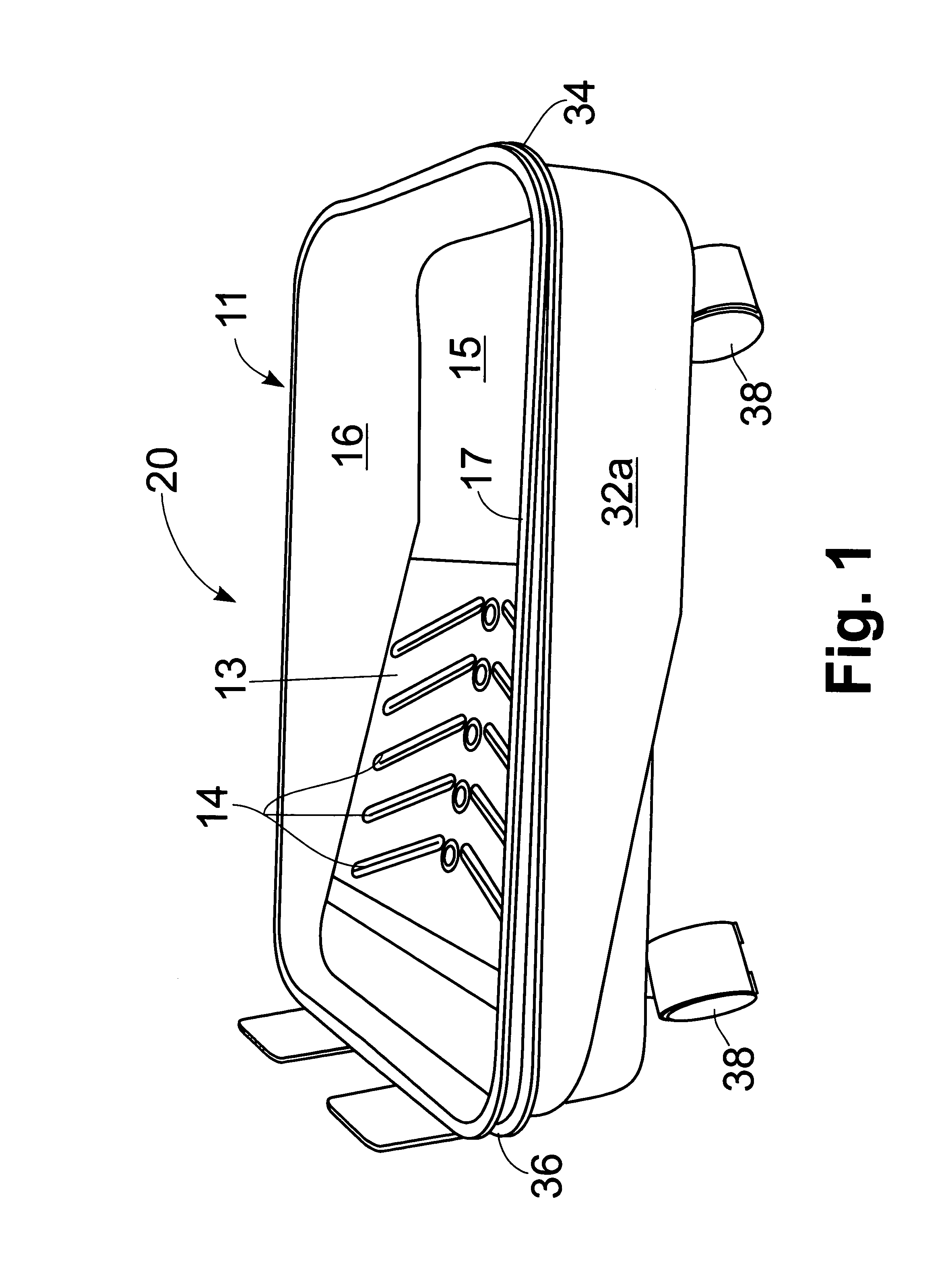

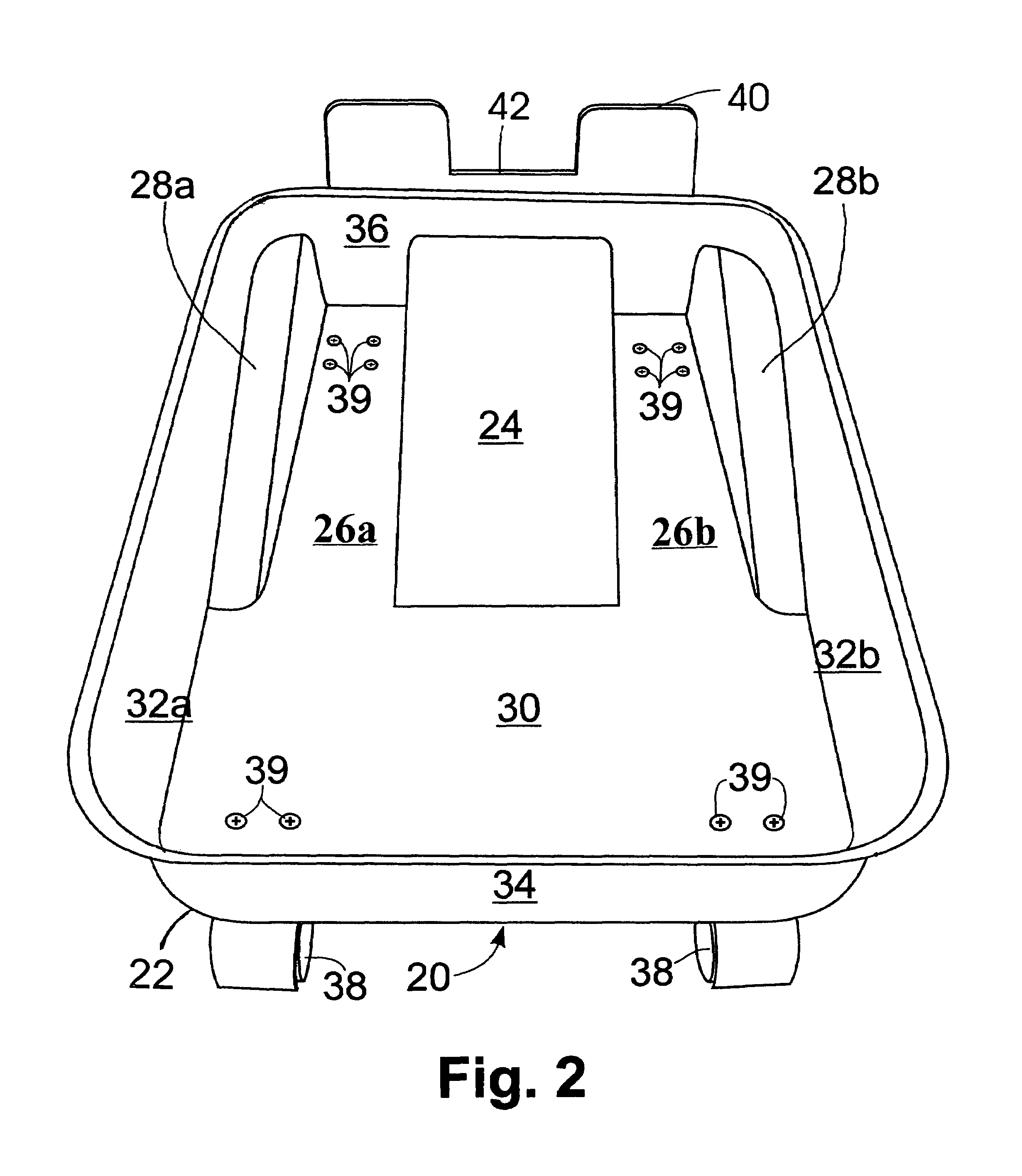

Manual snow plow

A manual snow plow with ergonomic features comprises a snow scoop, two (2) articulating struts extending upward from the scoop and two (2) hinged rounded braces placed against a user's shoulders during use. The struts are provided with cross bracing which provide size adjustability and stability to the plow. A set of position adjustable hand grips extend from each strut in a rearward fashion to control the device during use. A pair of casters provided on a rear of the snow scoop allows the device to ride over cracks and other uneven surface variations. The snow plow becomes an extension of the user's body and thus enables the user to use the force of their entire body to move snow.

Owner:WOYAK THOMAS L

Paint tray trolley

InactiveUS7424959B1Easy to moveEasy to useLiquid surface applicatorsCarpet cleanersEngineeringFlange

A base is equipped with wheels to receive a paint tray with stabilizing feet and enable the tray to be moved from place to place without the need to pick it up. An upwardly extending flange can be engaged by the paint roller to push / pull it to a new location.

Owner:BIEBEL DAVID R

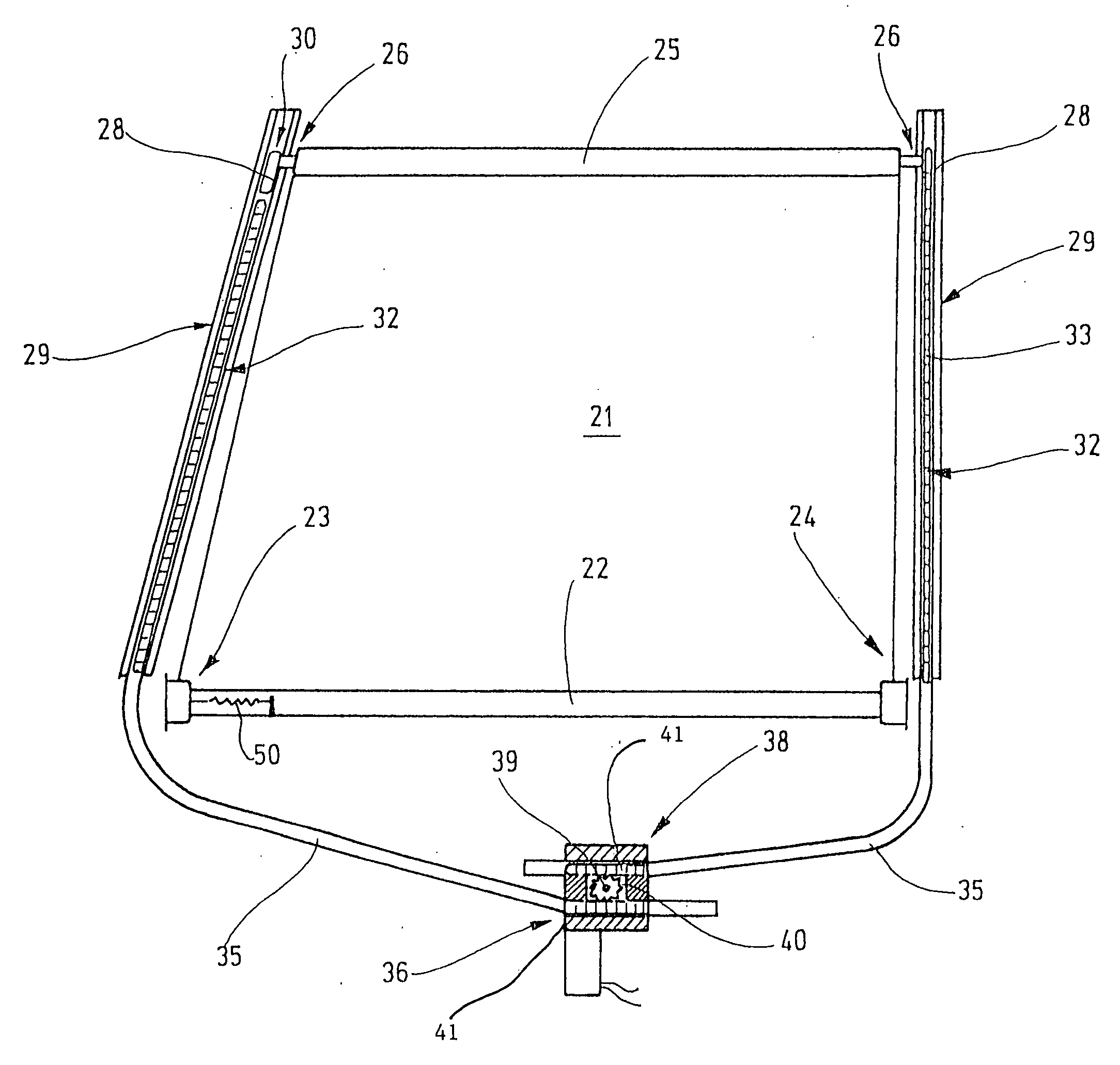

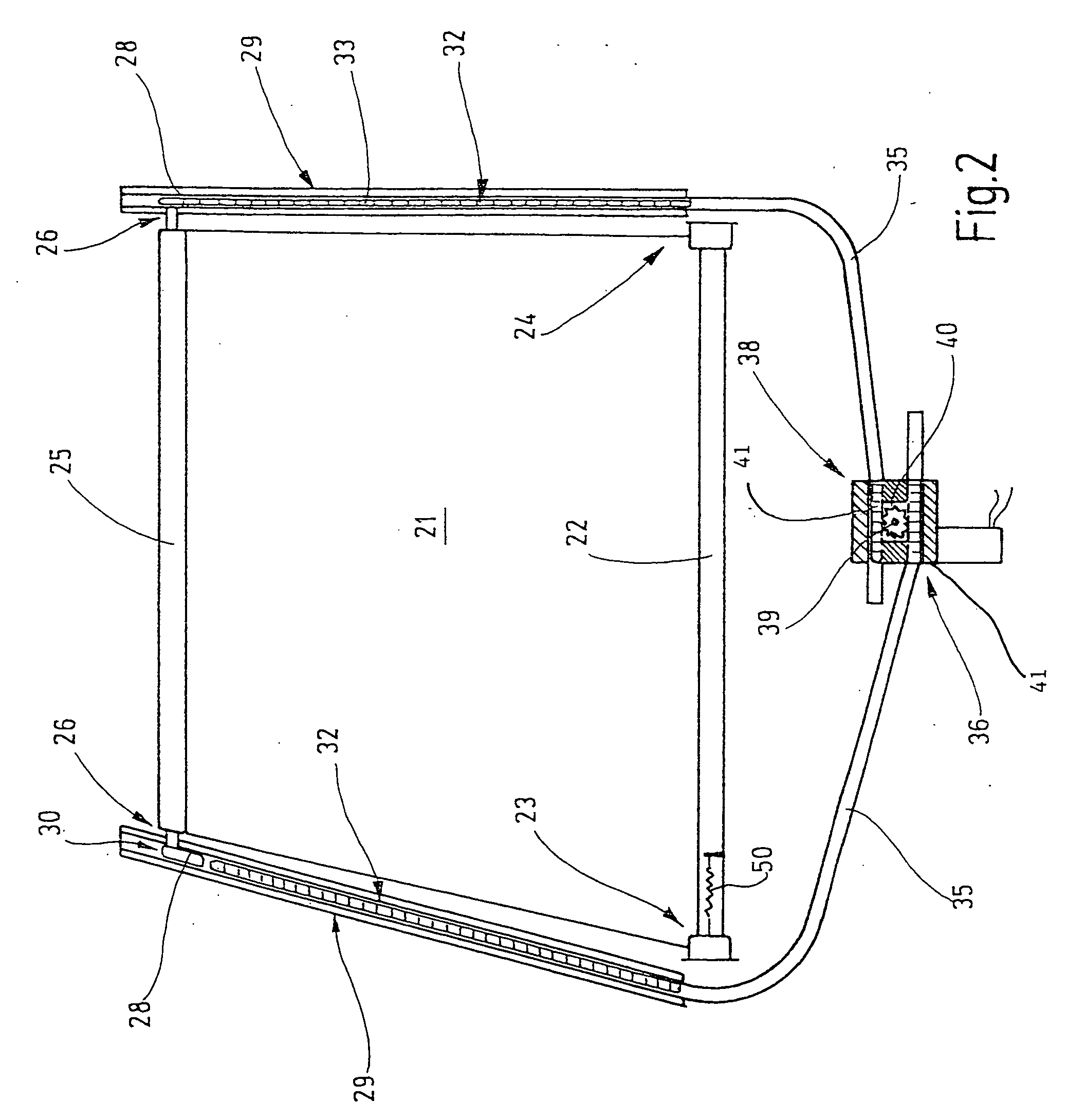

Window shade with pinch protection

InactiveUS20060237152A1Avoid personal injuryAvoid dangerWindowsAntiglare equipmentMotor driveElectric machinery

A window roller blind assembly for motor vehicles which includes a roller blind that can be drawn from a wind-up shaft by a motor driven driving element engageable with a pull rod of the roller blind. The pull rod, which is guided for movement in guide rails, has a braking device that causes at least part of the driving force necessary for moving the window shade to be fed into the guide rail to brake further movement of the roller blind when the pull rod bumps into an obstacle.

Owner:BOS

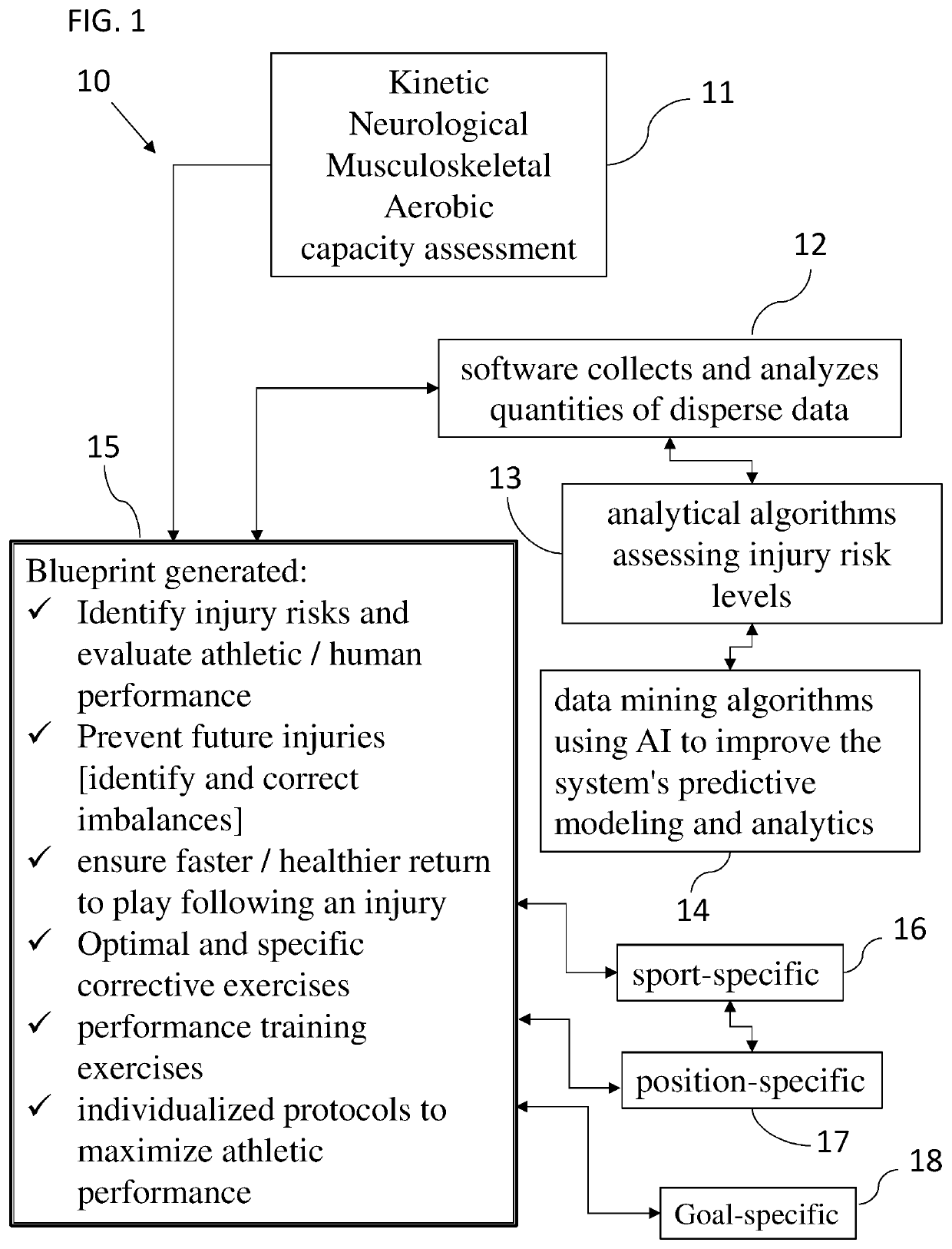

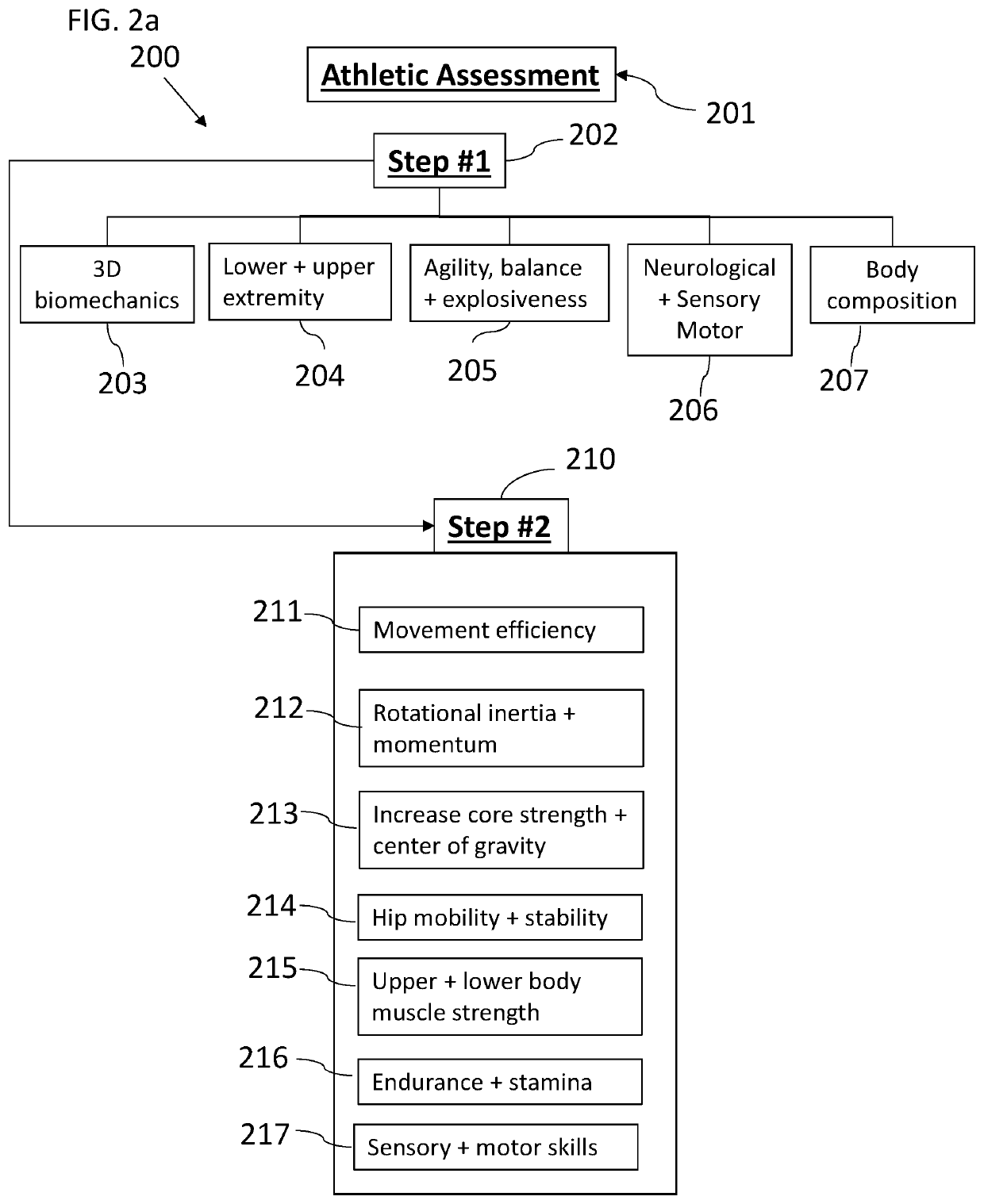

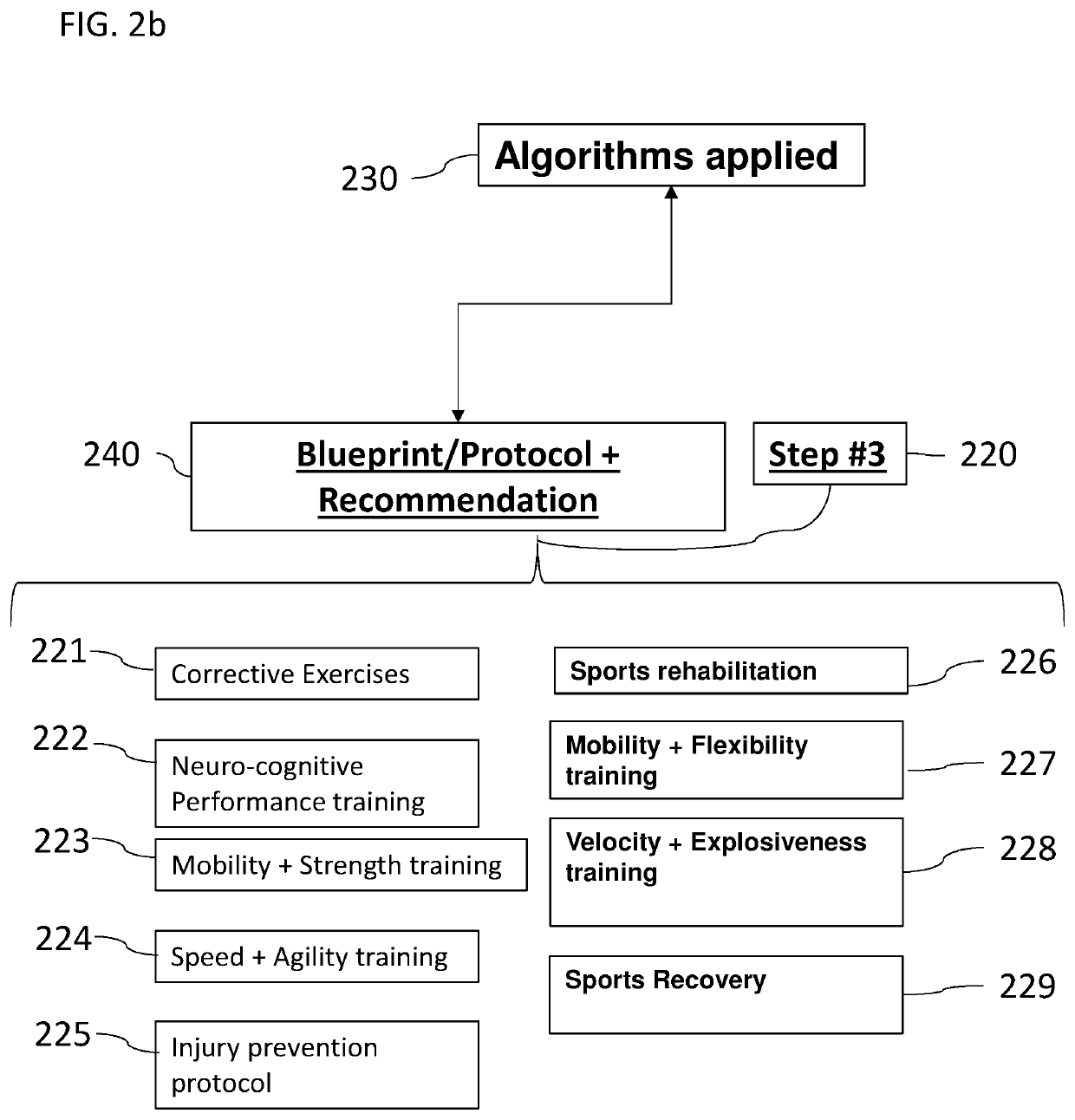

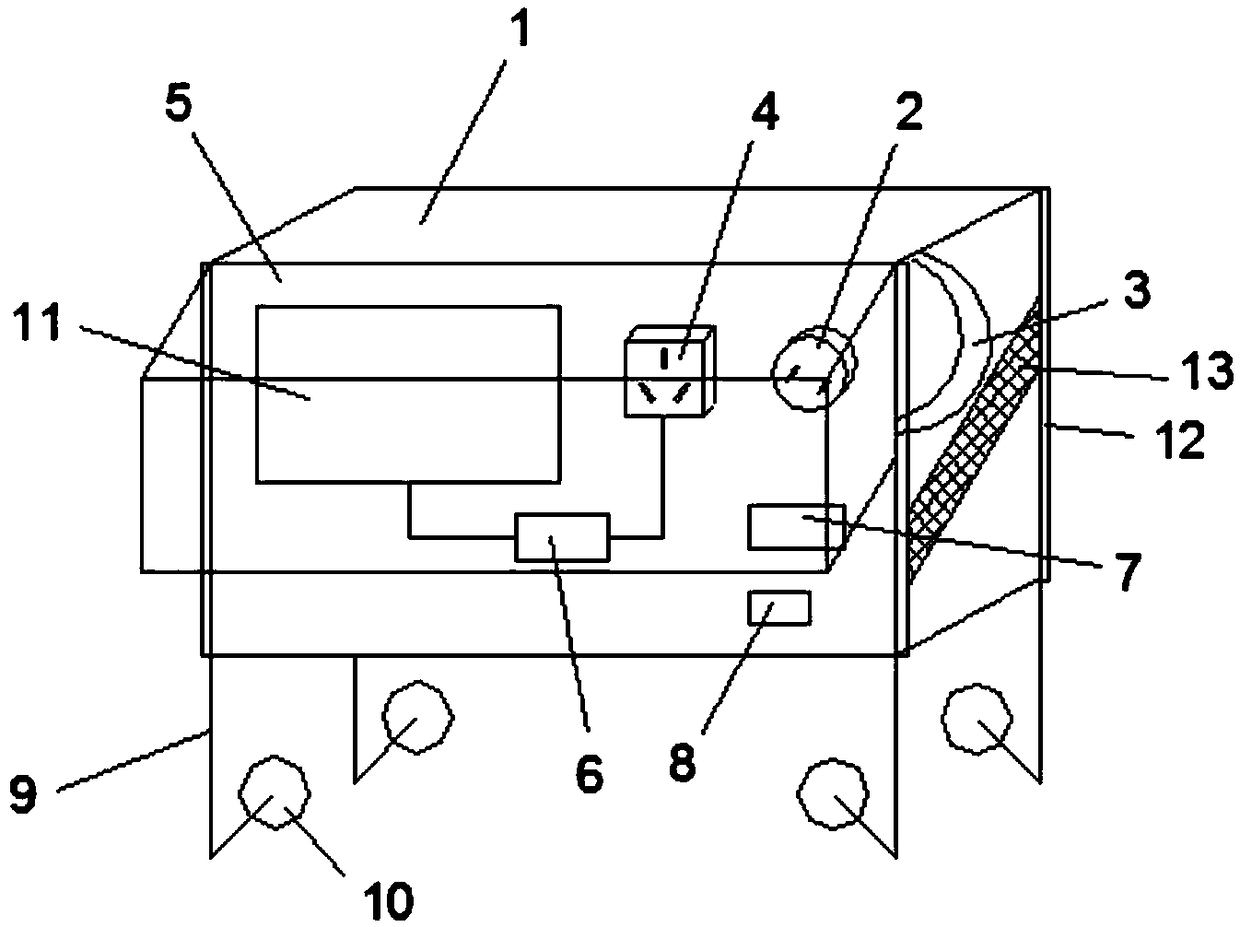

Device, system and method for automated global athletic assessment and / or human performance testing

ActiveUS20200108291A1Maximize athletic performance/physical performanceRisk of injuryPhysical therapies and activitiesMedical data miningHuman bodySimulation

A system, method, and computer-readable media collect and analyze the physical performance of an individual and structure and generate an athletic protocol. Athletic assessment devices perform an athletic assessment of an individual, including kinetic, neurological, musculoskeletal and aerobic capacity. Athletic data is collected and stored in a digital data storage medium of a computer system having a display, and a central processing unit (CPU) operable with programming executes one or more analytical algorithms to assess injury risk levels of said individual based on said athletic data. Data mining algorithms using artificial intelligence are used to execute predictive modeling and analytics. The resultant athletic protocol includes information to correct imbalances to treat and / or prevent injuries, corrective exercises, performance training exercises, and protocols to maximize physical performance.

