A kind of preparation method of metal matrix composite electronic package containing high volume fraction sic

A metal-based composite and electronic packaging technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low strength, reduce sintering temperature, avoid incomplete degreasing, and shorten the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

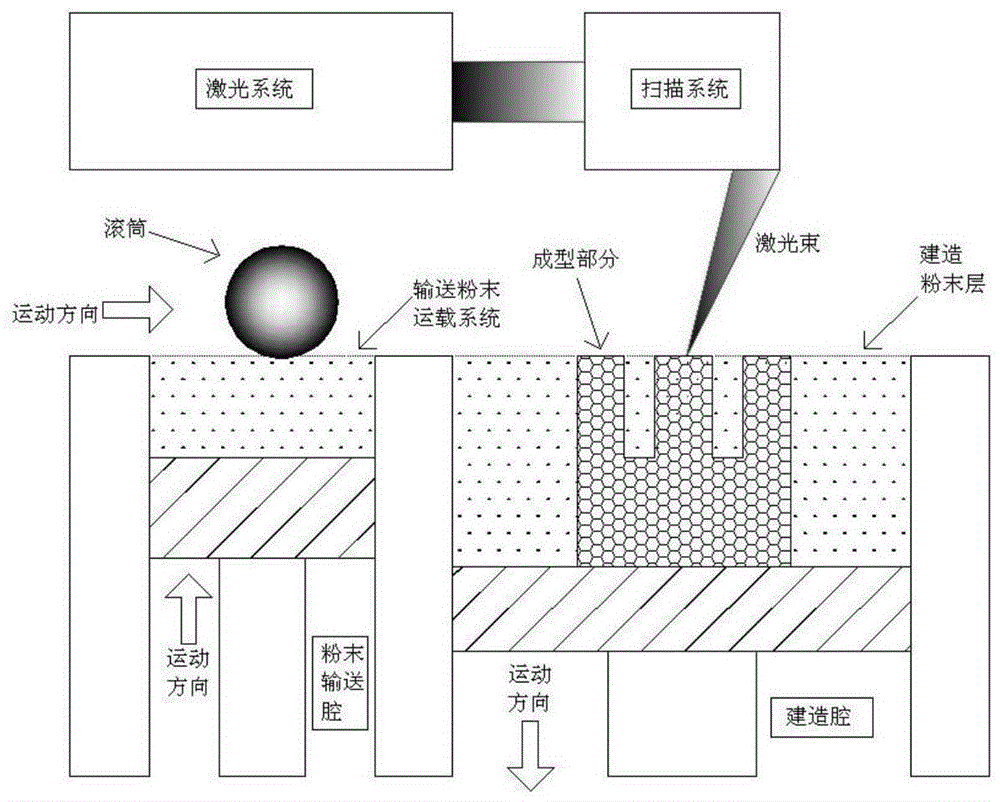

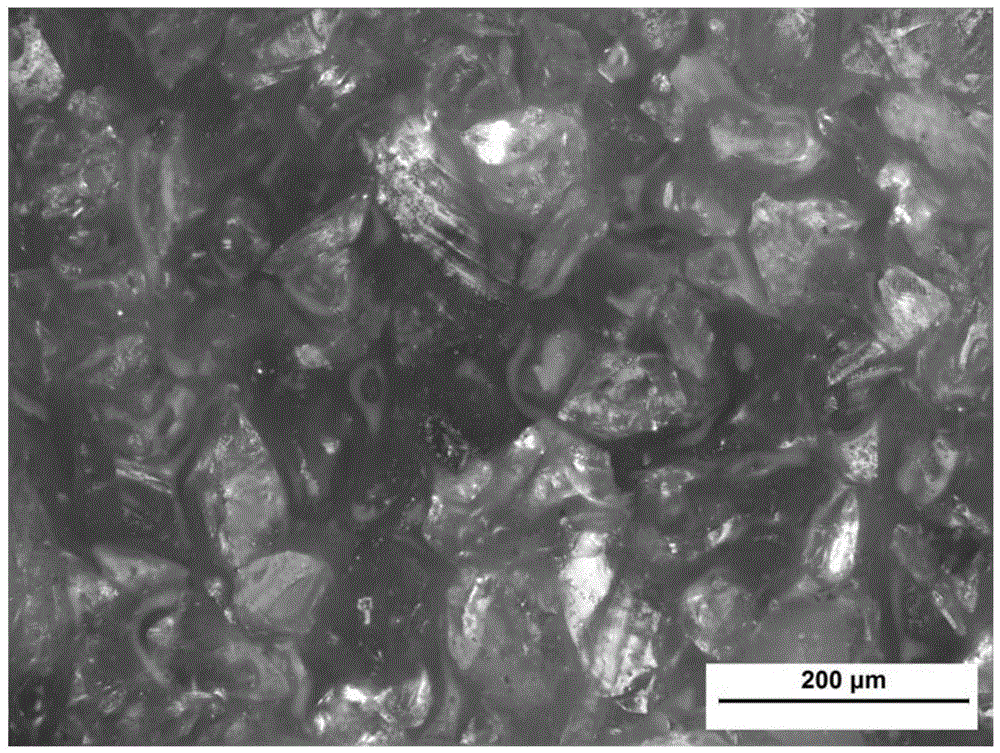

Embodiment 1

[0050] Weigh SiC particles with particle sizes of 10 μm, 85 μm, and 145 μm according to the mass ratio of 1:2:7, use 50 μm nylon 3200 powder as the binder, and the ratio of binder to the total mass of SiC particles is 1:5. The SiC particles with multimodal particle size distribution and the binder are mixed and dried, and the obtained mixed powder is used as a raw material for preparing a SiC preform. The SiC volume fraction is designed to be 60%, and the SiC prefabricated body file to be prepared is designed using a general-purpose three-dimensional design software CAD, and the file is imported into the selective laser sintering equipment, arranged in a three-dimensional non-repetitive space, and the slice thickness is determined to be 0.05 mm, The scanning distance is 0.05mm, the laser power is 200W, and the scanning rate is 100mm / s. SLS equipment is used to perform layer-by-layer selective laser sintering on the prepared material until a complete SiC preform is printed. Th...

Embodiment 2

[0053] Weigh SiC particles with particle sizes of 10 μm, 85 μm, and 145 μm according to the mass ratio of 1:2:7, and use 25 μm nylon 3200 powder as a binder; the ratio of binder to the total mass of SiC particles is 1:5, The SiC particles with multimodal particle size distribution and the binder are mixed and