Formable, porous, chemiluminescent reactant compositions and device therefor

A technology of chemiluminescence, composition, applied in the direction of luminescent materials, optical elements for changing the spectral characteristics of emitted light, lighting devices, etc., can solve the problems of not being able to minimize dark areas, and products not being able to exist independently of containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

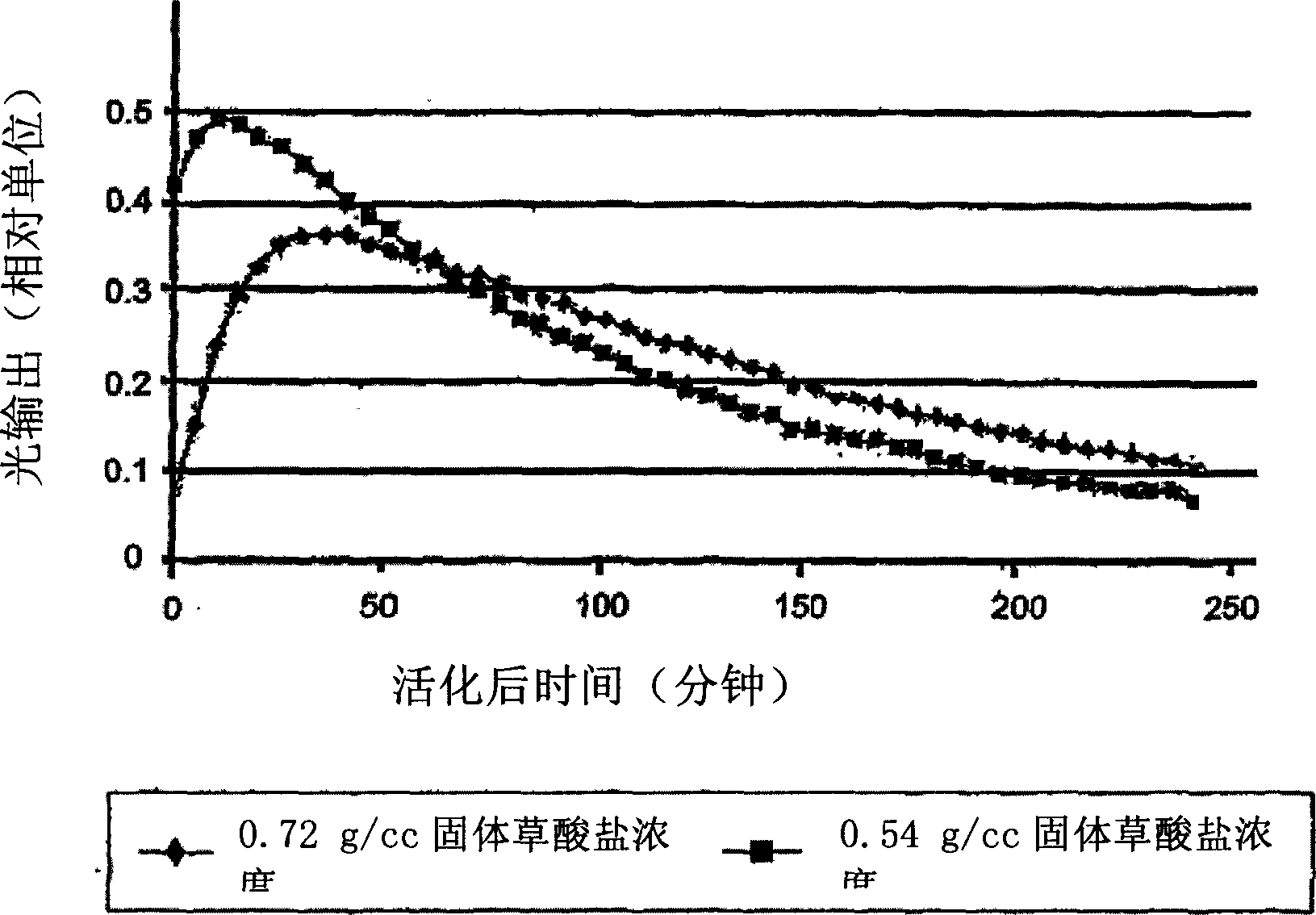

[0060] In order to investigate the effect of different curing times and temperatures and the thickness of the slurry on the porosity, 6 experiments were carried out; in each experiment, a liquid slurry weighing approximately 7 grams was placed in a small aluminum weighing pan , the latter is placed entirely on a spacer so that the bottom of the pan is slightly sloped to produce a slurry with a thickness in the range of 0.015” to 0.18”. In each experiment, the pans were placed on wire racks in a circulating gas oven. After curing for a specified time, each sample was removed from the pan, cut open, and examined for degree of cure and porosity. A properly cured sample was defined as one in which all of the oxalate solution was absorbed into the PVC matrix and showed no signs of overcuring. In a cured suitable matrix, low molecular weight PVC particles fuse with each other. However, even when the high molecular weight PVC particles absorbed the liquid oxalate solution, they did...

