Device for preparing porous ceramic and method for preparing porous ceramic by using polystyrene foam particles

A technology of polystyrene foaming and porous ceramics, applied in the field of porous ceramics, can solve the problems of high price of polyurethane porous frame structure, increased production cost of porous ceramics, and high cost of porous ceramics products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

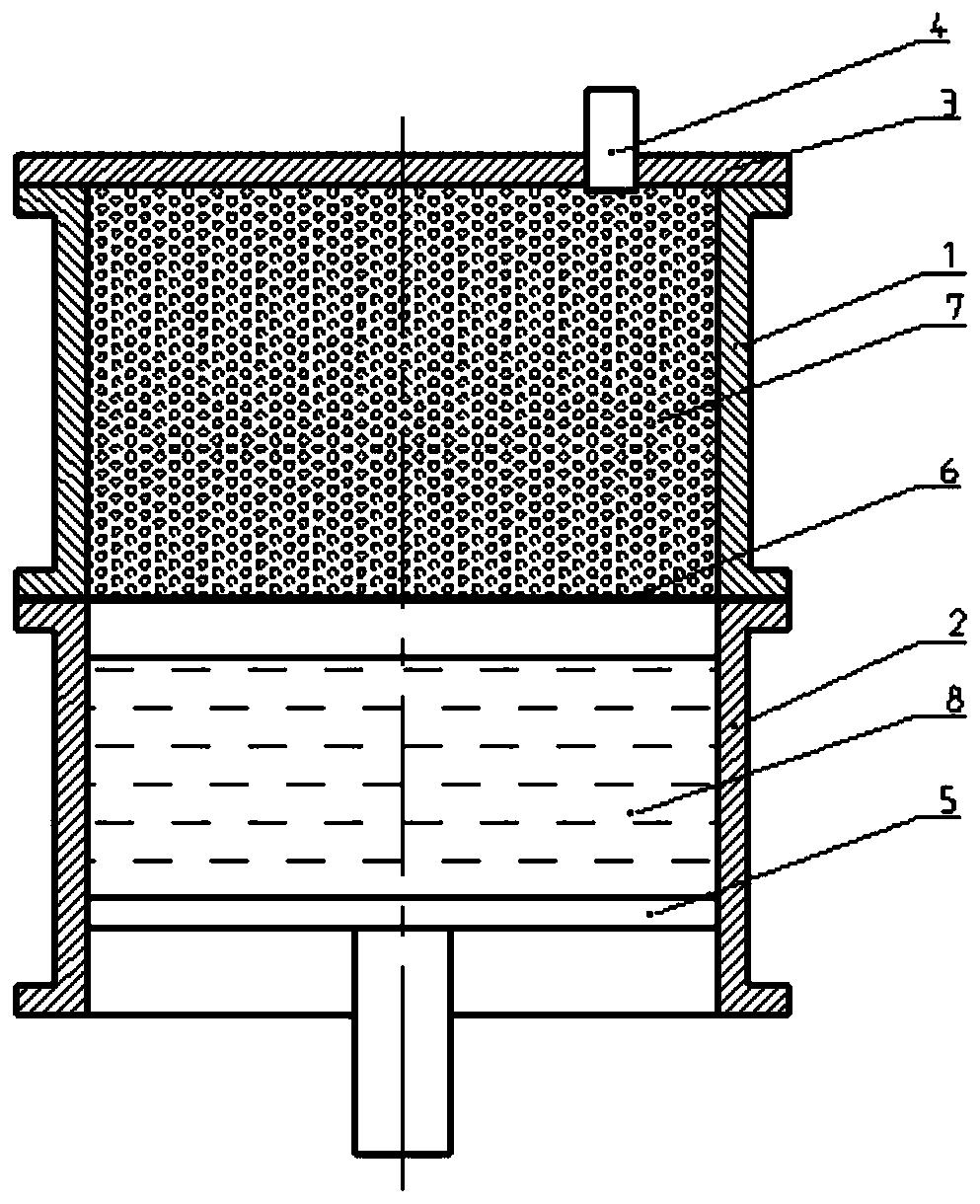

[0031] The device for preparing porous ceramics provided by the present invention includes a foaming cylinder 1 with a lower opening. In the present invention, the material of the foaming cylinder 1 is preferably aluminum alloy, and the model of the aluminum alloy is preferably ZL104 aluminum alloy. The present invention has no special requirements on the internal shape and size of the foaming cylinder 1, and the corresponding internal shape and size can be designed according to the shape and size of the porous ceramic. In a specific embodiment of the present invention, the internal shape of the foaming cylinder 1 is preferably cylindrical, and the internal size is preferably Φ90×200 mm.

