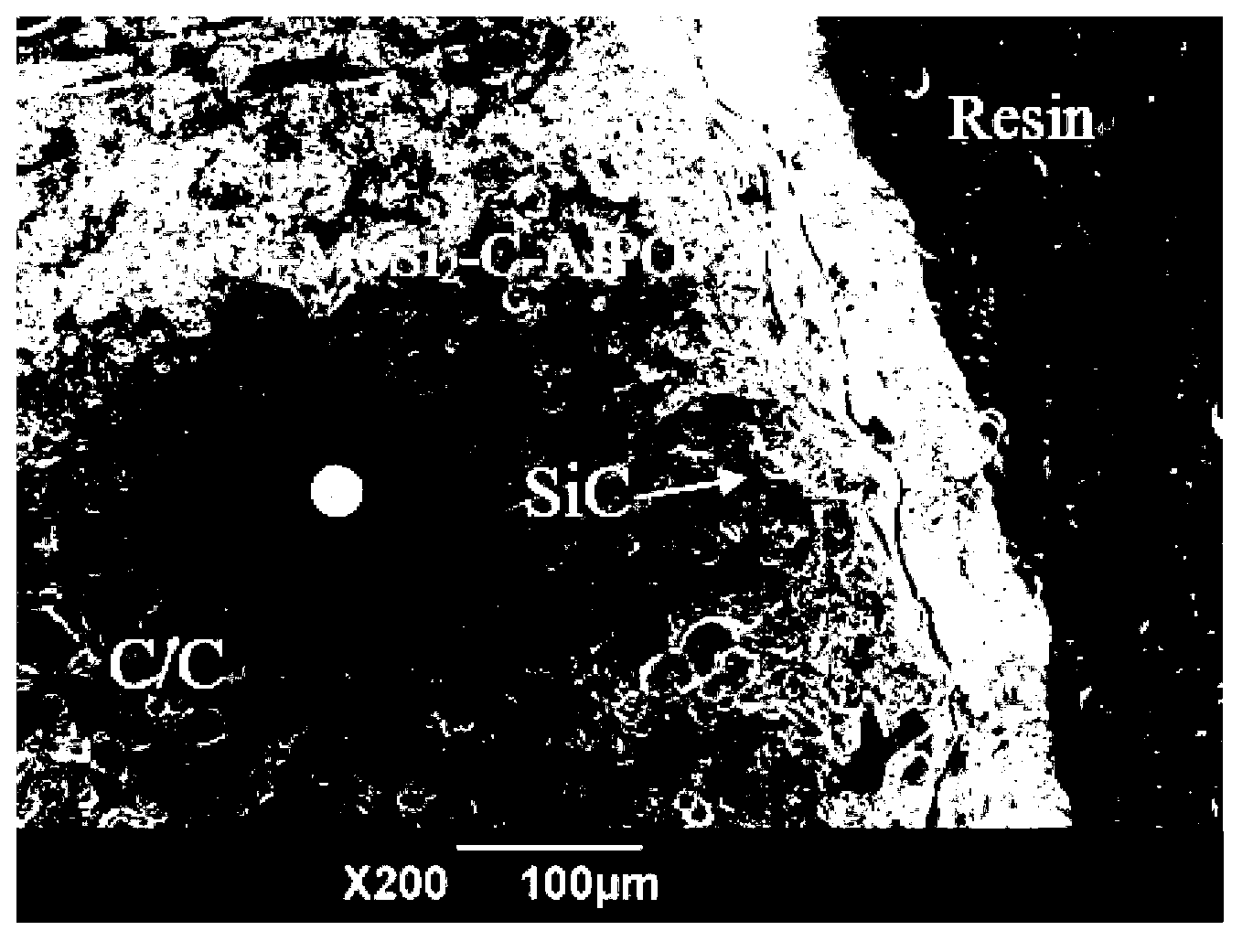

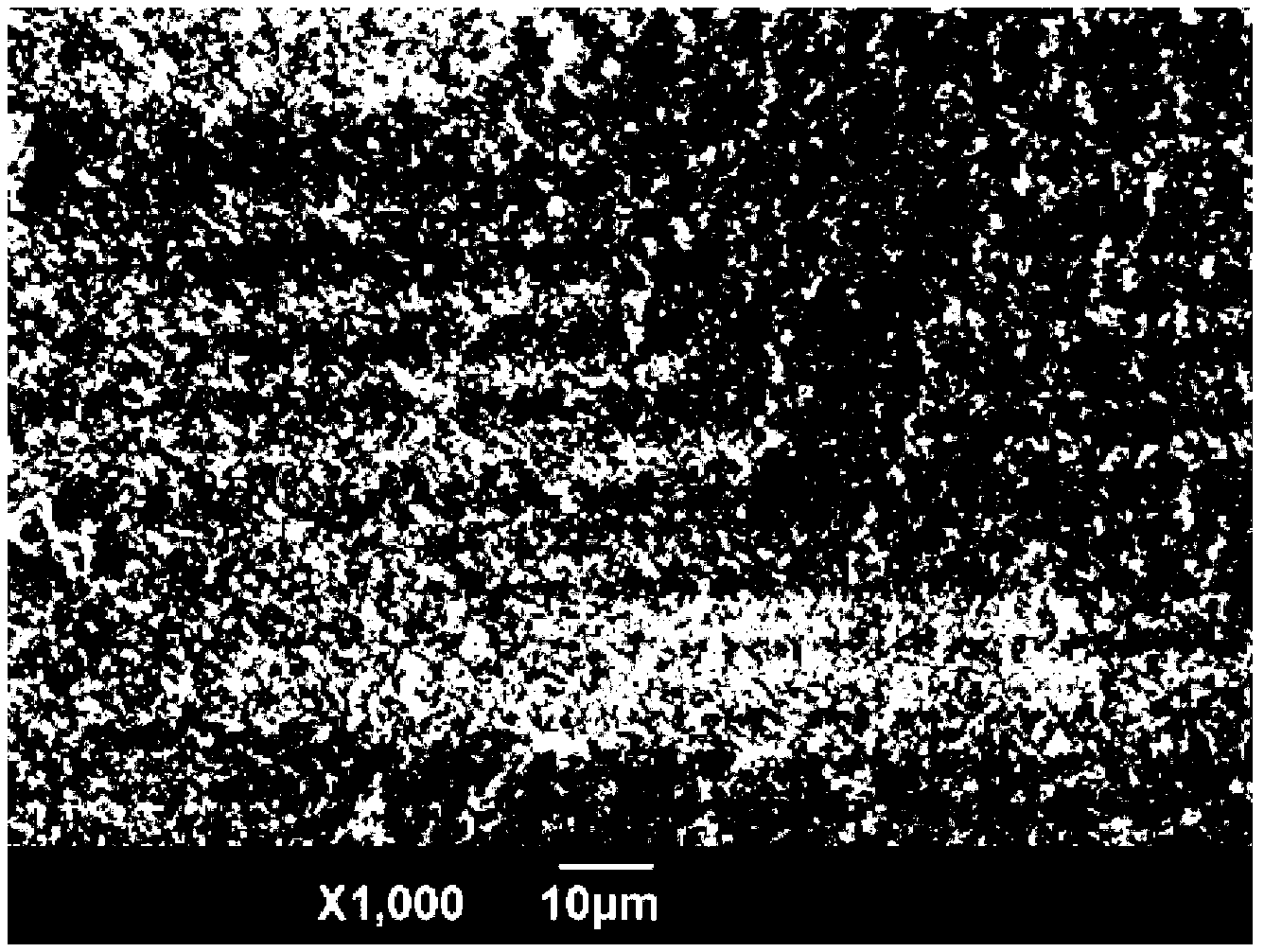

Method for preparing carbon/carbon composite material SiC-MoSi2-C-AlPO4 composite gradient external coating

A technology of sic-mosi2-c-alpo4 and carbon composite materials, which is applied in the field of preparing carbon/carbon composite composite gradient outer coatings, can solve the problems of easy cracking of the outer coating surface, insufficient coating thickness, and high requirements. Achieve the effects of simple and efficient preparation, complete and sufficient reaction, and accelerated deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Commercially available aluminum phosphate powder was calcined at 1300°C for 30 minutes, and then wet ball milled to produce C-AlPO with an average particle size of 3-6 μm 4 Powder, the commercially available molybdenum disilicide powder is dry-milled to make MoSi with an average particle size of 3-6 μm 2 powder, then C-AlPO 4 Powder, MoSi 2 Powder and nano-silicon carbide powder with an average particle size of 40nm, according to C-AlPO 4 :SiC:MoSi 2 = 1:20:1 mass ratio mixed evenly to form a mixed powder;

[0030] 2) Disperse the mixed powder in ethanol with a purity ≥ 99.8%, and prepare suspension A with a concentration of 30g / L, suspension B with a concentration of 20g / L and suspension C with a concentration of 25g / L;

[0031] 3) Put the suspensions A, B, and C into a 500W ultrasonic generator to vibrate for 40 minutes, take them out, and place them on a magnetic stirrer for 18 hours;

[0032] 4) Add elemental tellurium with a purity ≥ 99.7% to suspensions A,...

Embodiment 2

