Patents

Literature

52results about How to "Elevate evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

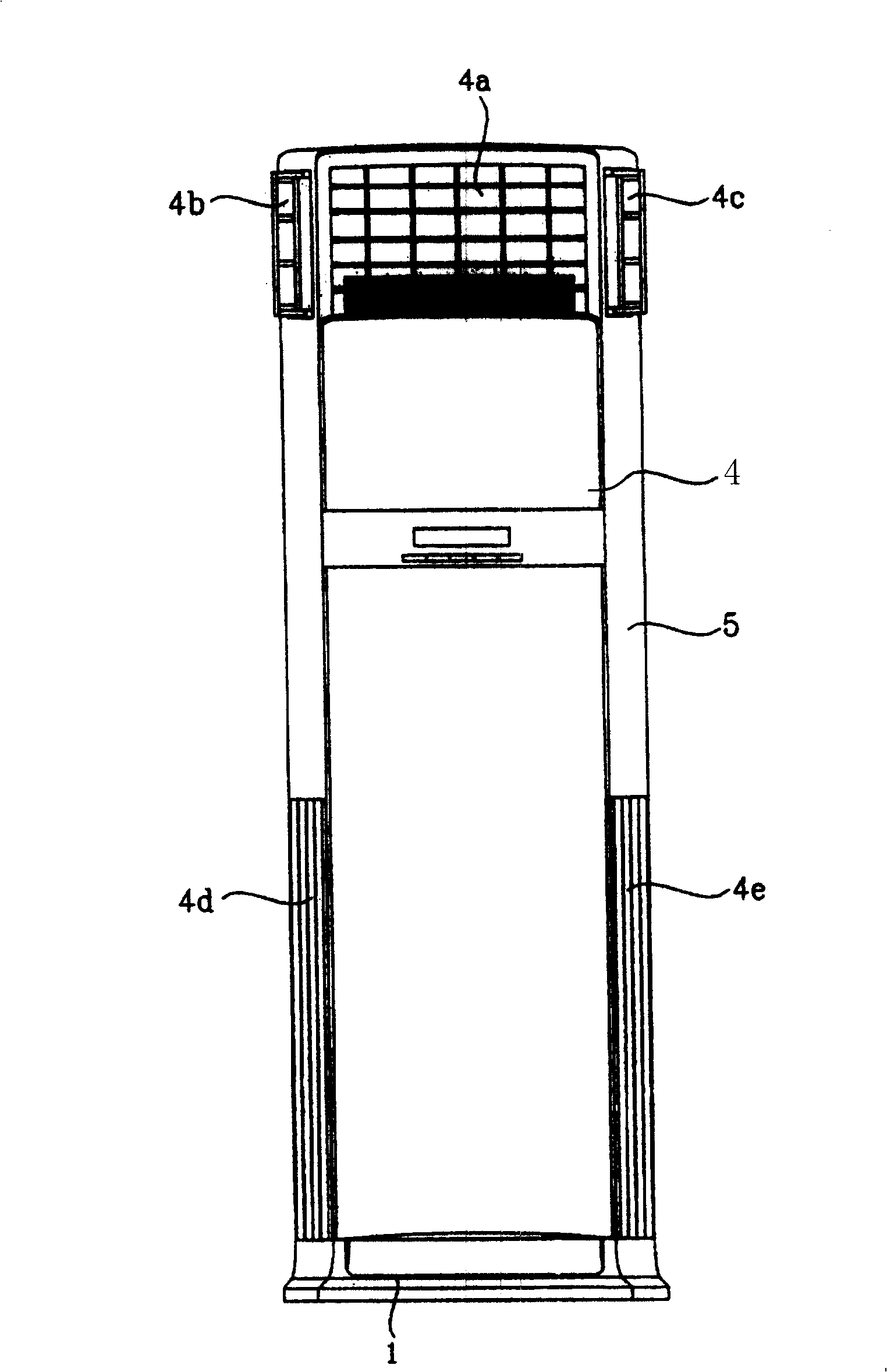

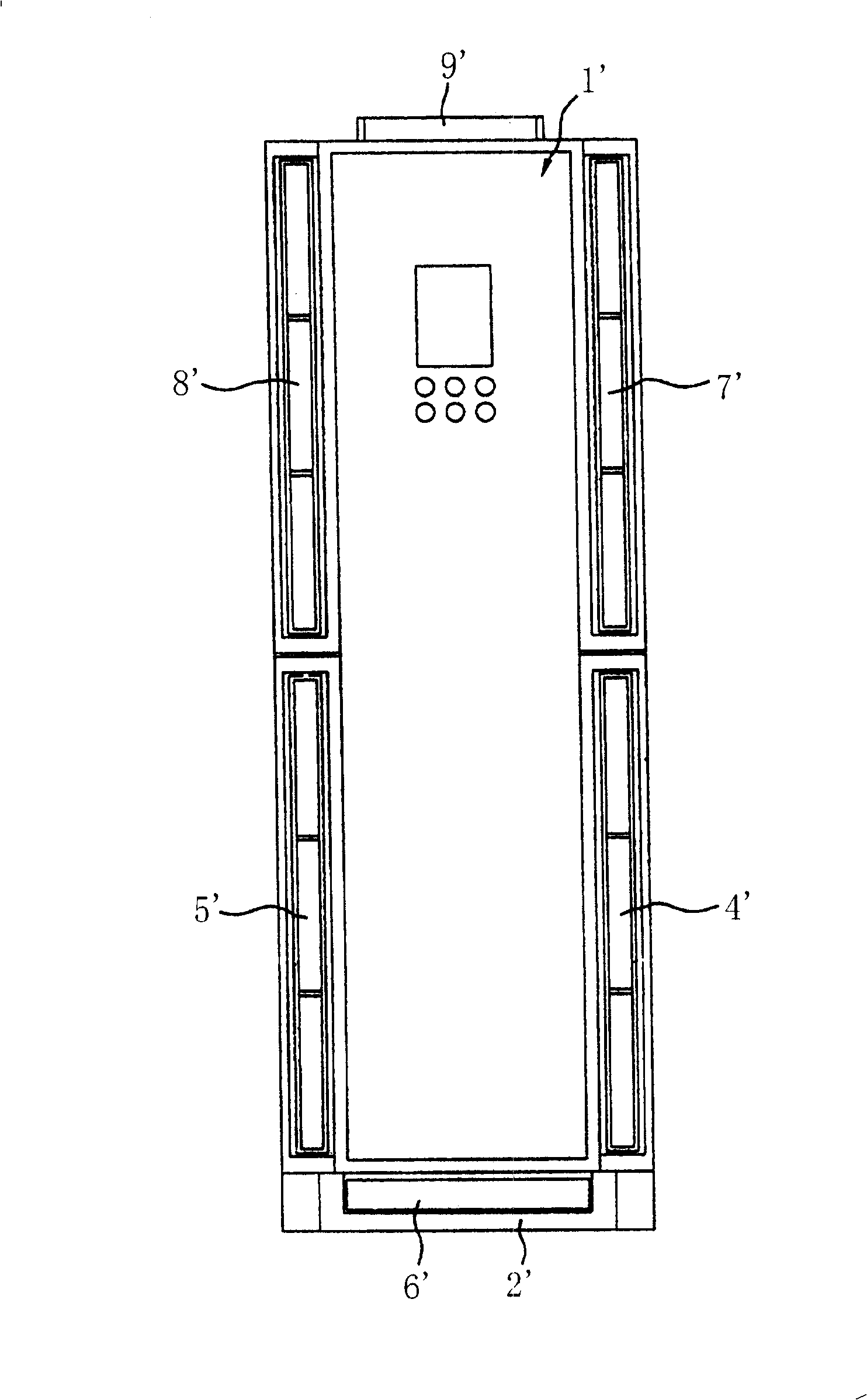

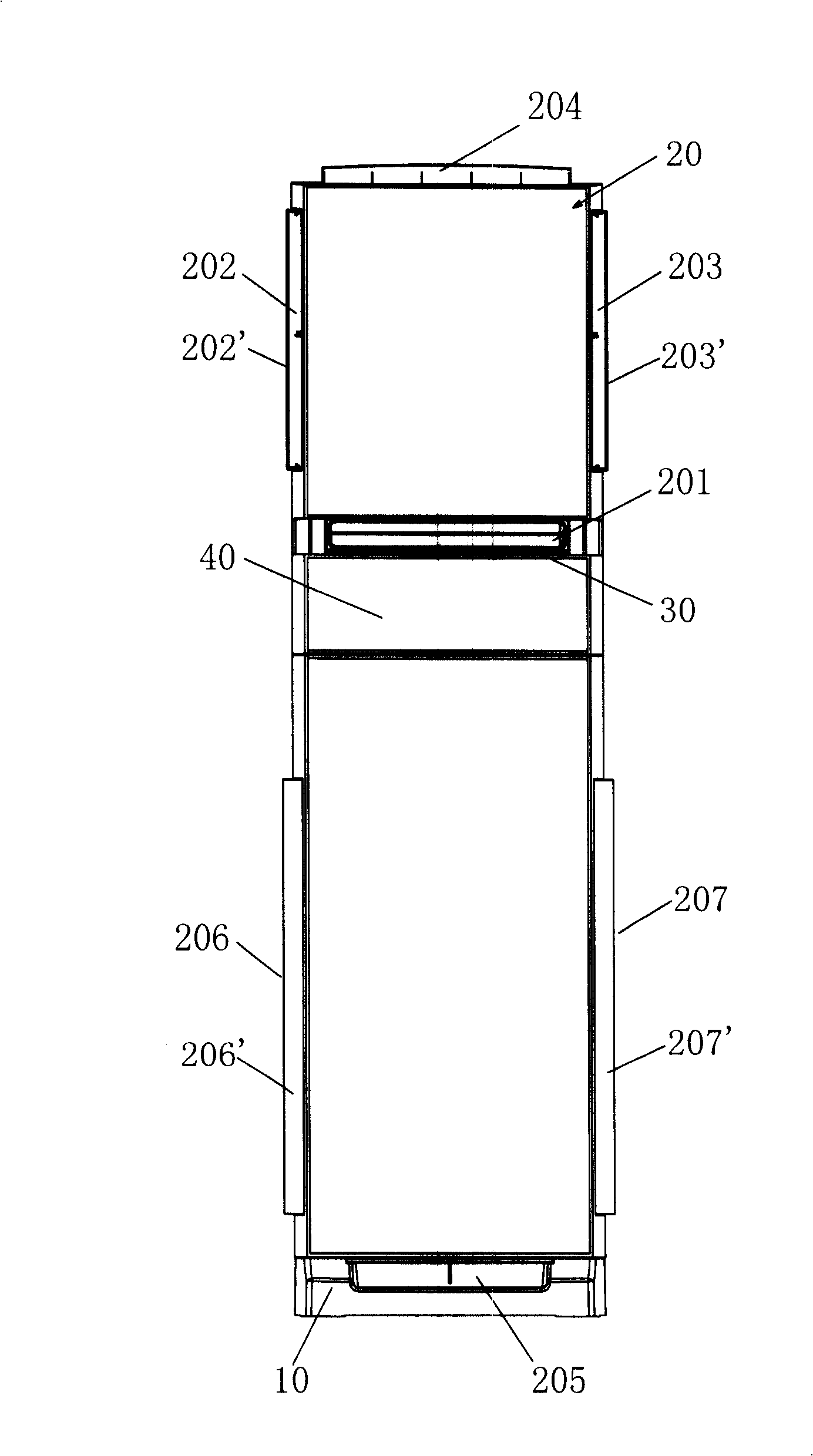

Four sides air-out air-conditioners

ActiveCN101256010AElevate evenlyExpand the range of air supplyDucting arrangementsLighting and heating apparatusEngineeringRefrigeration

The invention discloses an air conditioner with air outlets at four sides comprising a base and a housing. Four air outlets are disposed at four sides of the housing, comprising a front air outlet at the middle upper portion of the front side of the housing, side air outlets at upper portion of the left side and the right side of the housing, and an upper air outlet on the top of the housing; in addition, three other air inlets are also provided on the housing, wherein an air inlet is provided at each of the two sides of the lower portion of the housing, namely, the left side air inlet or the right side air inlet, and a front air inlet is provided at the front portion of the base; an air-out frame which can awing to supply air is disposed in the inner pivot of the front air outlet, and a display plate which can slide up and down to display operation state or block the air outlet is disposed on the housing out of the front air outlet. Air-out guiding plates of the four air outlets are all controlled by an electric motor and can be opened or closed at will, and the air-out angle is controlled freely according to user requirements. A large air outlet range, a wide covering area, and high efficiency of heat production or refrigeration are provided. The air outlet guiding plates reset automatically after the air conditioner shuts down, so that the air outlets are closed to prevent dust entering and ensure internal cleaning of the air conditioner.