Owner:PIAZZA JOHN +1

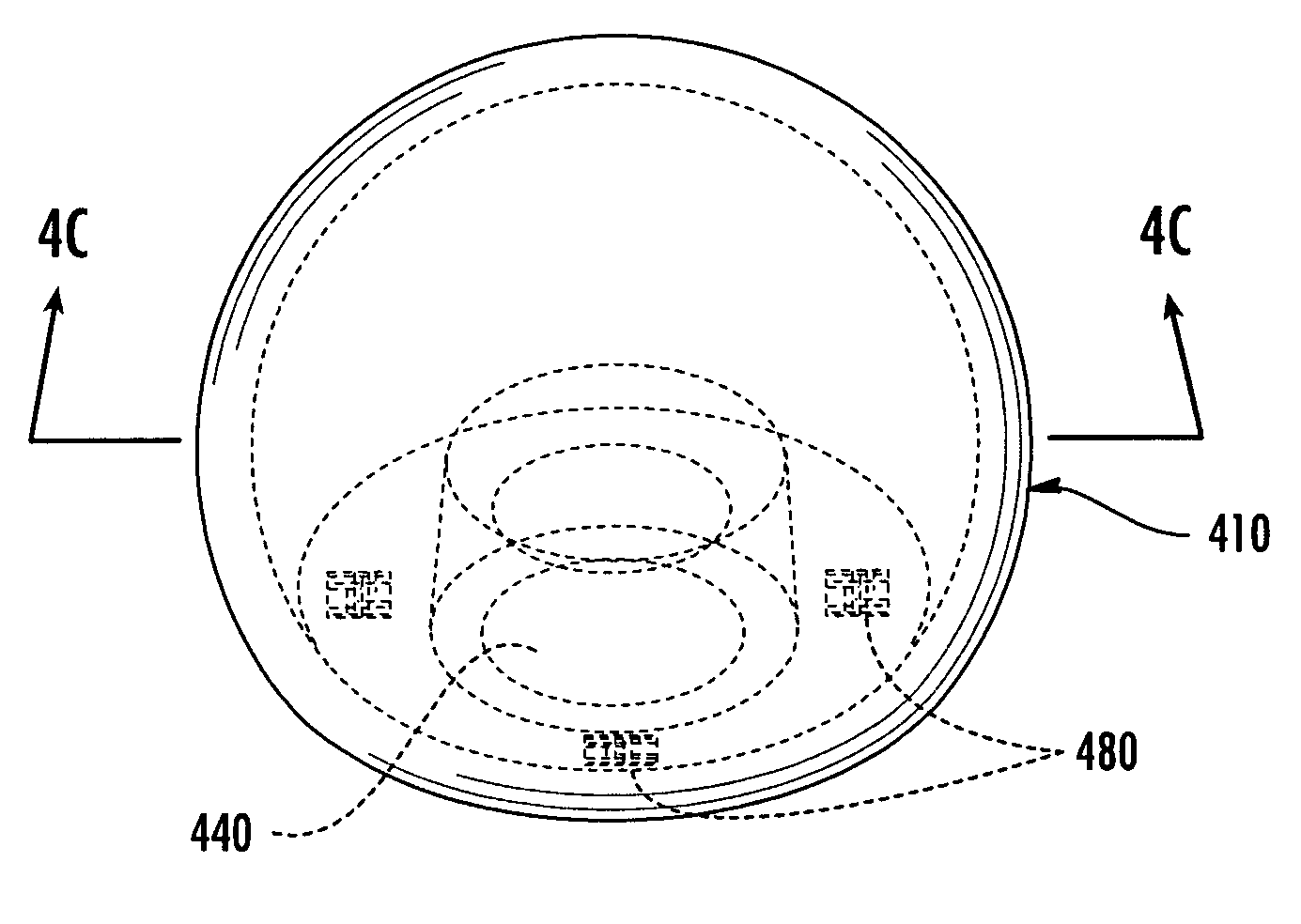

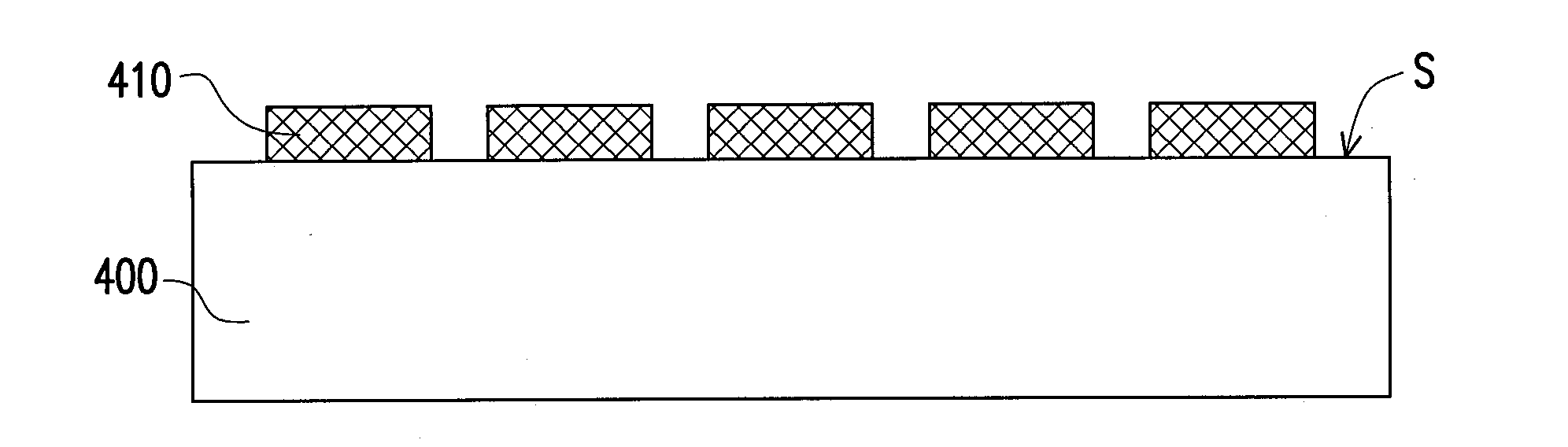

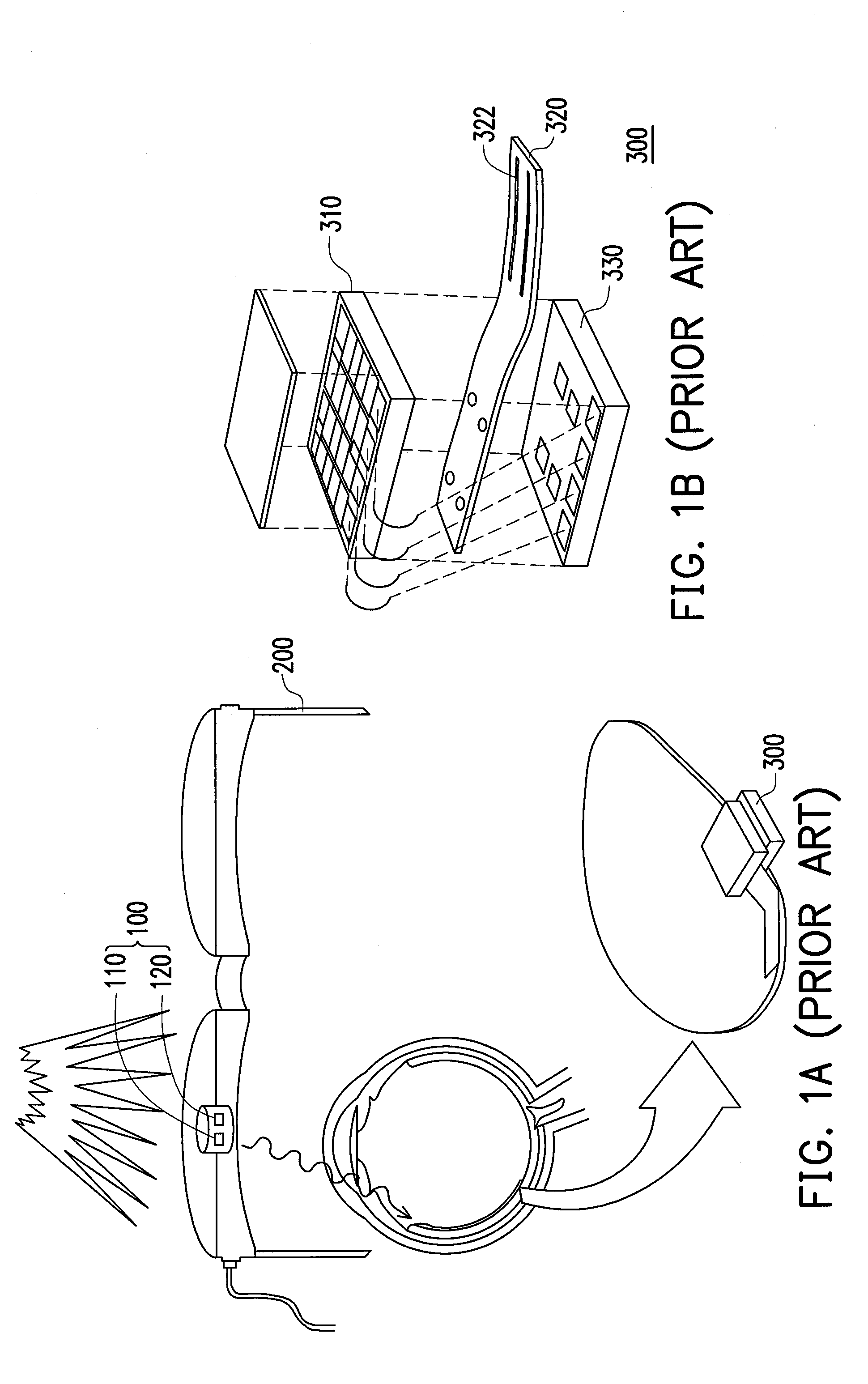

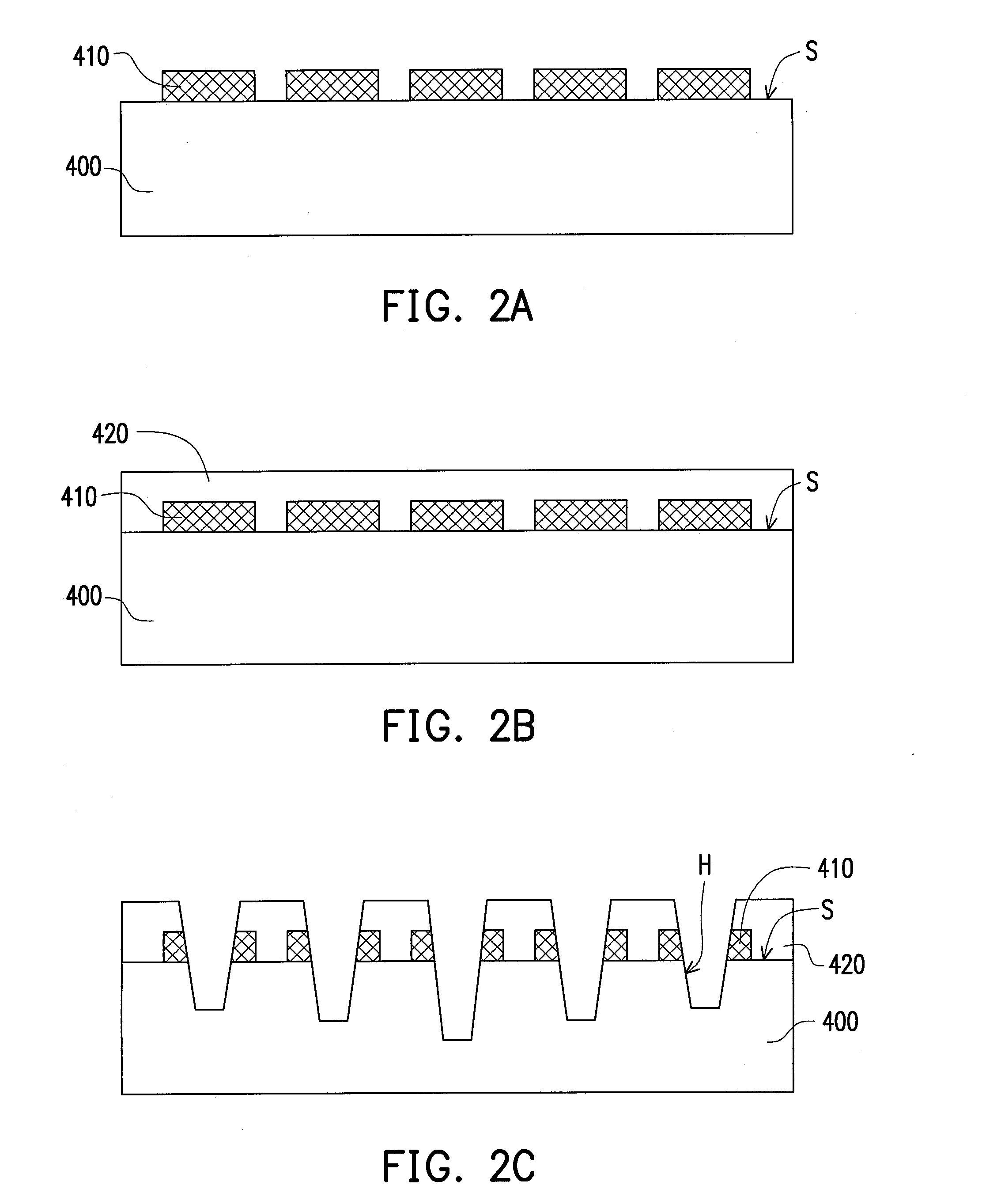

Artificial optic nerve network module, artificial retina chip module, and method for fabricating the same

An artificial retina chip module including a signal processing chip, a first polymer bump layer, and a photodiode array chip is provided. The signal processing chip includes a plurality of first pad disposed on a surface thereof. The first polymer bump layer includes a plurality of polymer bumps insulated from one another. Each of the first polymer bumps is composed of a polymer material and a conductive layer coated on the polymer material. Each first polymer bump is embedded into the corresponding first pad and the signal processing chip, wherein one end of the first polymer bump protrudes from the first pad and the other end thereof protrudes from a back surface of the signal processing chip. The photodiode array chip is disposed at one side of the signal processing chip and is electrically connected to the signal processing chip through the first polymer bumps.

Owner:IND TECH RES INST

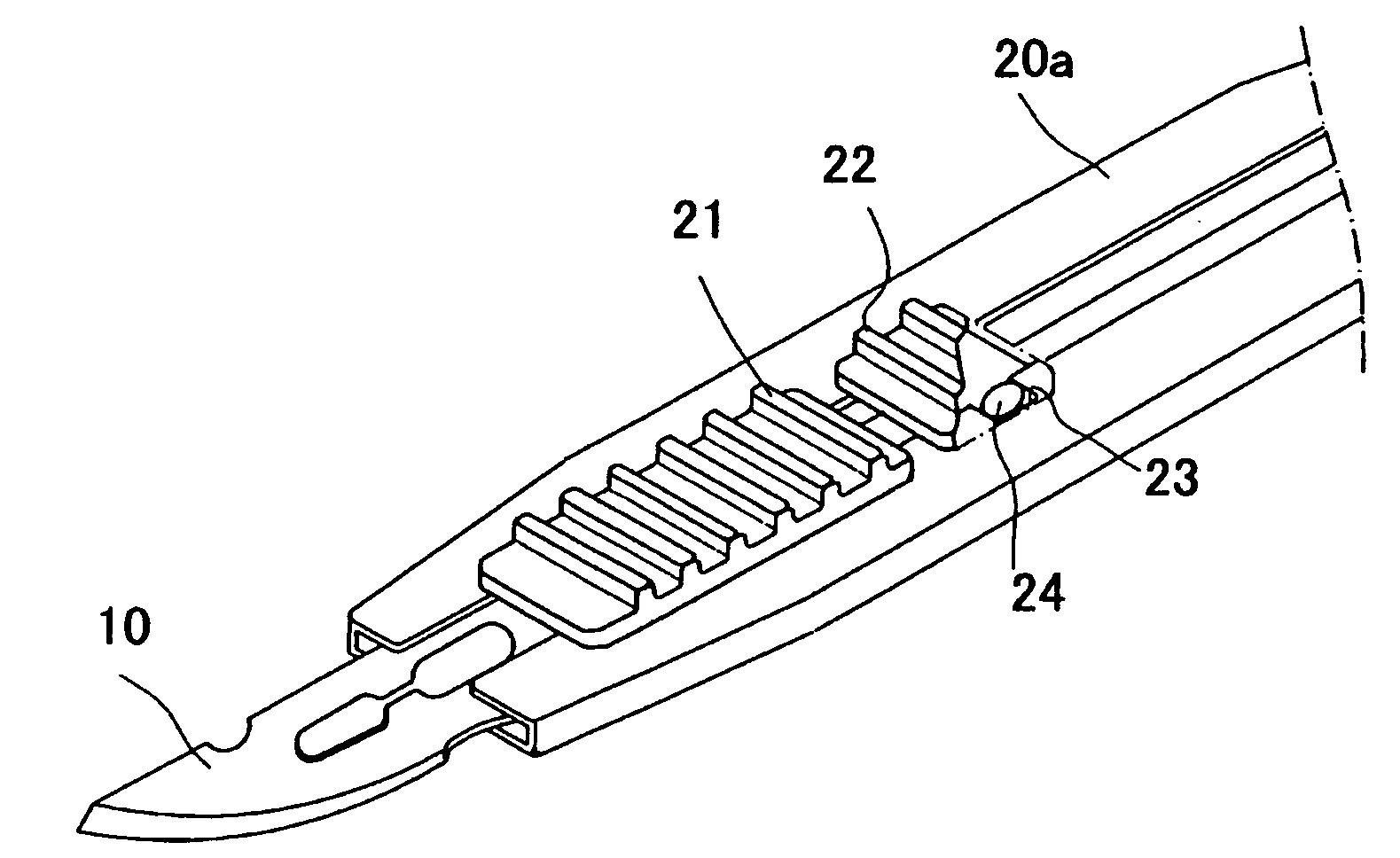

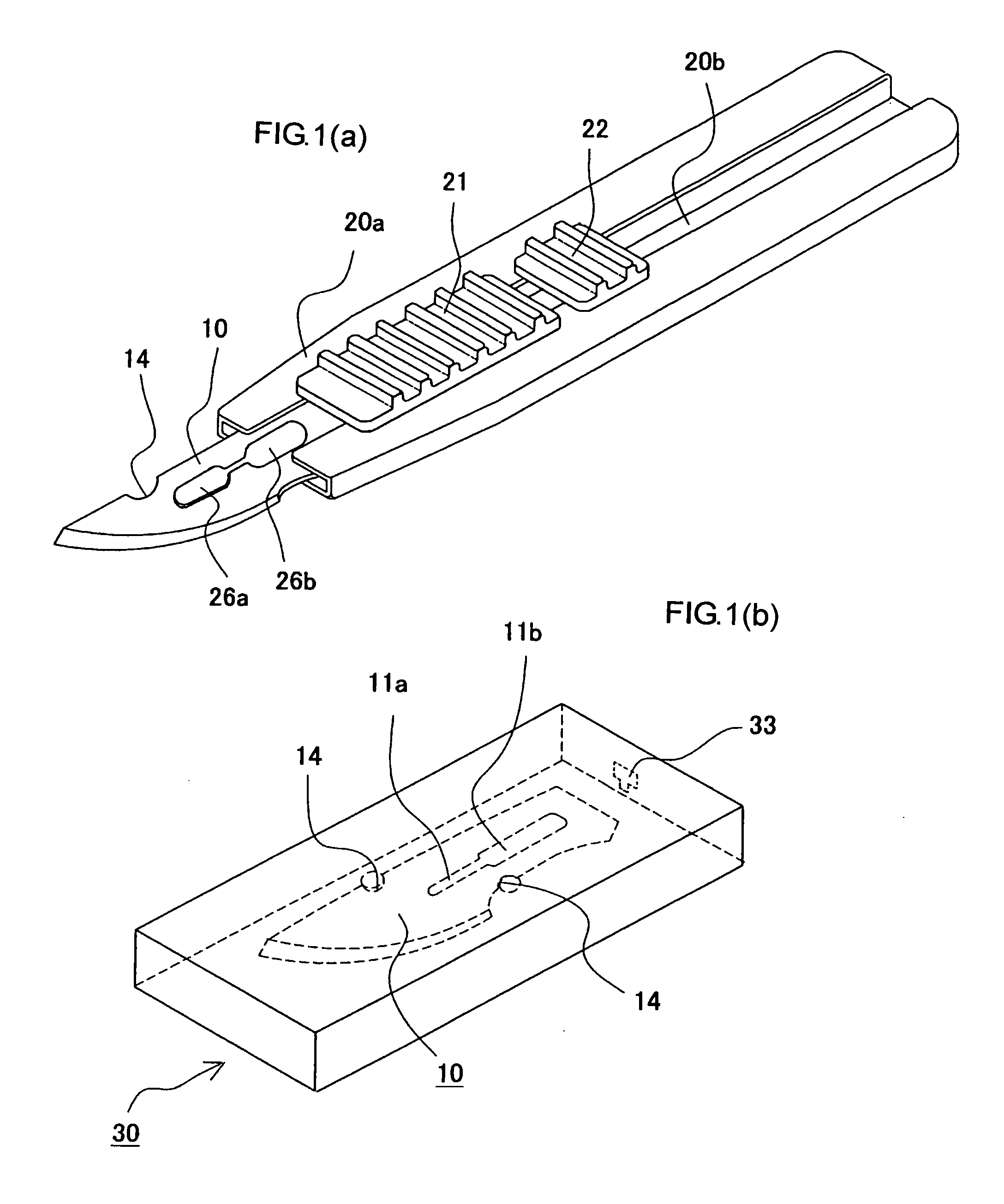

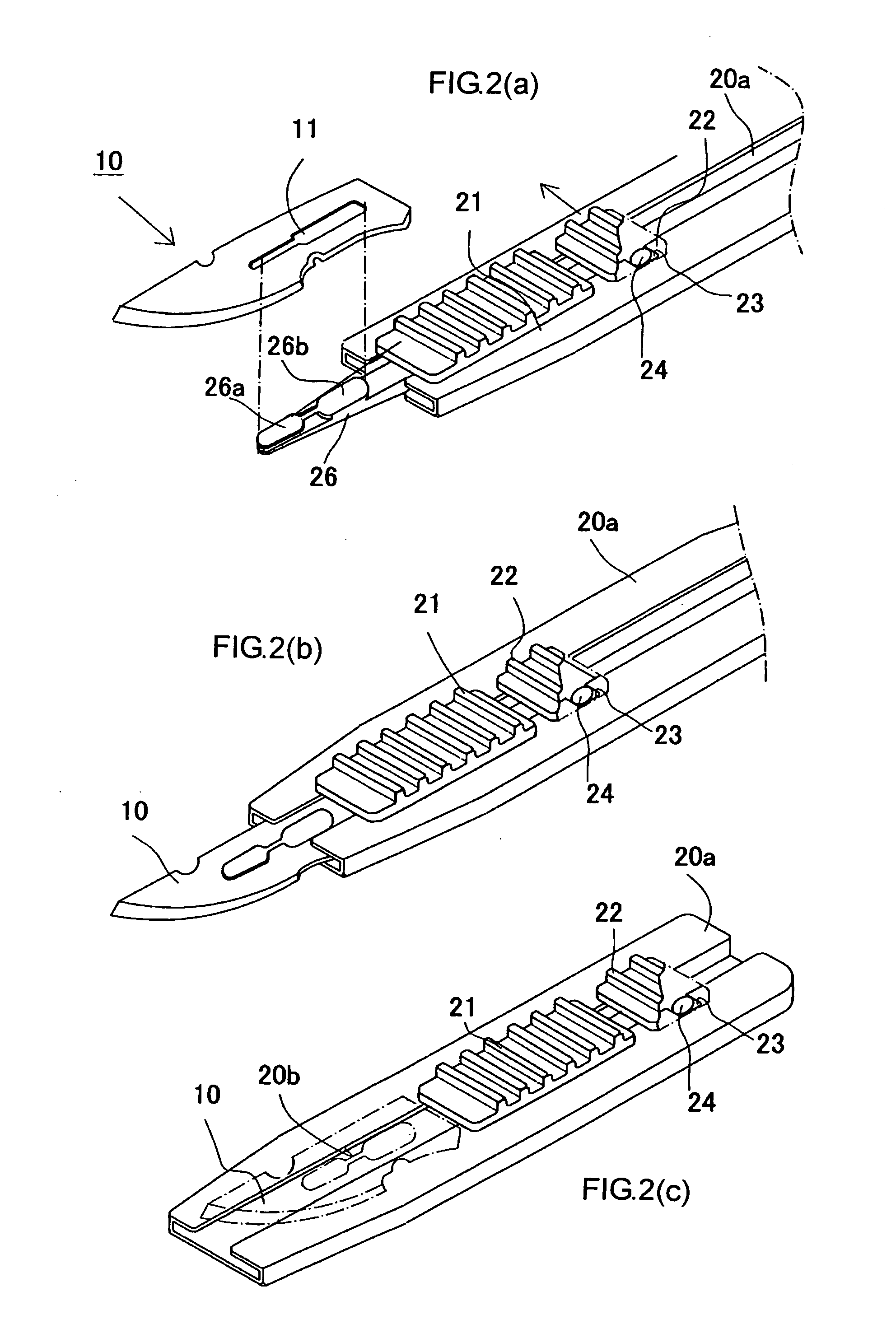

Blade Strage Case

InactiveUS20090259241A1Risk of injuryEasy to processIncision instrumentsDispensing apparatusEngineeringMechanical engineering

The invention provides a blade storage case which enables a blade to be attached to a holder body without touching the blade with the blade accommodated in the case, is safe and enables bacteria and the like to be prevented from adhering.The holder body is provided at its front end portion with an attaching finger to attach the blade, and in the blade is formed a fit hole adapted to an engagement portion such as a slit or the like formed in the attaching finger. The storage case that accommodates the blade is provided with an upper support face and a lower support face to sandwich upper and lower surfaces of the plate-shaped blade therebetween to store. As the upper and lower support faces, for example, the case is divided into two parts, and the upper support face is formed in the upper case while the lower support face is formed in the lower case. Alternately, an internal lid is provided to form the upper support face. In the box-shaped case body, an insertion guide hole to guide the attaching finger along the lower surface of the internal blade from the outside of the case and a blade fixing piece that positions and holds the blade are disposed in at least one of the upper and lower support faces.

