Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

A silicon-carbon composite material and silicon powder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsuitable preparation process, low charging and discharging efficiency, etc., so as to improve initial efficiency, low environmental pollution, and reduce volume the effect of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

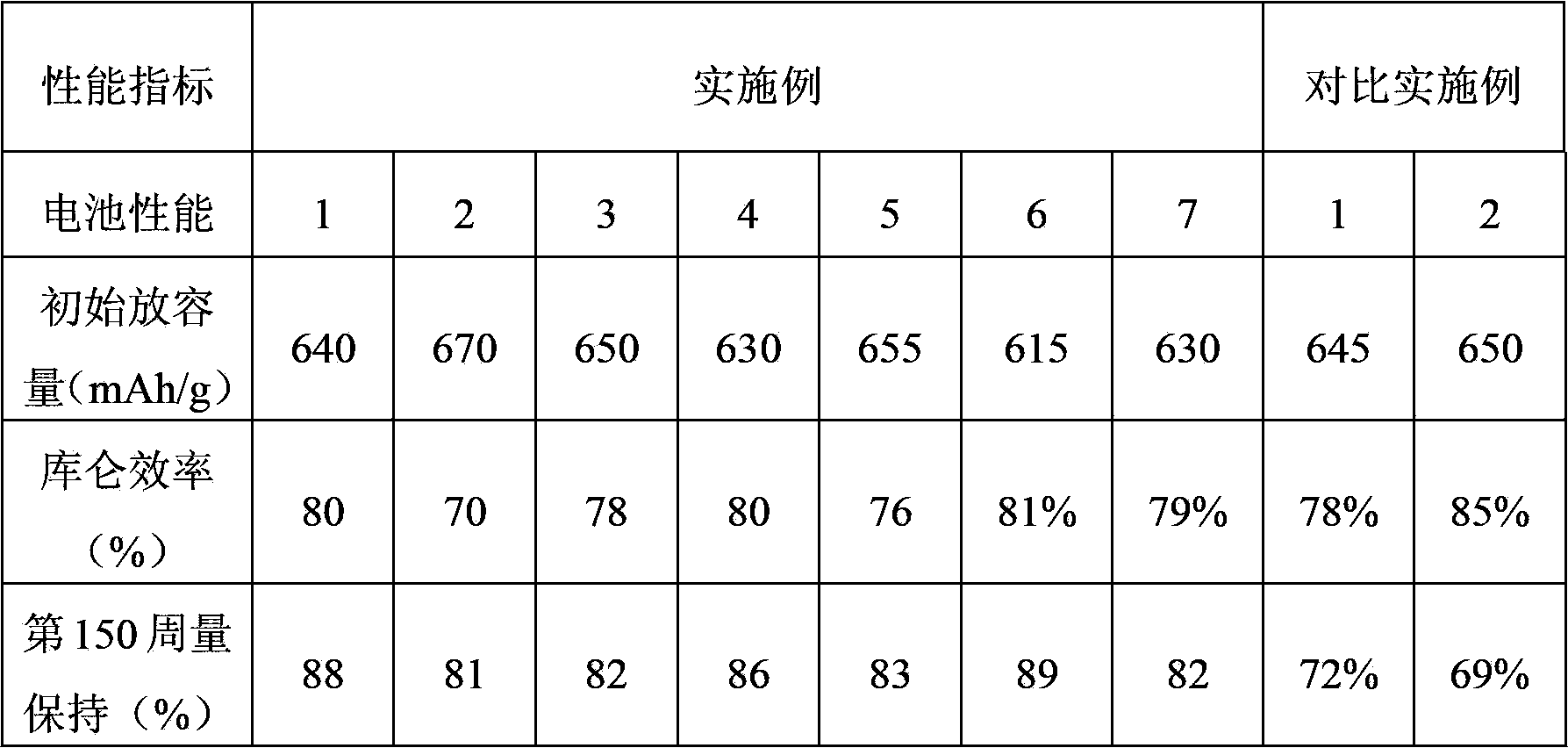

Embodiment 1

[0048] The preparation method of embodiment 1 silicon carbon composite material

[0049] (1) After mixing 1Kg of silicon powder and 0.5Kg of silicon oxide powder evenly, add them to 15Kg of aqueous solution containing 22.5g of CMC and 22.5g of PVA for wet ball milling to D 50 The particle size is 200nm to obtain a slurry;

[0050] (2) Put the slurry, 7.5Kg D 50 Mesophase graphite with a particle size of 10 μm and 90 g of carbon nanofibers are evenly mixed and spray-dried. The inlet temperature of the spray dryer is controlled to be 250 ° C, the outlet temperature is 100 ° C, the frequency of the feeding plate is 15 Hz, and the frequency of the atomizing plate is 250 Hz. Obtain spherical particles;

[0051] (3) Mix the spherical particles with 1.0Kg of petroleum asphalt, and perform coating treatment at 400°C for 6 hours under nitrogen atmosphere to obtain the coated material;

[0052] (4) Carbonize the coated material in a carbonization furnace at 1000°C for 6 hours in a ni...

Embodiment 2

[0053] The preparation method of embodiment 2 silicon-carbon composite material

[0054] (1) After mixing 1Kg of silicon powder and 0.67Kg of silicon oxide powder evenly, add them to 15Kg of aqueous solution containing 3.0g of CMC and 3.0g of PVA for wet ball milling to D 50 The particle size is 50nm, and the slurry is obtained;

[0055] (2) Put the slurry, 4Kg D 50 The mesophase graphite with a particle size of 1 μm and 6g nano-carbon fiber are mixed evenly and spray-dried. The inlet temperature of the spray dryer is controlled at 220°C, the outlet temperature is 120°C, the frequency of the feeding tray is 20Hz, and the frequency of the atomizing tray is 300Hz. Obtain spherical particles;

[0056] (3) Mix spherical particles with 1.0Kg coal tar pitch, and carry out coating treatment at 500°C for 4 hours under a nitrogen atmosphere to obtain the coated material;

[0057] (4) Carbonize the coated material in a carbonization furnace at 1100° C. for 8 hours in a nitrogen atmos...

Embodiment 3

[0058] Embodiment 3 The preparation method of silicon-carbon composite material

[0059] (1) After mixing 1Kg of silicon powder and 0.25Kg of silicon oxide powder evenly, add them to 6.5Kg of aqueous solution containing 25g of CMC and 25g of PVA for wet ball milling to D 50 Particle diameter is 500nm, obtains slurry;

[0060] (2) Put the slurry, 3.75Kg D 50 Mesophase graphite with a particle size of 5 μm and 100 g of carbon nanofibers are evenly mixed and spray-dried. The inlet temperature of the spray dryer is controlled at 270 ° C, the outlet temperature is 90 ° C, the frequency of the feeding disc is 10 Hz, and the frequency of the atomizing disc is 280 Hz. Obtain spherical particles;

[0061] (3) Mix the spherical particles with 3.33Kg coal tar pitch, and carry out coating treatment at 500°C for 10 hours under nitrogen atmosphere to obtain the coated material;

[0062] (4) The coated material is carbonized in a carbonization furnace at 900° C. for 8 hours in a nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com