[0032] In the present invention, the foaming cylinder 1 is provided with an upper cover 3 , and the upper cover 3 is provided with a gas inlet 4 . In the present invention, the material of the upper cover 3 is preferably aluminum alloy, and the model of the aluminum alloy is preferably ZL10...

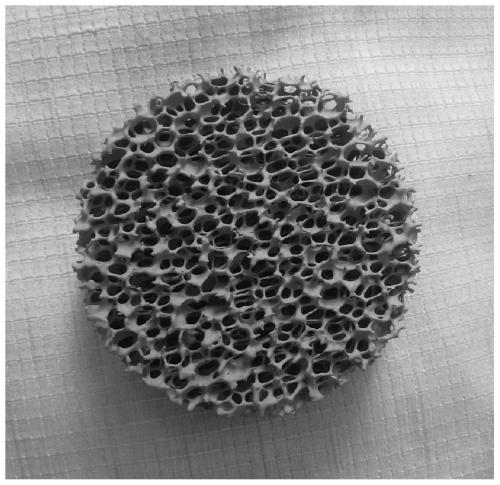

Embodiment 1

[0052] (a) Open the upper cover 3 of the foaming cylinder 1, put the polystyrene pre-expanded particles into the foaming cylinder 1, and carry out compaction; wherein, the specific volume of the pre-expanded particles is 18kg / m 3 , the particle size is 4-6mm, and the compaction degree after compaction is 75%;

[0053] (b) Close the upper cover 3 of the foaming cylinder 1, and take 2 m 3 The flow rate of / h is blown from the gas inlet 4 at a temperature of 115°C and a flow rate of 2m 3 / h of water vapor, the compacted polystyrene foamed particles are re-foamed for 2 h and the pressure is 0.1 MPa to obtain polystyrene foamed particles with a continuous porous structure;

[0054] (c) Add ceramic slurry to the ceramic slurry cylinder 2, push the pressurizing piston 5 inward with a pressure of 0.6 MPa, so that the ceramic slurry penetrates into the porous structure of the polystyrene foam particles, and the ceramic slurry is at room temperature After curing for 48 hours, a polyst...

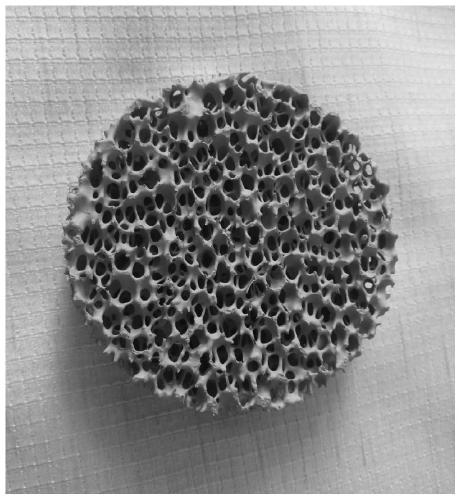

Embodiment 2

[0058] (a) Open the upper cover 3 of the foaming cylinder 1, put the polystyrene pre-expanded particles into the foaming cylinder 1, and carry out compaction; wherein, the specific volume of the pre-expanded particles is 17kg / m 3 , the particle size is 5-7mm, and the compaction degree after compaction is 78%;

[0059] (b) Close the upper cover 3 of the foaming cylinder 1, and blow the gas from the gas inlet 4 at a temperature of 120°C and a flow rate of 2.5m 3 The compacted polystyrene foamed particles are re-foamed with air per hour, the time is 1.5h, the pressure is 0.3MPa, and the polystyrene foamed particles with porous structure are obtained;

[0060] (c) Add the ceramic slurry to the ceramic slurry cylinder 2, push the pressurizing piston 5 inward with a pressure of 1 MPa, so that the ceramic slurry penetrates into the porous structure of the polystyrene foam particles, and the ceramic slurry is cured at room temperature After 48 hours, a polystyrene foam particle-ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com