Owner:ACP JAPAN +1

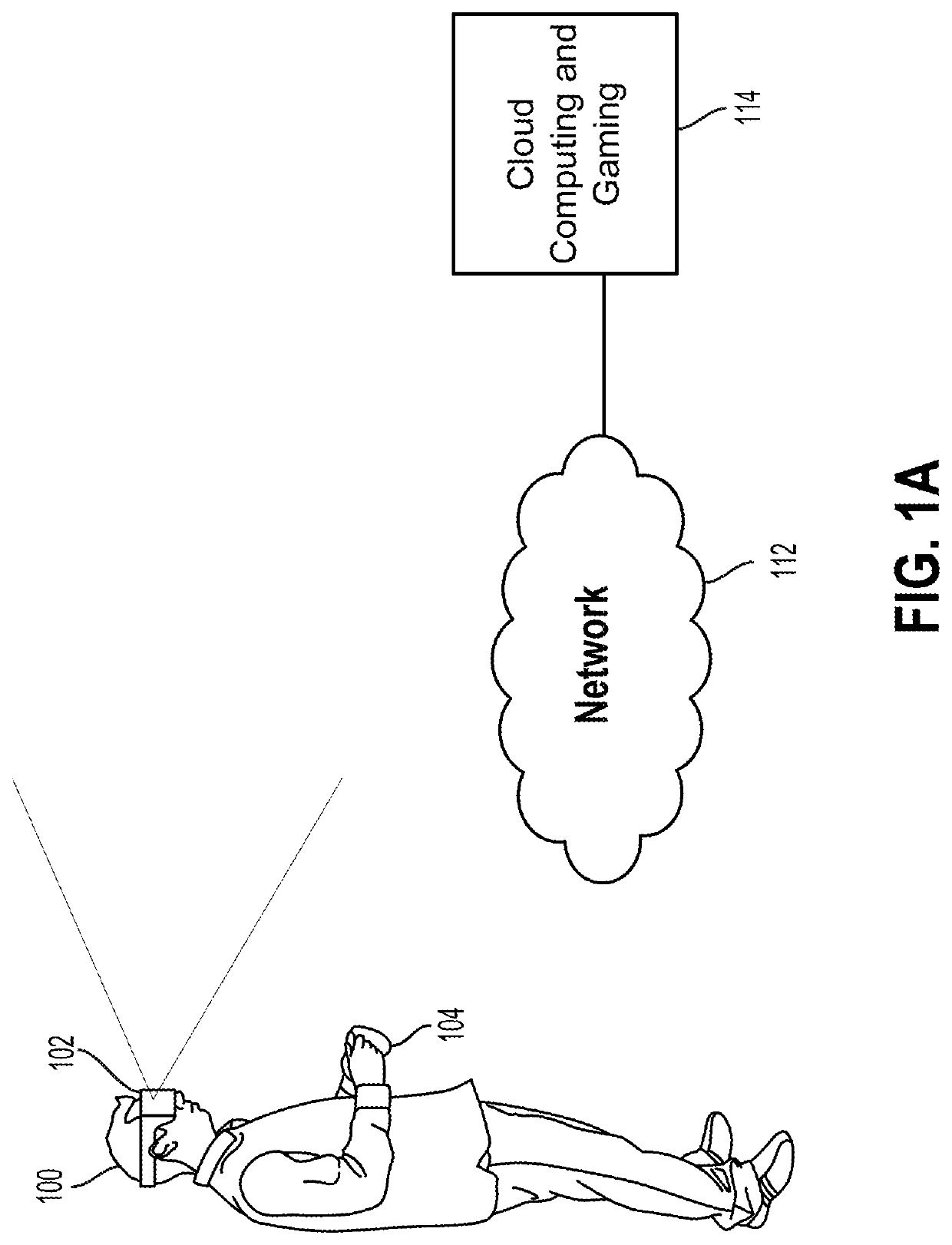

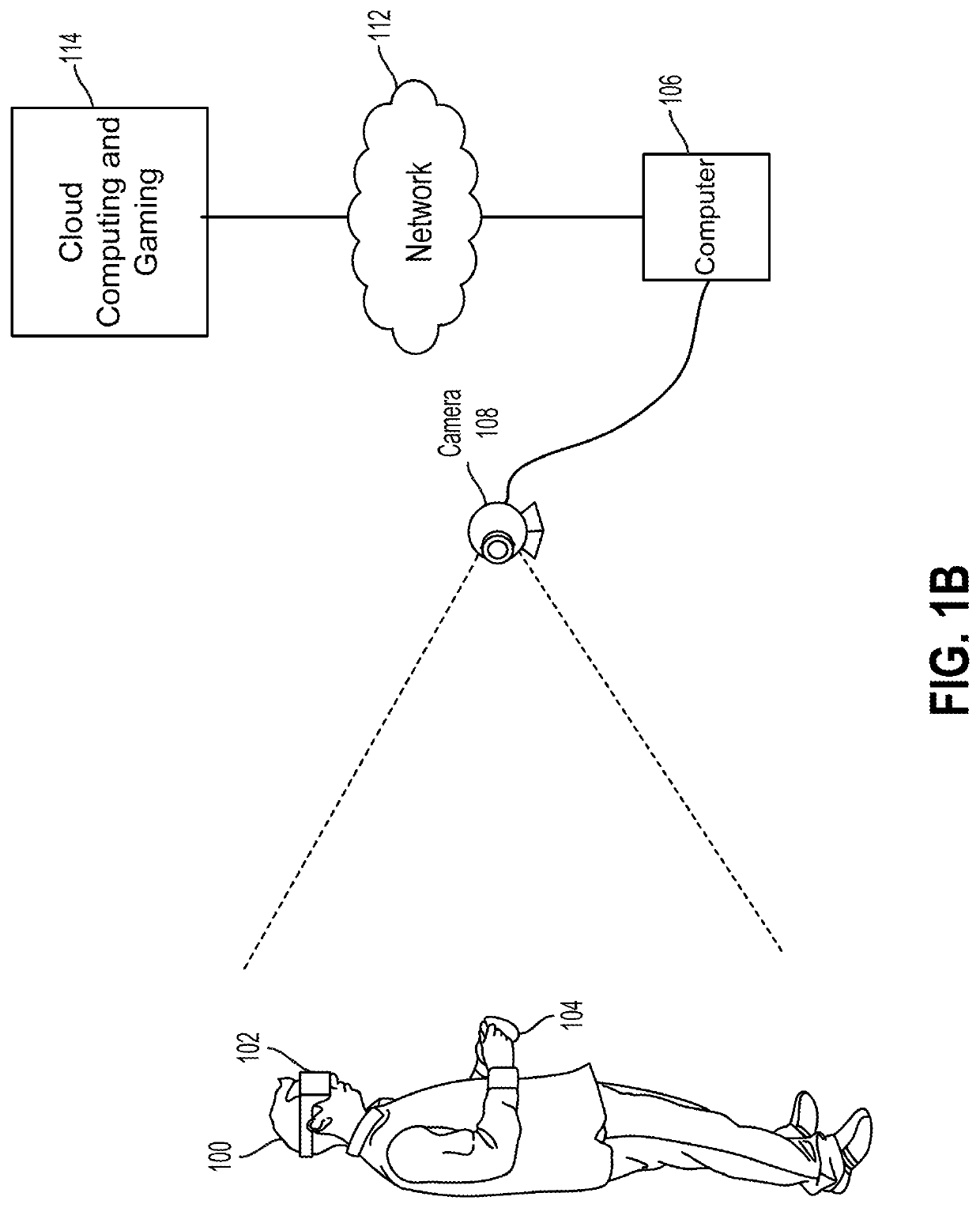

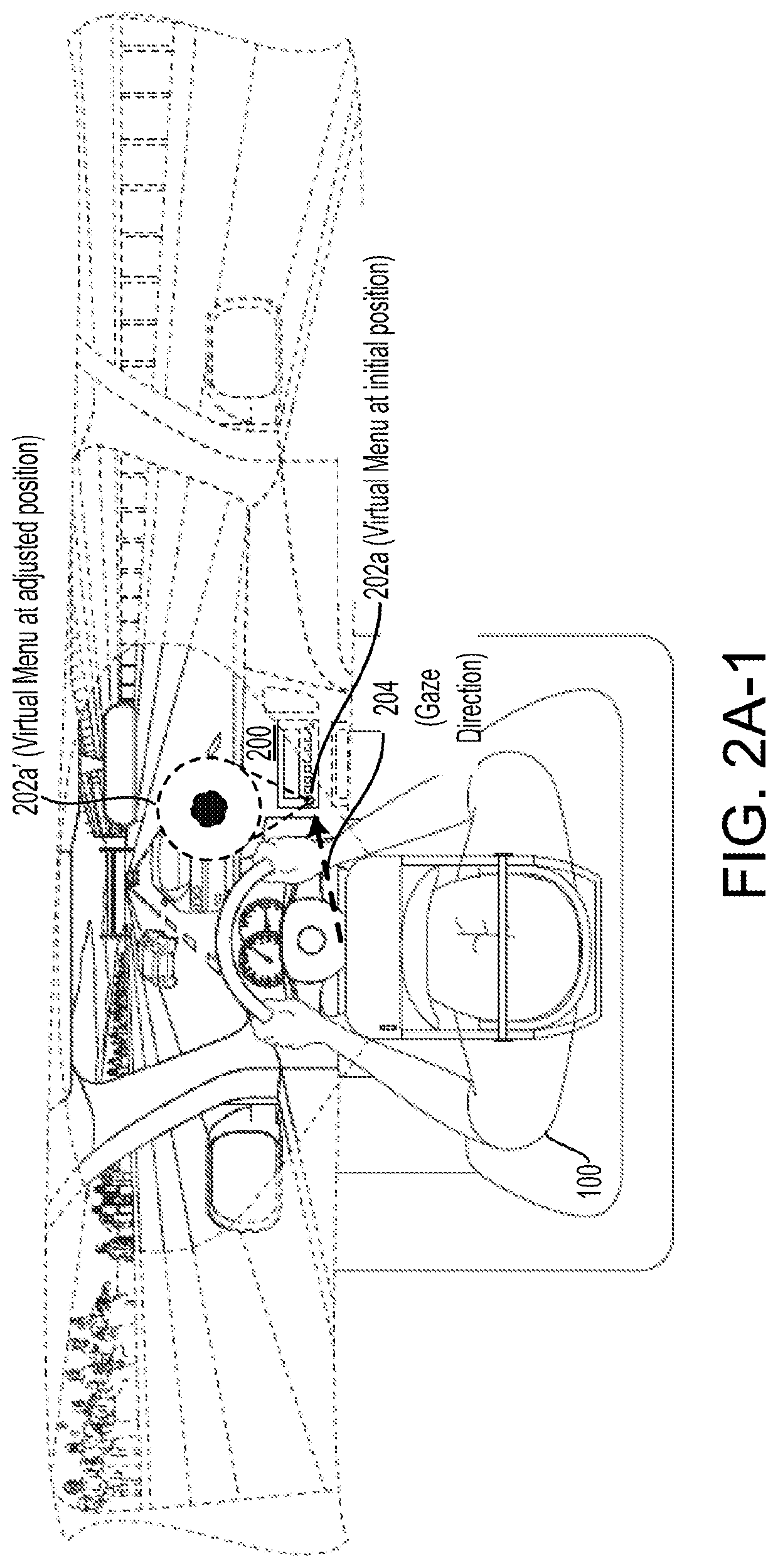

Menu placement dictated by user ability and modes of feedback

ActiveUS11278810B1Limit range of motionRisk of injuryGeometric image transformationDetails for portable computersComputer graphics (images)Virtual position

Methods and systems are provided for placing or moving a virtual menu (e.g., virtual object) to an adjusted virtual position within a virtual reality scene based on the ability of a user. The method includes capturing, by a computing system, head mounted display (HMD) gameplay by a user of a video game being executed on the computing system. The HMD presents virtual reality scene to the user. The method includes monitoring, by the computing system, physical actions of the user while the user is wearing the HMD and interacting with the virtual reality scene during the gameplay. The method includes identifying, by the computing system, an attempt by the user to make an input at a virtual object in the virtual reality scene based on the physical actions. The method includes generating, by the computing system, a movement of the virtual object from an initial virtual position in the virtual reality scene to an adjusted virtual position in the virtual reality scene. The movement has a virtual distance and a virtual direction that is predicted for the user based a model of interactivity of the user to enable said input with the virtual object. In this way, a virtual menu (e.g., virtual object) is dynamically placed or moved to a virtual position in the virtual reality scene that can be accessible by the user.

Owner:SONY COMPUTER ENTERTAINMENT INC

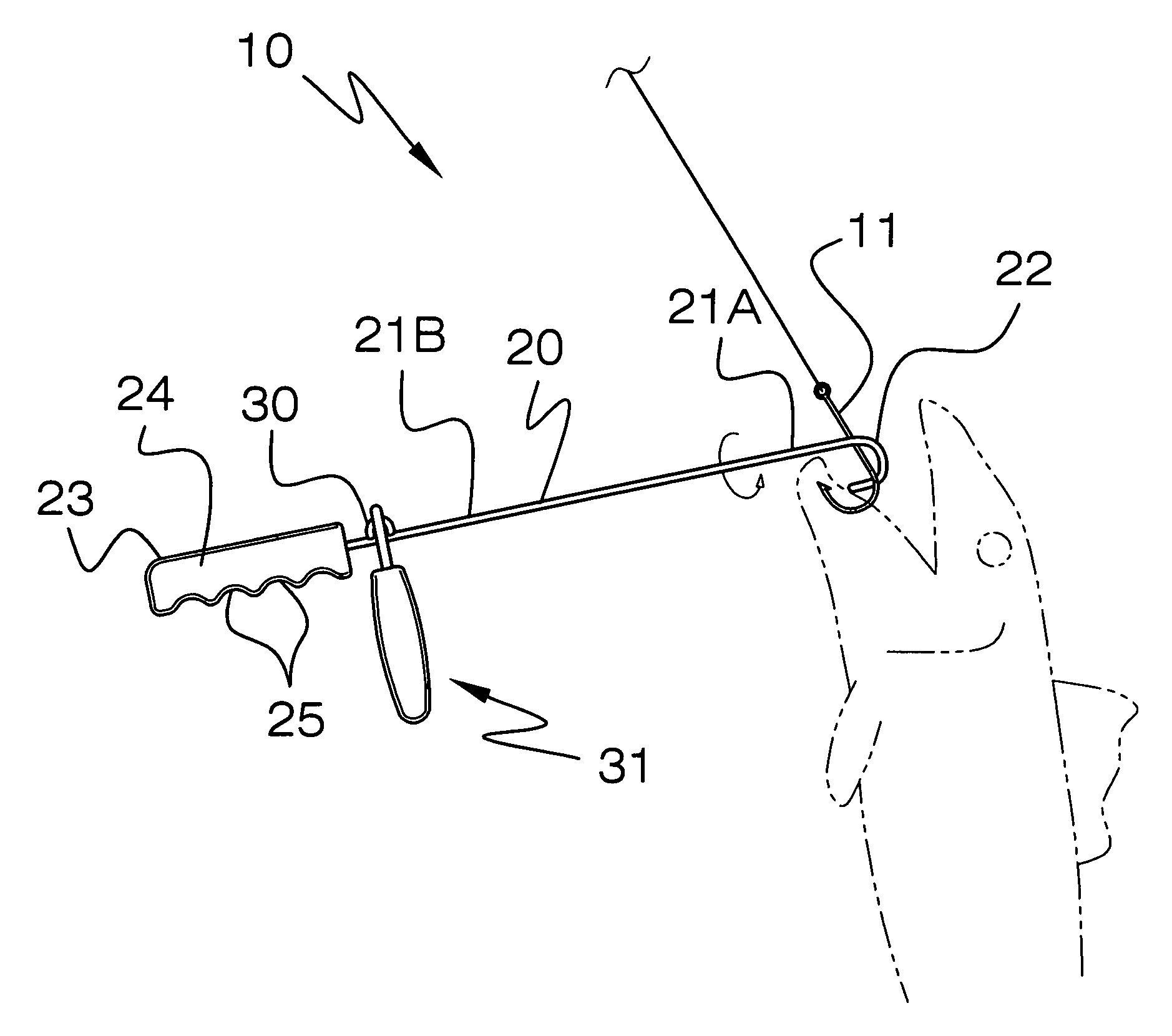

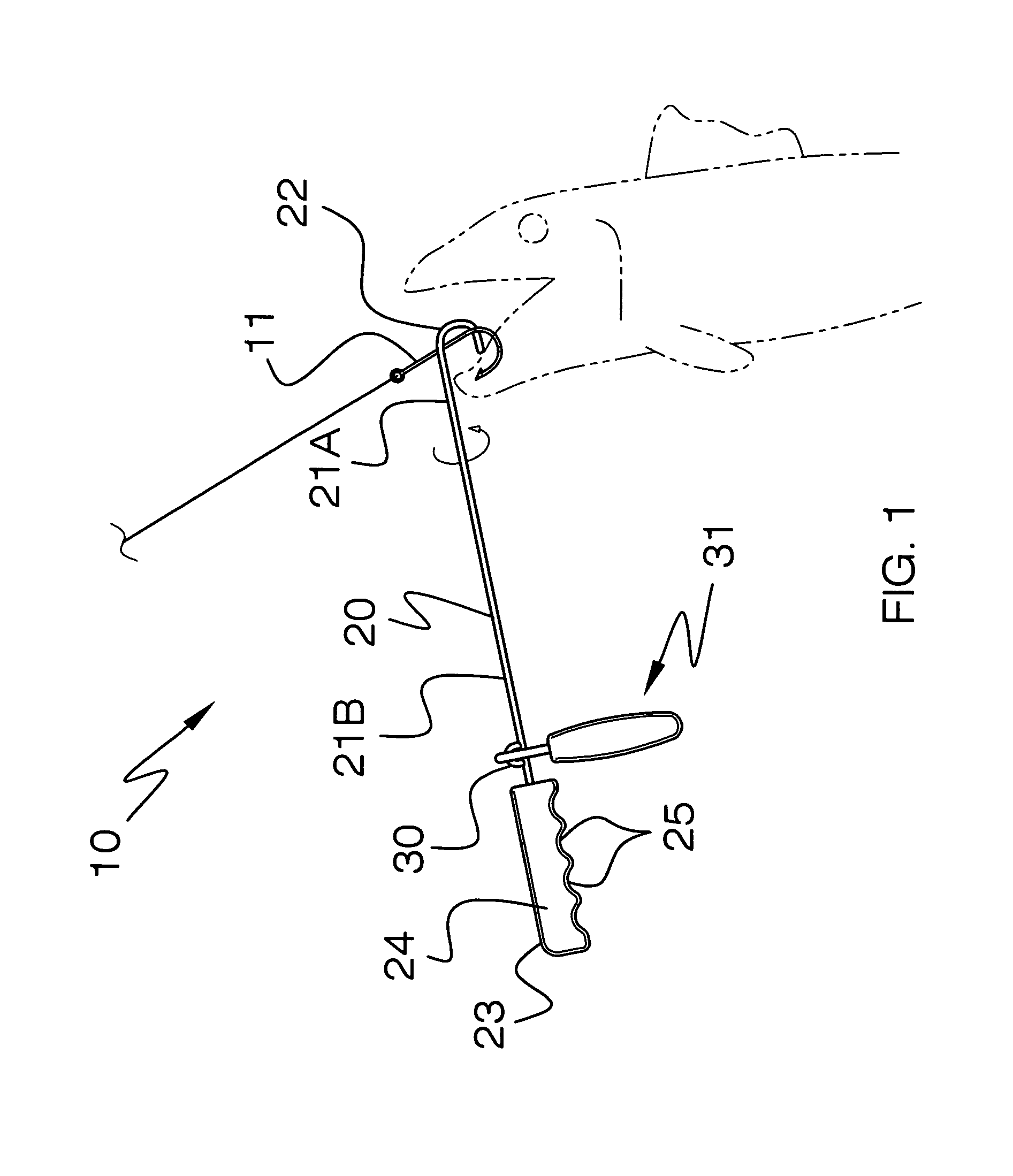

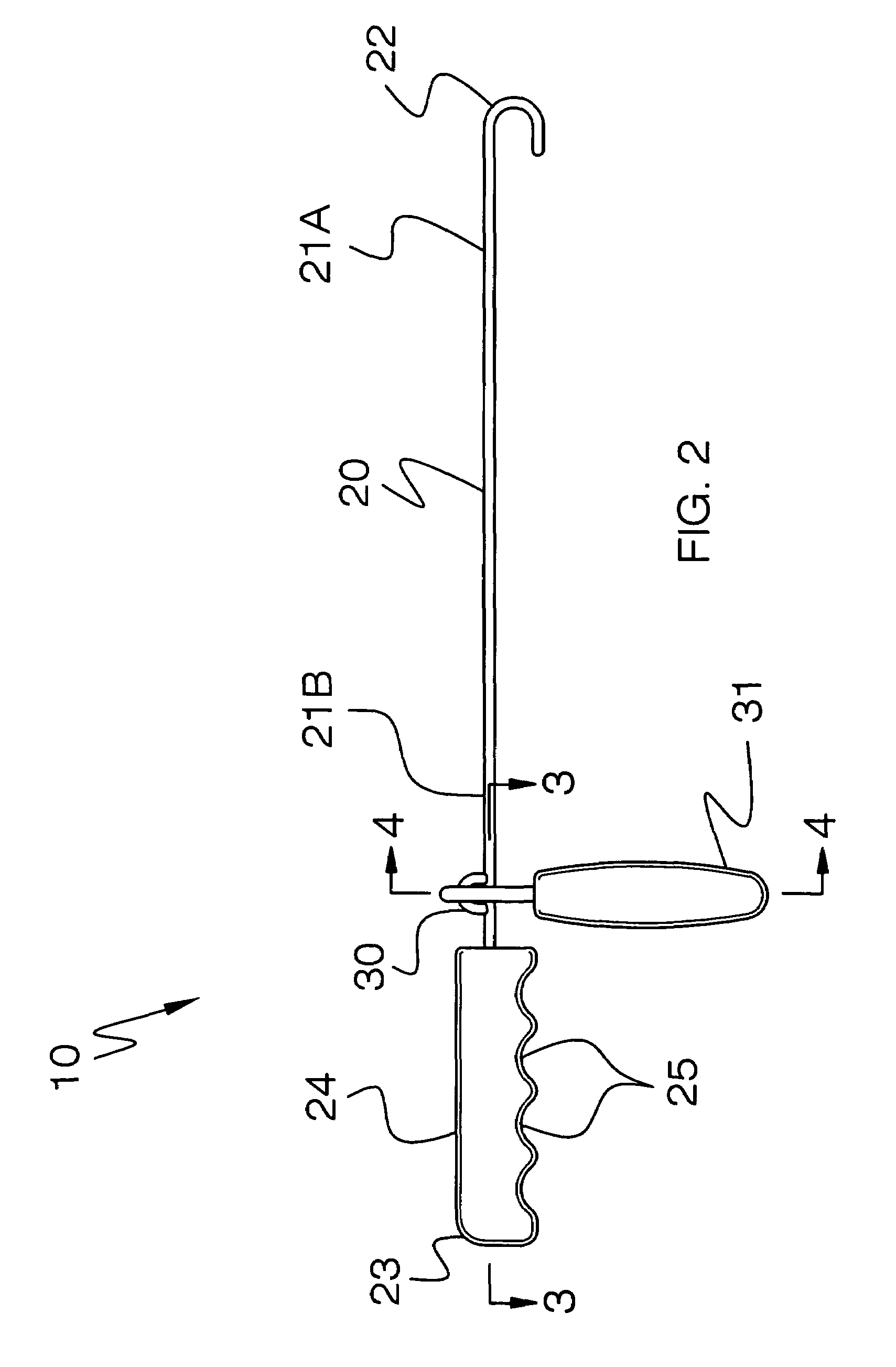

Two-handed fish hook removal apparatus

A fish hook removal apparatus includes a shaft having opposed end portions. One end portion defines a hook for fitting into a fish's mouth. Such a hook is engageable with a fish hook. The shaft enables a user to remove a hook from fish. A grip is positioned about another end portion. Such a grip includes indentations spaced along a length of the grip allowing for a firm grasp. A clevis is attached to the shaft and situated proximate to the grip. A handle includes body and rod portions. Such a rod portion has opposed end portions. The body portion is positioned about one end of the rod extending from the body. The handle is abutted against the shaft in such a manner that rotation of the handle causes the hook to twist about a fishing hook lodged within the fish's mouth, thereby dislodging the fishing hook.

