Novel crosslinker of single-component de-alcoholized room temperature vulcanized silicone rubber and preparation method thereof

A room temperature vulcanization and dealcoholization technology, which is applied in the field of silicone polymer processing additives, can solve the problems of non-curing during extrusion, poor physical and mechanical properties, and short storage period, and achieve the effect of improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

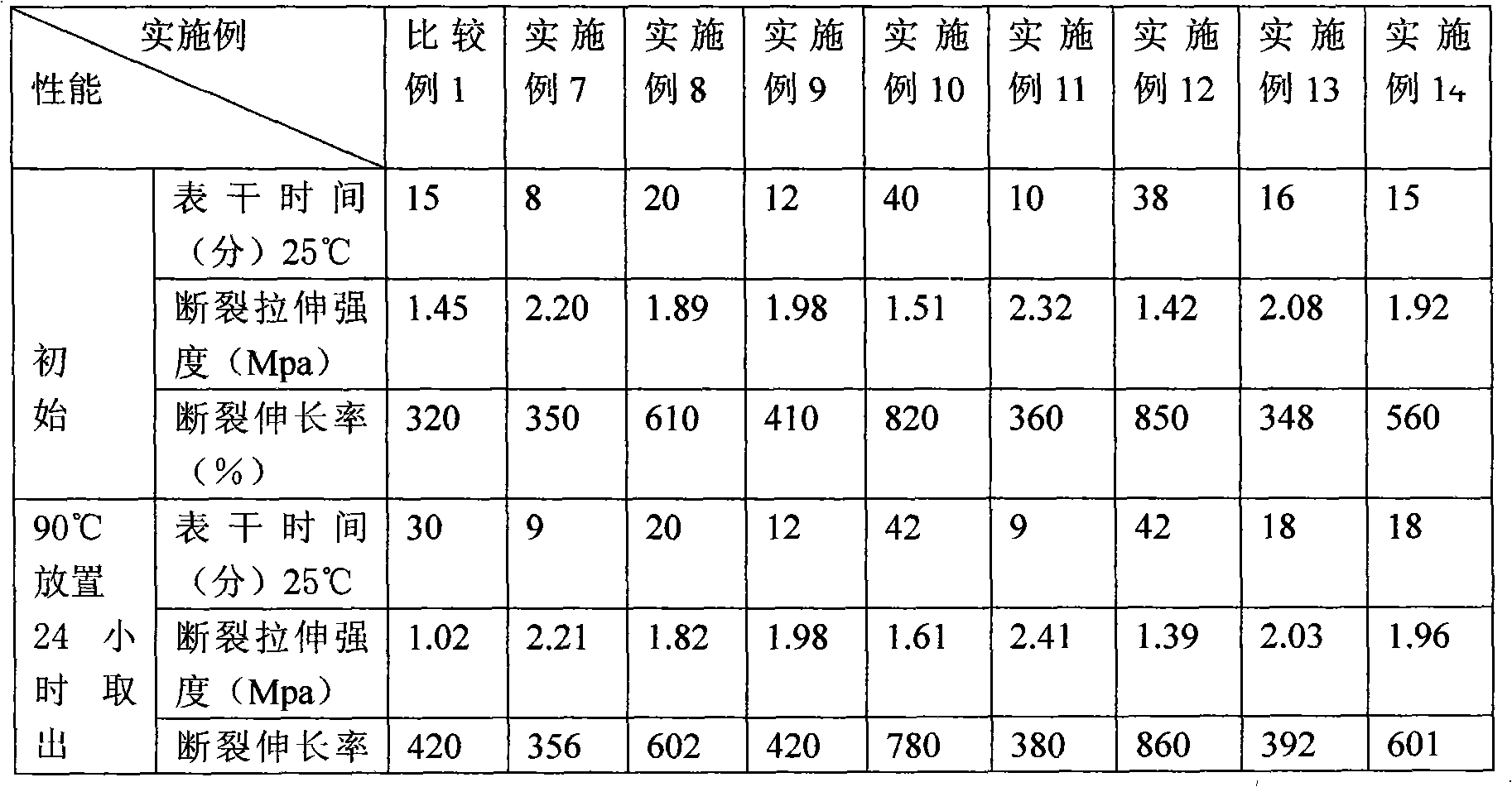

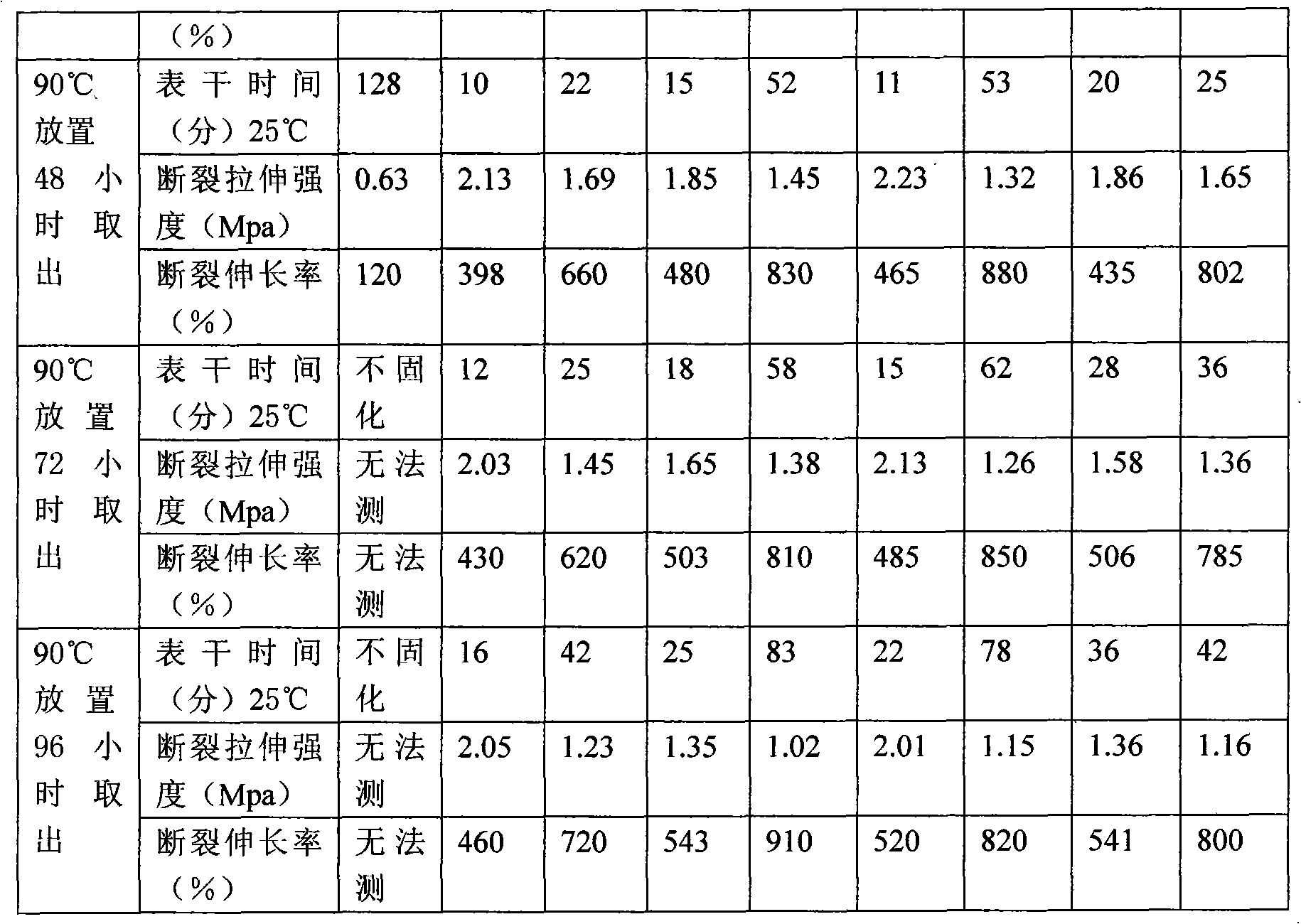

Examples

Embodiment 1

[0041] Add 10 moles of methyltrichlorosilane to a 2-liter four-necked bottle equipped with stirring, a reflux condenser (connected to a drying bottle and an exhaust pipe to discharge hydrochloric acid gas through the exhaust pipe), a thermometer, and a dropping funnel, and start stirring , 30 moles of methanol were gradually dropped in through the dropping funnel, and the temperature was lowered in an ice bath to control the reaction temperature below 30°C. After methanol was added dropwise, the ice bath was removed, and the mixture was stirred without heating for 1 hour. Then heat up to 80°C-120°C, and keep the reflux reaction for 3 hours (the reflux flow is small at the beginning, and the reflux flow is gradually increased). The reaction temperature is lowered to below 50°C, and 10 moles of water are gradually added dropwise under stirring, and the rate of addition is based on controlling the reaction temperature to be lower than 50°C. After dripping water, the mixture was ...

Embodiment 2

