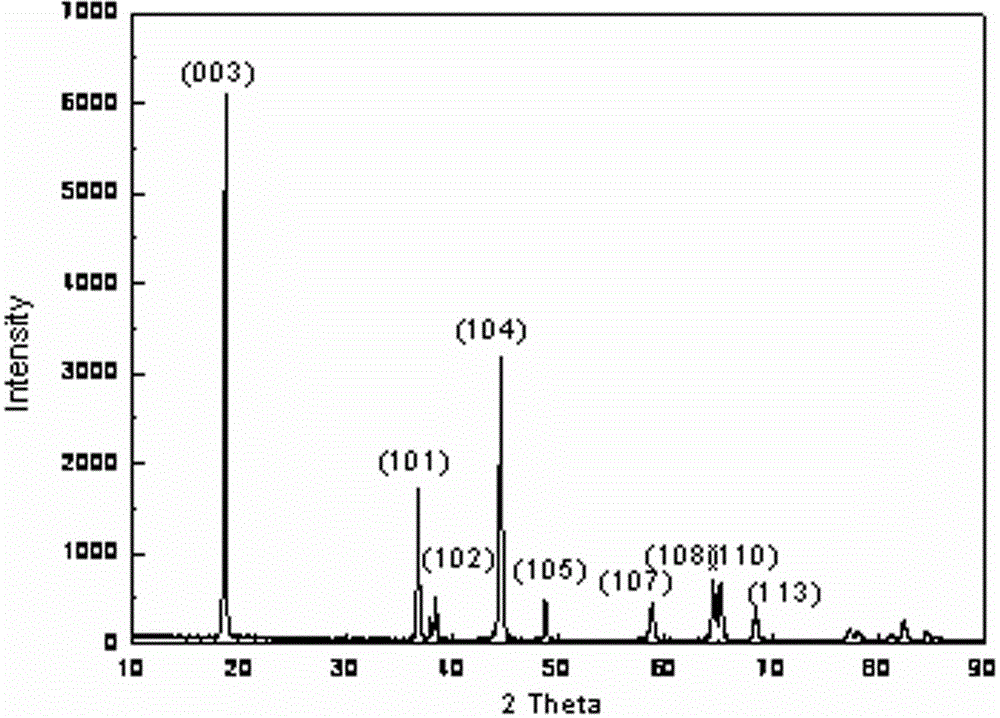

Wet-method preparation process of ternary positive material for lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of long production cycle, low charge-discharge efficiency and cycle life, large material particles, etc. Synchronization, the effect of improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