Owner:GOMEZ SR JERRY J +1

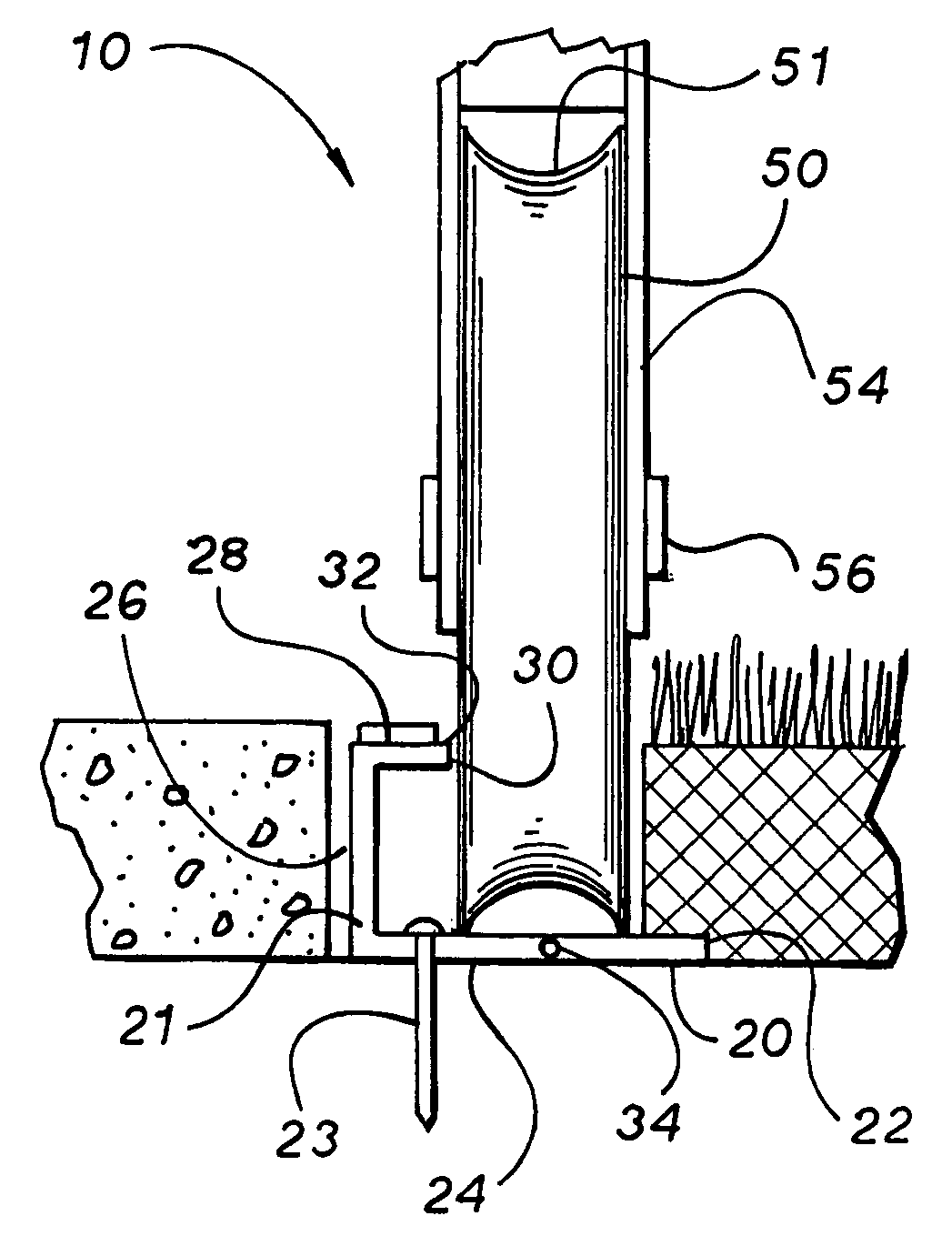

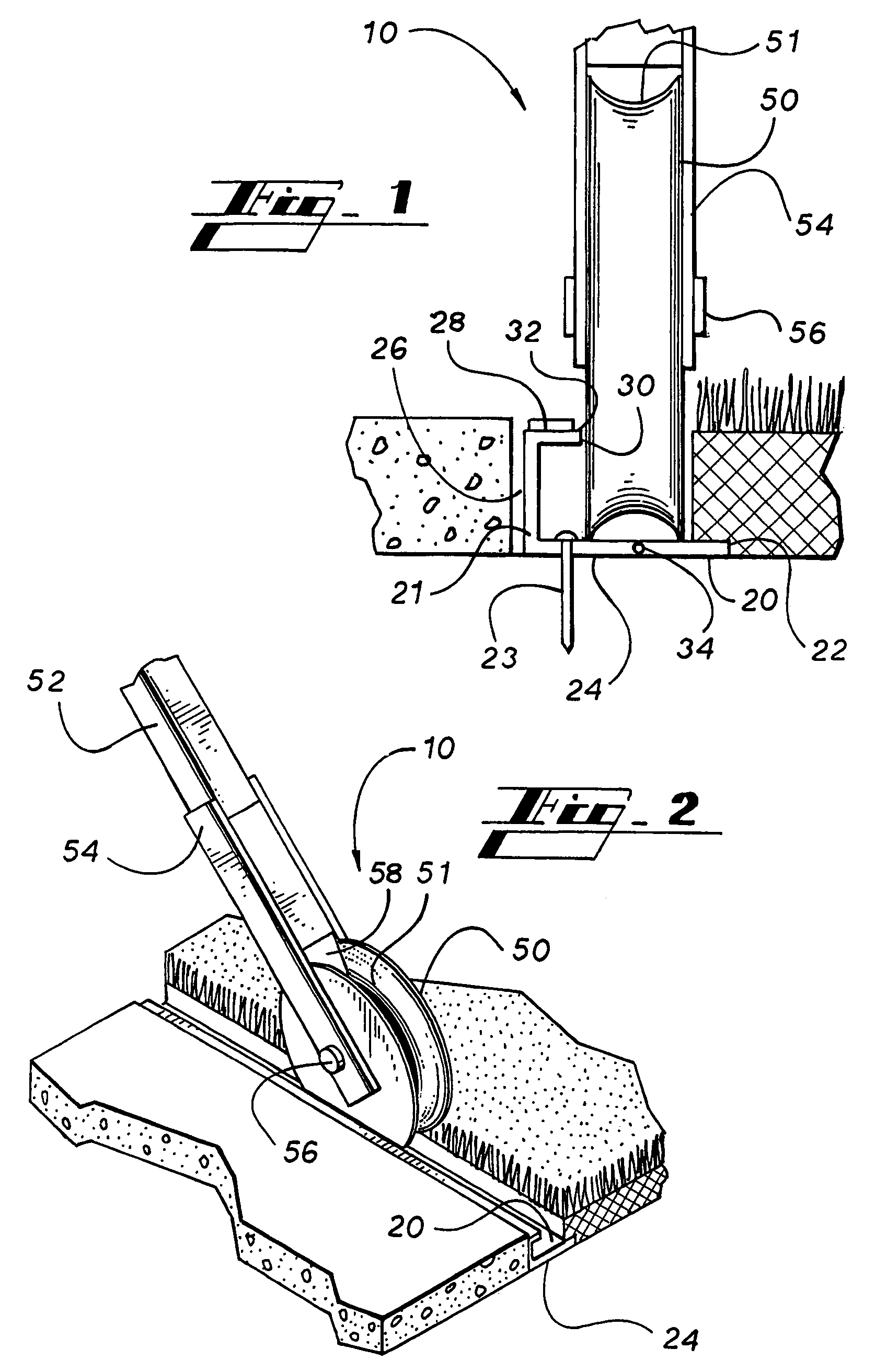

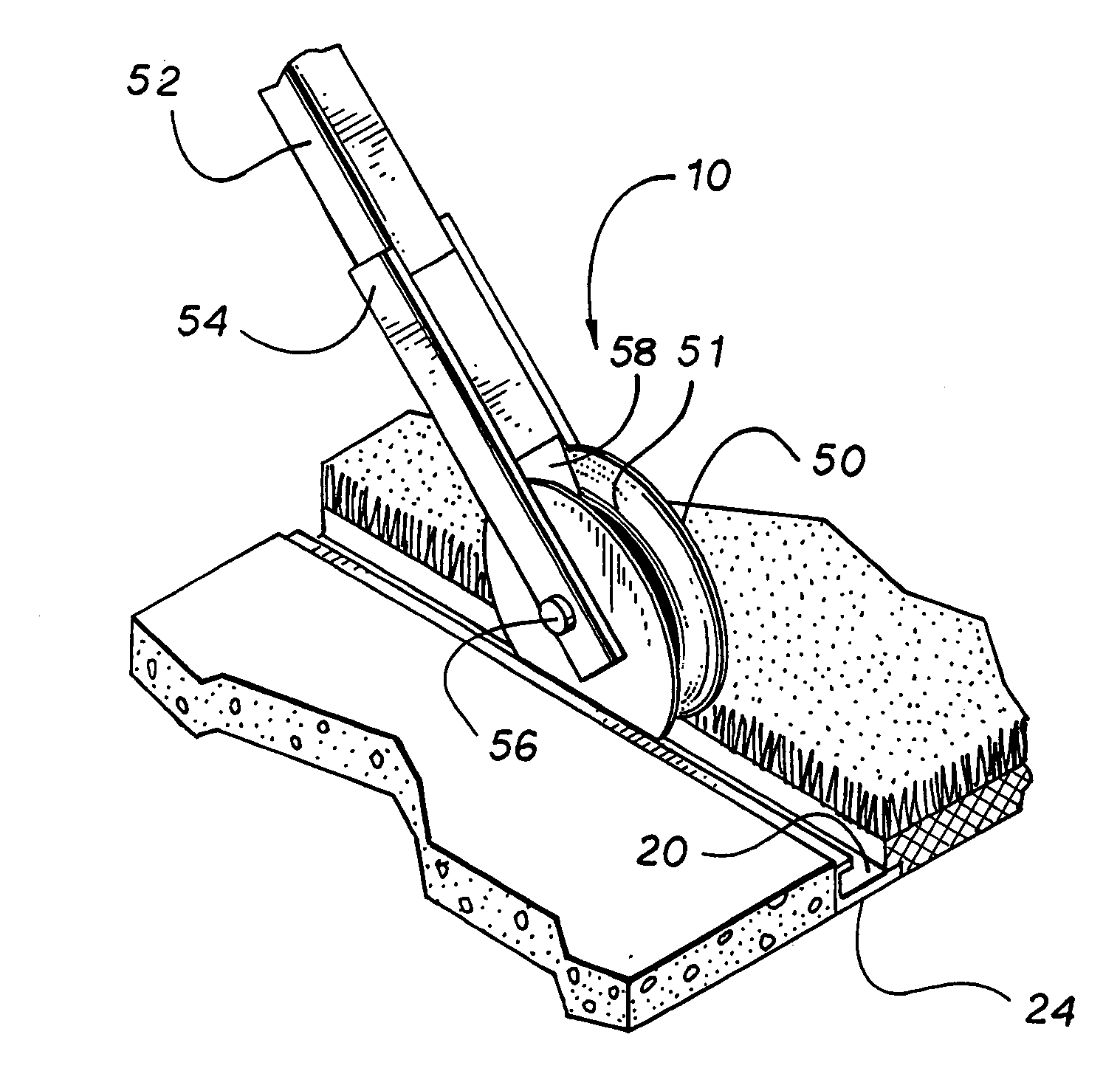

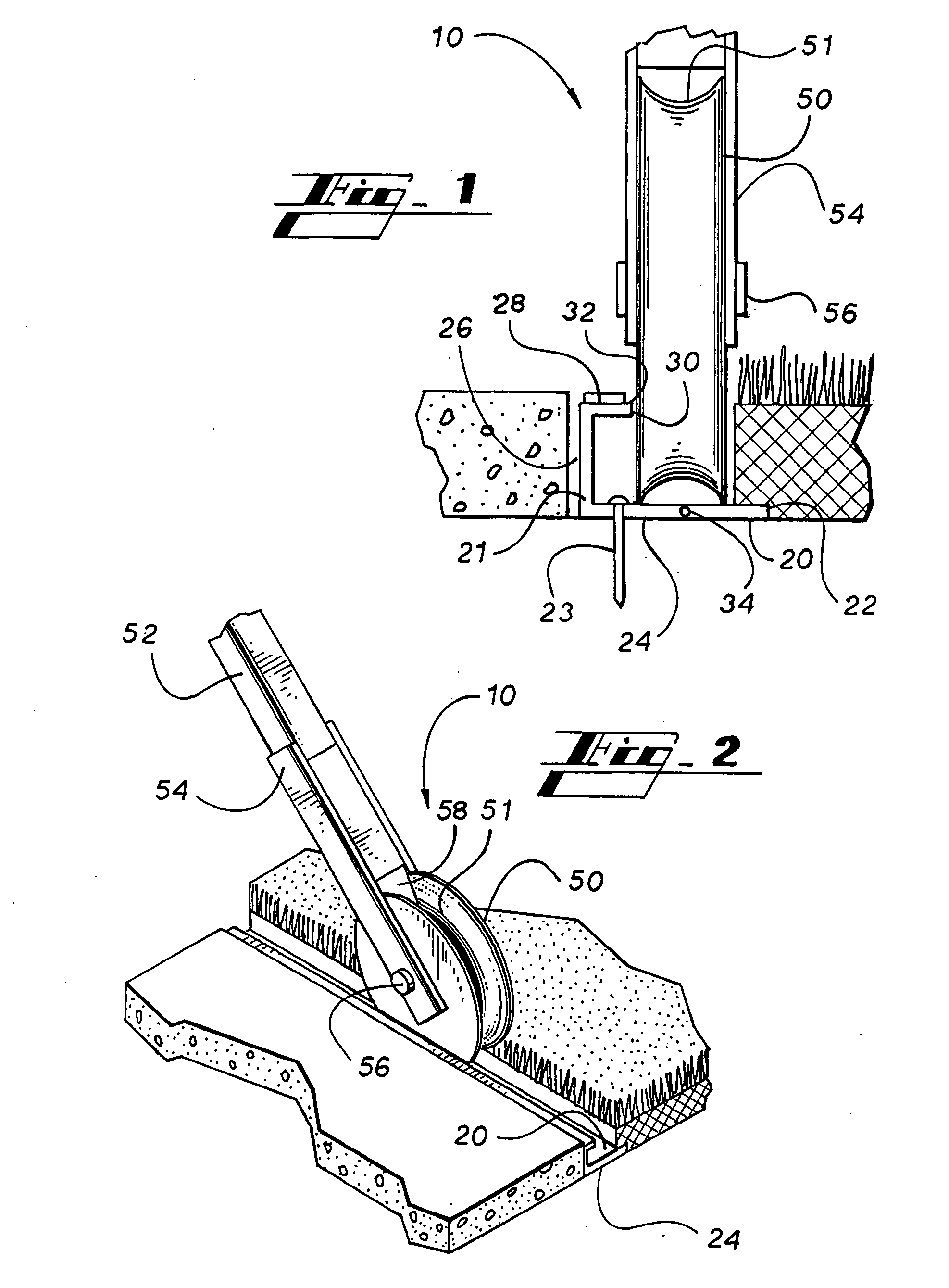

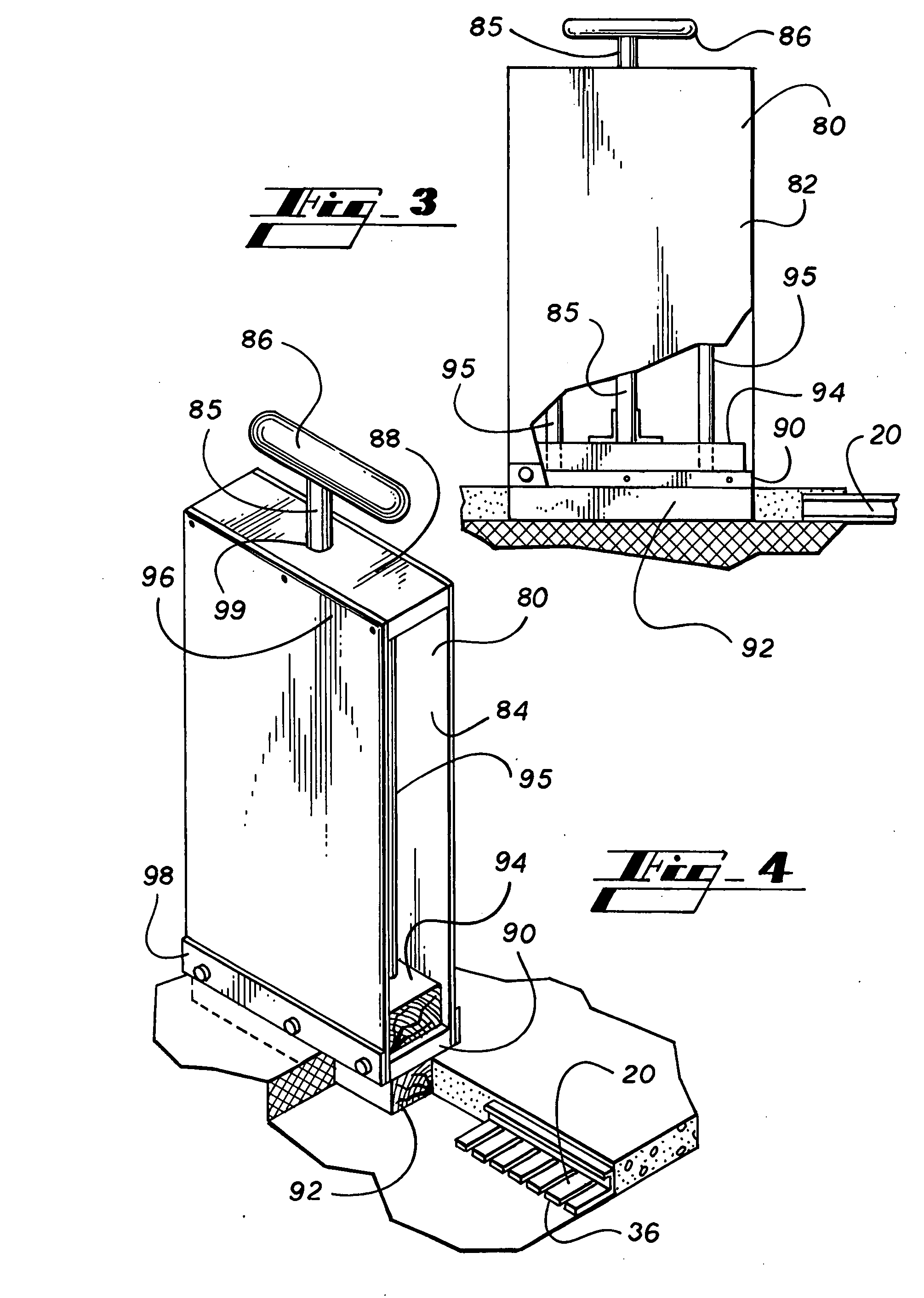

Landscape edging system and device and methods of installation and use thereof

A landscape edging system and device, and methods of installation and use thereof, wherein a J-shaped track system is installed in a trench along landscape edges, and wherein a pulley wheel attached to a rod is utilized to push the grass down onto a cutting edge of the track to execute the edging process, thereby simplifying the task of edging, eliminating risk of personal injury and allowing for essentially silent lawn care at any hour of the day, wherein decorative outer coverings may be incorporated along the track edging to simulate landscape features, such as rock or brick, and wherein lighted tubing may be installed within the track, thereby enhancing visual nighttime display and illuminating the landscape edge for aesthetic as well as safety reasons.

Owner:HALL RICHARD

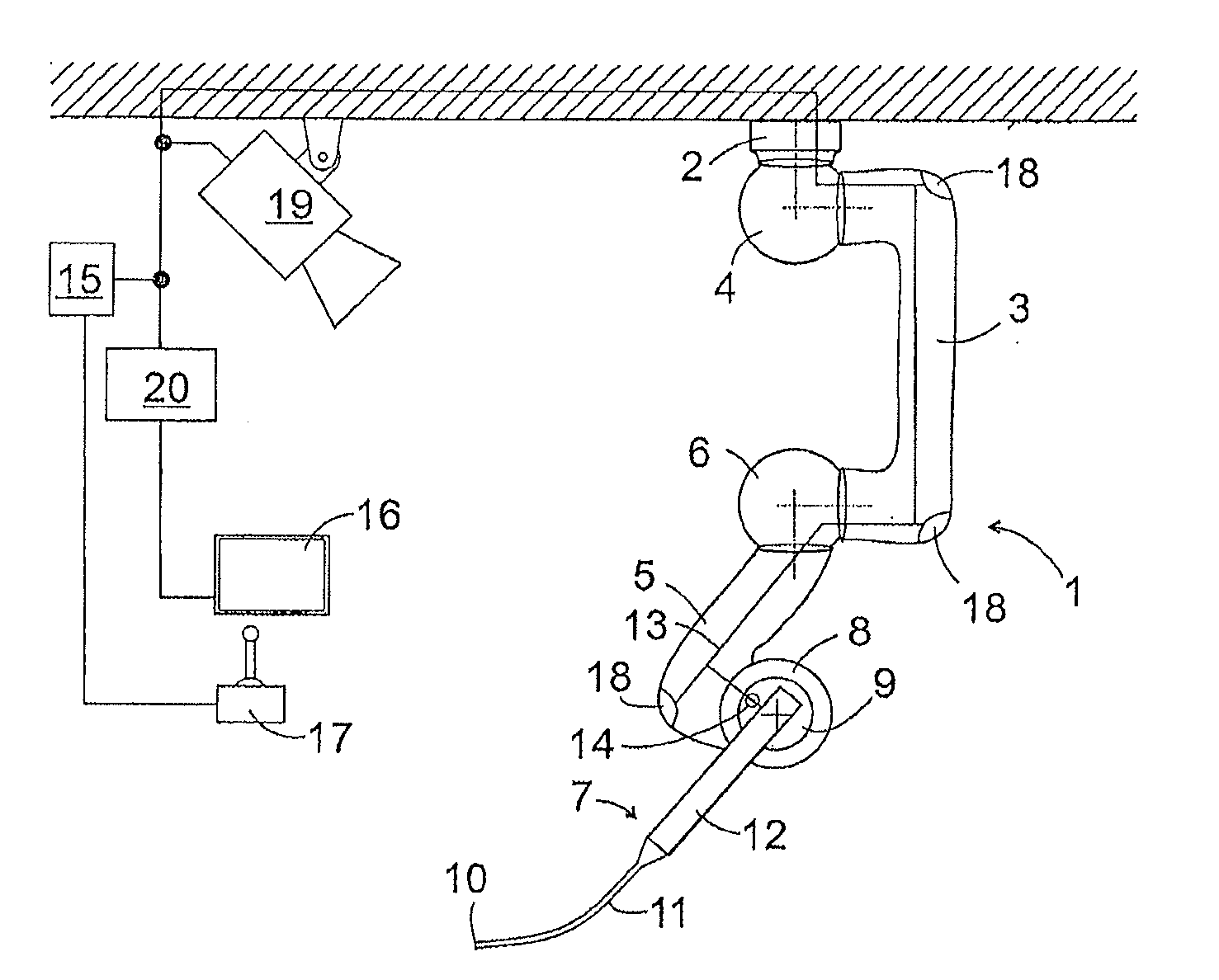

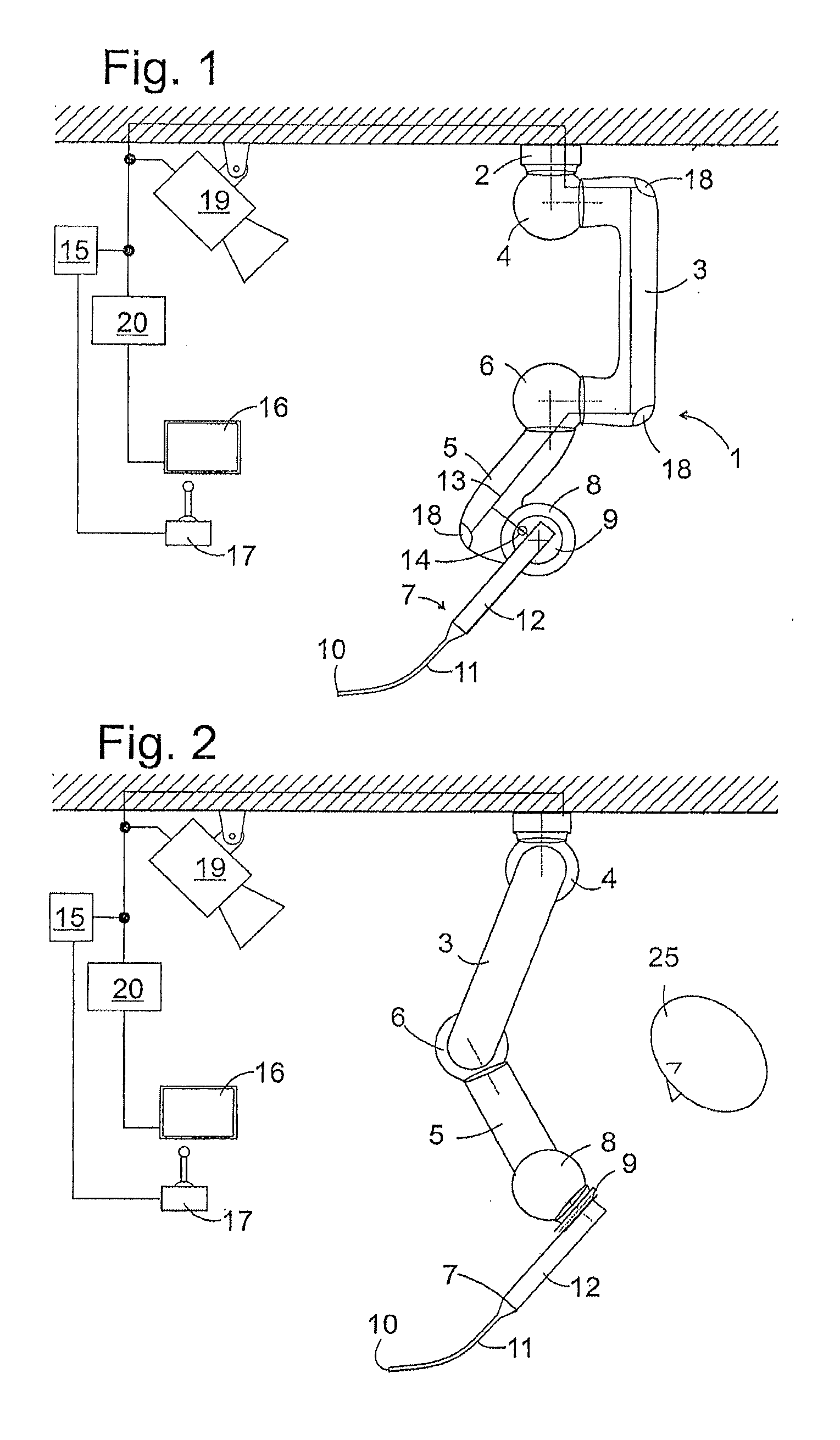

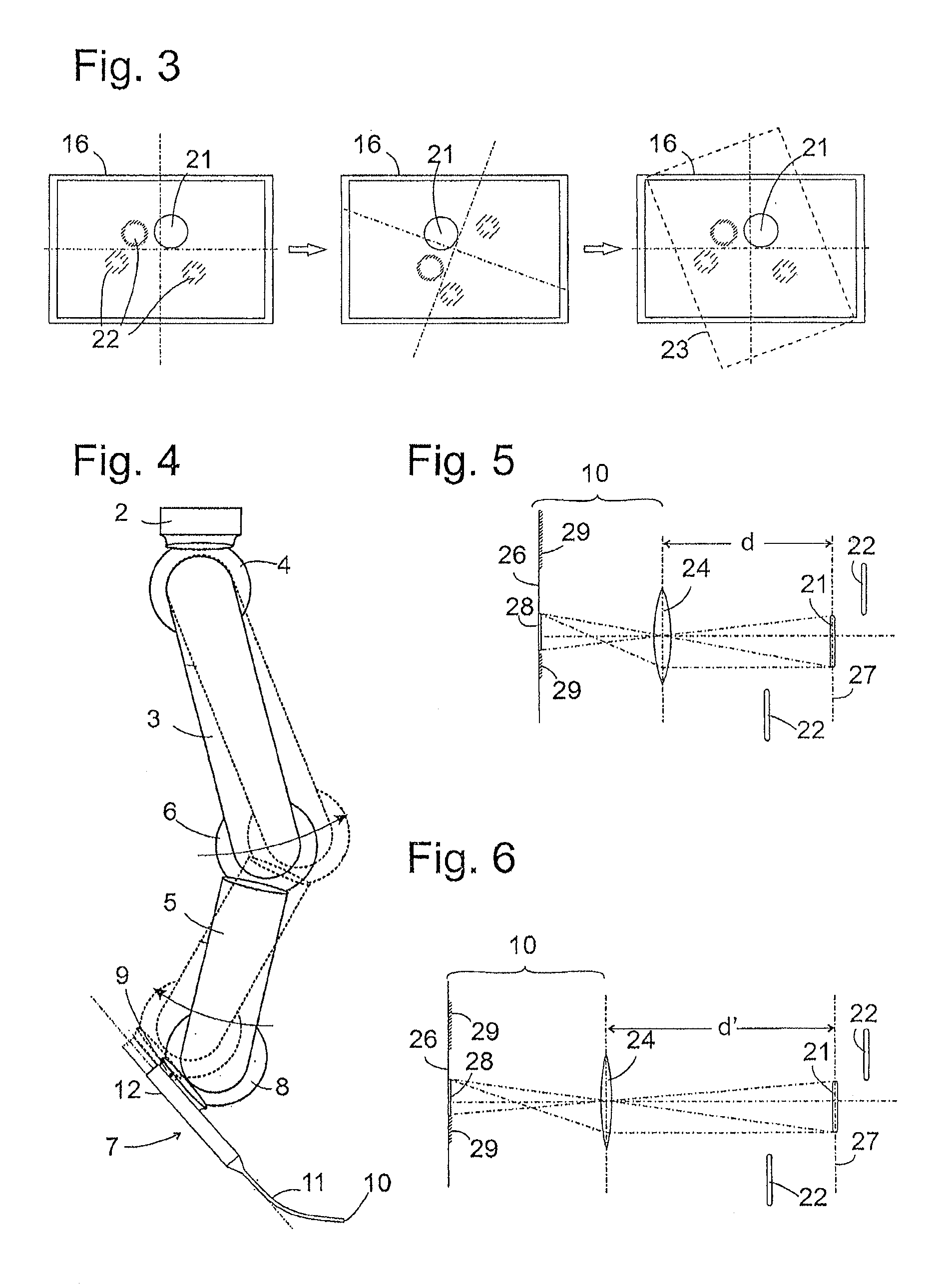

Robotic system

ActiveUS20160199140A1Risk of injuryEasier for a user to recogniseEndoscopesTelescopesRobotic systemsEngineering

A robot system comprises a base (2), a robot arm (1) connected to the base, a camera (10), at least one objective lens in the camera (10) being movable with the robot arm (1), and a screen (16). A control unit (15) is configured to detect a change in the distance between an object (21) detected by the camera (10) and the objective lens, and to vary the zoom factor of a zoom function of the camera (10) according to the change in distance.

Owner:ABB (SCHWEIZ) AG

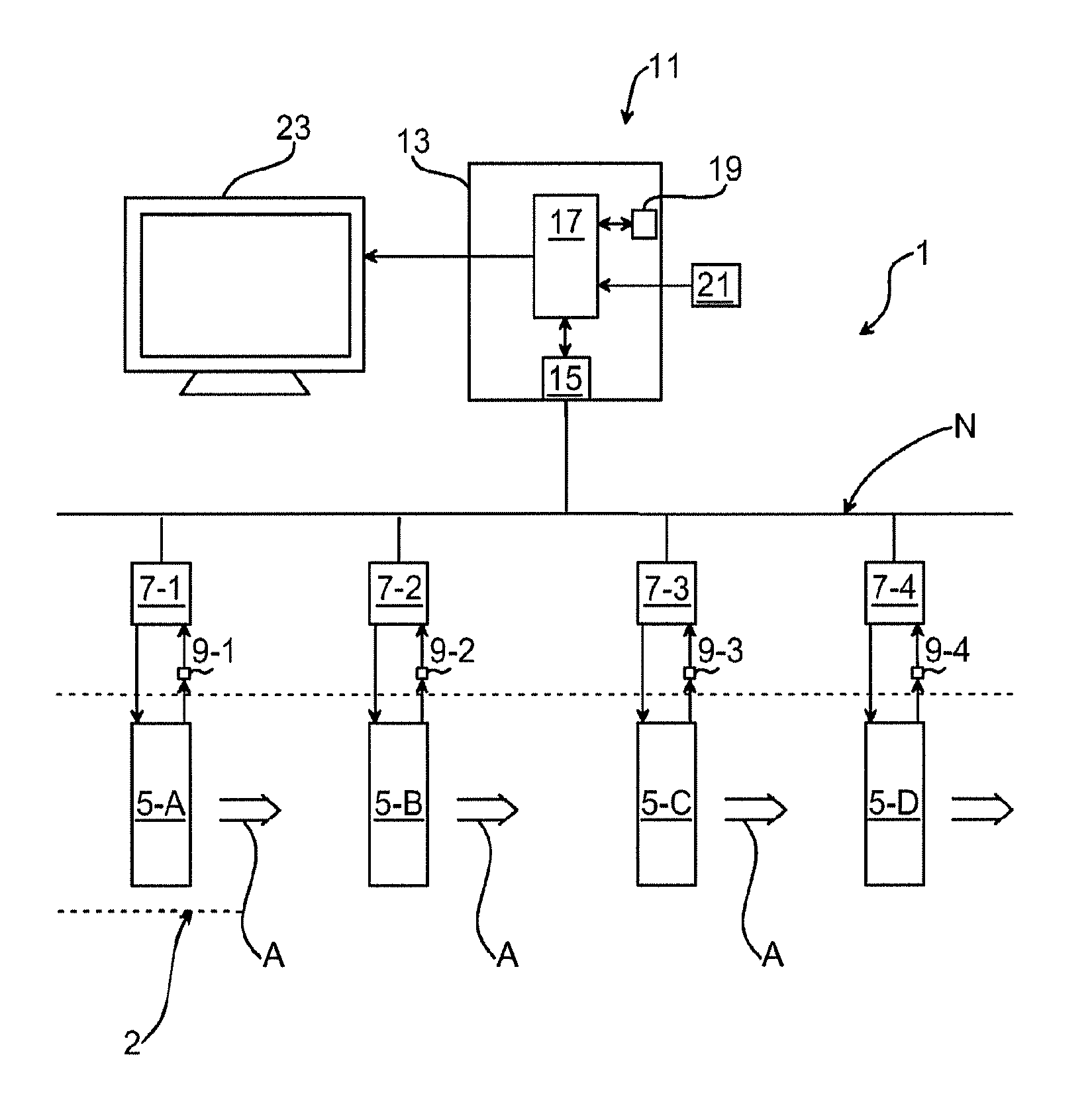

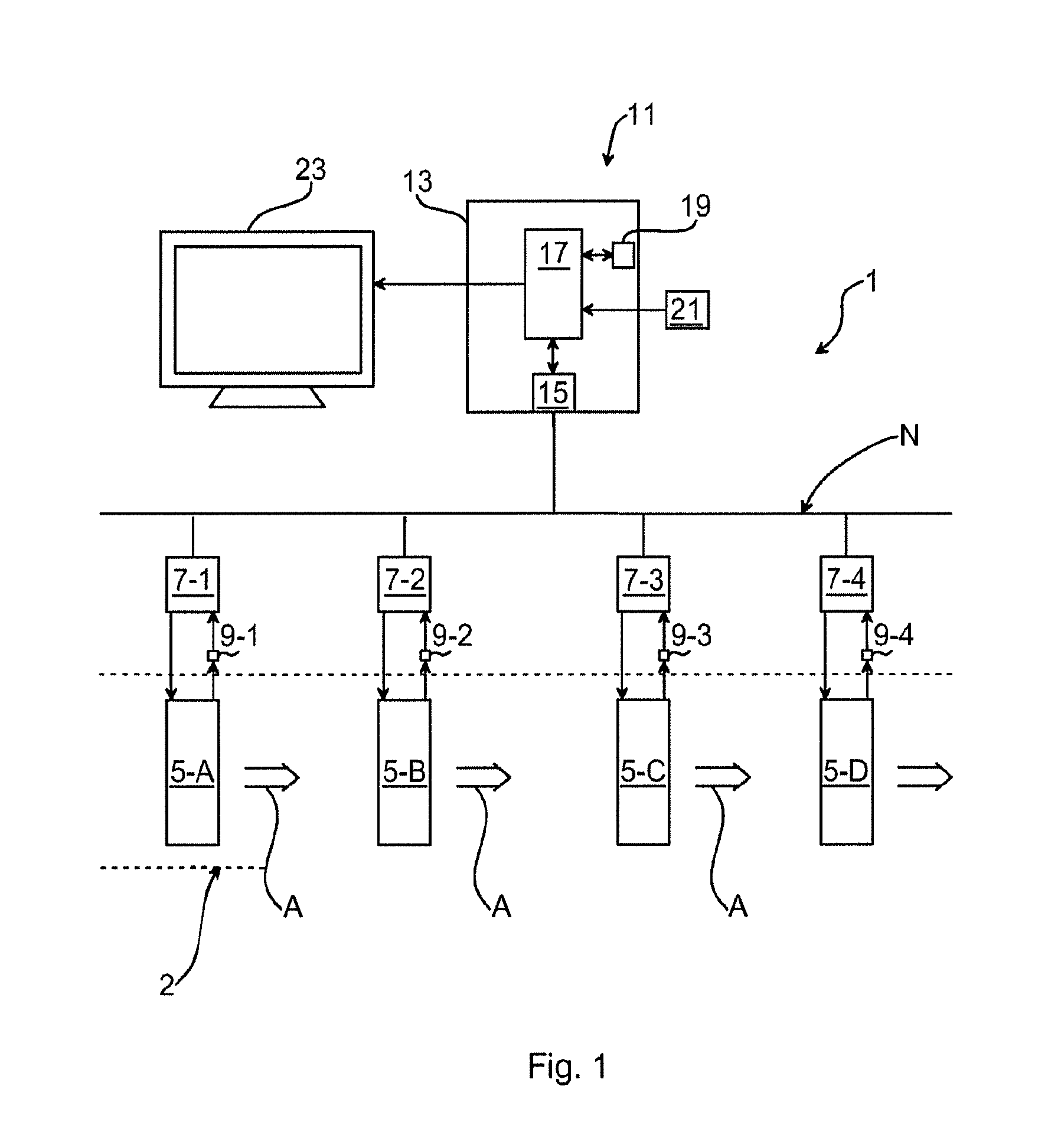

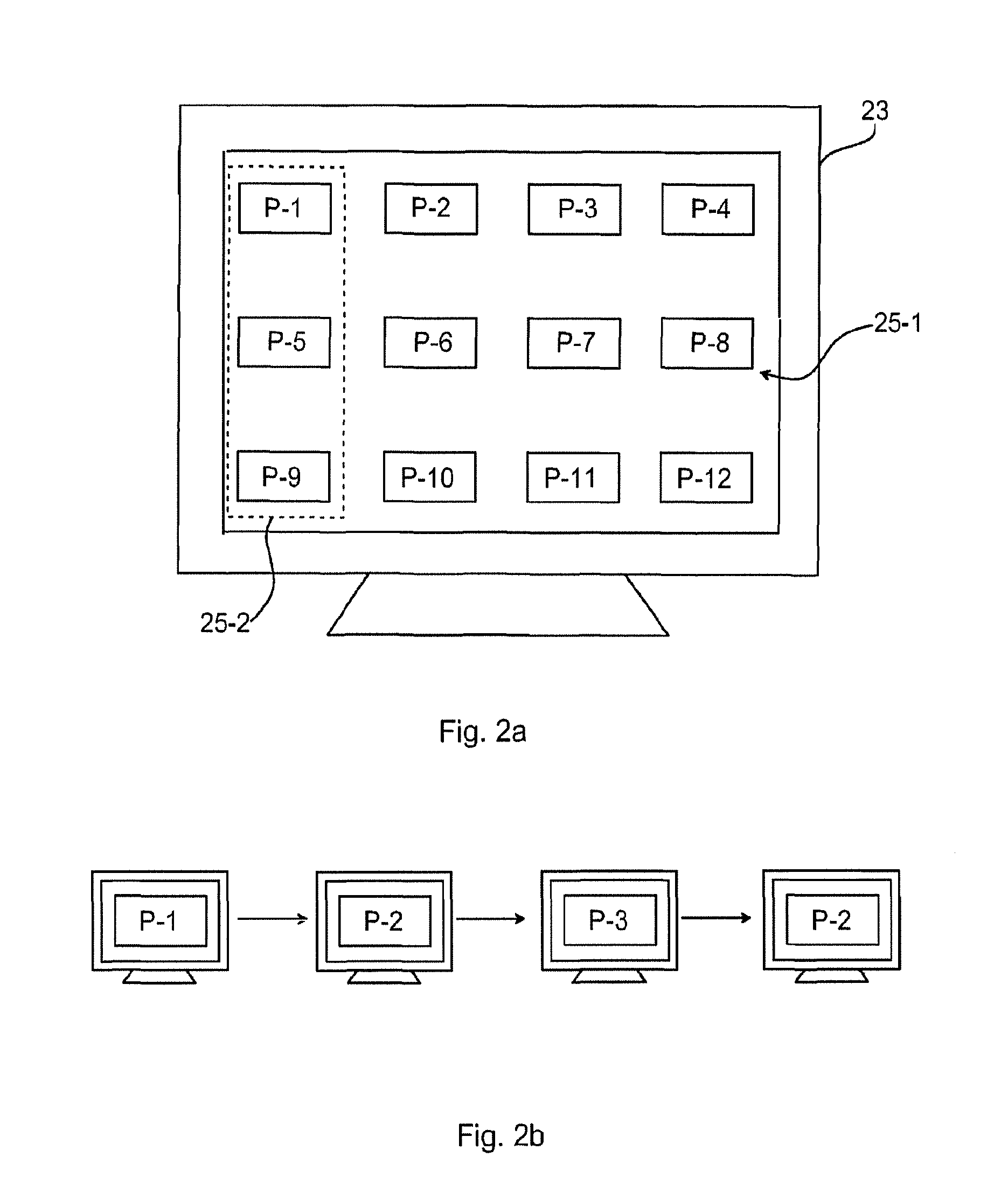

Method and system for controlling an industrial process

ActiveUS9201419B2Intuitive monitoringEasy to controlComputer controlElectric testing/monitoringControl systemDisplay device

A method of monitoring and controlling an industrial process associated with a plurality of process variables by a control system including displaying a set of process related images which are user-selected on a display device of the control system, each process related image of the set of process related images being associated with a process variable of the plurality of process variables; receiving process variable data of the plurality of process variables while the step of displaying is carried out, and when process variable data is received indicating that a process variable has a status value outside a predetermined accepted range; and displaying, on the display device, a process related image which is associated with the process variable with the status value outside the predetermined accepted range, receiving an input command for controlling the process variable, and controlling the process variable based on the input command.

