Optimization operation monitoring method of heating furnace

A technology for optimizing operation and heating furnaces. It is applied to fluid heaters, lighting and heating equipment. It can solve problems such as large excess air system, easy damage to heating furnaces, difficulties in diagnosing furnace failures and operating efficiency, and achieve effective protection. , optimize the effect of combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

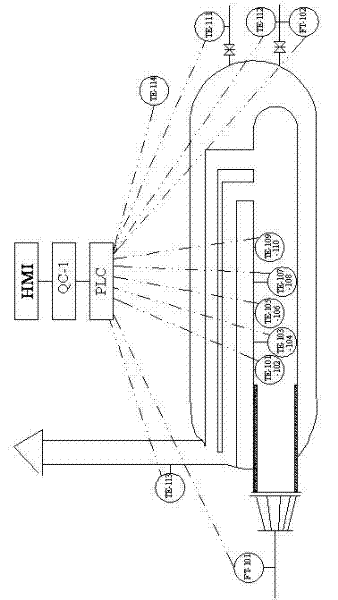

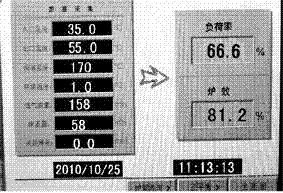

[0019] Depend on figure 1 Shown is the schematic diagram of the monitoring system used in the present invention, including the gas flow transmitter FT-101, the heated medium flow transmitter FT-102, the furnace tube temperature detection transmitter TE-101~TE-110, the Heating medium inlet temperature transmitter TE-111, heated medium outlet temperature transmitter TE-112, flue temperature detection system TE-113, ambient temperature transmitter TE-114, programmable controller QC-1 , programmable controller input and output module PLC, color touch screen HMI, the heating furnace optimization operation detection method of the present invention passes through above-mentioned detection system, after the signal that detects is sent into programmable controller QC-1, carries out normal operation Balance the display of furnace efficiency, furnace tube temperature, etc., and perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com