Preparation method of efficient increased-transmission and antireflection glass

A glass and high-efficiency technology, which is applied in the field of preparation of high-efficiency anti-reflection and anti-reflection glass, can solve the problems of inaccurate control of the refractive index of the film, easy peeling performance of the film, poor bonding force, etc., and achieve obvious anti-reflection effect, low cost, and enhanced binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix and heat 0.12 mol of water, 0.04 mol of ammonia water and 3 mol of anhydrous ethanol. When the temperature reaches the set temperature of 35°C, add 0.04 mol of tetraethyl orthosilicate, keep constant temperature, and continue stirring for 21 hours to obtain silica nanoparticle dispersion. solution, and then slowly add polystyrene latex balls with a diameter of 105 nm into the dispersion of silica nanoparticles and stir with a volume ratio of 2.6:1 to obtain a blended solution for use.

[0019] A roll coating method is used to coat the cleaned photovoltaic glass surface to obtain a transparent film. The coated photovoltaic glass is sintered at a temperature of 500° C. for 18 minutes to obtain high-efficiency anti-reflection and anti-reflection glass.

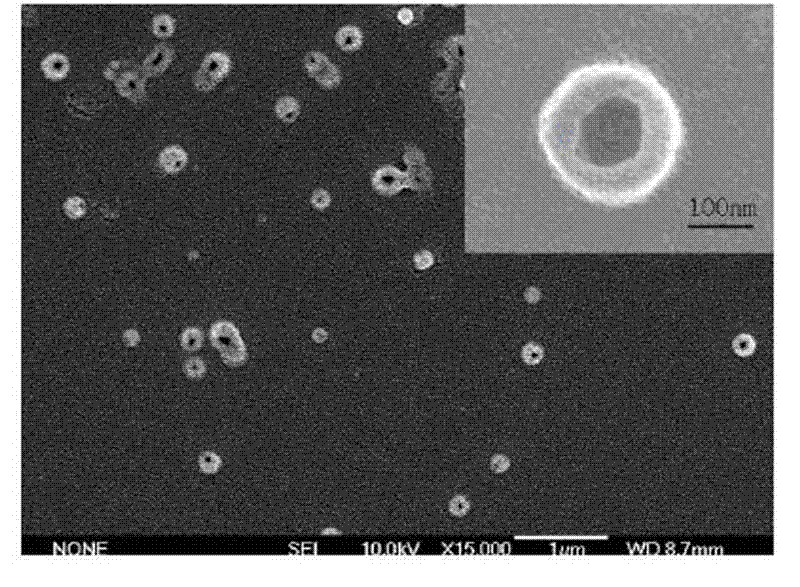

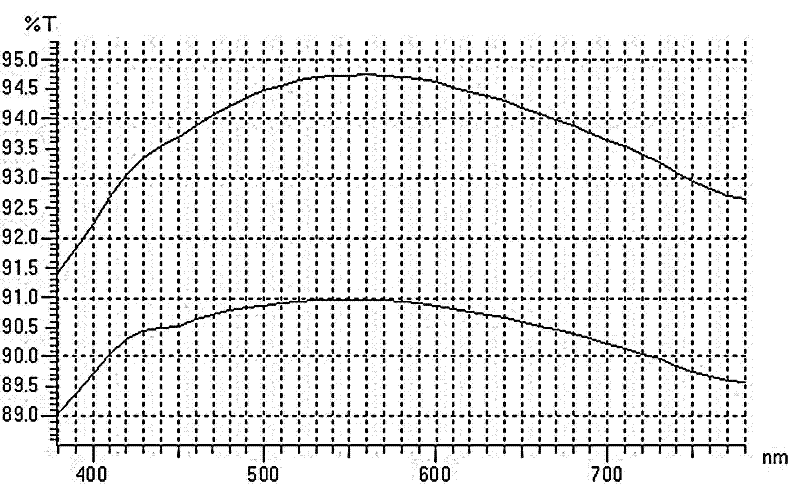

[0020] figure 1 It shows that the prepared film is a silicon dioxide film with porous cavity morphology, and the refractive index of the film layer is controlled; analysis figure 2 , we found that the transmittance ...

Embodiment 2

[0022] Mix and heat 0.4mol water, 0.4mol hydrochloric acid and 12mol ethylene glycol with stirring, and when the temperature reaches the set temperature of 20°C, add 0.04mol methyl orthosilicate, keep constant temperature, and continue stirring for 2 hours to obtain silica nanoparticle dispersion solution, and then slowly add polystyrene latex balls with a diameter of 10 nm into the dispersion of silica nanoparticles and stir at a volume ratio of 1:5 to obtain a blended solution for use.

[0023] A roll coating method is used to coat the cleaned photovoltaic glass surface to obtain a transparent film. The coated photovoltaic glass was sintered at 700°C for 5 minutes to obtain high-efficiency anti-reflection and anti-reflection glass. After testing, the transmittance of the anti-reflection glass increased by 2.6%.

Embodiment 3

[0025] Mix and heat 0.004mol of water, 0.002mol of sodium hydroxide and 0.4mol of propanol, and when the temperature reaches the set temperature of 50°C, add 0.04mol of methyl orthosilicate, keep constant temperature, and continue stirring for 40 hours to obtain silica nano Particle dispersion, and then slowly add polystyrene latex balls with a diameter of 200nm into the silica nanoparticle dispersion and stir at a volume ratio of 5:1 to obtain a blended solution for use.

[0026] Coating is carried out on the cleaned photovoltaic glass surface by a spraying method to obtain a transparent film. The coated photovoltaic glass was sintered at 300°C for 30 minutes to obtain high-efficiency anti-reflection and anti-reflection glass. After testing, the transmittance of the anti-reflection glass increased by 2.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com