Preparation methods for non-macroscopic-interface density gradually-changed type composite foam

A composite foam, gradient technology, which is applied in the field of preparation of composite foam without macro-interface density gradient, can solve the problems of lack of patents and reports, affecting the acoustic performance of composite foams such as sound transmission or sound absorption, and the method is simple and feasible. Strong design, the effect of solving poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

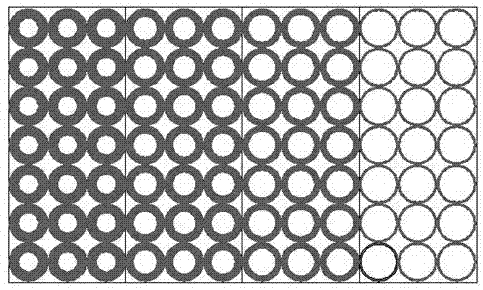

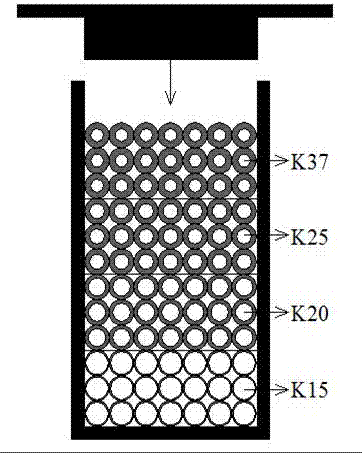

[0032] Taking the preparation of a four-layer density structure composite foam with no macro interface density gradient as an example, the density is designed to be 0.570 g / cm from low to high 3 , 0.600 g / cm 3 , 0.630 g / cm 3 , 0.702 g / cm 3 , each layer of syntactic foam occupies 1000 cm 3 .

[0033] The preparation steps are as follows:

[0034] S1. Preparation of resin matrix: Stir and mix epoxy resin E51, curing agent methyltetrahydrophthalic anhydride, and accelerator DMP-30, wherein the weight ratio of E51: methyltetrahydrophthalic anhydride is 100:80, and the weight ratio of DMP-30 It is 0.5% of the weight of the matrix resin. Vacuumize to remove air bubbles to obtain a resin matrix with a density of 1.2g / cm 3 ;

[0035] S2. Calculate the amount of raw materials corresponding to each layer of composite foam according to the designed density and volume:

[0036] Each layer of composite foam is composed of the resin matrix obtained in step S1 and hollow glass microsp...

Embodiment 2

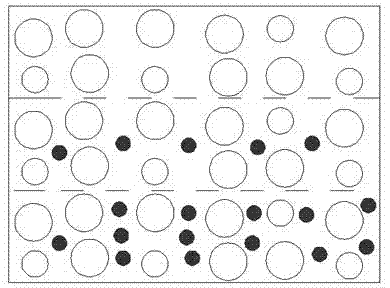

[0045] Taking the preparation of a three-layer density structure composite foam with no macro interface density gradient as an example, the density is designed to be 0.3 g / cm from low to high. 3 , 0.4 g / cm 3 , 0.5 g / cm 3 , each layer of syntactic foam occupies 1000 cm 3 .

[0046] The preparation steps are as follows:

[0047] S1. Preparation of resin matrix: Stir and mix epoxy resin E51, curing agent methyltetrahydrophthalic anhydride, and accelerator DMP-30, wherein the weight ratio of E51: methyltetrahydrophthalic anhydride is 100:80, and the weight ratio of DMP-30 It is 0.5% of the weight of the matrix resin. Vacuumize to remove air bubbles to obtain a resin matrix with a density of 1.2g / cm 3 ;

[0048] S2. Calculate the amount of raw materials corresponding to each layer of composite foam according to the designed density and volume:

[0049] Each layer of composite foam is composed of the resin matrix obtained in step S1, hollow glass microspheres and expandable mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com