dried, and the obtained mixed powder is used as a raw material for preparing a SiC preform. The SiC volume fraction is designed to be 65%, and the SiC prefabricated body file to be prepared is designed using a general-purpose three-dimensional design software CAD, and the file is imported into the selective laser sintering equipment, arranged in a three-dimensional non-repetitive space, and the slice thickness is determined to be 0.1mm, The scanning interval is 0.1mm, the laser power is 200W, and the scanning speed is 100mm / s. SLS equipment is used to perform layer-by-layer selective laser sintering on the prepared material until a complete SiC preform is printed. The pr...

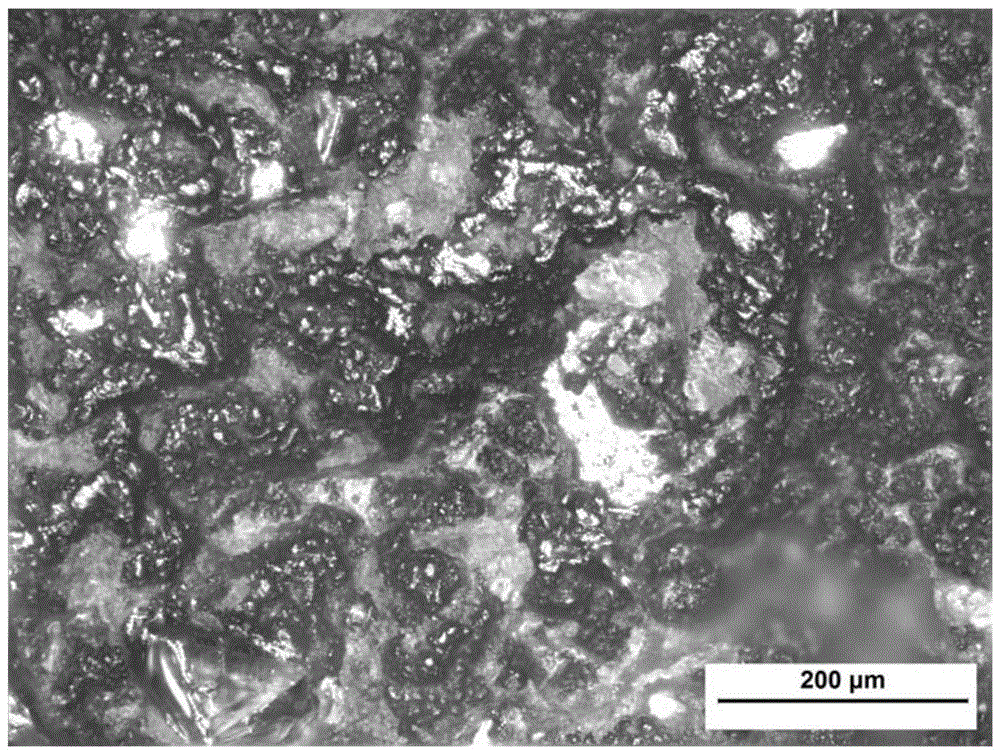

Embodiment 3

[0056] Weigh SiC particles with a particle size of 5 μm, 60 μm, and 145 μm according to the mass ratio of 1:1:8, and use nylon 3200 powder with a particle size of 50 μm as a binder. The ratio of the binder to the total mass of SiC particles is 1: 4. Mix and dry the SiC particles with multi-modal particle size distribution and the binder, and the obtained mixed powder is used as the raw material for preparing the SiC preform. The volume fraction of the SiC porous preform is designed to be 70%, and the SiC preform file to be prepared is designed using a general-purpose three-dimensional design software CAD, and the file is imported into the selective laser sintering equipment, arranged in a three-dimensional non-repetitive space, slice thickness, feeding speed , laser power, scan rate and other parameters are the same as in Embodiment 1, and the FDM (Fused Deposition Modeling) technical parameter settings are initialized. FDM (Fused Deposition Modeling) technology is used to sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com