Owner:ABB (SCHWEIZ) AG

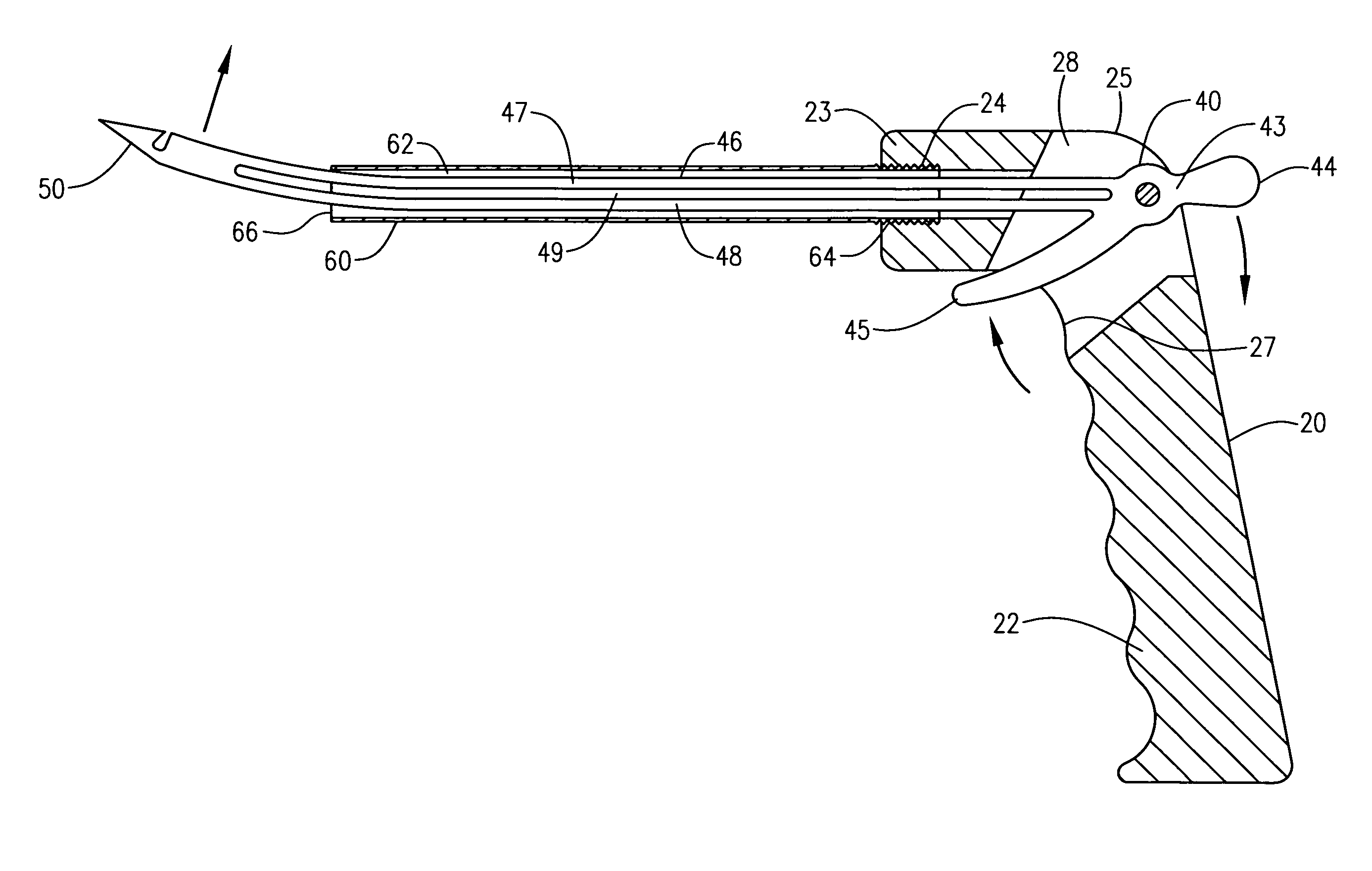

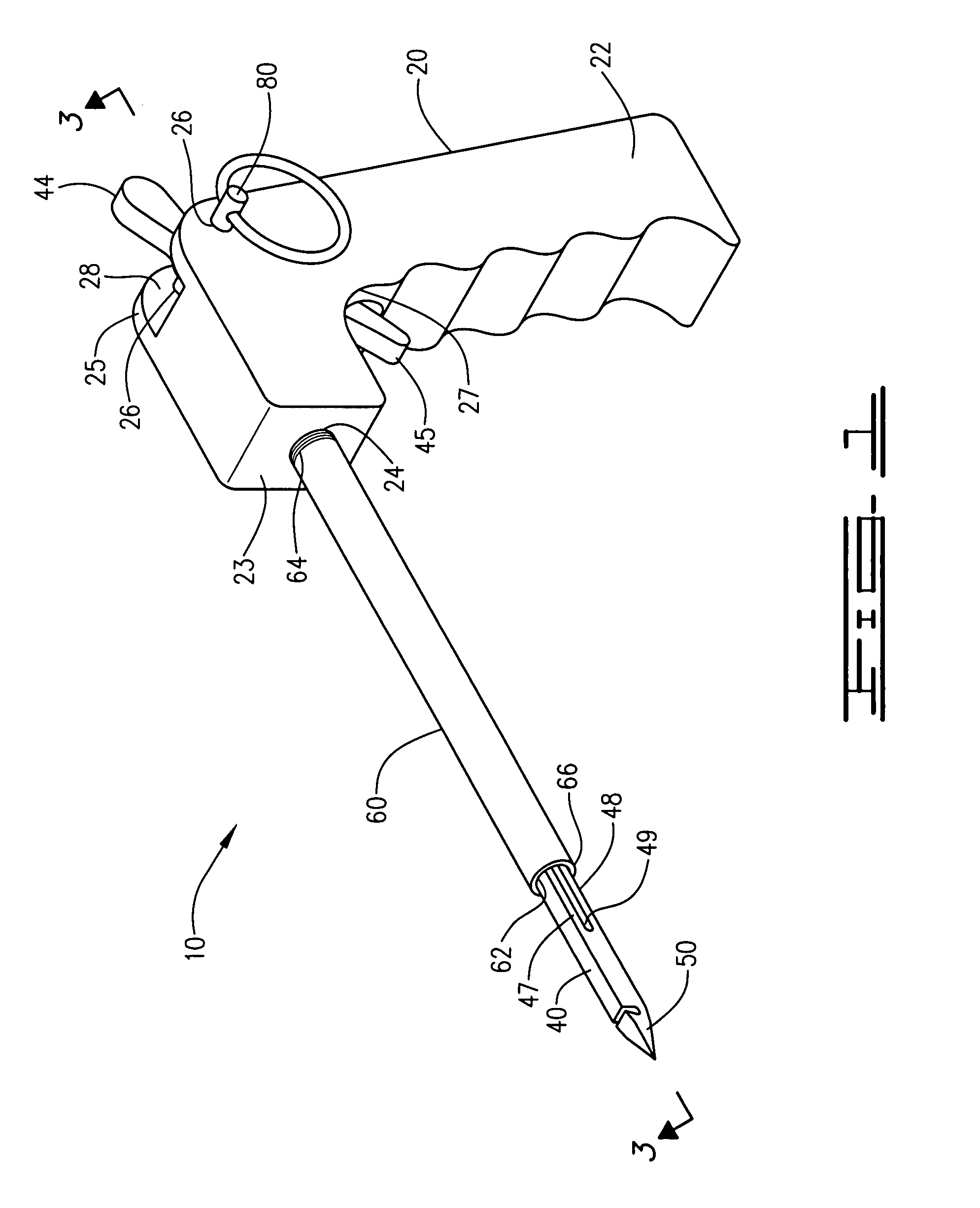

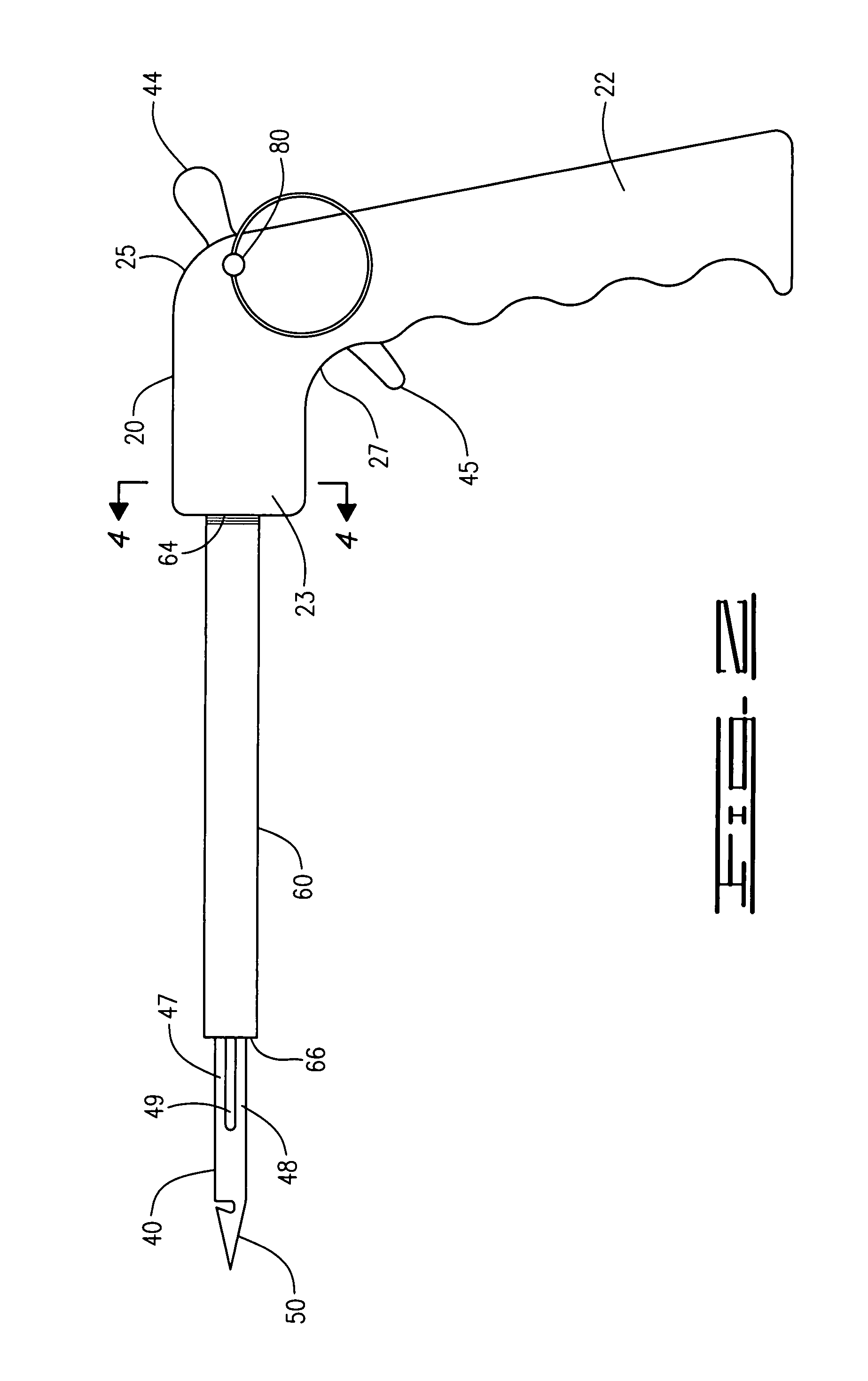

Steerable suture instrument

InactiveUS9101356B1Keep for a long timeRisk of injurySuture equipmentsSurgical needlesEngineeringSuturing instrument

A steerable surgical suture passer providing single hand operation to selectively direct the operation tip in an upward or downward direction to reduce the degree of collateral tissue damage during the use of the instrument, the suture passer providing a shaped handle for ambidextrous use and defining an inner socket, an integrated inner member defining an upper trigger and lower trigger at a proximal end, a pair of resilient intermediate parallel shaft members and a distal operational tip, the inner member pivotally secured within the inner socket by a single pin and a rigid hollow shaft support tube connected to the handle through which the resilient parallel shaft members are directed, allowing the surgeon to steer the operations tip and required when performing a surgical procedure.

Owner:JORDAN CHRISTOPHER S

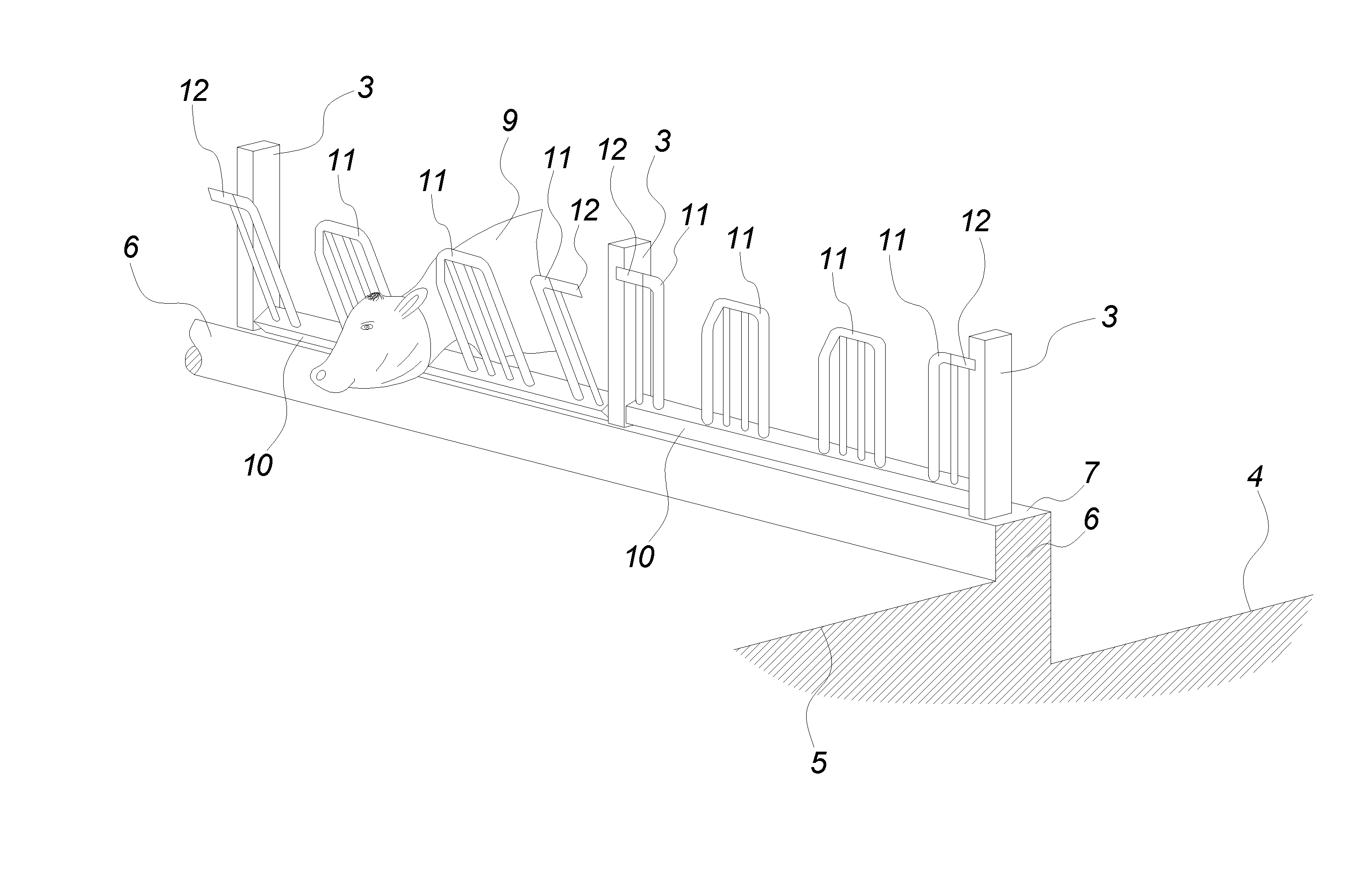

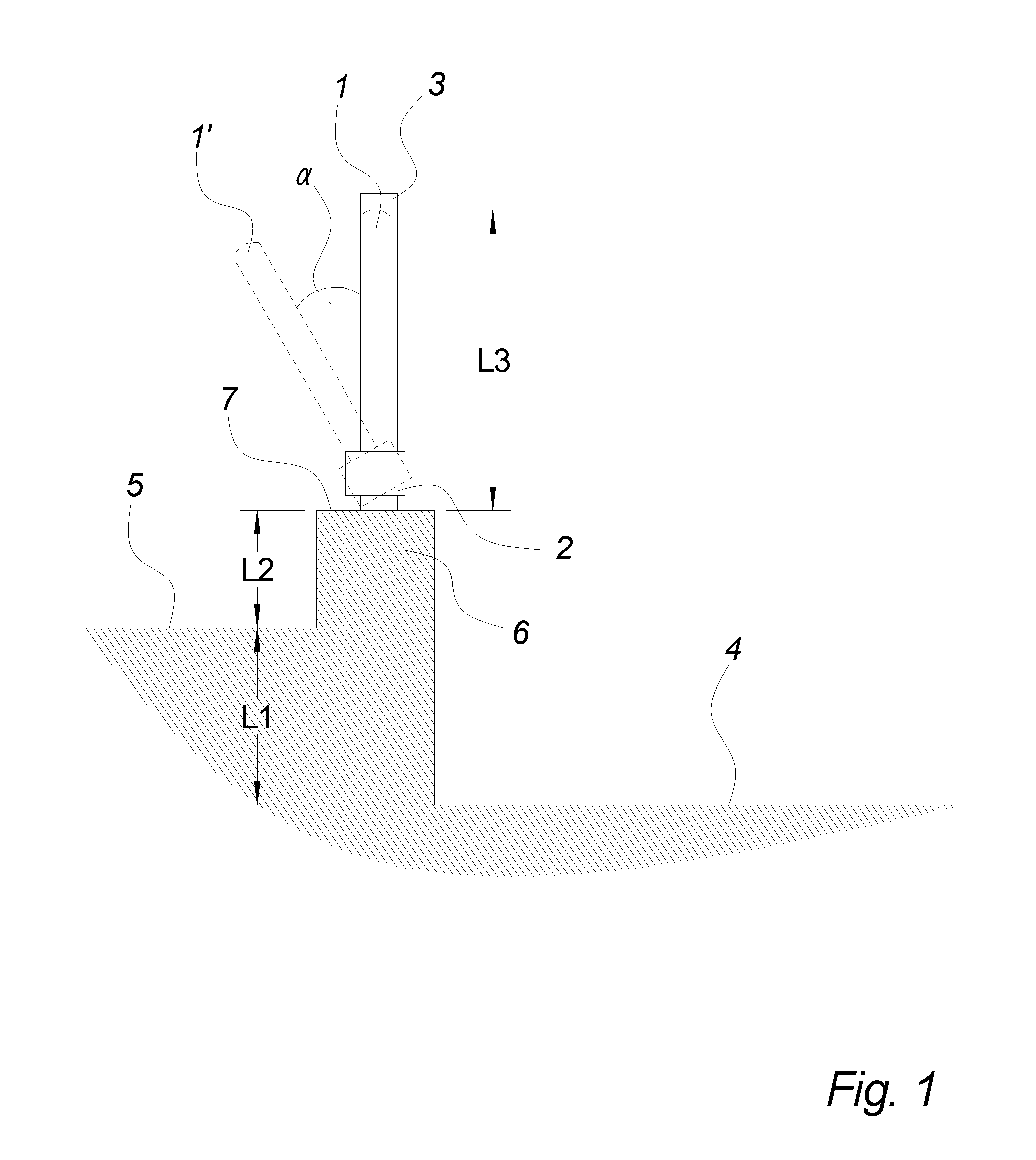

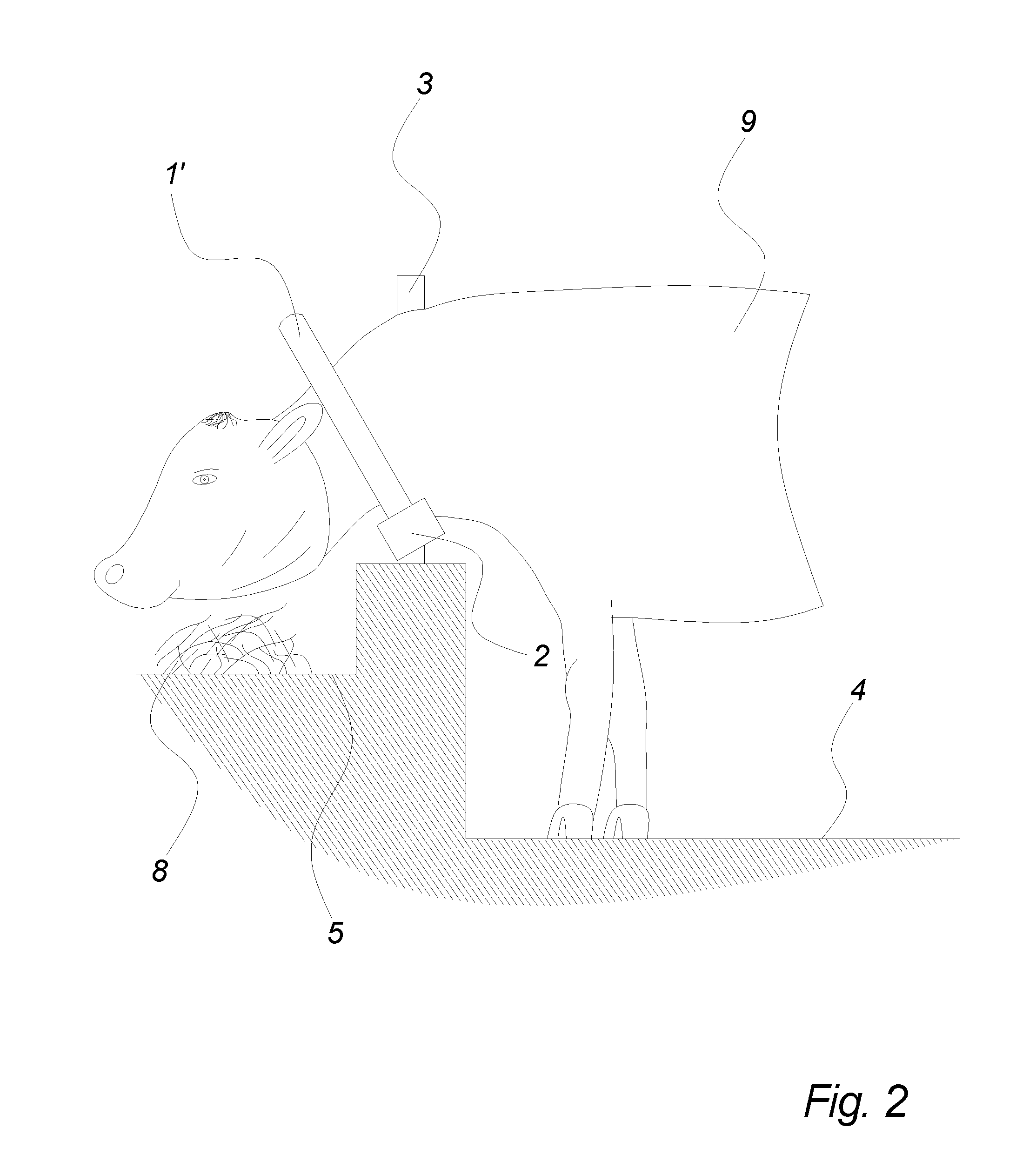

Feeding fence section

ActiveUS20150322716A1Simple designEasy to installGates/doorsAnimal feeding devicesEngineeringMechanical engineering

Owner:COW WELFARE

Landscape edging system and device and methods of installation and use thereof

A landscape edging system and device, and methods of installation and use thereof, wherein a J-shaped track system is installed in a trench along landscape edges, and wherein a pulley wheel attached to a rod is utilized to push the grass down onto a cutting edge of the track to execute the edging process, thereby simplifying the task of edging, eliminating risk of personal injury and allowing for essentially silent lawn care at any hour of the day, wherein decorative outer coverings may be incorporated along the track edging to simulate landscape features, such as rock or brick, and wherein lighted tubing may be installed within the track, thereby enhancing visual nighttime display and illuminating the landscape edge for aesthetic as well as safety reasons.

