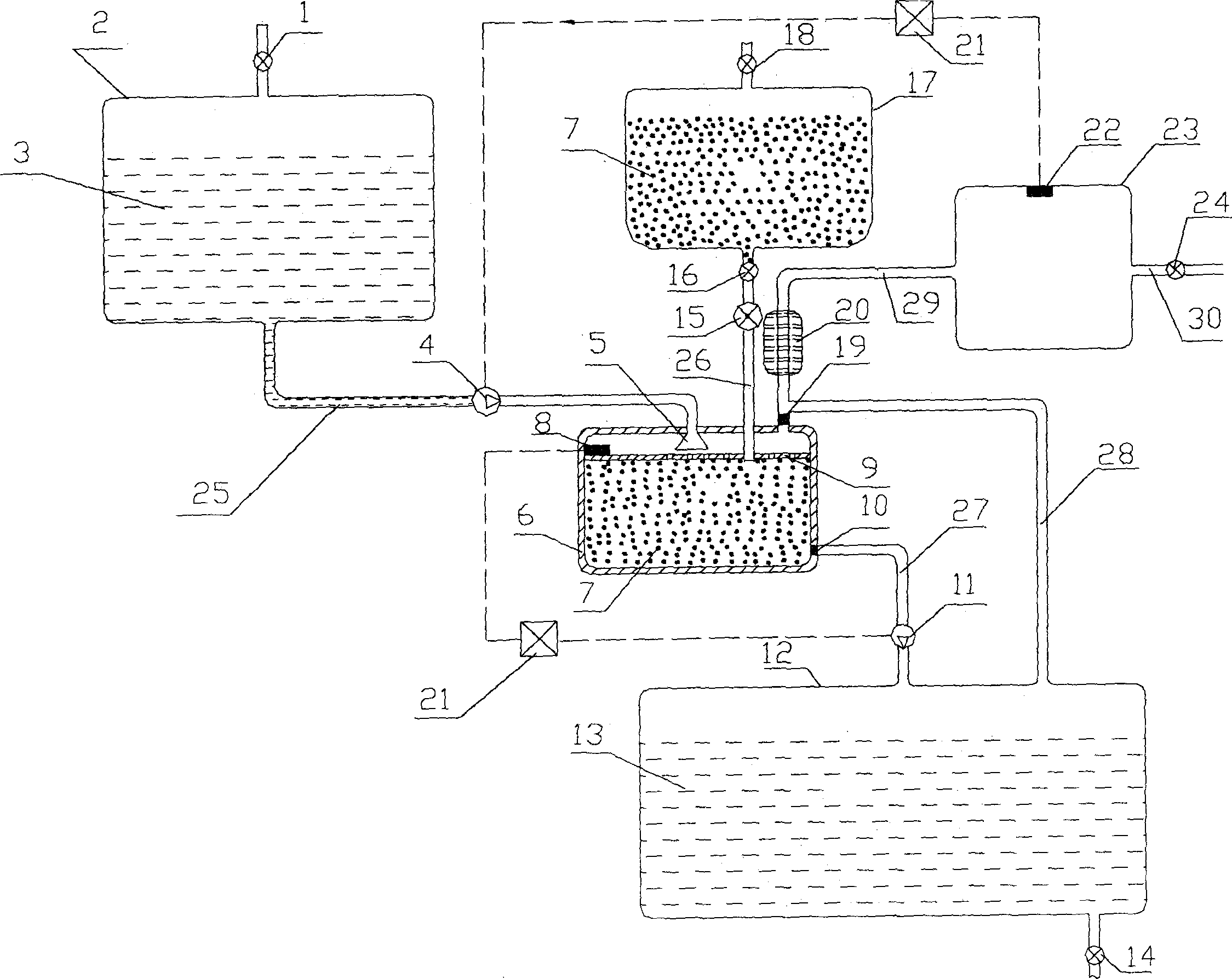

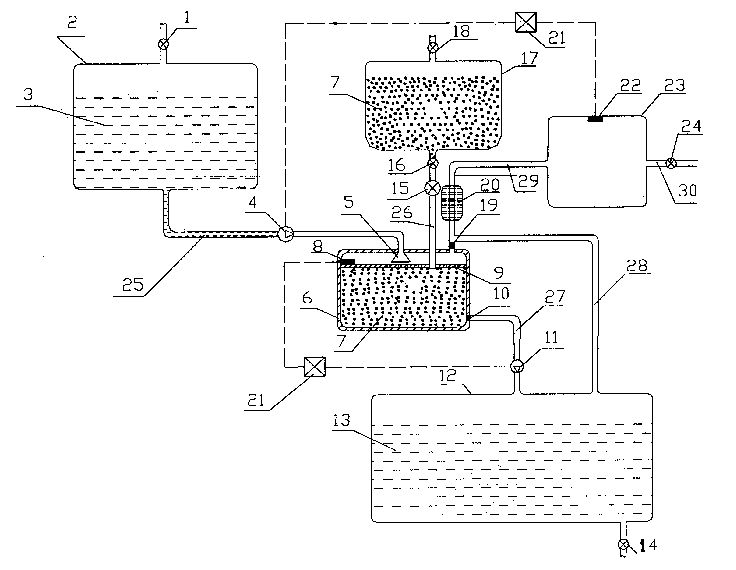

Hydrogen preparing method and device

A technology for preparing equipment and hydrogen, applied in the production of hydrogen and other directions, can solve the problems of inability to achieve zero emission of harmful gases, inability to apply high-power fuel cells, and high cost of hydride raw materials, achieving abundant reserves, easy control of reaction speed, and energy. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the reactor with feeding port, gas outlet, temperature measurement insertion port, adding average particle size is 177 microns, 1 gram of aluminum powder with a purity of 96%, and then the weight percentage concentration is 5% sodium hydroxide aqueous solution 35ml was added to the reaction vessel, the initial reaction temperature was 20°C, and the temperature rose after the reaction started, and the aluminum powder and sodium hydroxide aqueous solution reacted in the reactor to obtain the hydrogen product.

Embodiment 2

[0041]In a reactor with a feeding port, a gas outlet, and a temperature measurement insertion port, add 1 gram of aluminum powder with an average particle diameter of 74 microns and a purity of 99%, and then add 35 ml of a 5% aqueous sodium hydroxide solution Add it into the reaction vessel, the reaction starting temperature is 20°C, the temperature rises after the reaction starts, and the temperature is 88°C at the end of the reaction, the aluminum powder and the sodium hydroxide aqueous solution react in the reactor to obtain the hydrogen product.

Embodiment 3

[0043] The conditions and steps are the same as in Example 1, the average particle size of the aluminum powder used is 0.177mm, and the purity is 96%; the concentration of the sodium hydroxide aqueous solution is 10% by weight; the hydrogen product is obtained by the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com