[0037] 1) Commercially available aluminum phosphate powder was calcined at 1300°C for 30 minutes, and then wet ball milled to produce C-AlPO with an average particle size of 3-6 μm 4 Powder, the commercially available molybdenum disilicide powder is dry-milled to make MoSi with an average particle size of 3-6 μm 2 powder, then C-AlPO 4 Powder, MoSi 2 Powder and nano-silicon carbide powder with an average particle size of 40nm, according to C-AlPO 4 :SiC:MoSi 2 = 1:1:1 mass ratio mixed evenly to form a mixed powder;

[0038] 2) Disperse the mixed powder in ethanol with a purity ≥ 99.8%, and prepare suspension A with a concentration of 35g / L, suspension B with a concentration of 30g / L and suspension C with a concentration of 22g / L;

[0039] 3) Put the suspensions A, B, and C into an ultrasonic generator with a power of 800W to vibrate for 60 minutes, take them out, and place them on a magnetic stirrer for 24 hours;

[0040] 4) Add elemental tellurium with a purity ≥ 99.7% t...

Embodiment 3

[0045] 1) Commercially available aluminum phosphate powder was calcined at 1300°C for 30 minutes, and then wet ball milled to produce C-AlPO with an average particle size of 3-6 μm 4 Powder, the commercially available molybdenum disilicide powder is dry-milled to make MoSi with an average particle size of 3-6 μm 2 powder, then C-AlPO 4 Powder, MoSi 2 Powder and nano-silicon carbide powder with an average particle size of 40nm, according to C-AlPO 4 :SiC:MoSi 2 = 1:2:1 mass ratio mixed evenly to form a mixed powder;

[0046] 2) Disperse the mixed powder in ethanol with a purity ≥ 99.8%, and prepare suspension A with a concentration of 32g / L, suspension B with a concentration of 25g / L and suspension C with a concentration of 30g / L;

[0047] 3) Put the suspensions A, B, and C into an ultrasonic generator with a power of 1200W to vibrate for 90 minutes, take them out, and place them on a magnetic stirrer for 36 hours;

[0048] 4) Add elemental tellurium with a purity ≥ 99.7% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com