Owner:HALL RICHARD

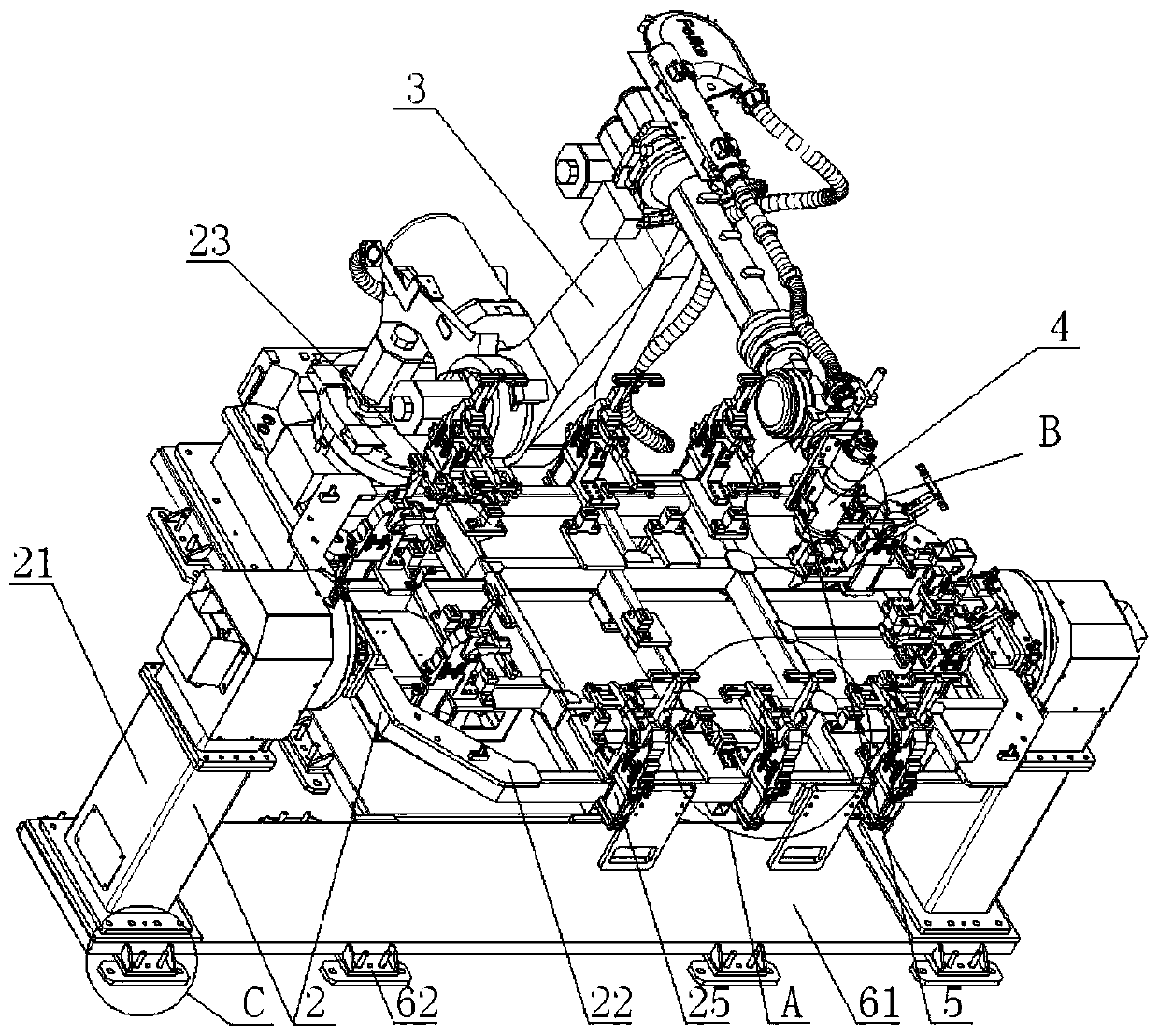

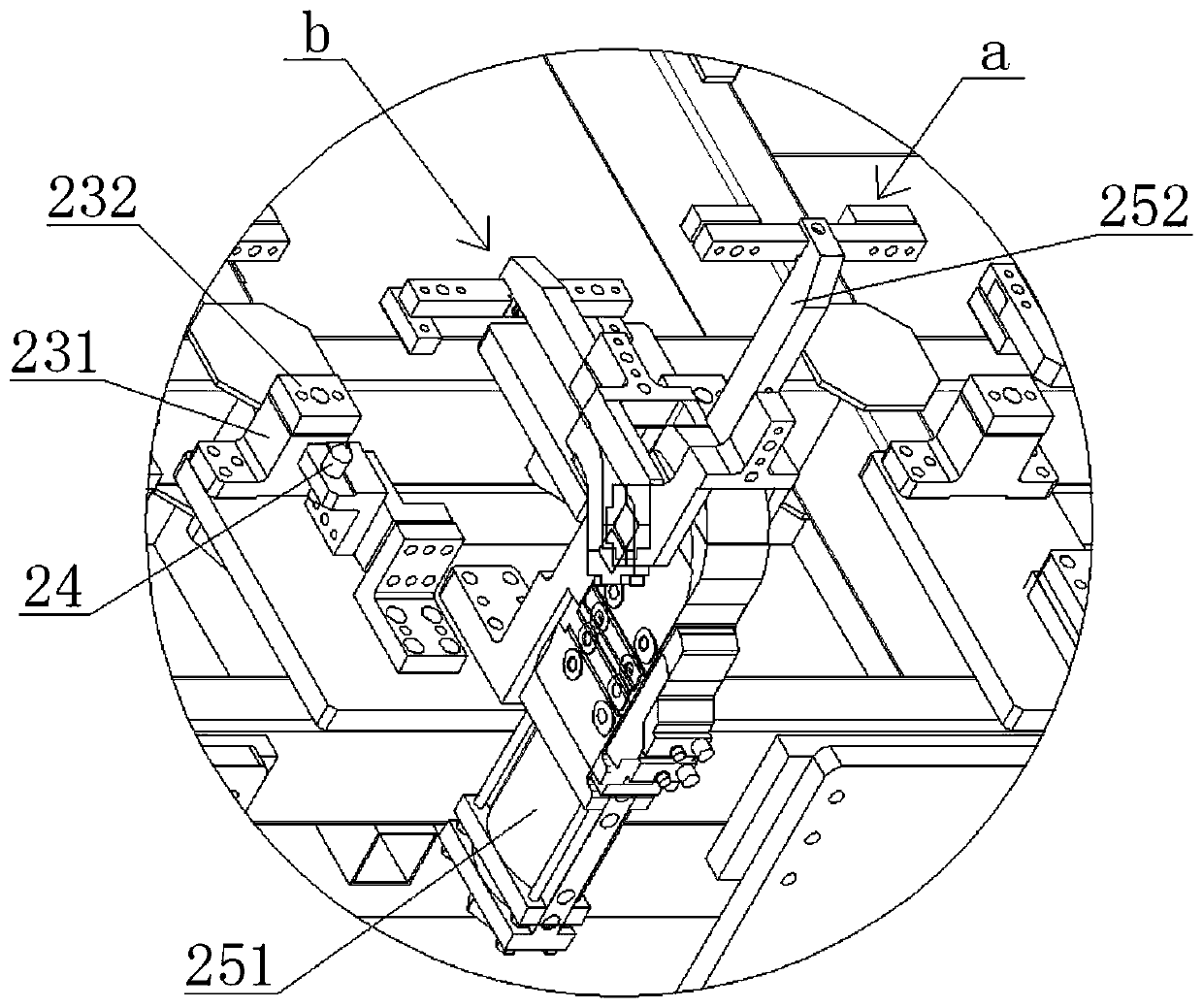

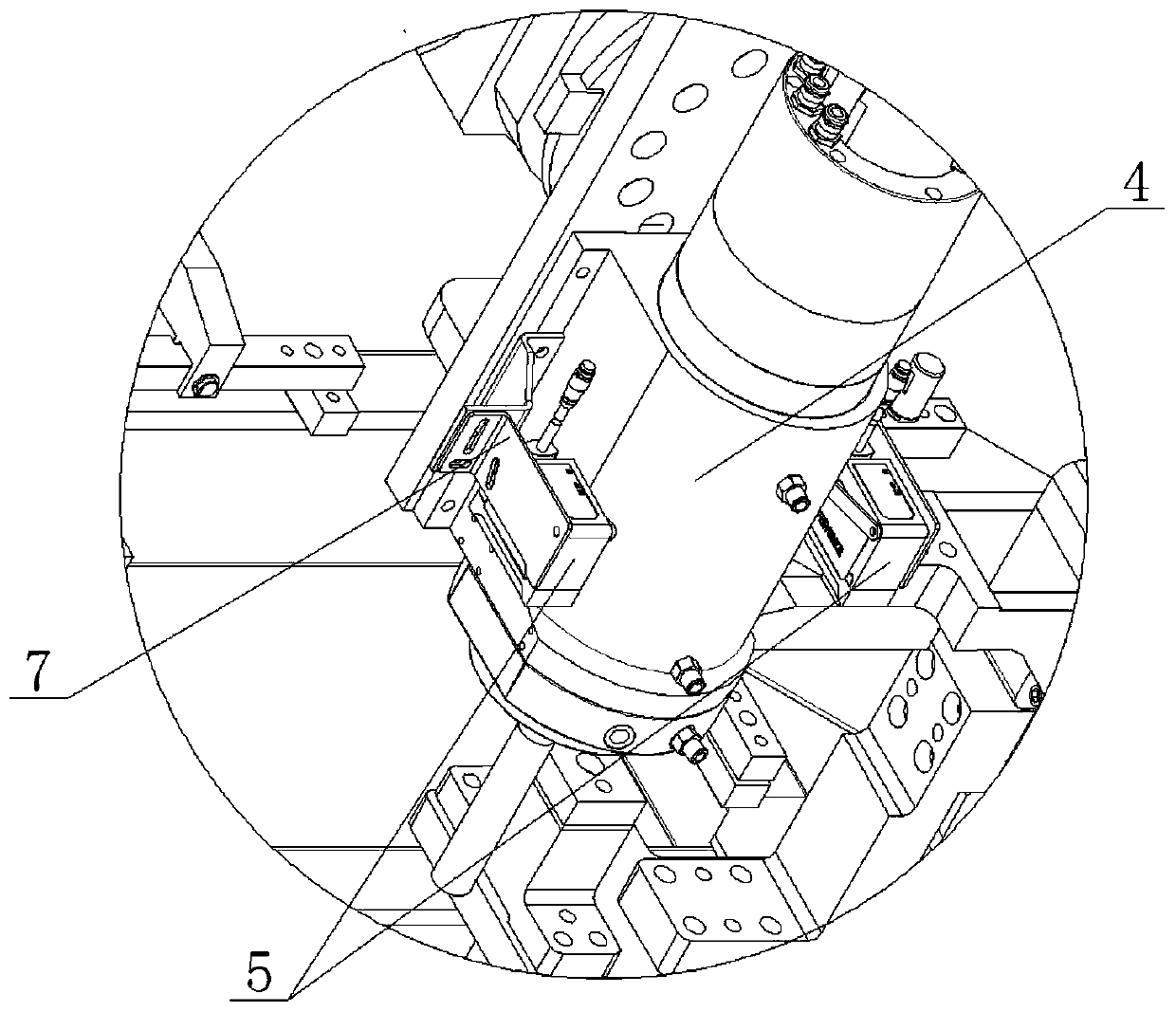

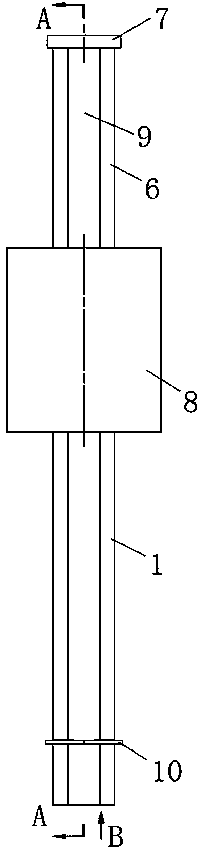

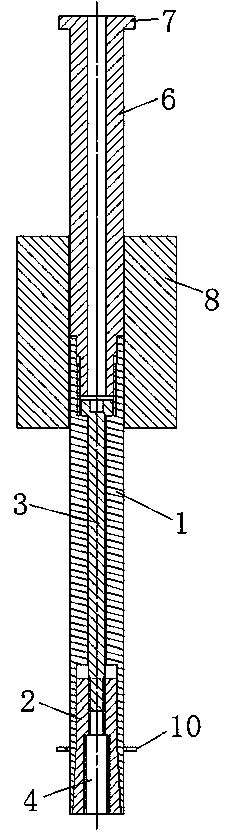

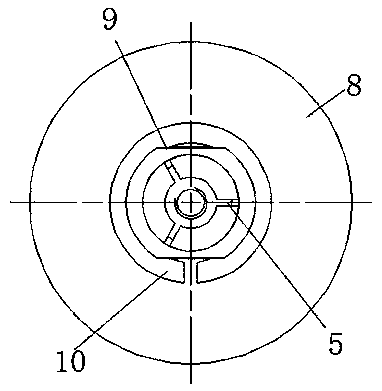

Automatic grinding and milling device and working method thereof

InactiveCN111112709AImprove efficiencyRealize fully automatic operationWork clamping meansMeasurement/indication equipmentsLaser rangingMilling cutter

The invention discloses an automatic grinding and milling device and working method thereof. The automatic grinding and milling device comprises a support for placing a workpieve, a workpiece positioning and clamping mechanism is arranged on the support, the workpiece positioning and clamping mechanism is used for fixing the workpiece to the support, a mechanical arm is arranged on one side of thesupport, an electric milling cutter device and a laser ranging device are arranged at the outer end of the mechanical arm, the laser ranging device is used for obtaining the actual thickness of eachdetection point position in a to-be-grinded area of the workpiece, and the mechanical arm drives the electric milling cutter device to grind and mill along the surface of the to-be-grinded area of theworkpiece according to the actual thickness of each detection point position. A robot is utilized to be matched with a milling cutter and high-precision laser to achieve full-automation operation, and the efficiency is high; the beat is fast, the efficiency is high, and the performance cost ratio is high; personnel is avoided in the whole process, and the risk of causing injury to the personnel is avoided; and the grinding height can be automatically adjusted in real time for products with inconsistent flatness, and the situation that milling is too deep or too shallow is avoided.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

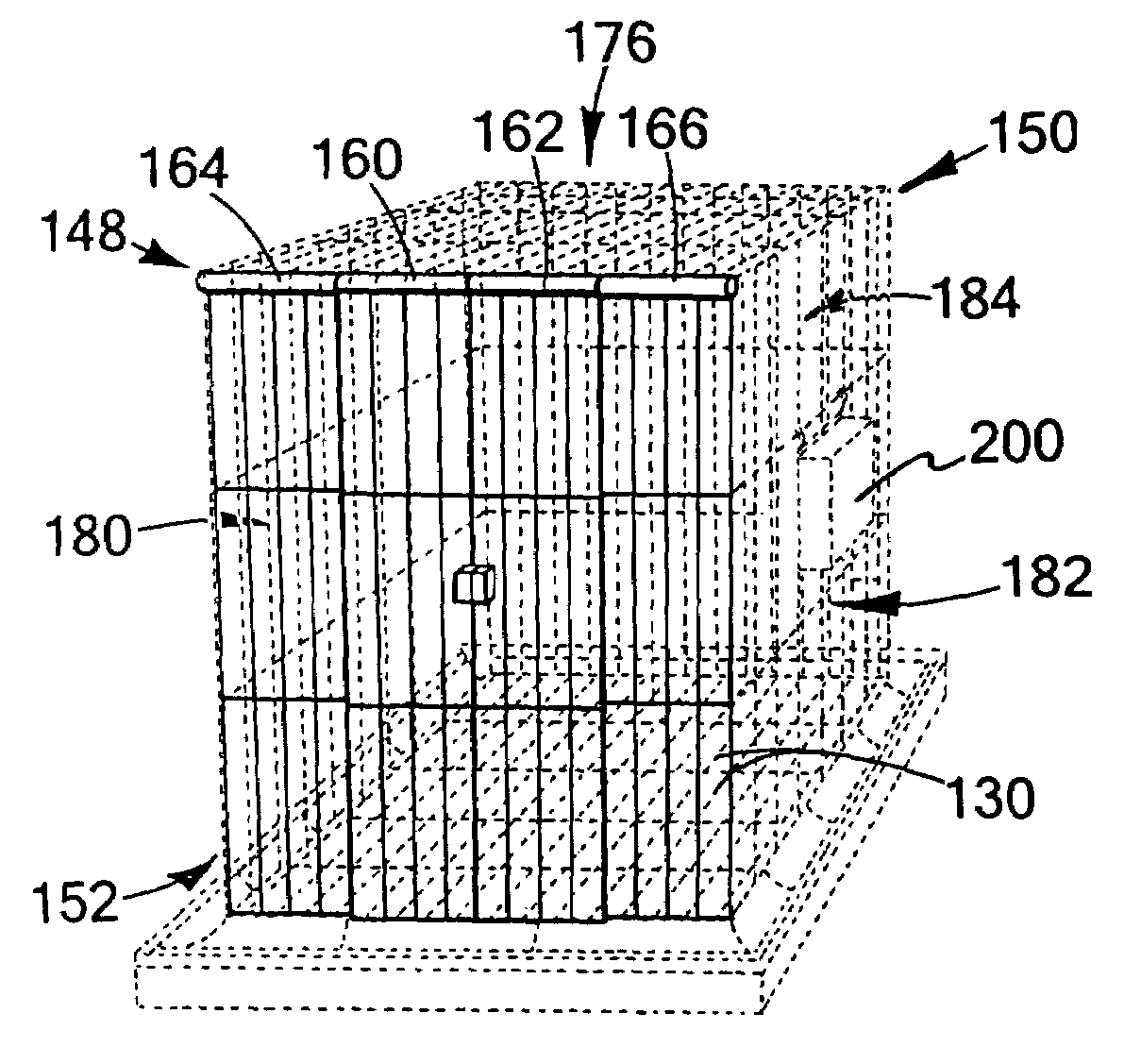

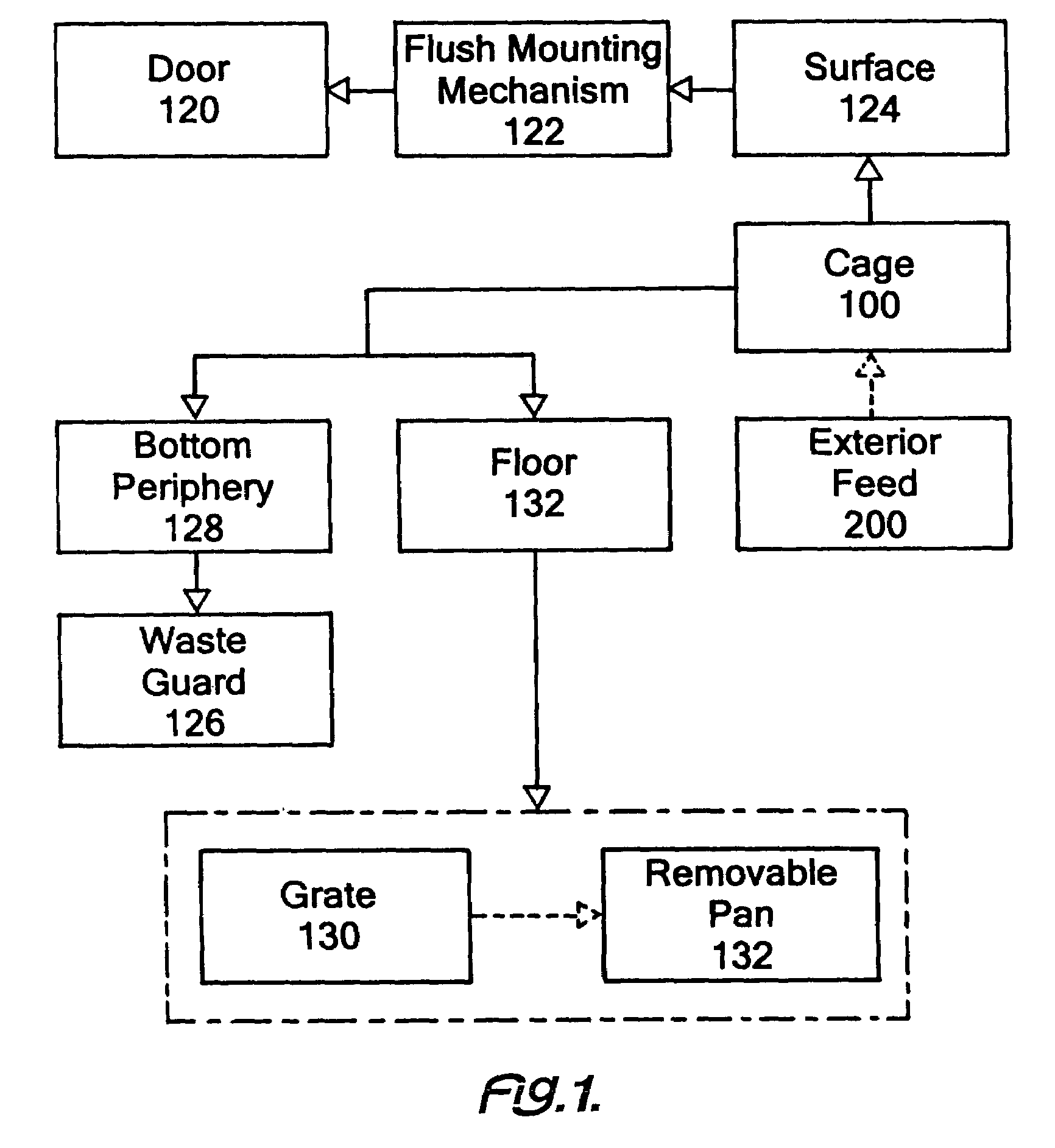

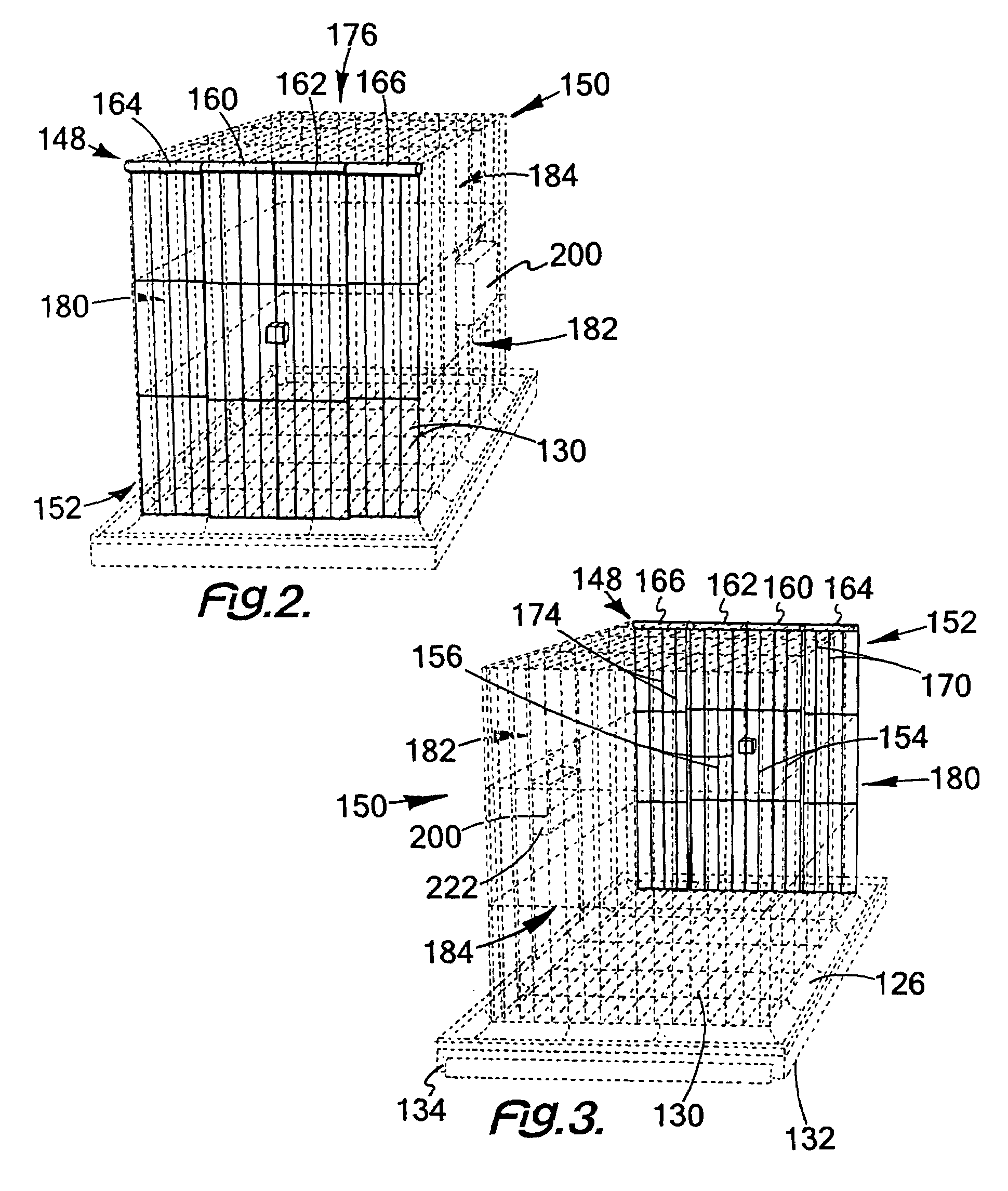

Birdcage

InactiveUS7343877B1Prevent overflowAvoid pollutionAnimal watering devicesAnimal feeding devicesEngineeringPerch

