Based on pbbr 2 Micropore-regulated all-inorganic cspbbr 3 Perovskite solar cell and its preparation method and application

A solar cell and perovskite technology, which is applied in the manufacture of circuits, electrical components, and final products, and can solve problems such as improving the photoelectric conversion efficiency of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] This embodiment provides a PbBr-based 2 All-inorganic CsPbBr prepared by micropore regulation 3 Film, which is obtained by the following preparation method:

[0017] (1), 840~860 mg SnCl 2 and 330~350 mg CH 4 N 2 Dissolve S in 25-35 mL deionized water, and stir at high speed for 20-40 h in an open container at room temperature. The white precipitate was removed by centrifugation, and filtered with a PTFE filter membrane to obtain yellow and transparent SnO 2 Quantum dot solution.

[0018] (2) Put the conductive surface of the FTO conductive glass upwards and place it in a plasma cleaning machine for cleaning. The cleaning time is 5 to 10 minutes. The SnO described in (1) 2 The quantum dot solution and the FTO conductive glass after plasma cleaning are preheated on the heating table, and the preheating temperature is 70~90 o C, SnO 2 The preheating time of the quantum dot solution is 15-30 minutes, and the preheating time of the FTO conductive glass is 3-12 minu...

Embodiment 2

[0028] The PbBr-based 2 All-inorganic CsPbBr prepared by micropore regulation 3 Film, which is obtained by the following preparation method:

[0029] (1), 853 mg SnCl 2 and 338 mg CH 4 N 2 S was dissolved in 30 mL deionized water and stirred at room temperature for 36 h in an open container. Centrifuge to remove the white precipitate, and filter with PTFE membrane to obtain yellow transparent SnO 2 Quantum dot solution.

[0030] (2) Place the FTO conductive glass with the conductive side up in the plasma cleaner for 5 minutes. The SnO prepared in step 1 2 The quantum dot solution and the FTO conductive glass after plasma cleaning were placed at 80 o Preheated on the heating stage of C, SnO 2 The preheating time of the quantum dot solution is 20 minutes, and the preheating time of the FTO conductive glass is 5 minutes.

[0031] (3), the preheated SnO 2 The quantum dot solution was spin-coated on the preheated FTO conductive glass at a speed of 2000 rpm / s for 30 s. A...

