Method used for producing imitated coral artificial bone from cuttlebone, and products of method

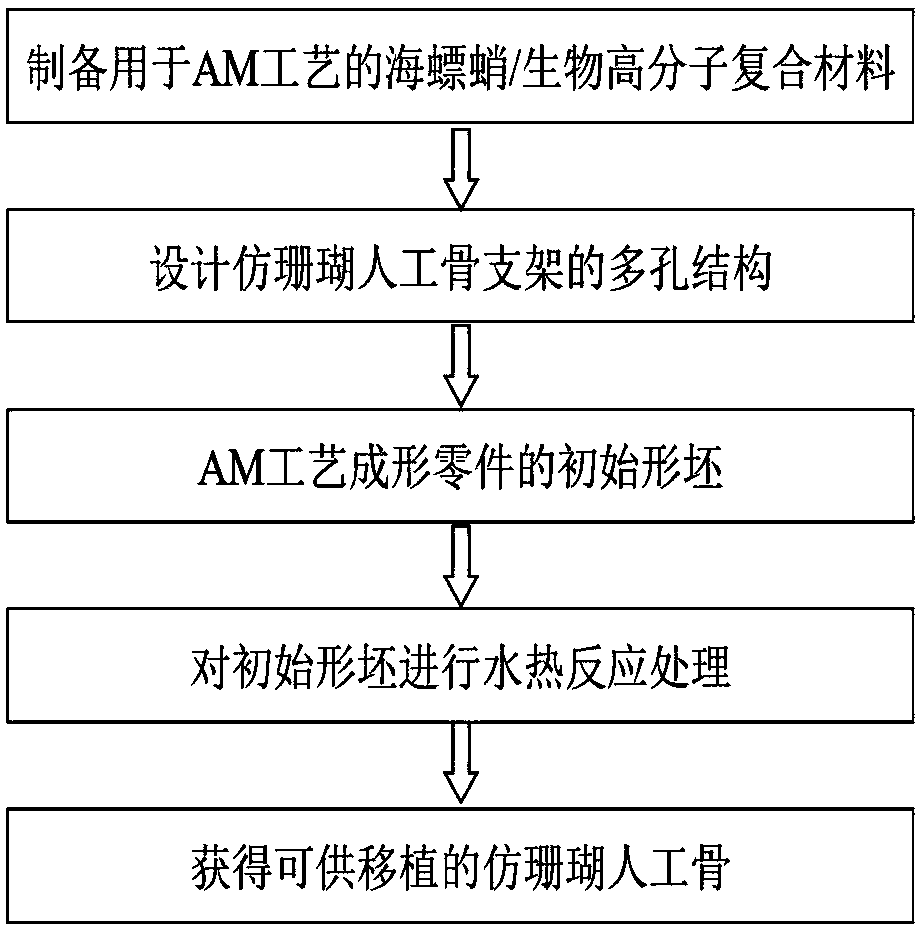

A technology for artificial bone and sea octopus, which is applied in the field of increasing material manufacturing, can solve problems such as porosity and pore size that cannot be effectively controlled, cell adhesion, influence on metabolic growth and reproduction, scarcity of raw materials, etc., to achieve precise control of mechanical properties, material The effect of high utilization and rich sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) select sea octopus powder and poly-L-lactic acid (PLLA) powder with a particle size range of 20 to 70um, and the particle size of PLLA powder as a binder is smaller than that of the sea octopus powder, wherein the binding agent The mass fraction is 10%.

[0043] (2) the sea octopus powder and PLLA powder (mass content is 15%) selected in step (1) adopt ball mill to carry out mechanical mixing to these two kinds of powders, carry out mechanical mixing to these two kinds of powders with ball mill, two The ingredients are mixed well. The specific steps of mechanical mixing are as follows:

[0044] Clean the table of the ball mill to ensure that the table is clean and tidy;

[0045] Before operation, check whether the frame, reducer, and bearing seat are installed properly, and tighten each mounting screw;

[0046] After installing the inner and outer barrels, rotate them for a few minutes without load to see if the equipment is operating normally;

[0047] After th...