Owner:MCDONALD JOHN SCOTT

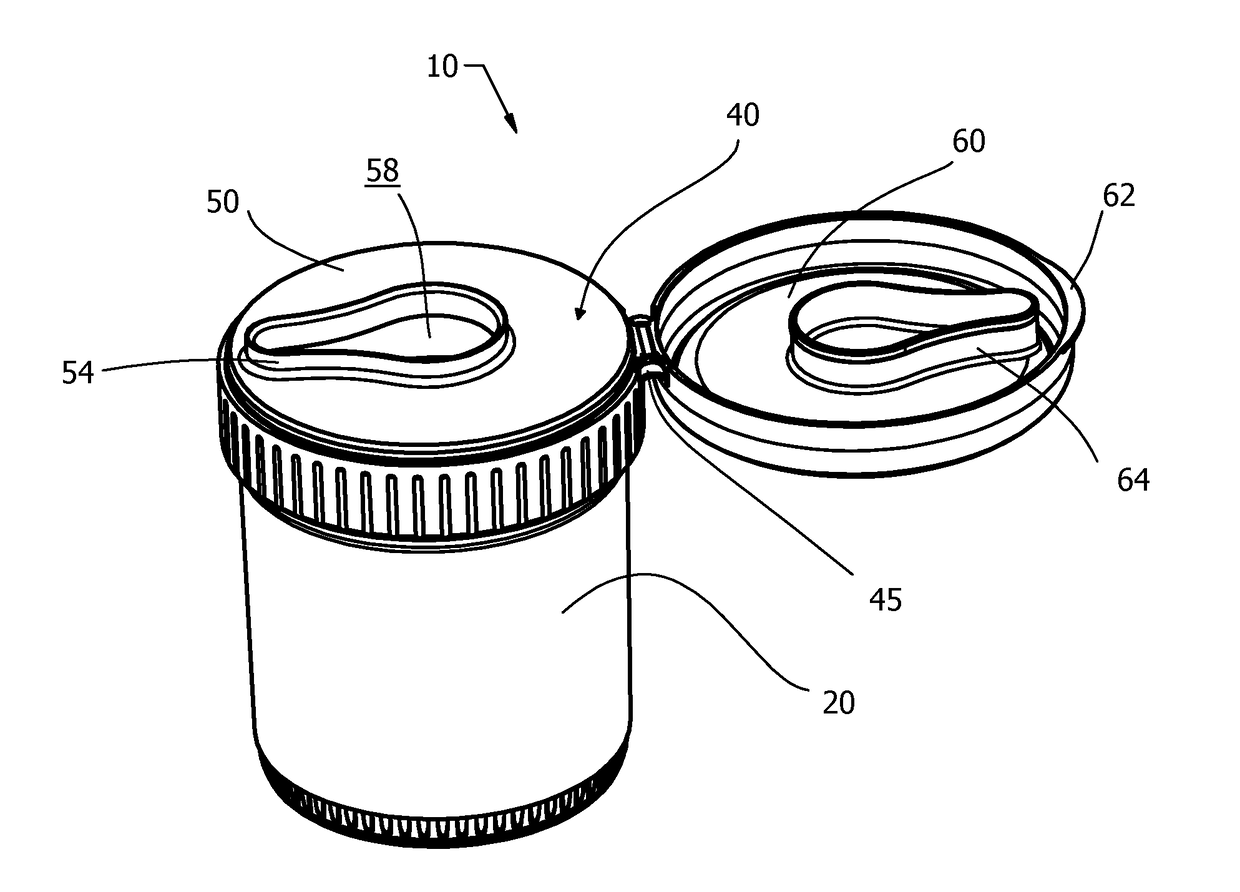

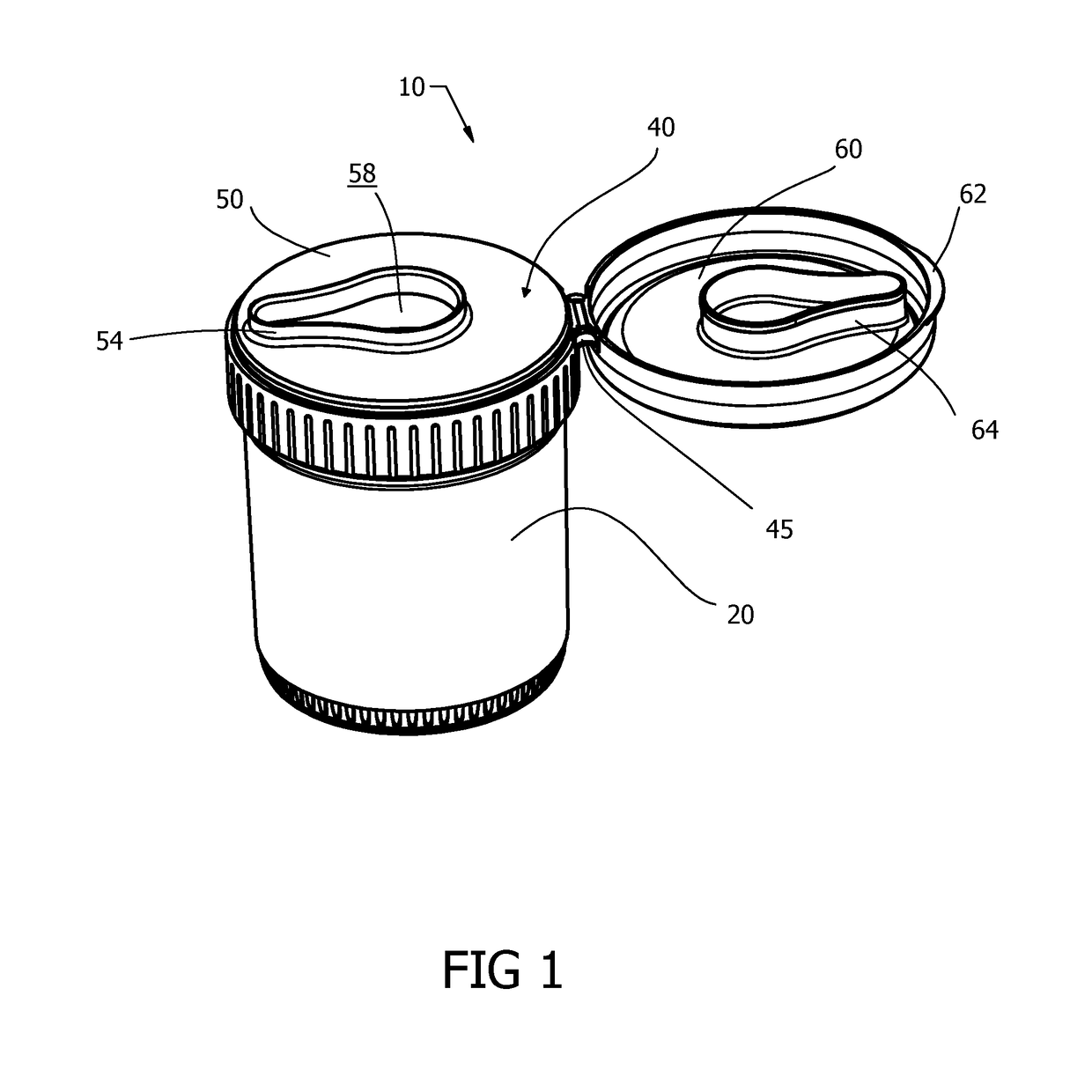

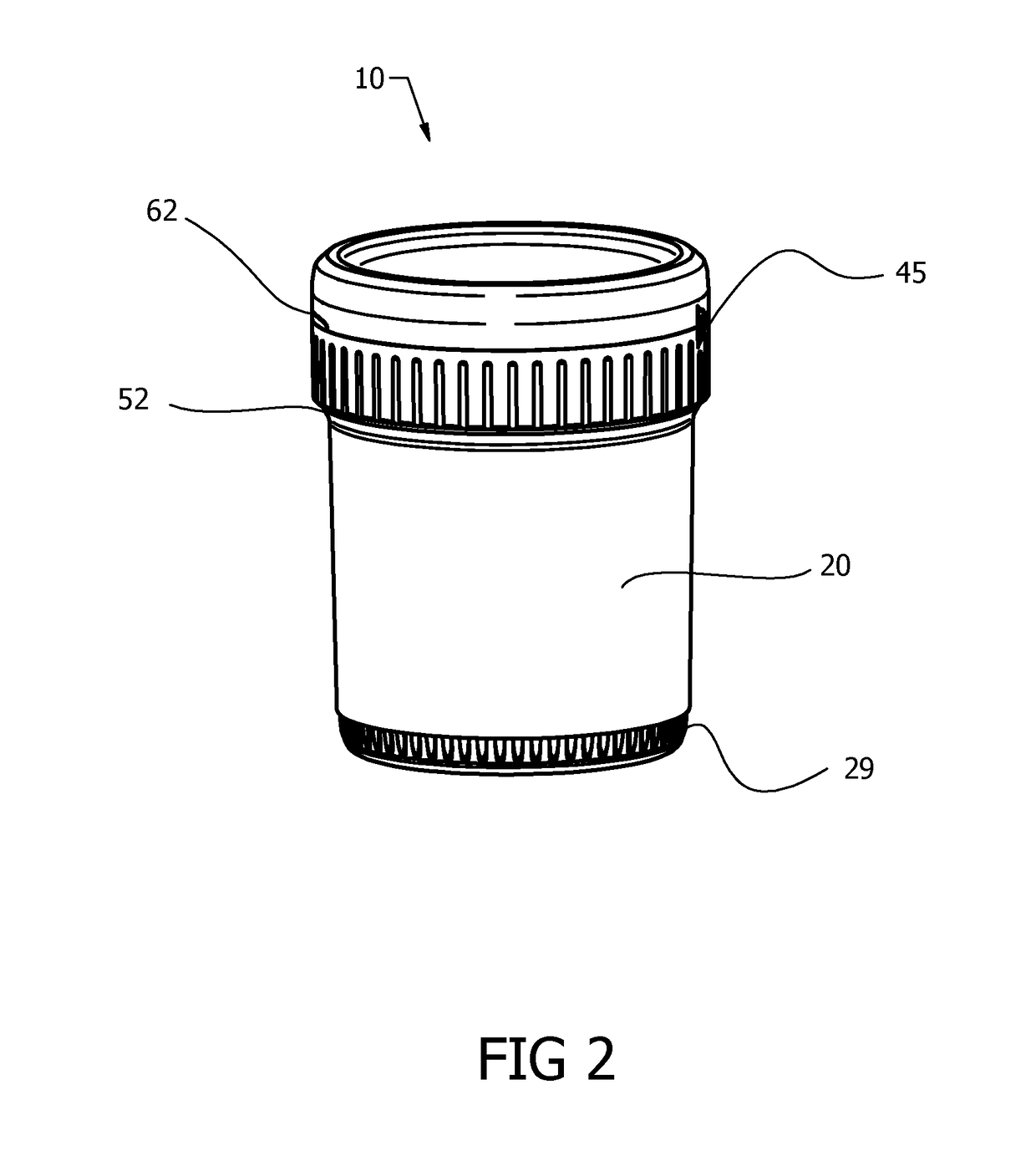

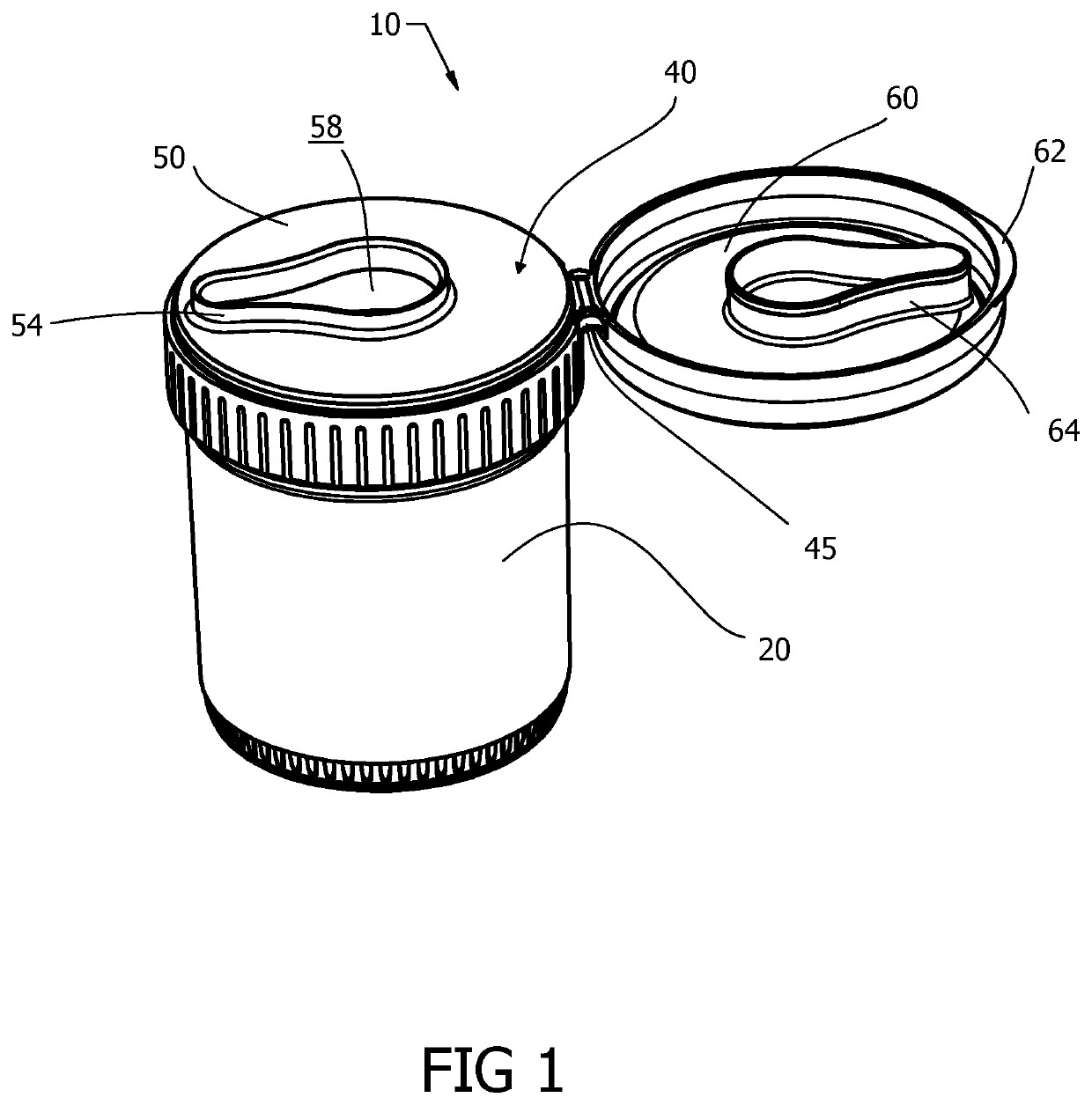

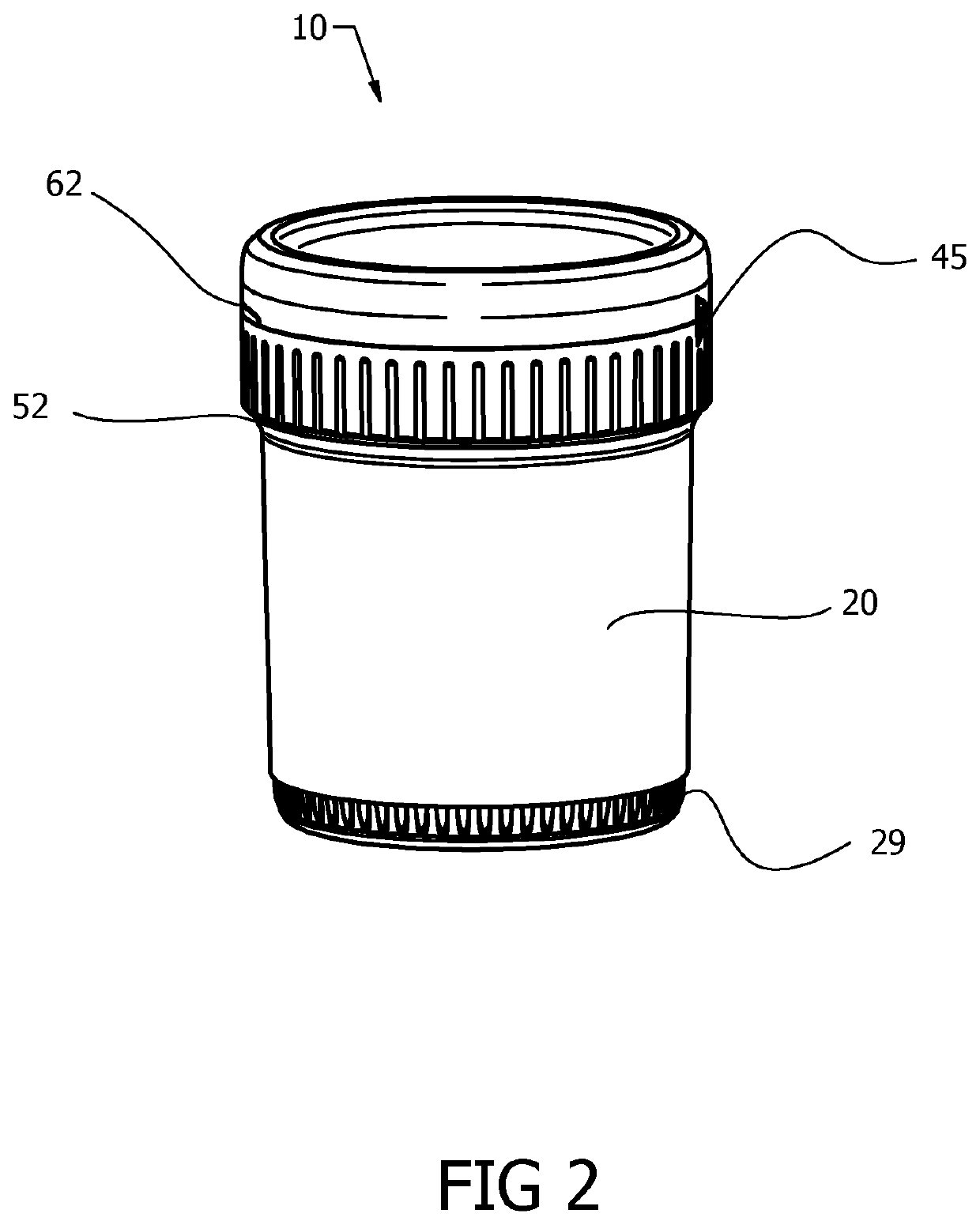

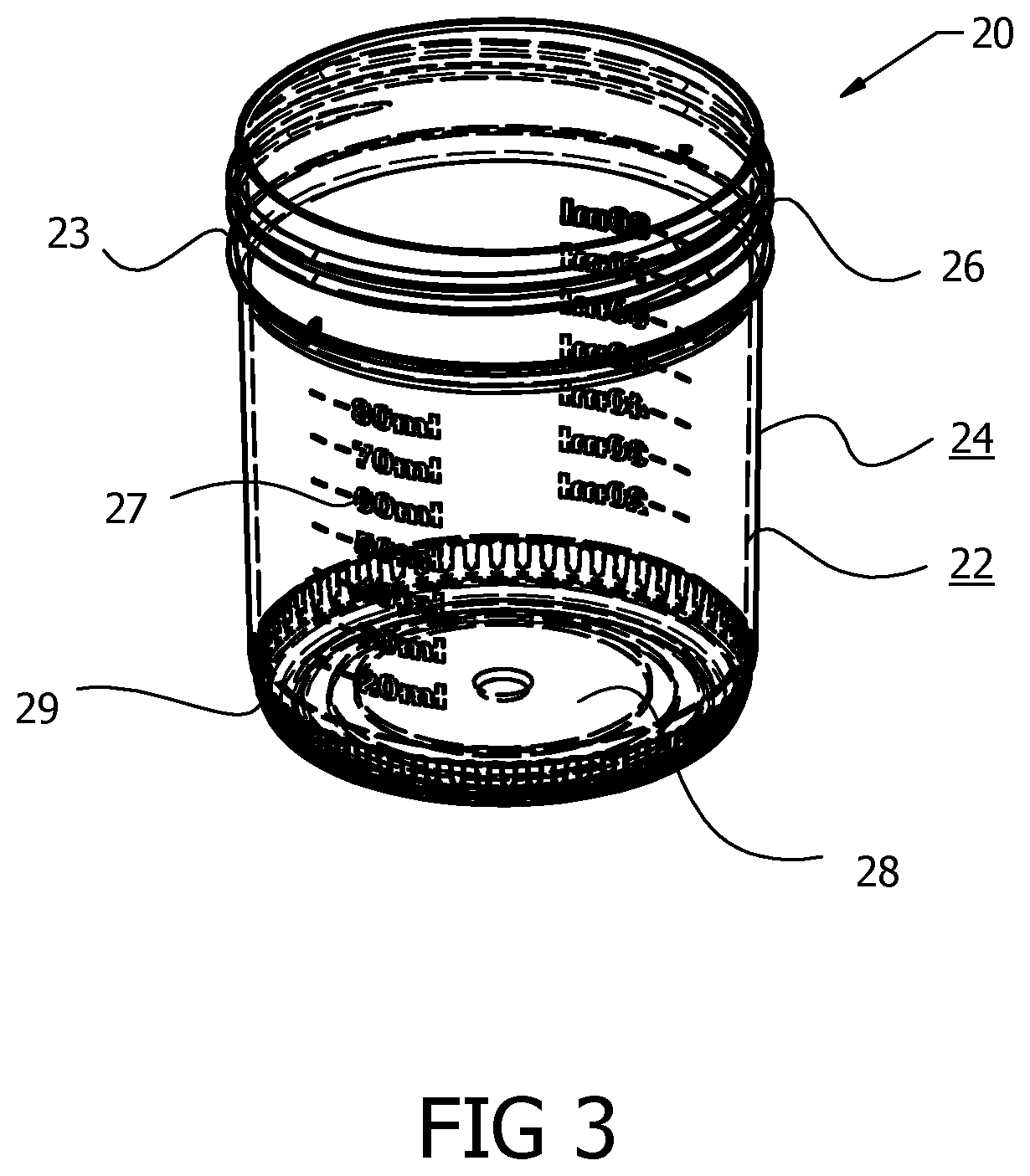

Specimen Container System

ActiveUS20180280002A1Reduce the risk of contaminationIncreased riskWithdrawing sample devicesSurgeryEngineeringSpecimen containers

A specimen container system and methods of use are described herein for capturing, storing and accessing fluids for lab testing. A cup is removably secured to a cap assembly. The cap assembly is comprised of cover and a lid which are connected by a hinge assembly having a biasing member for maintain the lid in an open position. An aperture in the cap has two sections that in combination with the lid decreases the contamination risk compared to prior art container system.

Owner:KOPOIAN MARC

Blind pin puller

PendingCN109397186ANo damageEasy to operateMetal-working hand toolsEngineeringMechanical engineering

Owner:无锡哨东自动化技术有限公司

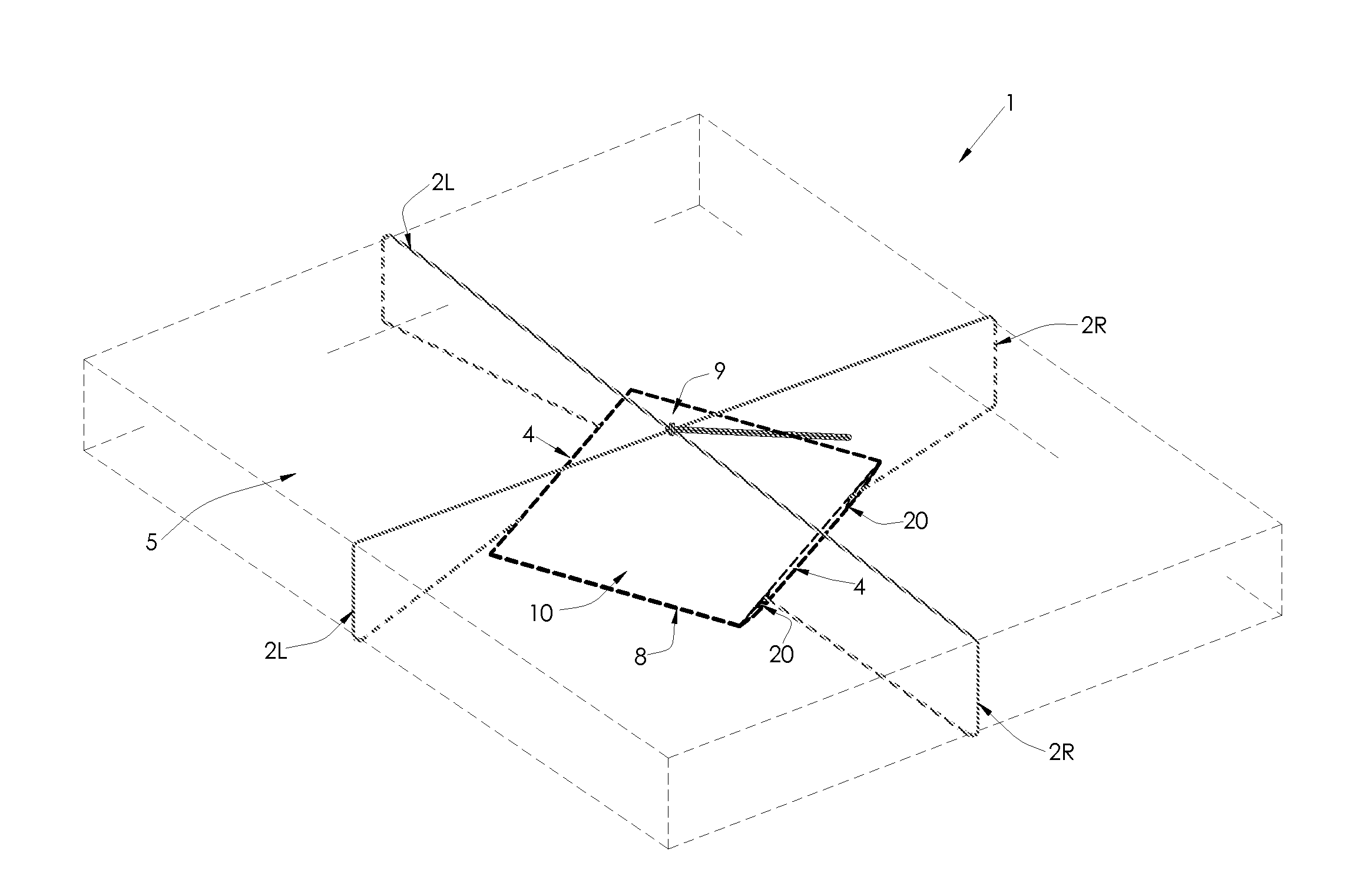

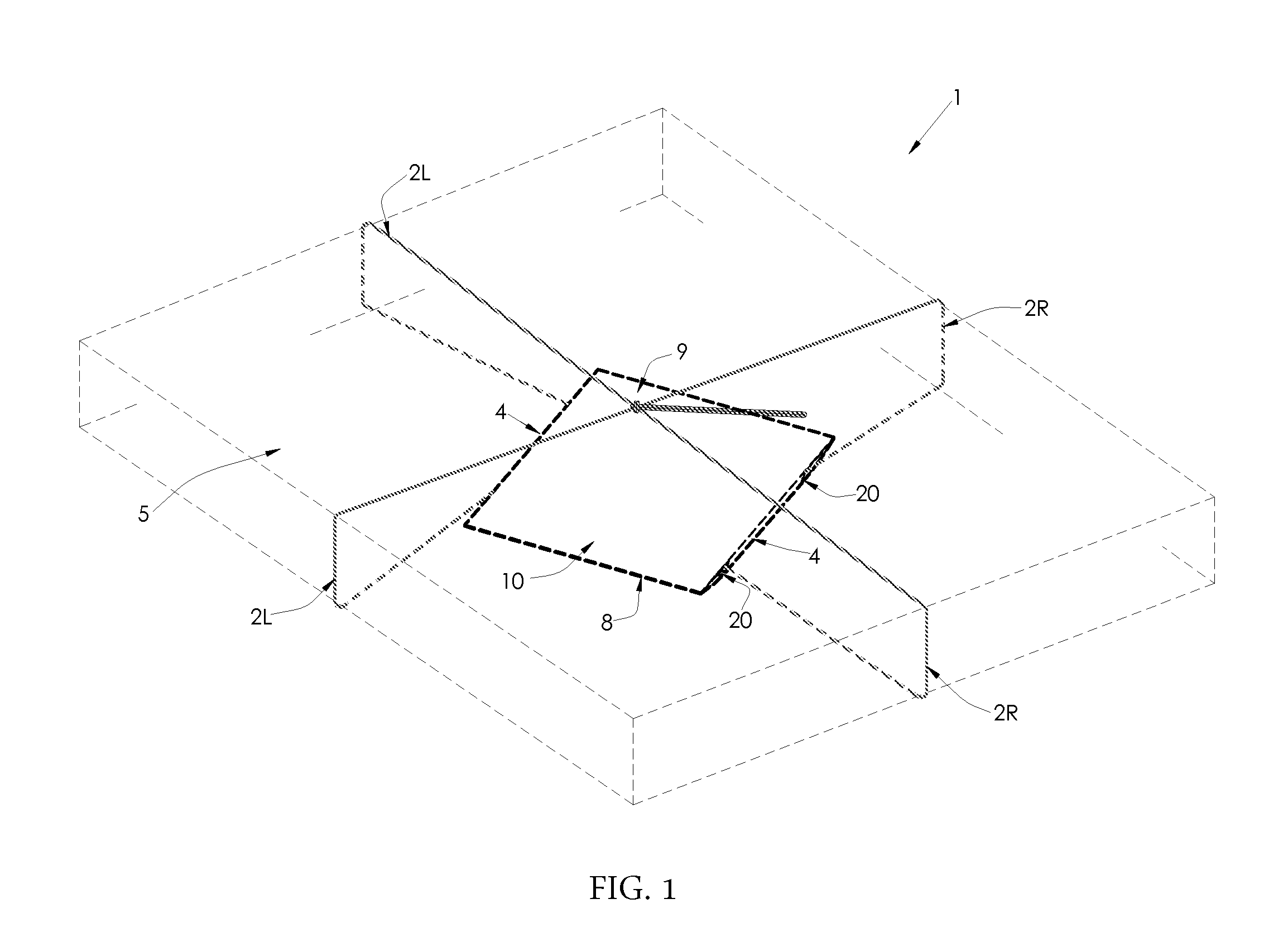

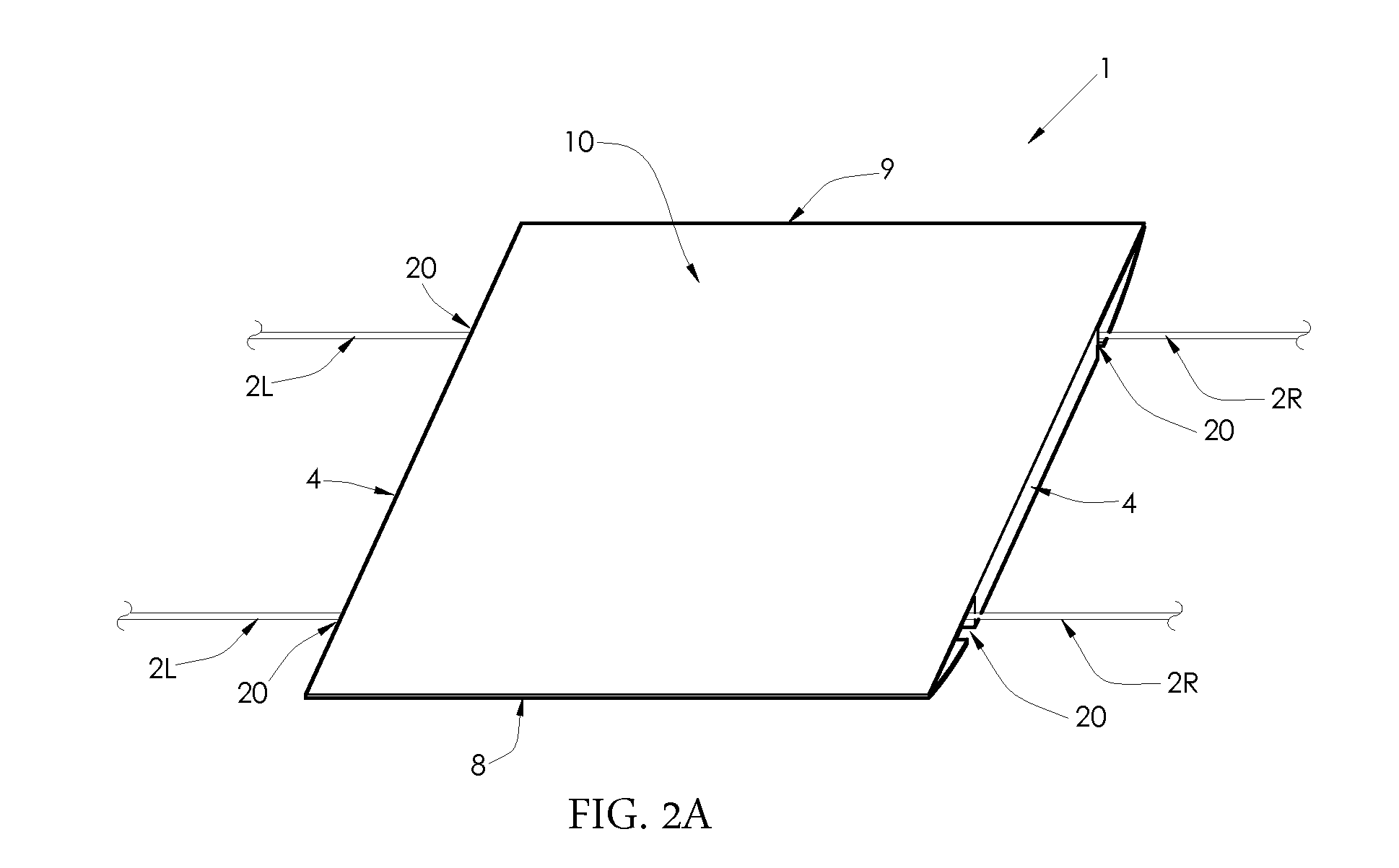

Portable paper stacking and storage device

ActiveUS20160122050A1Easy to passEasy to liftPaper article packagingBinding material applicationCardboardEngineering

A hand-sized, disposable device, and its method of use for bundling and transporting a stack of small consumer goods, such as boxes, newspapers and magazines for recycling. The method comprises dispensing a pre-cut loop of twine residing in a prefabricated device made of recyclable paper board or cardboard. The twine crosses itself in the cavity of the device and is free to slide in any direction via four total device corner holes for adjusting to a range of sizes of stacked goods. Bundling is completed by drawing two opposing ends of the twine loop from the device corner holes, passing the two ends perpendicularly and simultaneously over the four sides of a stack of goods, and forming a knot on the center of the bundle's top surface. The bundle may then be easily lifted, carried, dropped and disposed of via the knot, one-handedly, without slippage of items from the bundle.

Owner:FABRIZI DANIEL

Specimen container system

ActiveUS10966690B2Reduce the risk of contaminationIncreased riskWithdrawing sample devicesSurgeryClassical mechanicsEngineering

A specimen container system and methods of use are described herein for capturing, storing and accessing fluids for lab testing. A cup is removably secured to a cap assembly. The cap assembly is comprised of cover and a lid which are connected by a hinge assembly having a biasing member for maintain the lid in an open position. An aperture in the cap has two sections that in combination with the lid decreases the contamination risk compared to prior art container system.