[0043] In a 2-liter four-necked bottle equipped with stirring, a reflux condenser (connected to a drying bottle and an exhaust pipe, and to discharge hydrochloric acid gas through the exhaust pipe), a thermometer, and a dropping funnel, add 5 moles of methyltrichlorosilane and 5 moles of Dimethyldichlorosilane was started to stir, and 25 moles of methanol were gradually dropped in through the dropping funnel, and the temperature was lowered in an ice bath to control the reaction temperature below 30°C. After methanol was added dropwise, the ice bath was removed, and the mixture was stirred without heating for 1 hour. Then heat up to 80°C-120°C, and keep the reflux reaction for 3 hours (the reflux flow is small at the beginning, and the reflux flow is gradually increased). The reaction temperature is lowered to below 50°C, and 10 moles of water are gradually added dropwise under stirring, and the rate of addition is based on controlling the reaction temperature to be lower than...

Embodiment 3

[0045] Add 10 moles of methyltrichlorosilane to a 2-liter four-necked bottle equipped with stirring, a reflux condenser (connected to a drying bottle and an exhaust pipe to discharge hydrochloric acid gas through the exhaust pipe), a thermometer, and a dropping funnel, and start stirring , 30 moles of methanol were gradually dropped in through the dropping funnel, and the temperature was lowered in an ice bath to control the reaction temperature below 30°C. After methanol was added dropwise, the ice bath was removed, and the mixture was stirred without heating for 1 hour. Then heat up to 80°C-120°C, and keep the reflux reaction for 3 hours (the reflux flow is small at the beginning, and the reflux flow is gradually increased). The reaction temperature was lowered to below 50°C, and 5 moles of water were gradually added dropwise under stirring, and the rate of addition was based on controlling the reaction temperature to be lower than 50°C. After dripping water, the mixture wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com