Functional gradient foamed aluminum and preparation method thereof

A technology of functional gradient and aluminum foam, which is applied in the field of functional gradient aluminum foam and its preparation, can solve the problems of inability to accurately control foam porosity, pore size, poor structure and performance of gradient aluminum foam, and deformation of foam joints, etc., to achieve good Energy-absorbing effect, uniform distribution of cells, and increased cushioning and energy-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

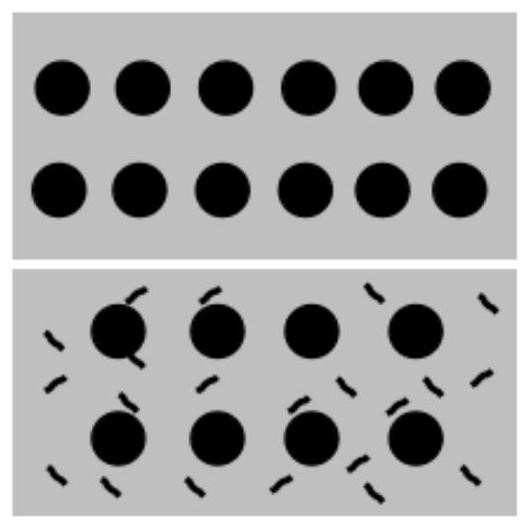

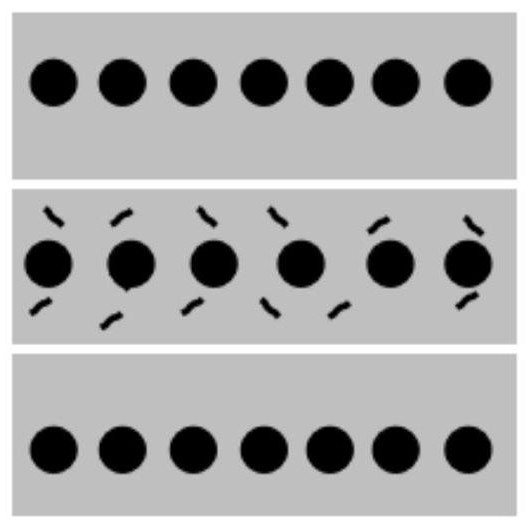

[0041] A functionally graded aluminum foam with upper and lower layers, comprising a carbon nanotube-reinforced foamed aluminum matrix composite material layer with a porosity of 50% and a pure foamed aluminum layer with a porosity of 70%.

[0042] The gradient aluminum foam of this embodiment is prepared by the following method:

[0043] (1) Calculate and weigh the composite powder and pore-forming agent of pure aluminum powder, carbon nanotubes and aluminum powder required for two layers, and the carbon nanotube reinforced foamed aluminum-based composite material layer takes by weighing 14.33g urea particles (2mm), Take by weighing 28.78g carbon nanotube / aluminum composite powder (carbon nanotube content 3wt.%) as group 1; Pure foamed aluminum layer takes by weighing 20.06g urea particle (2mm), takes by weighing 17.45g pure aluminum powder (180 order) as Group 2;

[0044] (2) Add dropwise 5% ethanol by mass fraction to each group of mixed powders, and mix evenly to obtain a...

Embodiment 2

[0048] A functionally graded aluminum foam with upper, middle and lower layers, the upper and lower layers have a porosity of 70%, corresponding to a pure foamed aluminum layer, and the middle layer has a porosity of 60%, corresponding to a carbon nanotube-reinforced foamed aluminum-based composite material layer.

[0049] The gradient aluminum foam of this embodiment is prepared by the following method:

[0050] (1) Calculate and weigh the composite powder and pore-forming agent of pure aluminum powder, carbon nanotubes and aluminum powder required for the three layers. The pure foamed aluminum layer takes 13.38g urea particles (1.5mm), and weighs 11.64g pure Aluminum powder (180 mesh) is as group 1 and group 3; Carbon nanotube reinforced foamed aluminum matrix composite material layer takes by weighing 11.47g urea particle (1.5mm), takes by weighing 15.32g carbon nanotube / aluminum composite powder (carbon nanotube content 2wt.%) as group 2;

[0051] (2) Add dropwise 5% etha...

Embodiment 3

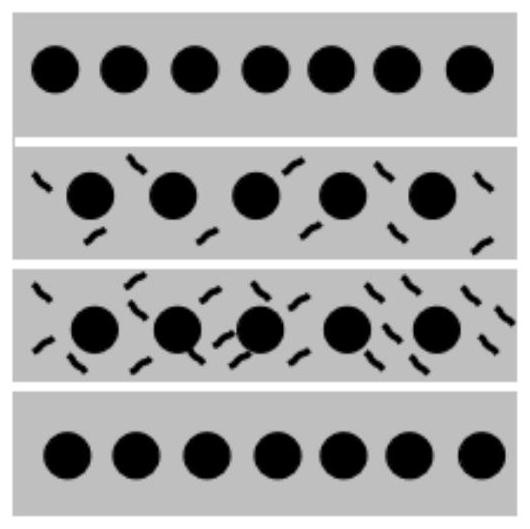

[0055] A four-layer functionally graded aluminum foam, the porosity of the uppermost layer and the lowermost layer is 70%, corresponding to the pure foam aluminum layer; the porosity of the middle and upper layers is 50%, corresponding to 1.5wt.% carbon nanotube reinforced aluminum foam matrix composite material layer; the middle and lower layers have a porosity of 50%, corresponding to a 3wt.% carbon nanotube-reinforced foamed aluminum matrix composite material layer.

[0056] The gradient aluminum foam of this embodiment is prepared by the following method:

[0057] (1) Calculate and weigh the composite powder and pore-forming agent of pure aluminum powder, carbon nanotubes and aluminum powder required for the four layers, take 10.03g urea particles (1.5mm) for the pure foamed aluminum layer, and weigh 8.73g pure Aluminum powder (180 mesh) is as group 1 and group 4; Carbon nanotube reinforced foamed aluminum matrix composite material layer takes by weighing 7.16g urea partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com