Owner:HAIER GRP CORP +1

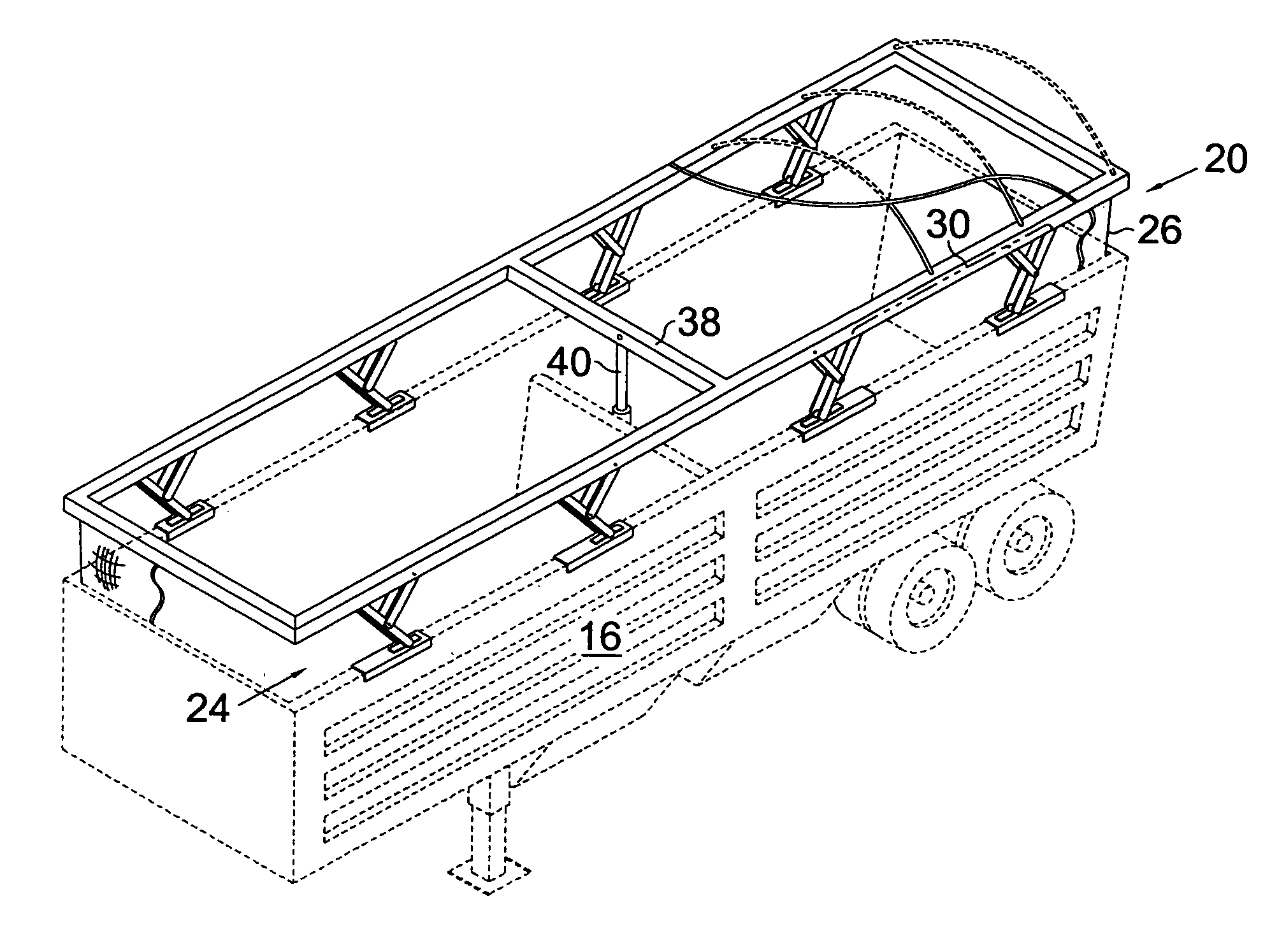

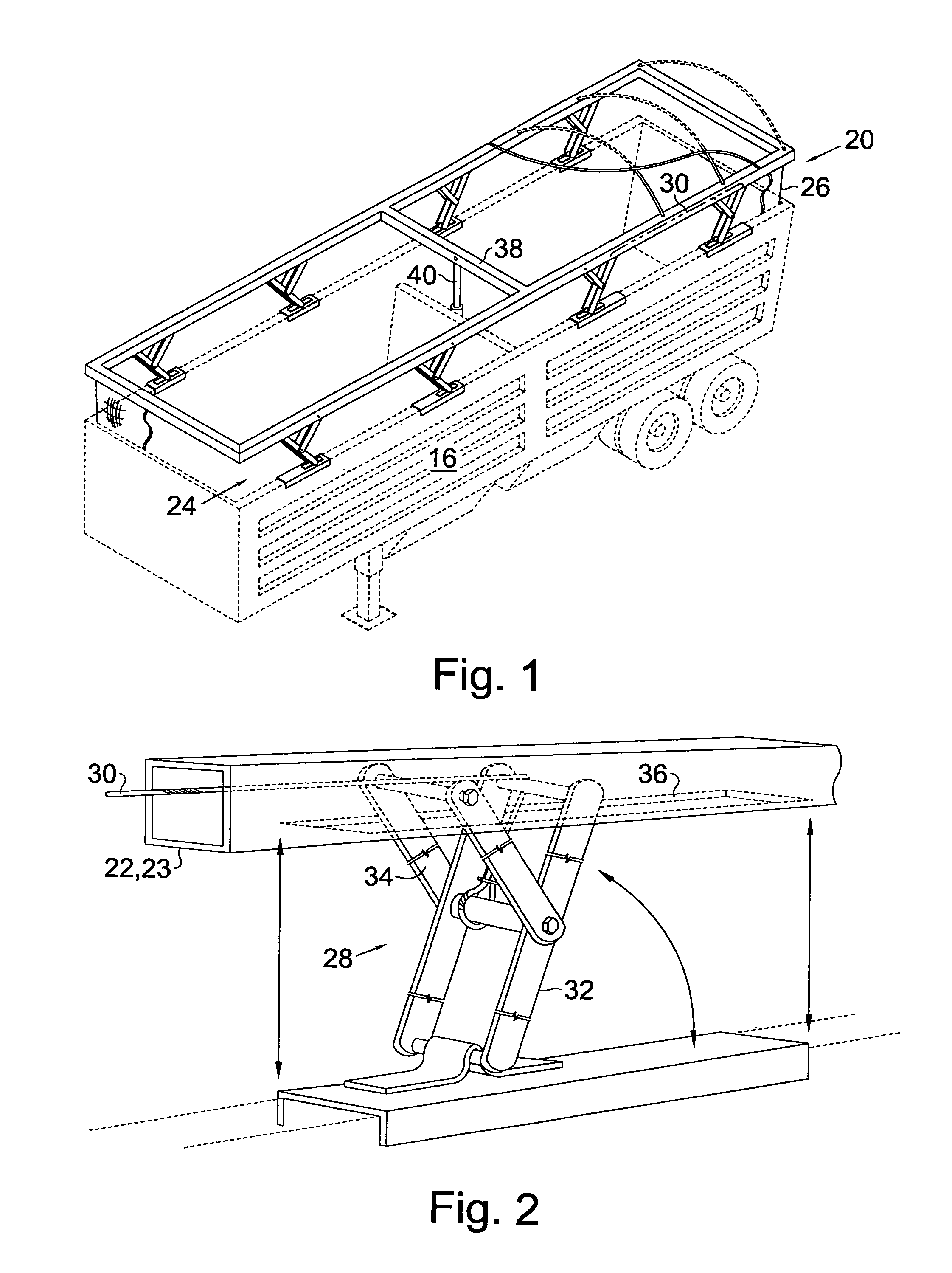

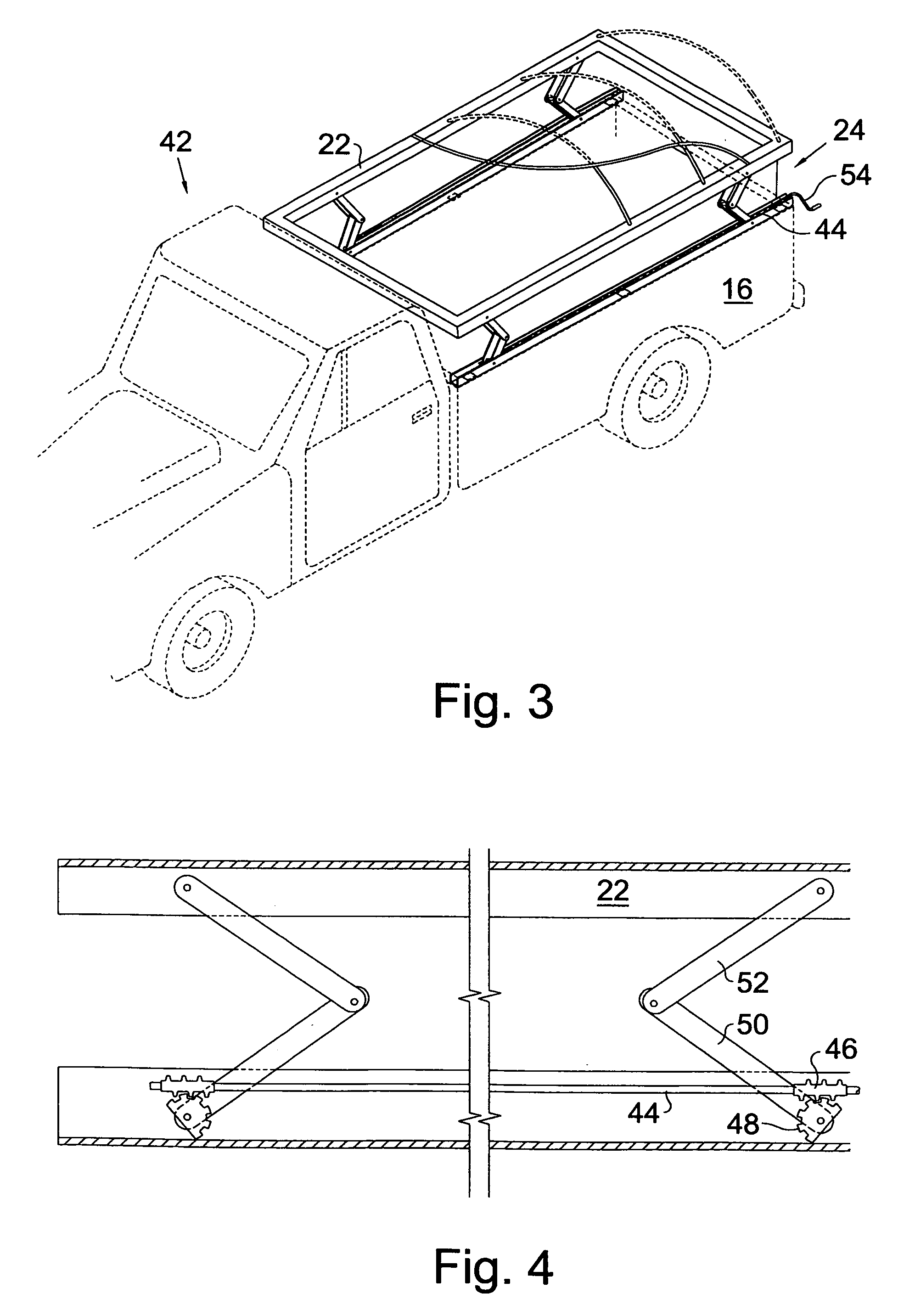

Flexible and stiff wall extension for an open load hauling box on a truck

InactiveUS7118165B2Improve transportation capacityIncrease heightVehicle with living accommodationItem transportation vehiclesEngineeringTruck

A collapsible upright wall extends the height of the sides on the load hauling box on a truck. The collapsible upright wall comprises a fabric which when vertically stretched provides adequate resistance to substantial lateral load. A method of increasing the volumetric capacity of the box on a truck comprises the steps of: a) providing a rectangular frame above, and dimensioned to seat adjacent to an open top side portion of the load hauling box on the truck; b) providing a substantial lift mechanism to uniformly lift the rectangular frame above the box; and, c) providing and attaching an elongate strip of fabric having a top elongate side portion peripherally attached to the rectangular frame, and a bottom elongate side portion peripherally attached to the open top side portion of the box. Then when the rectangular frame is lifted to an upper operable position the fabric is stretched taut and is thereby able to sustain significant lateral load.

