Metal-oxide gas sensor array concentration detecting method based on drift compensation

A gas sensor and concentration detection technology, applied in the direction of material resistance, etc., can solve the problems of difficult concentration detection scheme, statistically obtained resistance R linear law, difficulties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

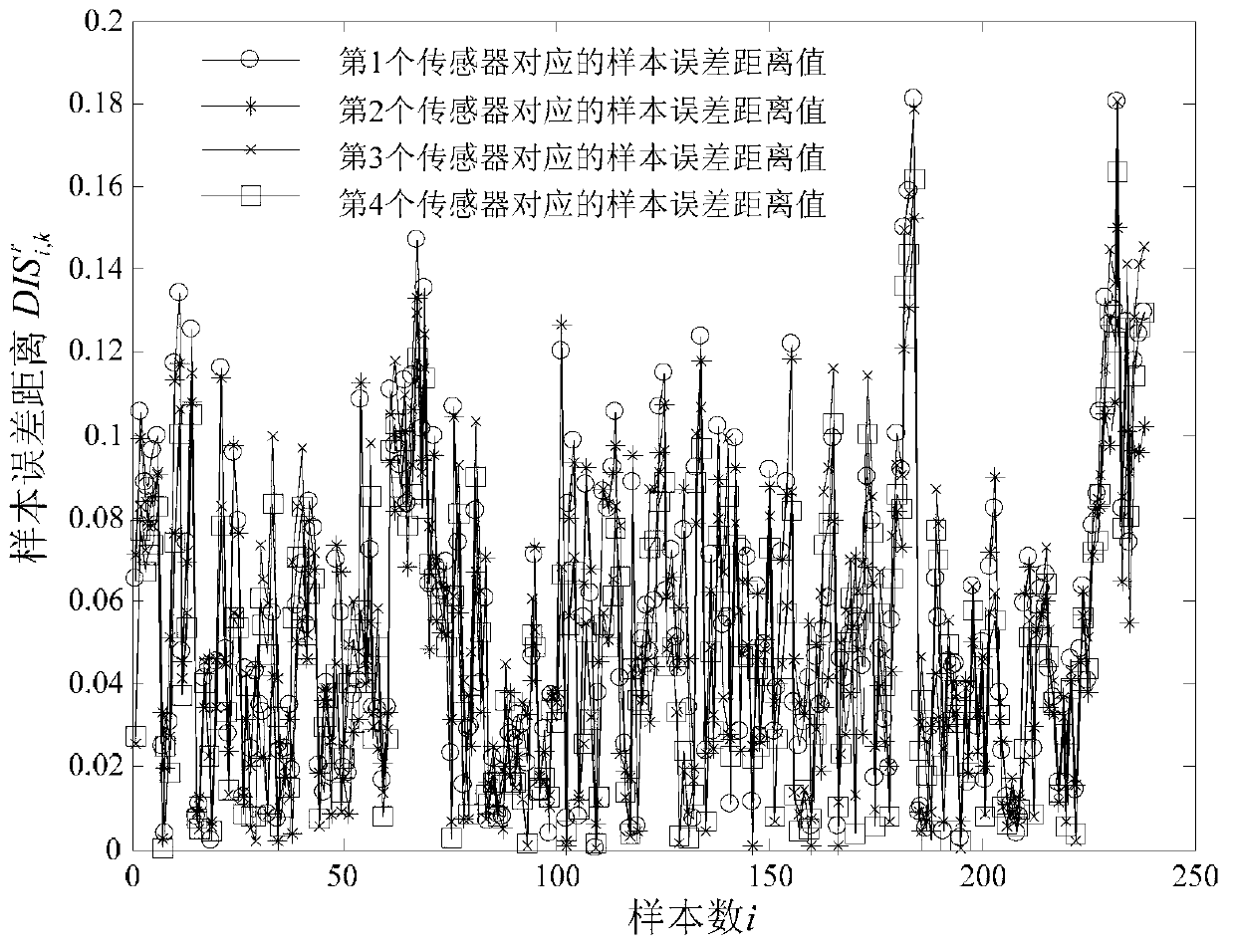

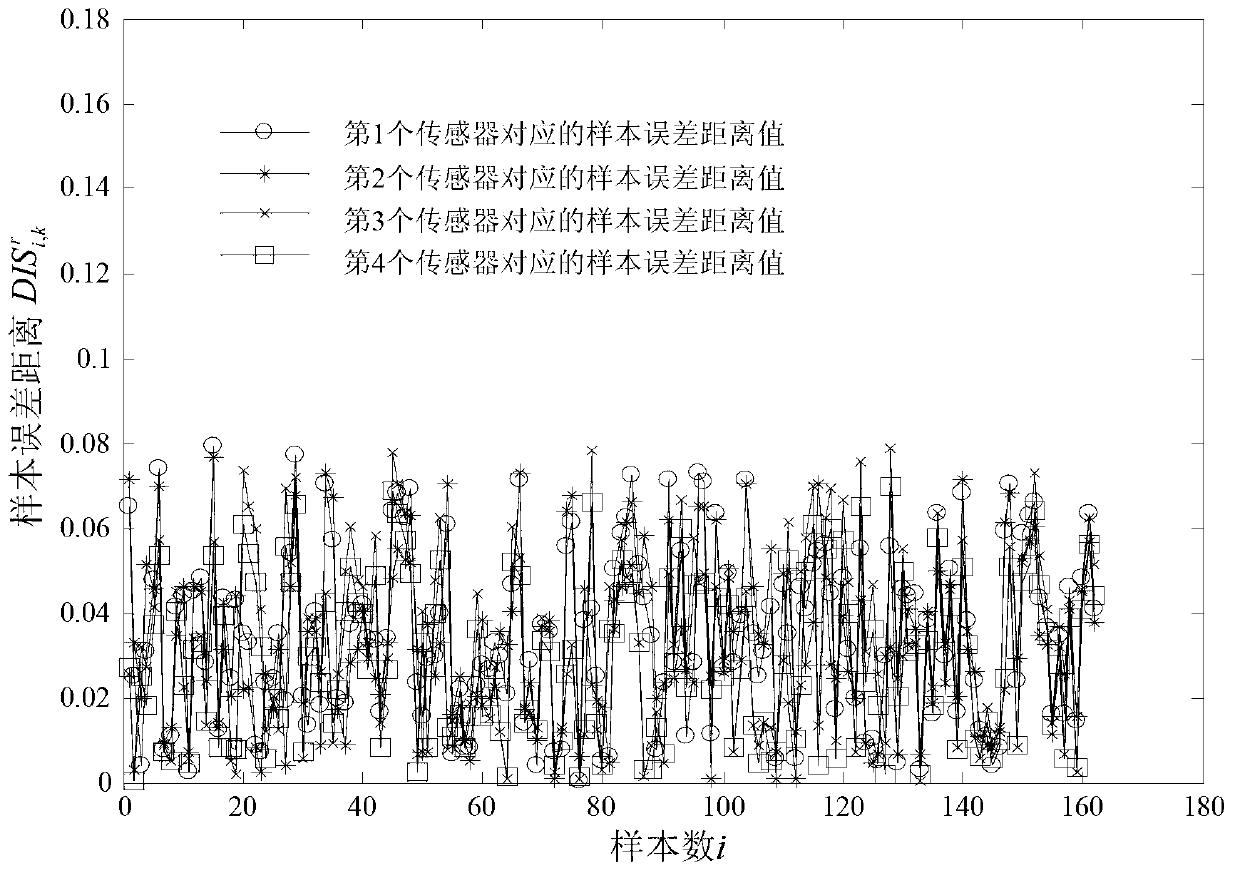

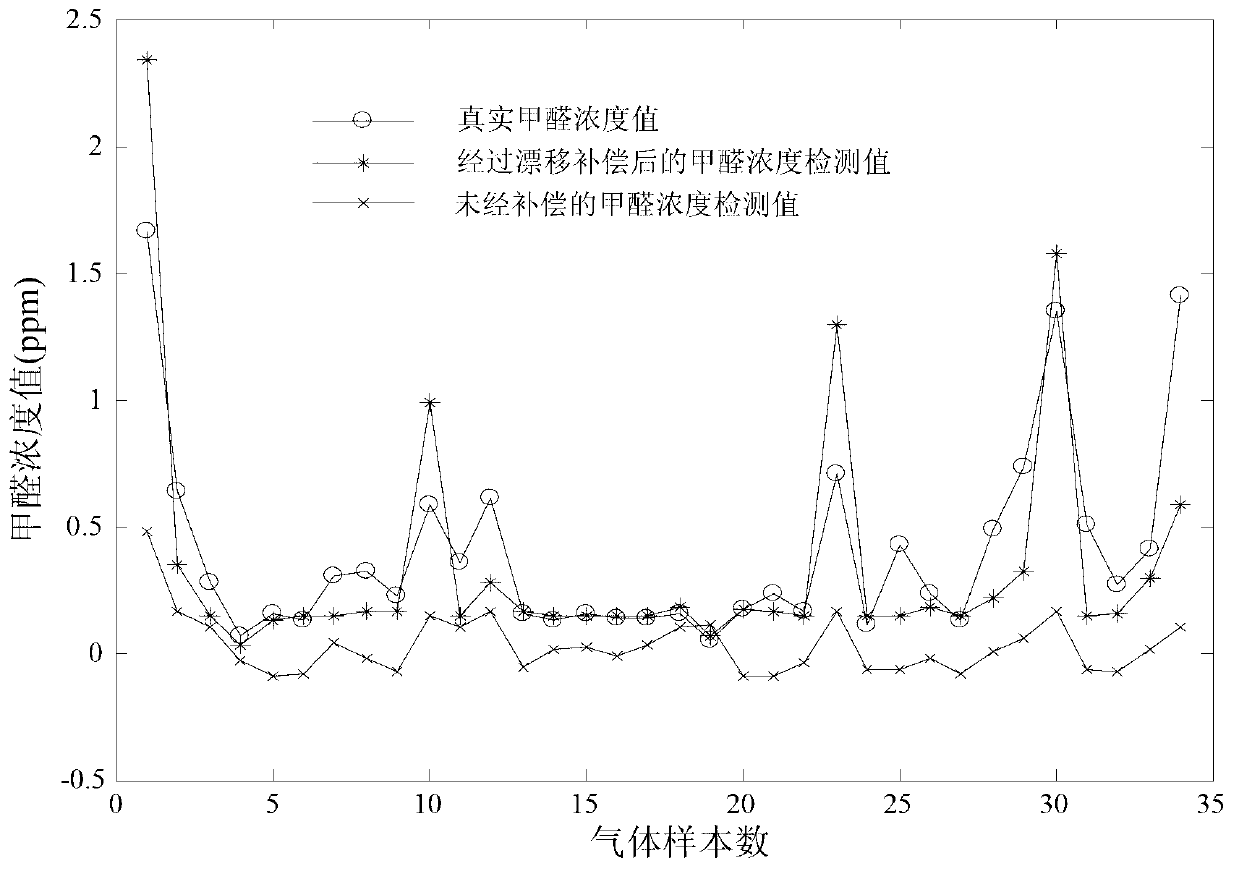

[0103] Independent Component Analysis (ICA for short) is a statistical analysis method to find its inherently independent factors or components from multivariate (or multidimensional) data, which is used to reveal independent information hidden in random variables or measurement data. It is widely used as an effective blind source signal separation technology in the field of signal and data processing technology. The method for detecting the concentration of the metal oxide gas sensor array based on drift compensation in the present invention relies on independent component analysis, uses sensitive gases for training and collects training response value vector data before the metal oxide gas sensor array drifts, and adopts independent component Analyze and find out the independent components related to temperature and humidity in each training response value vector data, so as to remove the correlation between each training response value vector data and temperature and humidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com