Embodiment 3

[0038] Embodiment 3, the performance test of the prepared perovskite solar cell

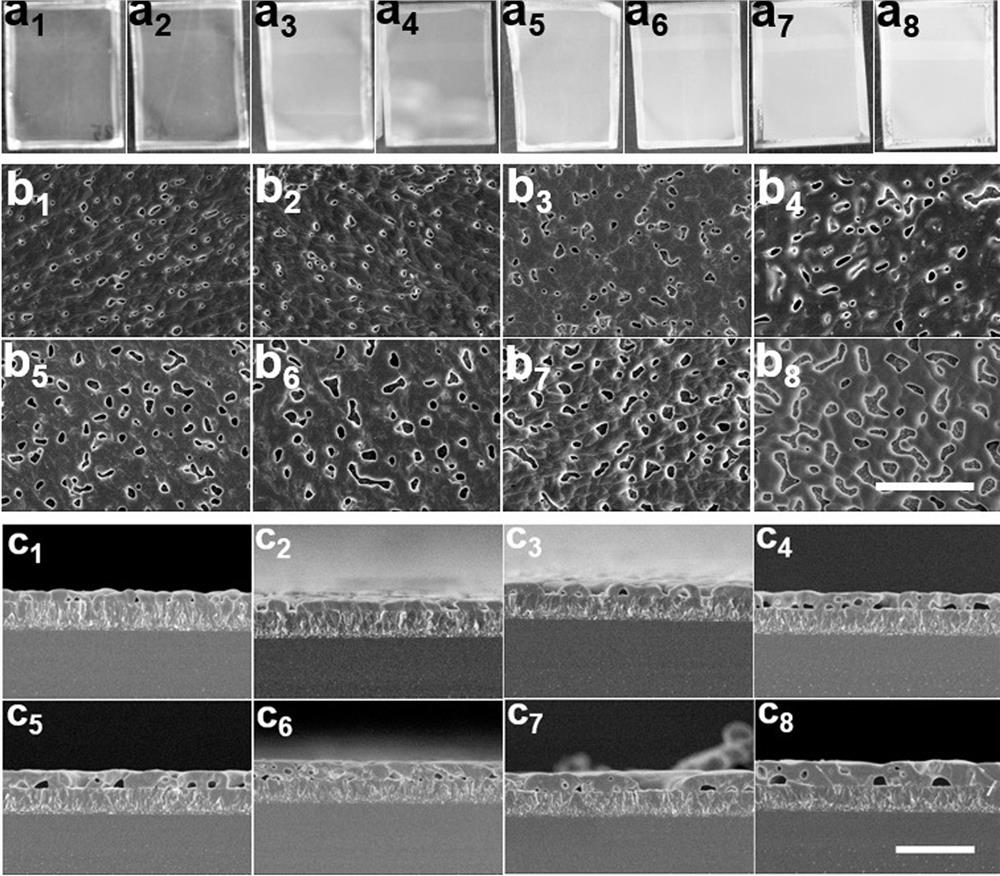

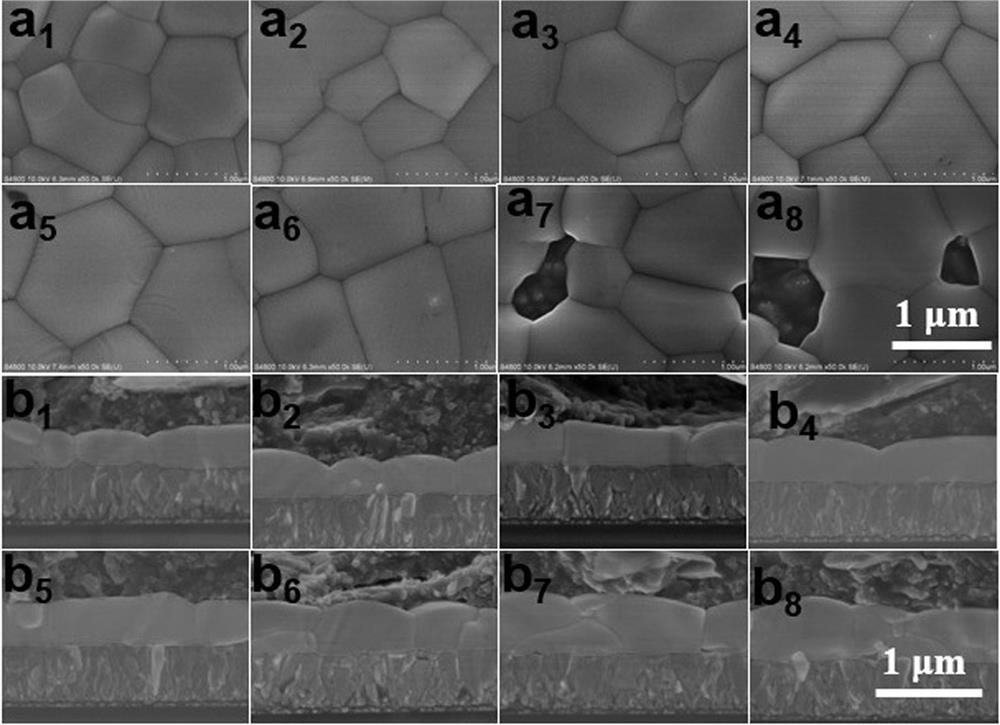

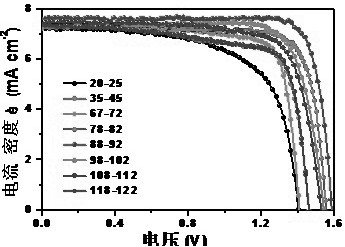

[0039] 1. Test the FTO / SnO prepared under different crystallization temperature conditions 2 / PbBr 2 Film photos, surface SEM images and cross-sectional SEM images, such as figure 1 shown.

[0040] from figure 1 It can be seen that in Fig. a 1 -a 8 respectively at 20~25 o C, 35~45 o C, 67~72 o C, 78~82 o C, 88~92 o C, 98~102 o C, 108~112 o C, 118~122 o PbBr prepared at the crystallization temperature of C 2 The photo of the film, it can be seen that as the crystallization temperature increases, the PbBr 2 The film changes from transparent to translucent or even opaque. Figure b 1 -b 8 and c 1 -c 8 respectively at 20-25 o C, 35-45 o C, 67-72 o C, 78-82 o C, 88-92 o C, 98-102 o C, 108-112 o C, 118-122 o PbBr prepared at the crystallization temperature of C 2 Surface and cross-sectional SEM images of the film. It can be seen from the figure that as the crystallization te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com