Owner:NELSON DARWIN D +1

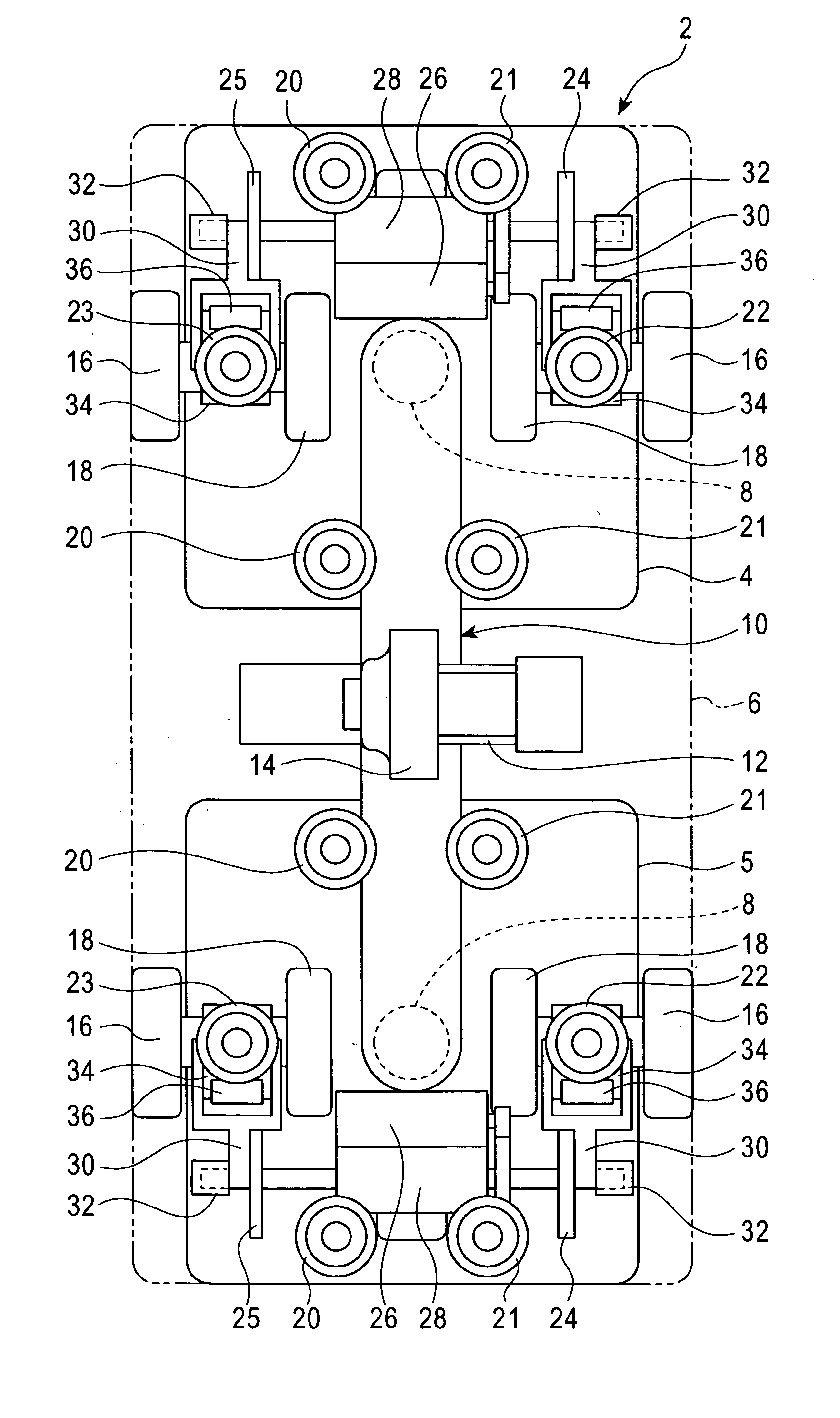

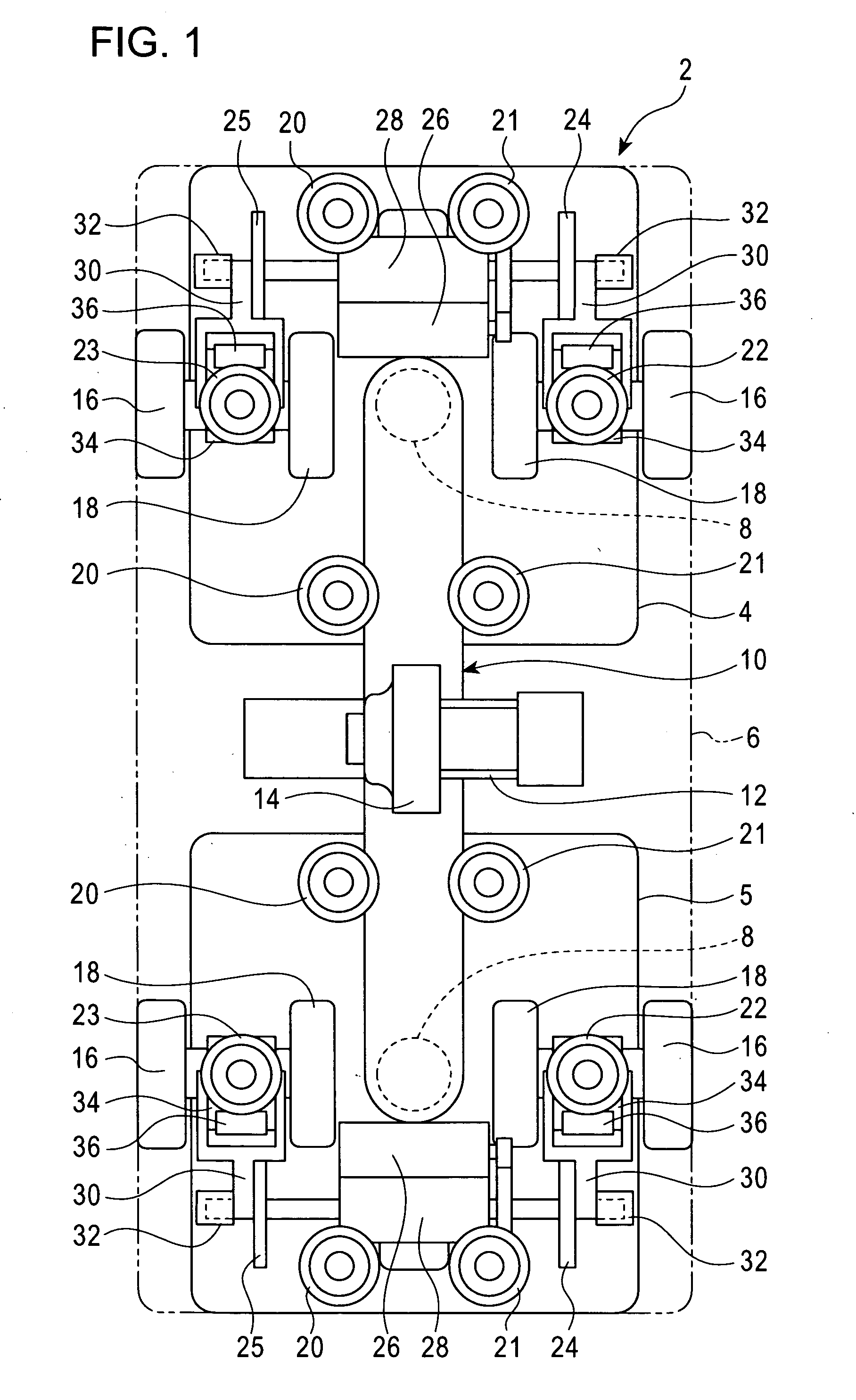

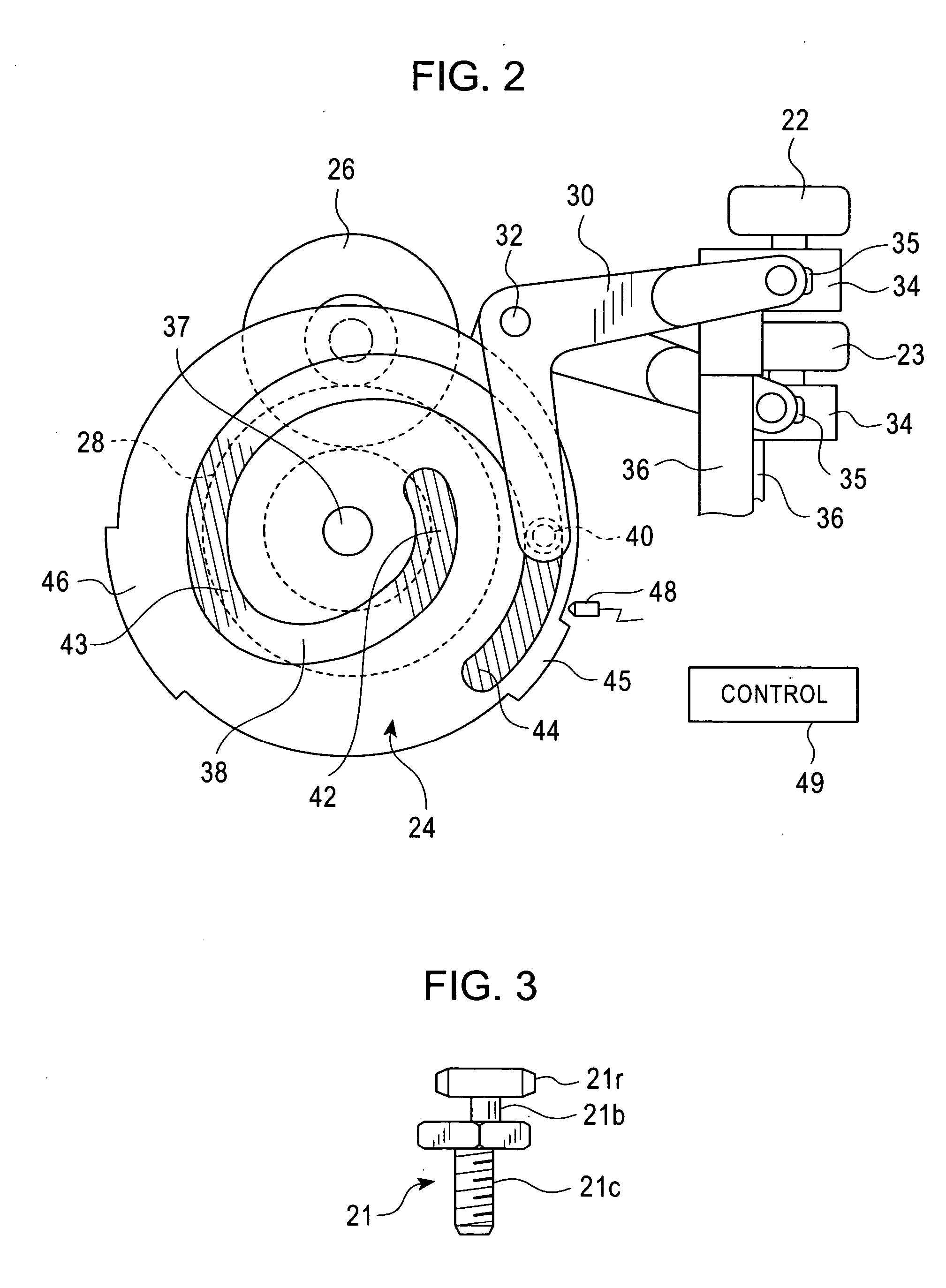

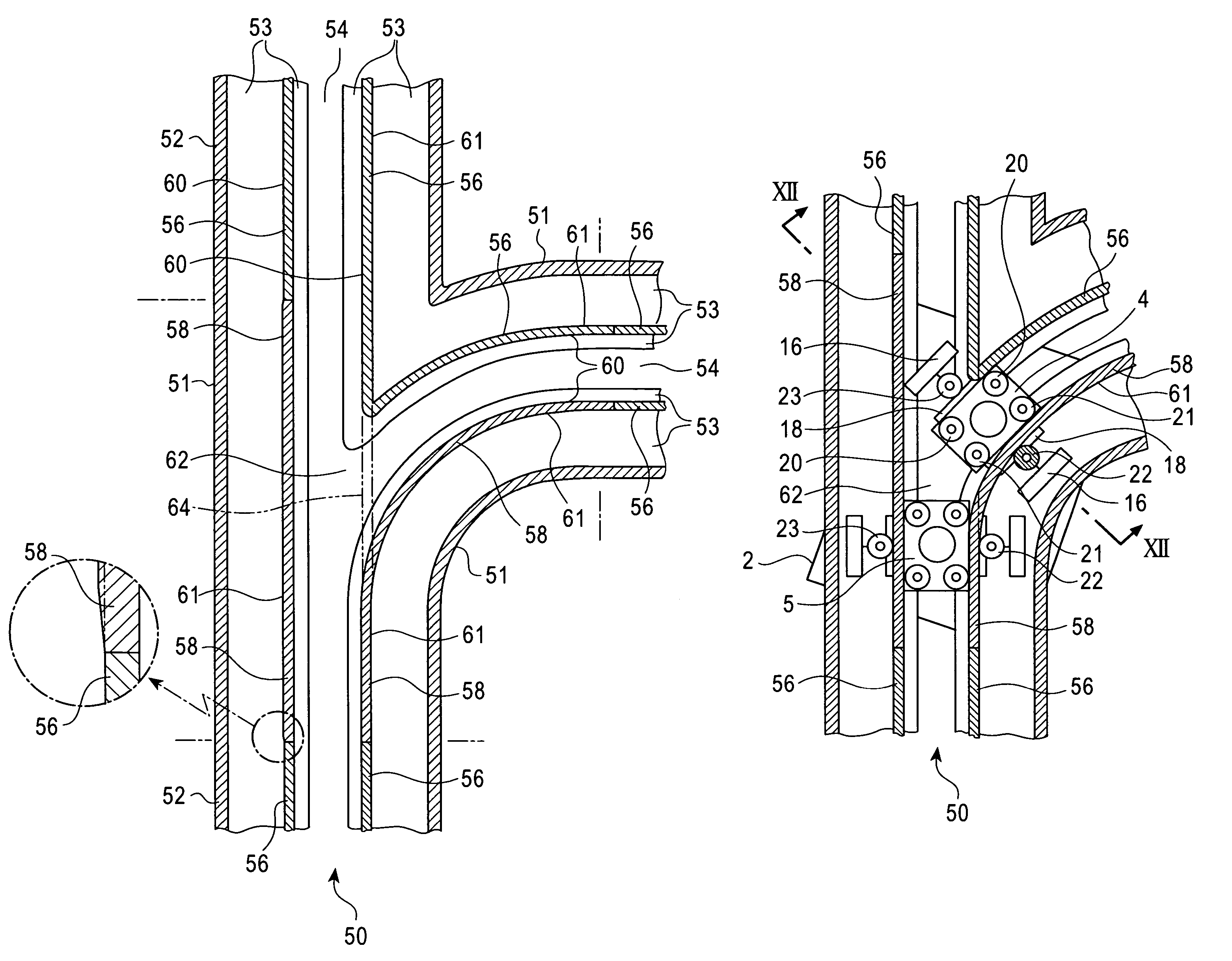

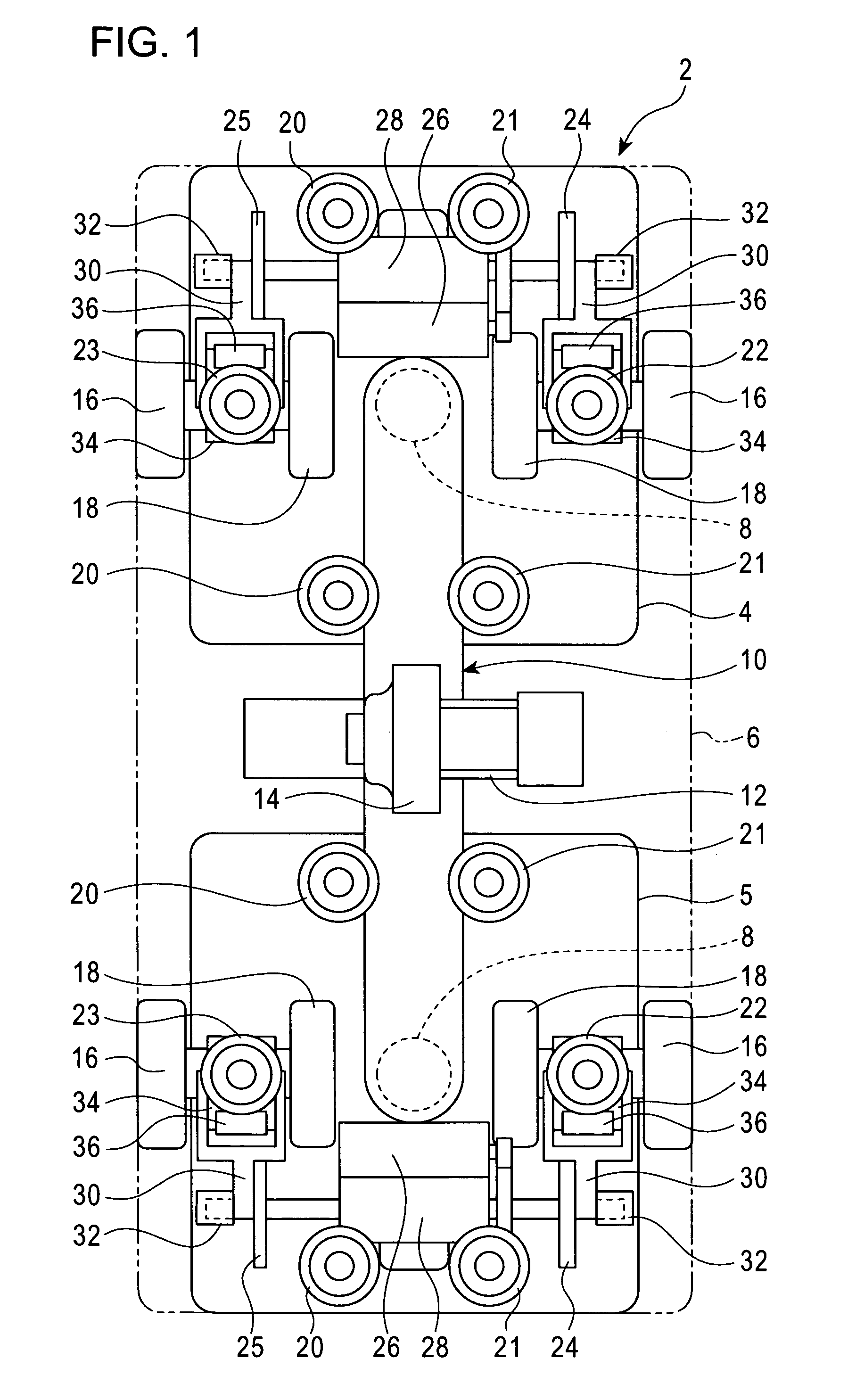

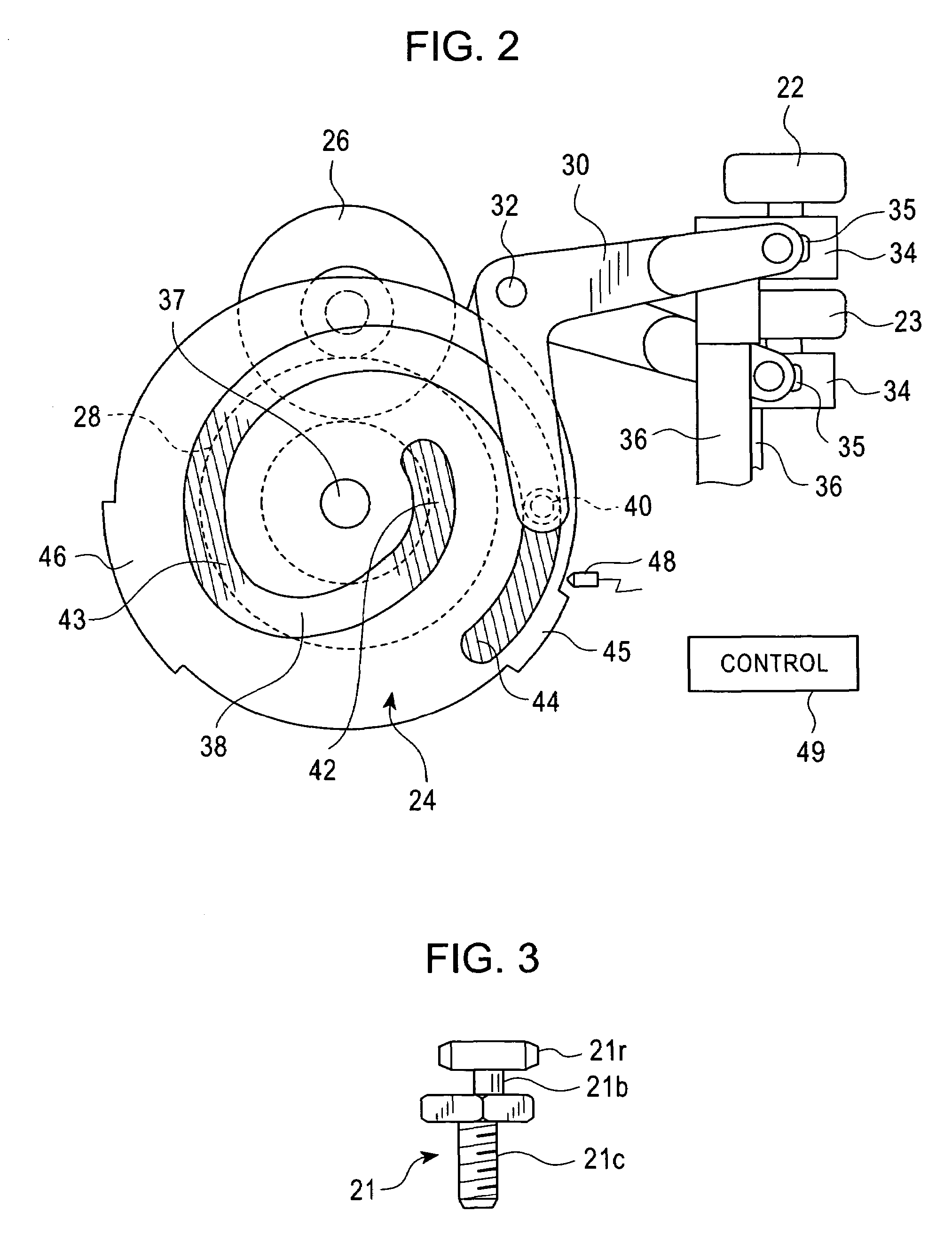

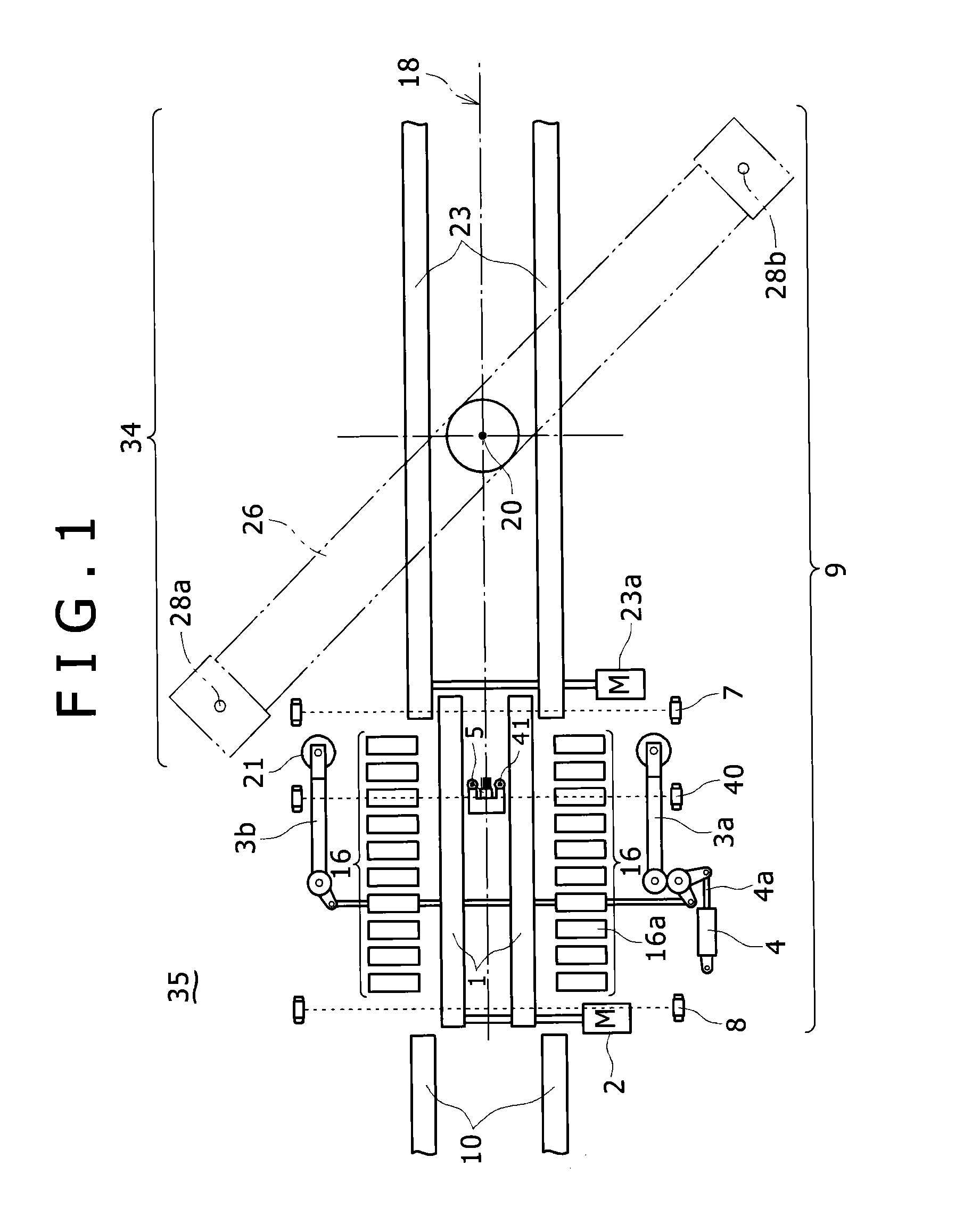

Track guided vehicle system

Guide tracks 56, 56 projecting in a vertical direction are provided in a right and left of a running track 50 and left and right guide rollers 20, 21 are provided on a track guided vehicle and guided using inner surfaces of the left and right guide tracks. Branching rollers 22, 23 each comprising elevating and lowering means are provided in the right and left of the track guided vehicle and outside the right and left guide tracks. Thus, branching and rectilinear progression of the track guided vehicle is controlled by switching between a state where the branching rollers 22, 23 are elevated or lowered to guide the track guided vehicle using outer surfaces of the guide tracks 56, 56 and a state where the branching rollers 22, 23 do not contact with the outer surfaces. Whether the track guided vehicle runs straight or shifts to a branch line can be controlled by contacting one of the branching rollers 22, 23 with the outer surface of the corresponding guide tracks 56, 56, which guide the guide rollers 20, 21 in the section (rectilinear progression section 52) different from the branching portion 51.