Embodiment 2

[0056] (1) Select sea octopus powder and polyether ether ketone (PEEK) powder with a particle size range of 20 μm to 70 um, and the particle size of PEEK powder used as a binder is smaller than that of sea octopus powder, and the quality of the binder The score is 40%.

[0057] (2) As in Example 1, the sea octopus / PEEK composite powder material was prepared by mechanical mixing method, and the specific preparation steps were similar to Example 1.

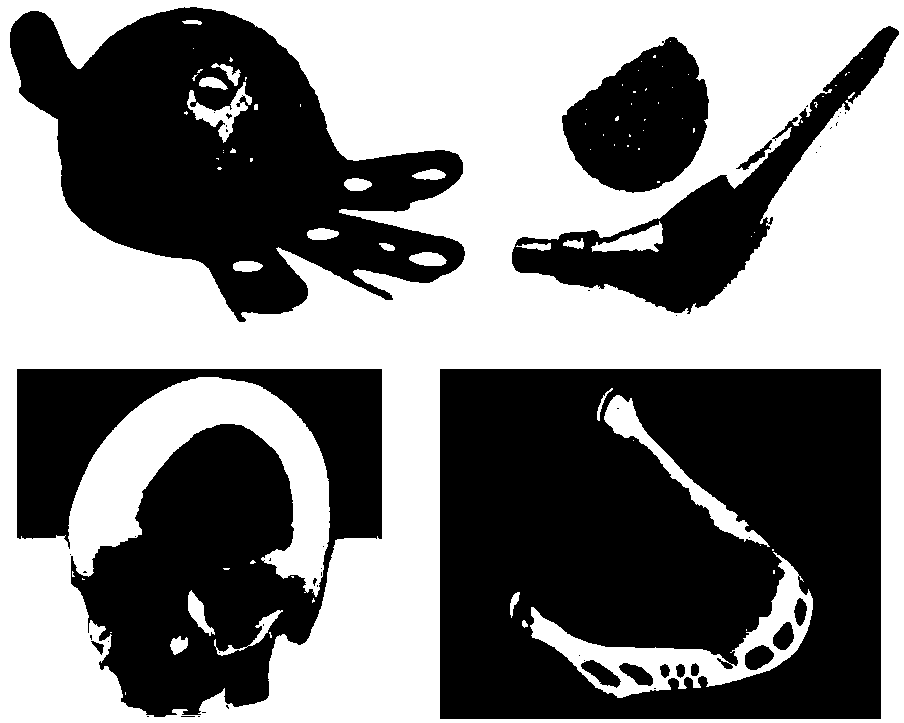

[0058] (3) Design the structure of imitation coral artificial bone. Natural coral has a completely through pore structure with a porosity of 60% and a bending strength of 0.25MPa. The structure designed in this embodiment is as Figure 4 shown.

[0059] (4) Convert the three-dimensional model of the artificial bone structure designed in step (3) into STL format, and import it into the SLS device, so that the uniformly mixed composite powder in step (2) is formed into the structure designed in step (3), Get the initial shape of t...

Embodiment 3

[0062] (1) Preparation of sea octopus / PLLA composite filamentary material for FDM process. Concrete preparation steps are as follows:

[0063] The sea octopus and PLLA were vacuum-dried at 70°C and 150°C for 24 hours, respectively, and then the dried sea octopus and PLLA were mixed according to the mass ratio of 6:1.

[0064] In order to make the raw materials uniform during the melt blending process, pre-mix the prepared materials with a high-speed mixer that has been fully cleaned and dried in advance, then start the high-speed mixer at a low speed, and then proceed at a speed of 100r / min. Stir, the stirring time can be set to 10-15min.

[0065] Put the preliminarily obtained mixed material into the twin-screw extruder, melt and mix at the screw speed of 100r / min, and the cylinder temperature of 210°C. The air dryer completes the preliminary drying.

[0066] The blended material was prepared by pelletizing with an automatic pelletizer.

[0067] The prepared pellets are e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com