Embodiment 7

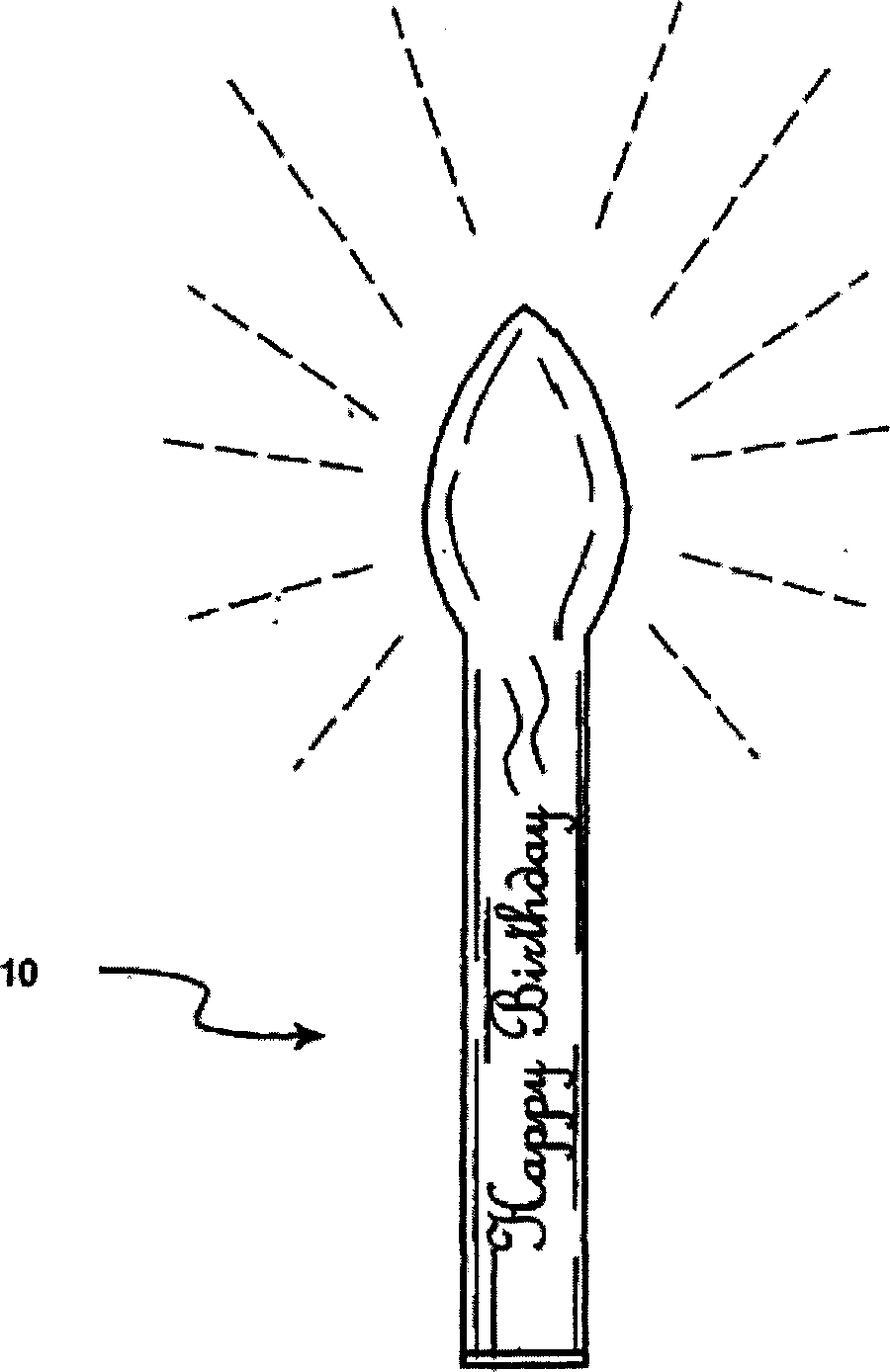

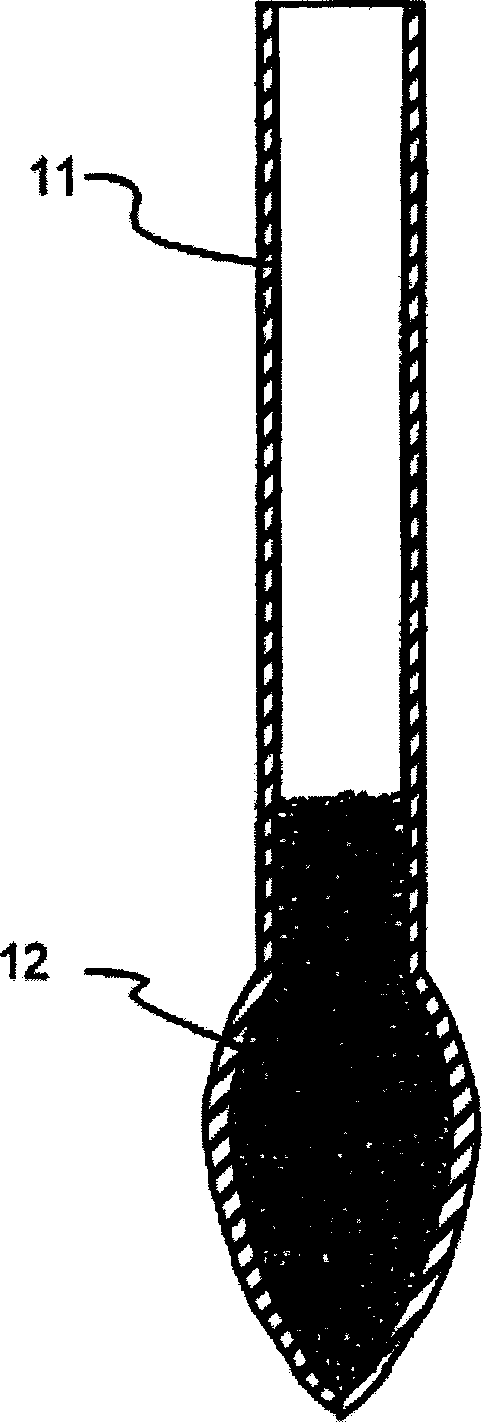

[0066] A chemiluminescent candle was made by the same liquid slurry forming method as described in Experiments 1-6 above. In making this candle, approximately 3.2 grams of the liquid slurry is injected into a polyethylene candle envelope with a syringe. A glass ampoule containing the chemiluminescent activator was inserted into the slurry so that the lower end of the ampoule touched the inner bottom surface of the candle envelope. The assembled parts were cured for 12 minutes in a circulating air oven set at 82°C. The assembled parts were then removed and allowed to cool at room temperature, and the candle envelope was observed separately from the solidified slurry. The PVC matrix (cured slurry) was fully cured in appearance, but was black and dense. The PVC matrix portion was removed from the envelope and placed in an aluminum weighing pan. A chemiluminescent activator is added to this part of the substance, and the cured slurry emits hazy light. It was observed that the ...

Embodiment 8

[0068] According to these results, we extract a certain amount of pulp, support it with a breathable substrate (such as a non-woven polyester blanket with a length of 10 cm and a thickness of 2 cm), and put it in an oven with circulating air at 82 ° C. Hold for 8 minutes. It is expected that the felt will provide uniform air entry to the slurry and that the slurry will cure in such a way that the outer layer will not form the dark, non-porous surface that occurs when the slurry is previously cured on a non-permeable aluminum pan. area. When each successive layer of slurry cures from the outside in, a porous layer is formed, thus allowing air to reach the next layer. The sample was removed from the oven and allowed to cool. Examination of the liner revealed no dark dense areas and was highly porous. The sample is activated with a chemiluminescent activator, and the whole body emits uniform bright light.

[0069] A theoretical model that can explain the formation of intersti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com