Owner:KOPOIAN MARC

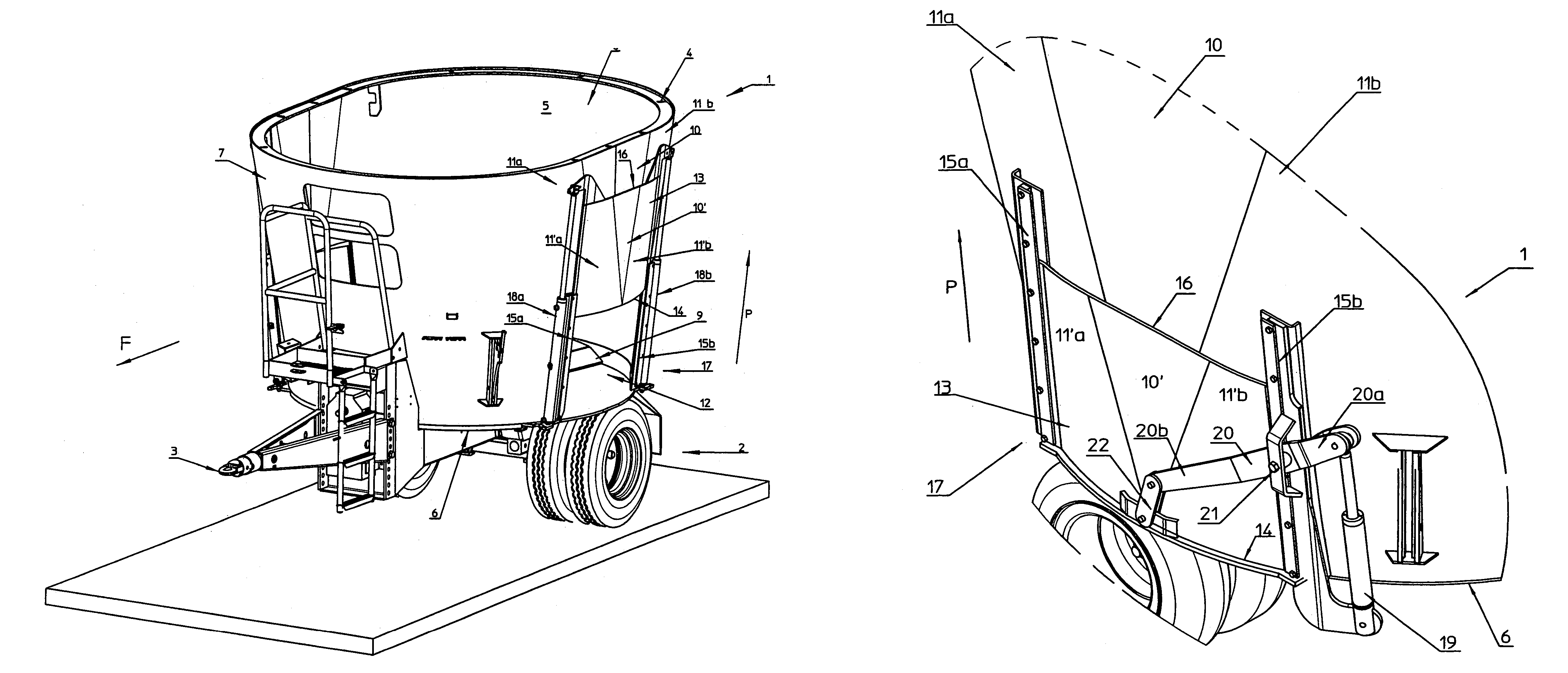

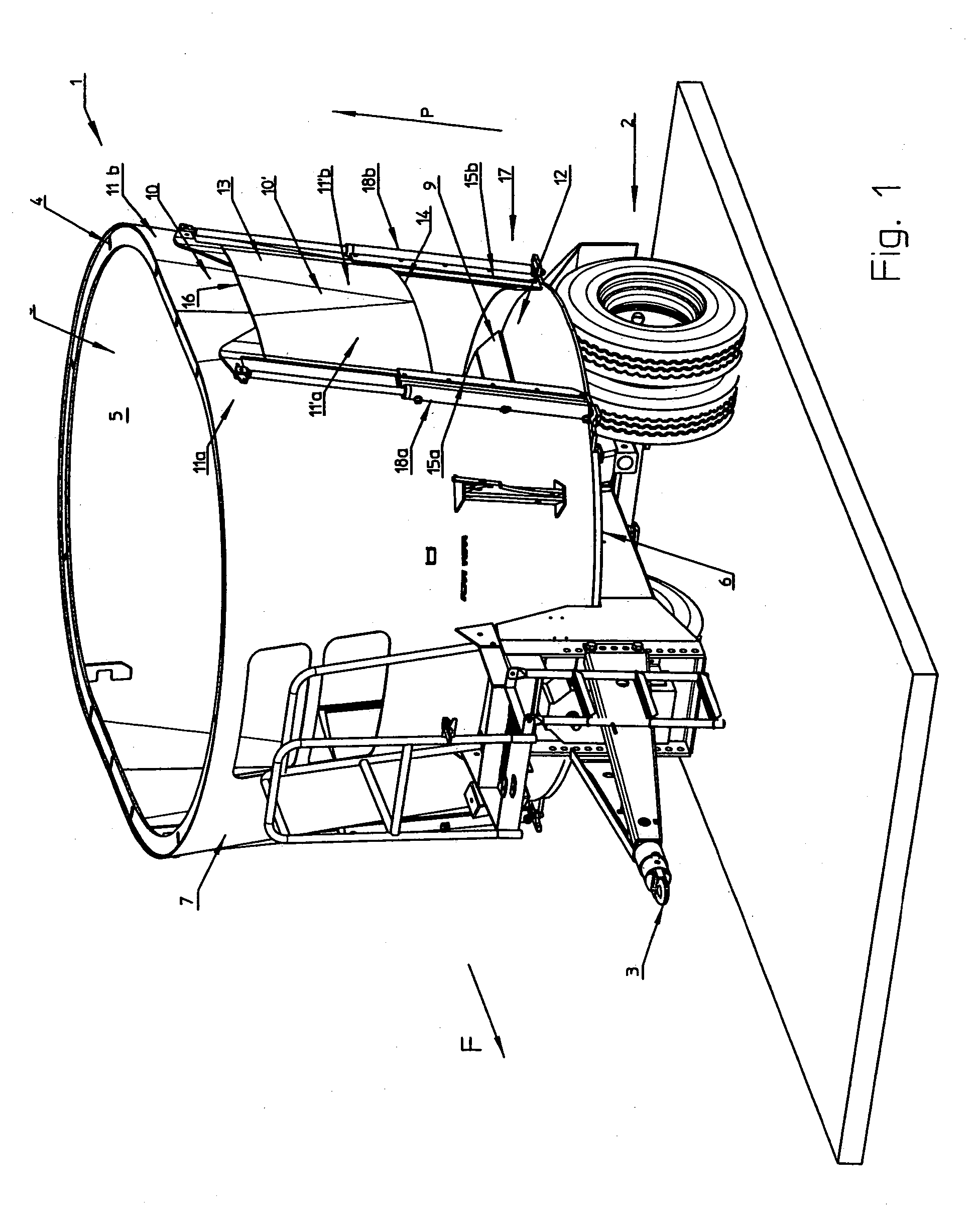

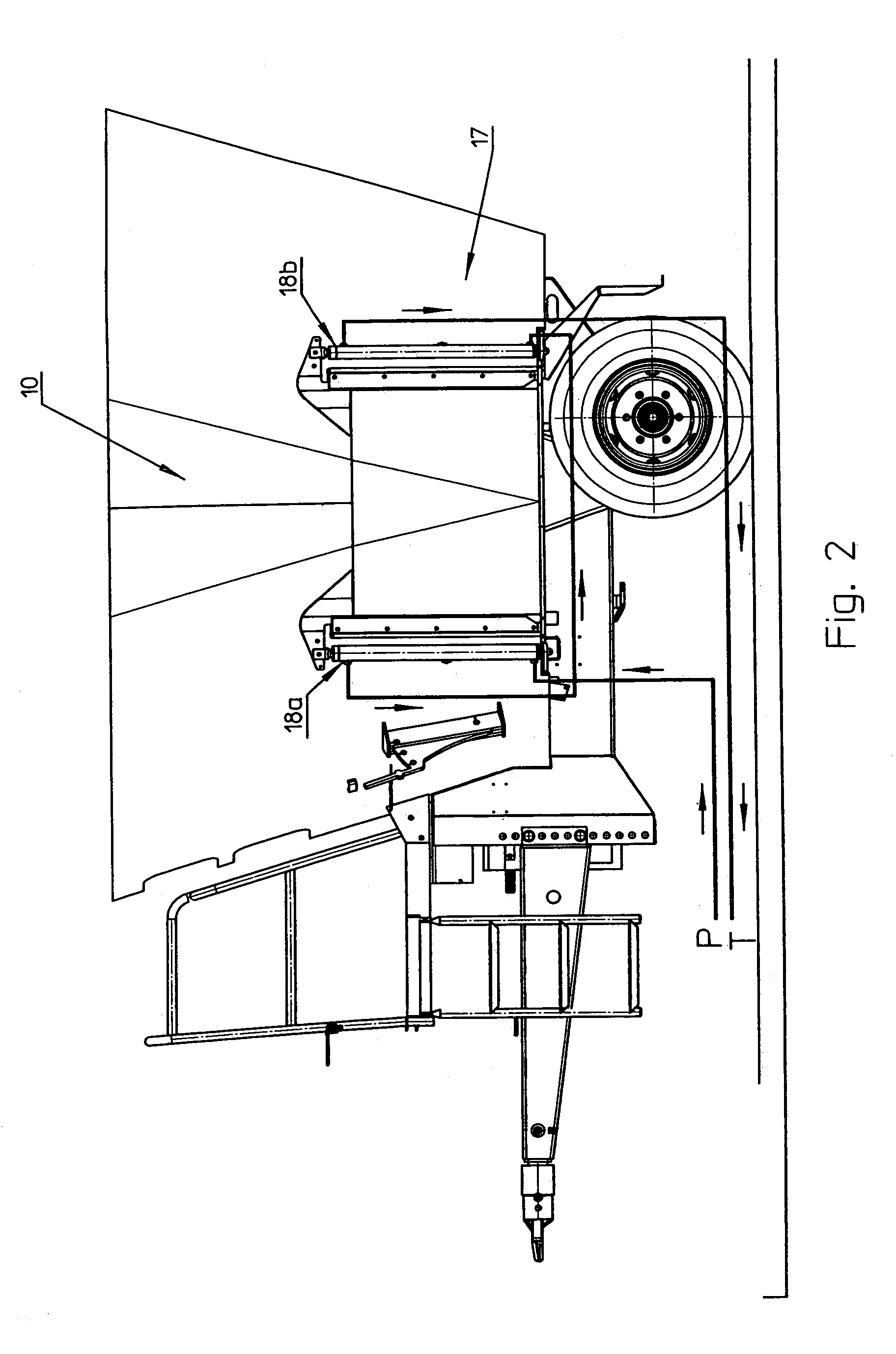

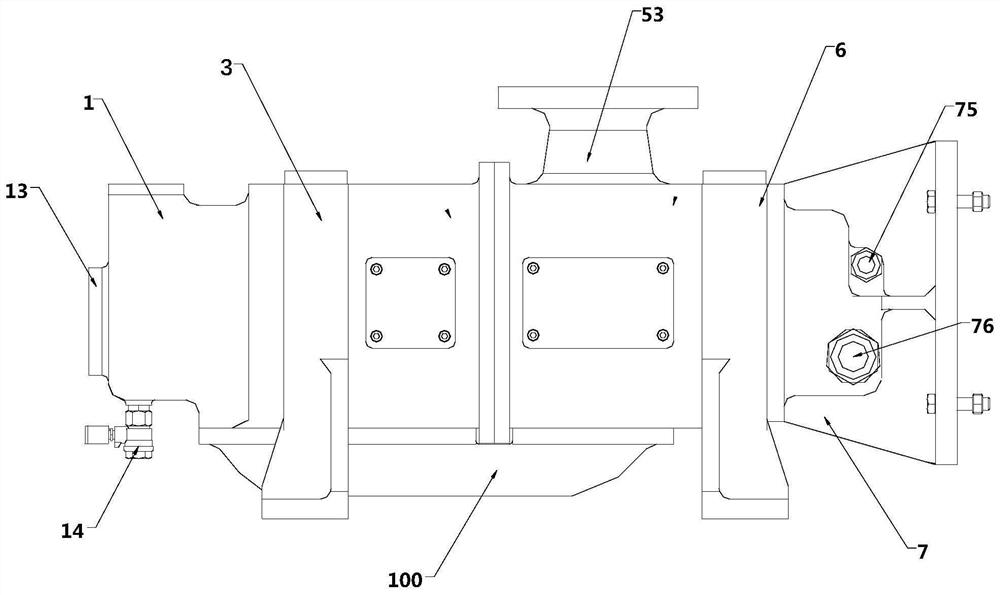

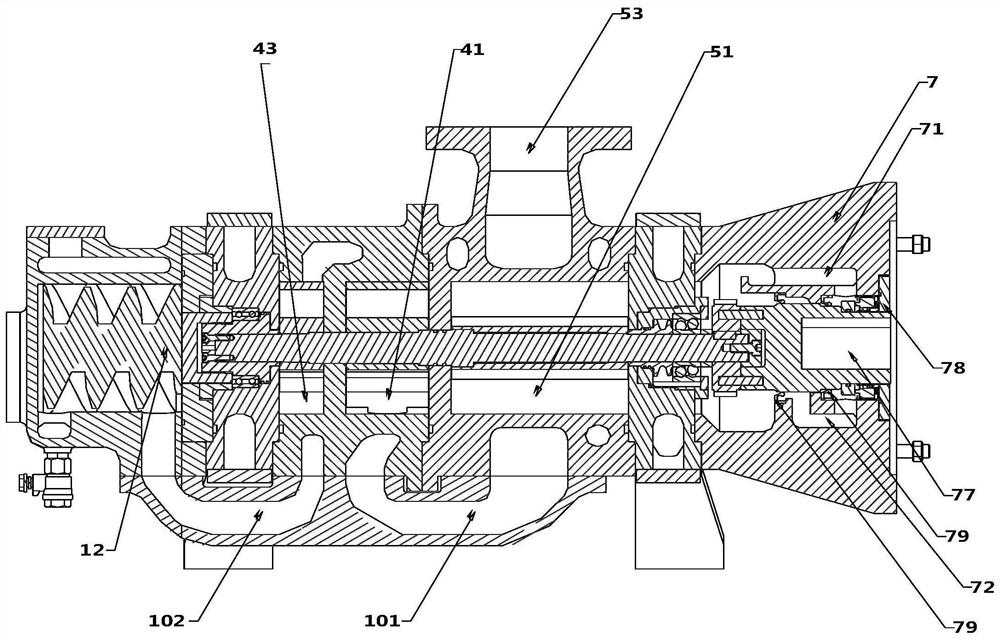

Mixer wagon

ActiveUS7153020B2Risk of injuryRisk of damageOther chemical processesRotary stirring mixersEngineeringFodder

Owner:TRIOLIET MULLOS BV

Anti-collision automobile charging pile

InactiveCN108162776AImprove securityImprove cleanlinessCharging stationsLighting elementsElectricityEngineering

The invention discloses an anti-collision automobile charging pile. A main housing is internally provided with a power supply terminal, and the power supply terminal is connected with a power supply;the tip end of a charging gun extends to the outside of the main housing, and a connection of the charging gun protrudes into the main housing and is electrically connected with the power supply terminal; the connection is wound on an automatic take-up device in the main housing through an extension cord, and then is electrically connected with the power supply terminal; the bottom of the main housing is evenly provided with multiple telescopic support feet in the circumferential direction, and the bottom ends of the telescopic support feet are connected with self-locking wheels, and the tailends of rotating shafts of the self-locking wheels are hinged to the bottom ends of the telescopic supporting feet in a folding way and fastened by locking members; and transparent anti-collision barsare arranged on the outsides of the multiple edges of the main housing, contour lamps are embedded in the interiors of the anti-collision bars, and stripe reflective strips are adhered on multiple surfaces of the main housing. The anti-collision automobile charging pile has a simple structure, is convenient to use, can effectively contour to alert a driver to avoid, is prevented from being damaged, and reduces the maintenance cost.

Owner:华睿企业管理咨询(衢州)有限公司

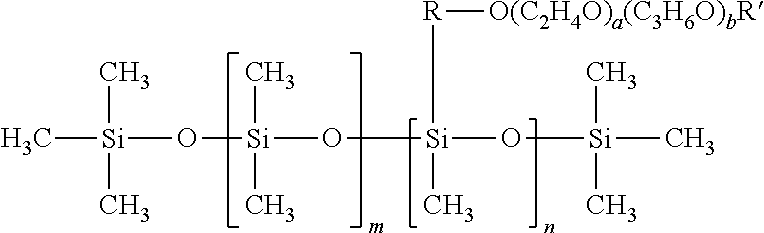

Pest control composition

ActiveUS8986722B2Good control effectImprove securityBiocideSilicon compound active ingredientsFood additivePest control

It is an object of the present invention to provide a pest control composition capable of exerting a high effect on pests such as spider mites and aphids even at low concentration using a food / food additive with high safety to the human body and the environment. The present inventors have intensively studied to solve the above problem and found that, among polyglycerol fatty acid esters widely used as a food additive, a composition containing a polyglycerol fatty acid ester which has an HLB of 5 or less and is liquid at ordinary temperature and also a nonionic surfactant has a high effect on pests even at low concentration, and that the possibility for pests to develop resistance to the composition is extremely low, and the present invention has been completed.

Owner:NIPPON KAYAKU CO LTD

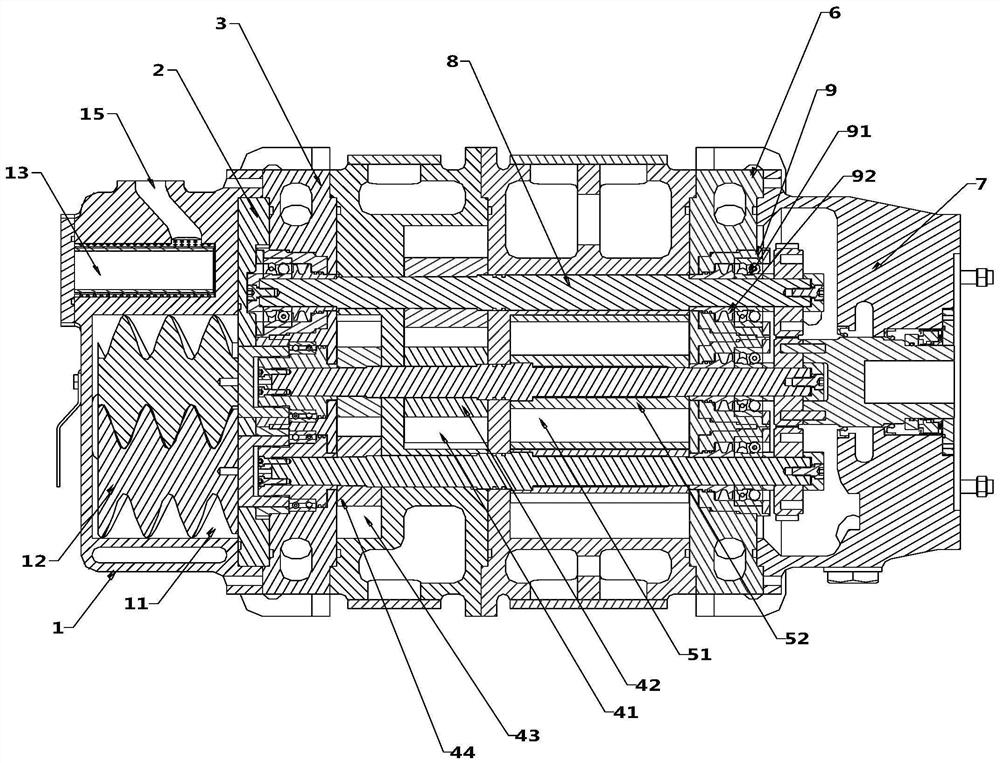

Cantilever mixed type dry vacuum pump

ActiveCN113048056AWon't clogReasonable designRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsEngineeringCantilever

The invention discloses a cantilever mixed type dry vacuum pump which comprises a cantilever cavity and a non-cantilever body, the non-cantilever body is a pump cavity set formed by connecting a plurality of pump cavities in series, and any adjacent parts of the cantilever cavity and the non-cantilever body are positioned in an embedded mode. Each pump cavity in the non-cantilever body and the cantilever cavity are connected in series through a gas circuit, a bottom connecting piece is arranged below the non-cantilever body and the cantilever cavity to serve as an independent gas connecting part, and the bottom connecting piece is detachably connected with the cantilever cavity and the non-cantilever body. The cantilever mixed type dry vacuum pump is reasonable in design and compact in structure. The bottom connecting piece can reserve enough stacking space for sediments and can be freely disassembled, cleaned, overhauled, maintained and replaced without blocking an airflow channel. Positioning pin holes do not need to be formed in the side faces of the adjacent parts for positioning, and therefore the defects that an airflow channel arranged in a pump cavity of a traditional dry vacuum pump is narrow, washing and maintenance cannot be carried out, and faults are caused are overcome.

Owner:上海樊容工业技术中心

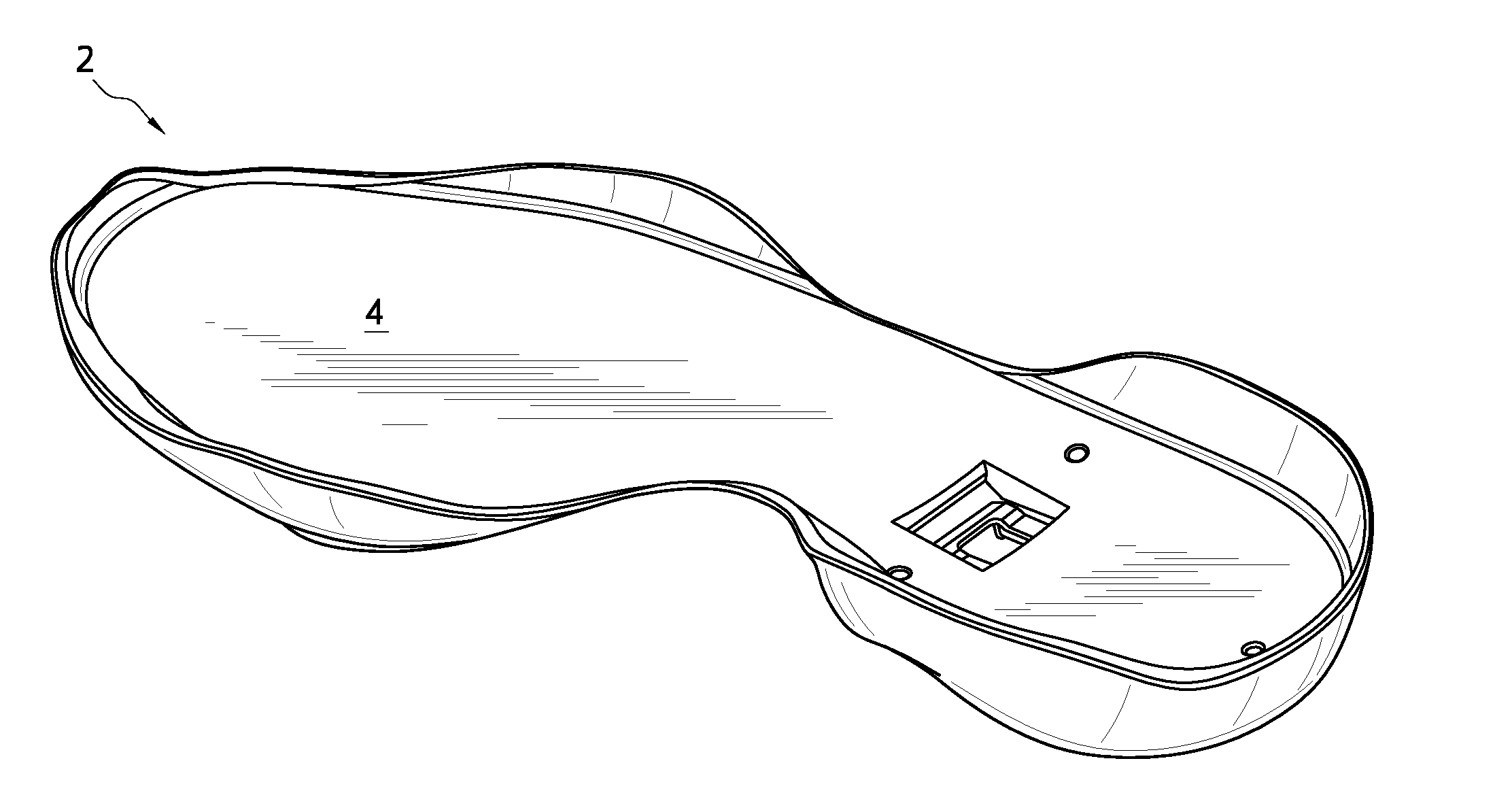

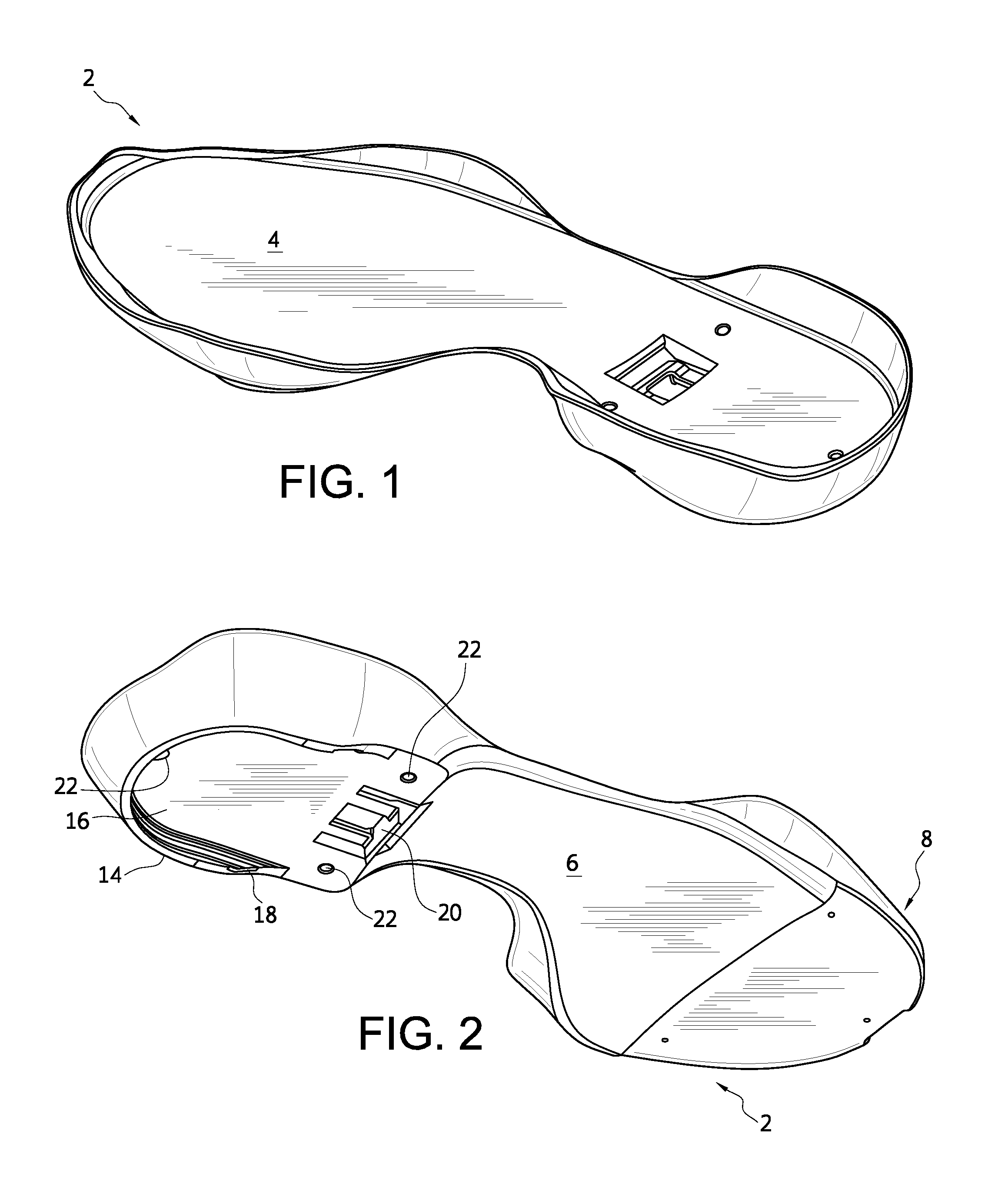

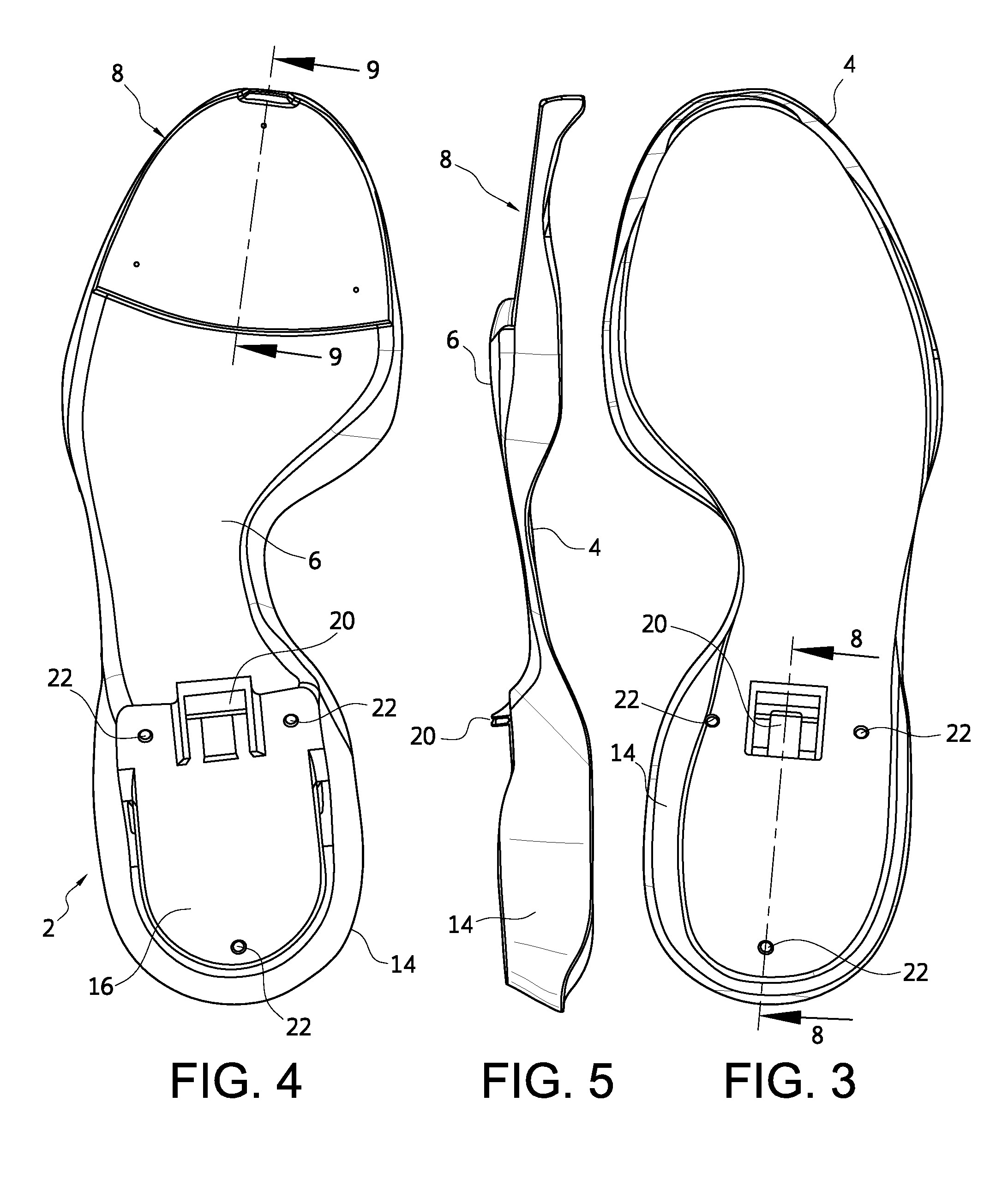

Shoe sole and interchangeable heel

A shoe sole and heel assembly includes a sole, an interchangeable heel removably connected with the sole, and at least one locking device for fixing the heel to the sole. The sole includes a wall extending from the heel area of the lower surface of the sole to define a cavity. The inner surface of the wall contains a channel. The heel includes a track extending from the side and rear portions of the heel. The heel is arranged adjacent to the sole with the heel track entering the sole channel. As the heel is displaced rearwardly, the track enters the channel of the sole and prevents vertical and lateral movement of the heel relative to the sole. A latch on the lower surface of the sole engages a notch on the upper surface of the heel to prevent longitudinal displacement of the heel. The sole and heel contain aligned threaded openings for receiving screws to secure the heel to the sole.

Owner:BALLET MAKERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com