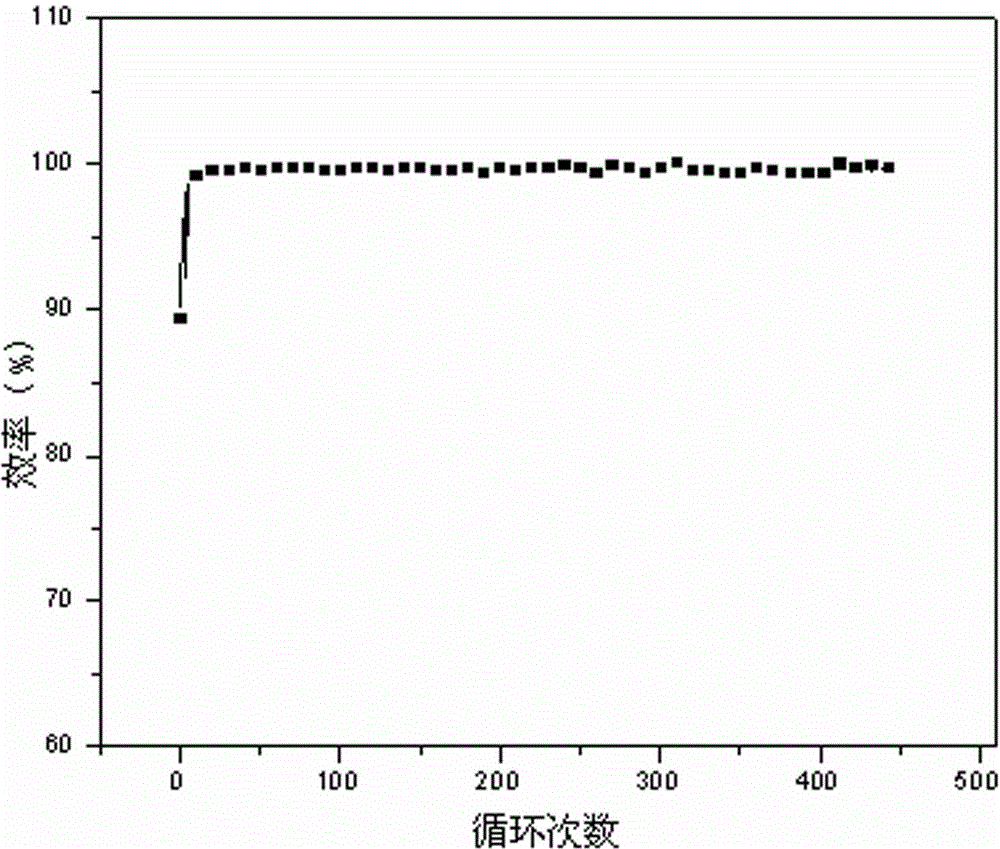

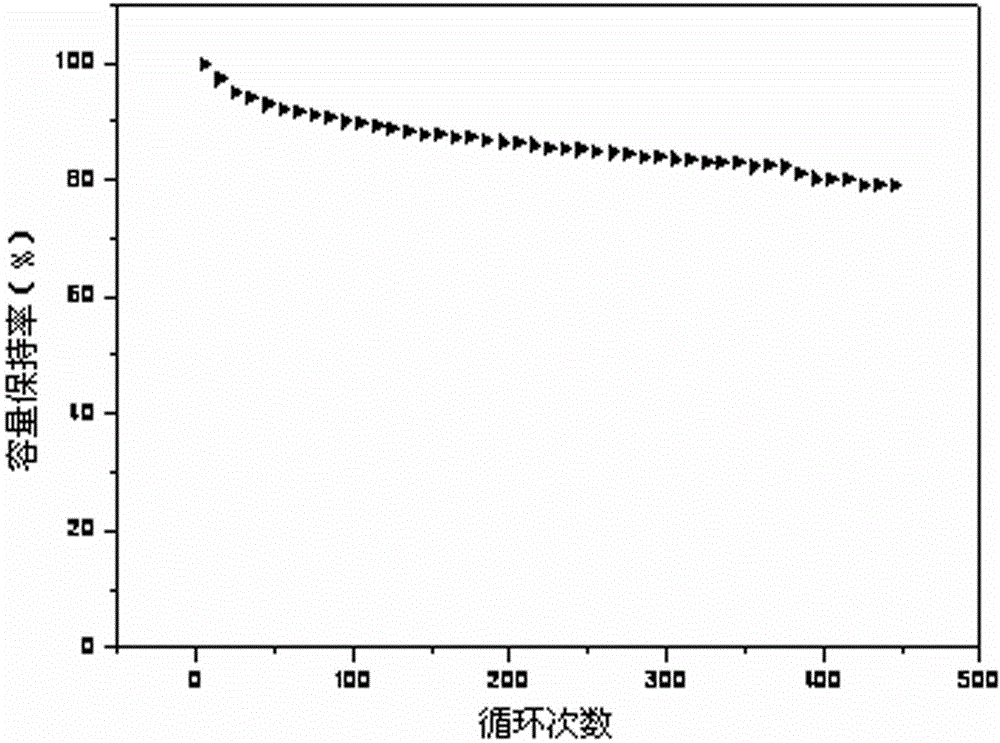

Embodiment 1

[0028] Prepare nickel-cobalt-manganese ternary cathode material according to the following steps

[0029] (1) Preparation of ternary precursor

[0030]In the reaction kettle of the bottom liquid dissolved with ammonia water, nitrogen or argon gas was passed in advance for 60 minutes, and then the nickel, cobalt, and manganese nitrates weighed according to the molar ratio of 5:2:3 were dissolved in the solution, and the total molar concentration of metal ions was Control it at 2mol / L, use 1mol / L sodium hydroxide solution to adjust the pH value of the liquid in the kettle between 8-11, and continue the reaction for 20 hours; after the reaction, carry out solid-liquid separation, and finally obtain the nickel hydroxide cobalt manganese precursor body.

[0031] (2) Synthesis of ternary materials

[0032] Weigh the ternary precursor nickel cobalt manganese hydroxide and lithium salt according to the ratio of 1:1.1, use ball milling equipment to control the particle size and preli...

Embodiment 2

[0039] Weigh the ternary precursor nickel cobalt manganese hydroxide and lithium salt in a ratio of 1:1.02, use ball milling equipment to control the particle size and mix them initially, add the material to the mixer after discharging, and weigh the corresponding mass dispersant according to the mass ratio Add and stir. After continuous stirring for 2 hours, the particle size is controlled by slurry crushing equipment, and the mixed material is dried instantly in a rapid drying equipment at 150°C to ensure the uniformity of material distribution in a wet environment. Spread the dry material obtained above in a sagger, and control the thickness of the material at 1.2 cm. Then, the muffle furnace was used to keep the temperature at 500° C. for 7 hours to obtain the front-stage sintered material of the ternary positive electrode material. After the above-mentioned sintered material is cooled, weigh the material quality, introduce the lithium salt for the second time at a ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com