Owner:MURATA MASCH LTD

Track guided vehicle system

Owner:MURATA MASCH LTD

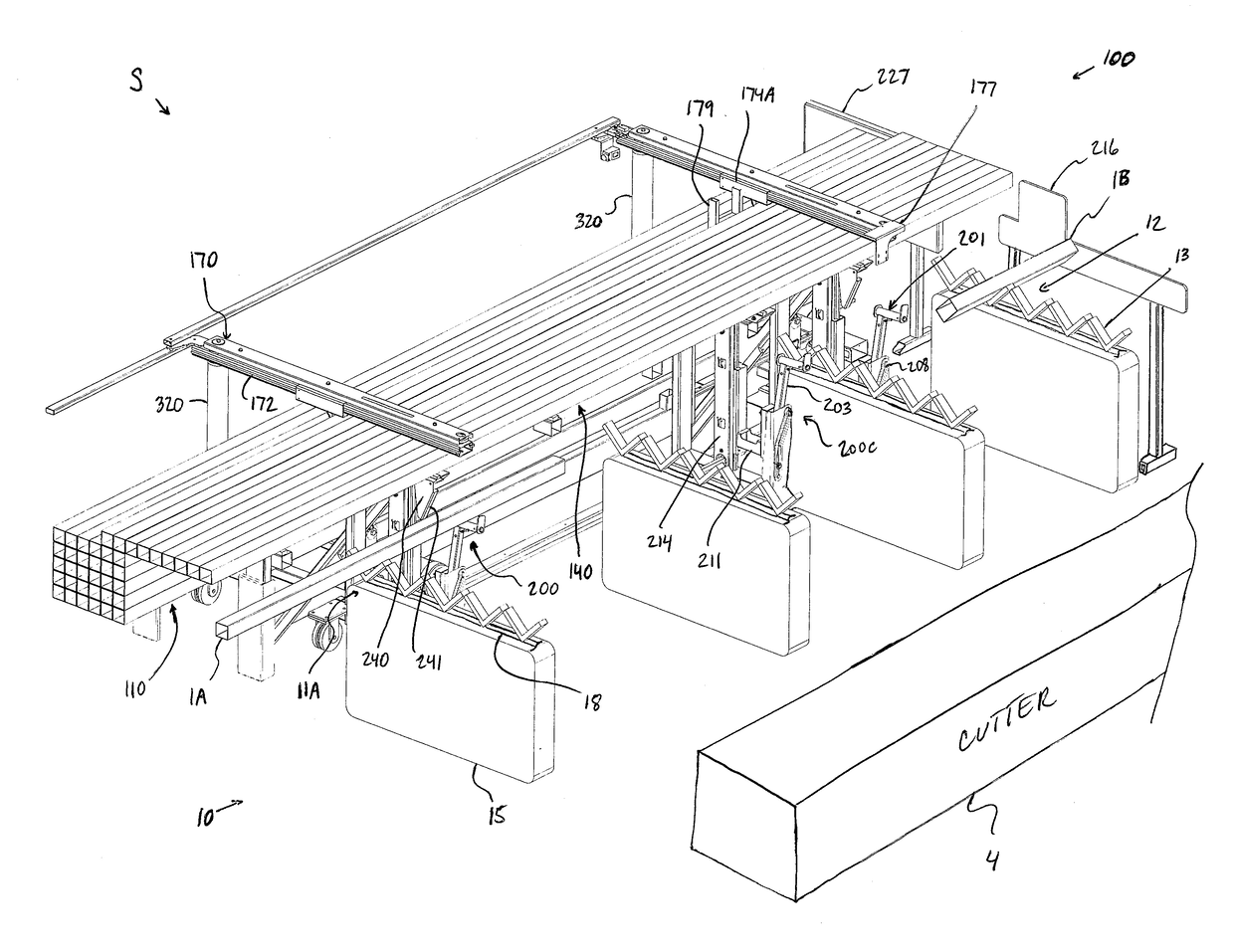

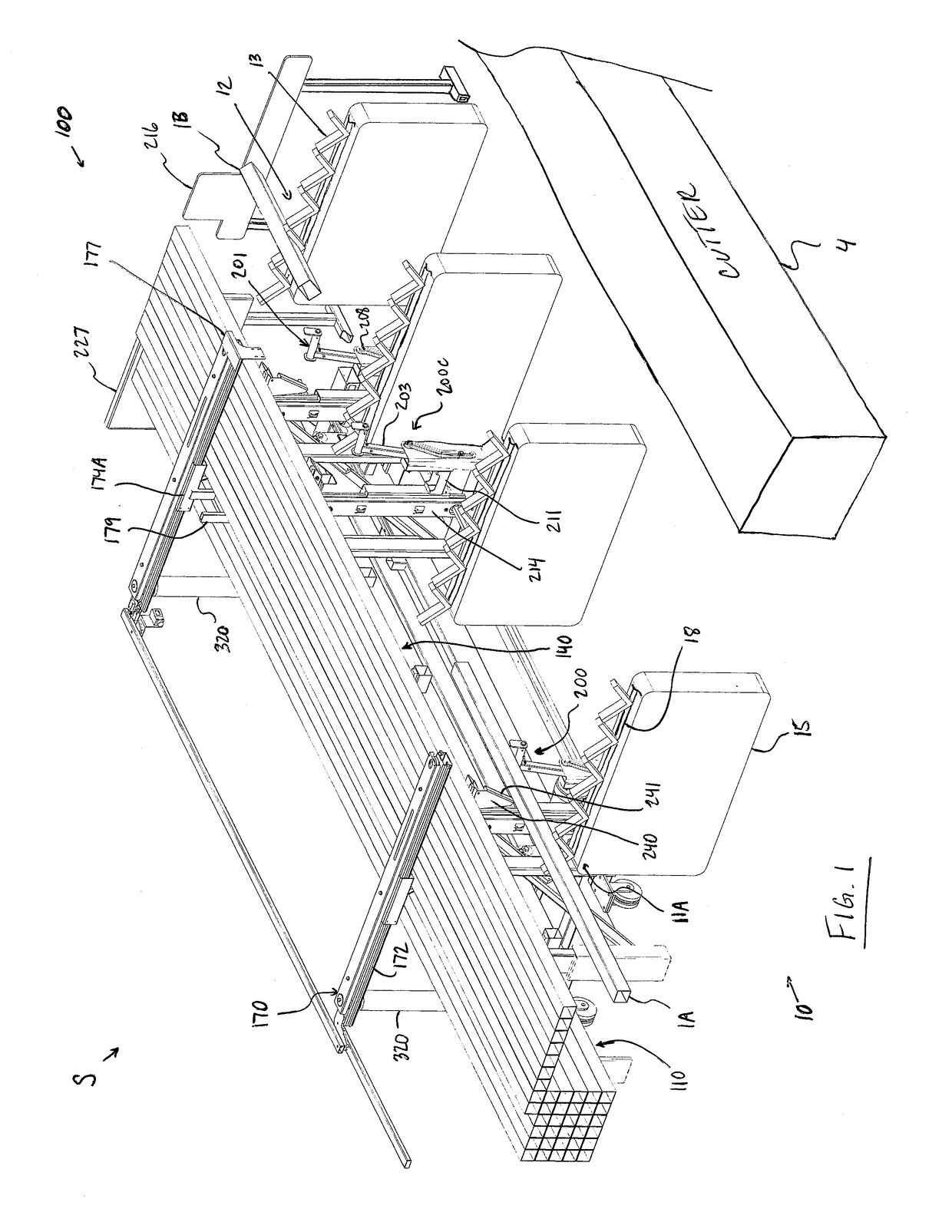

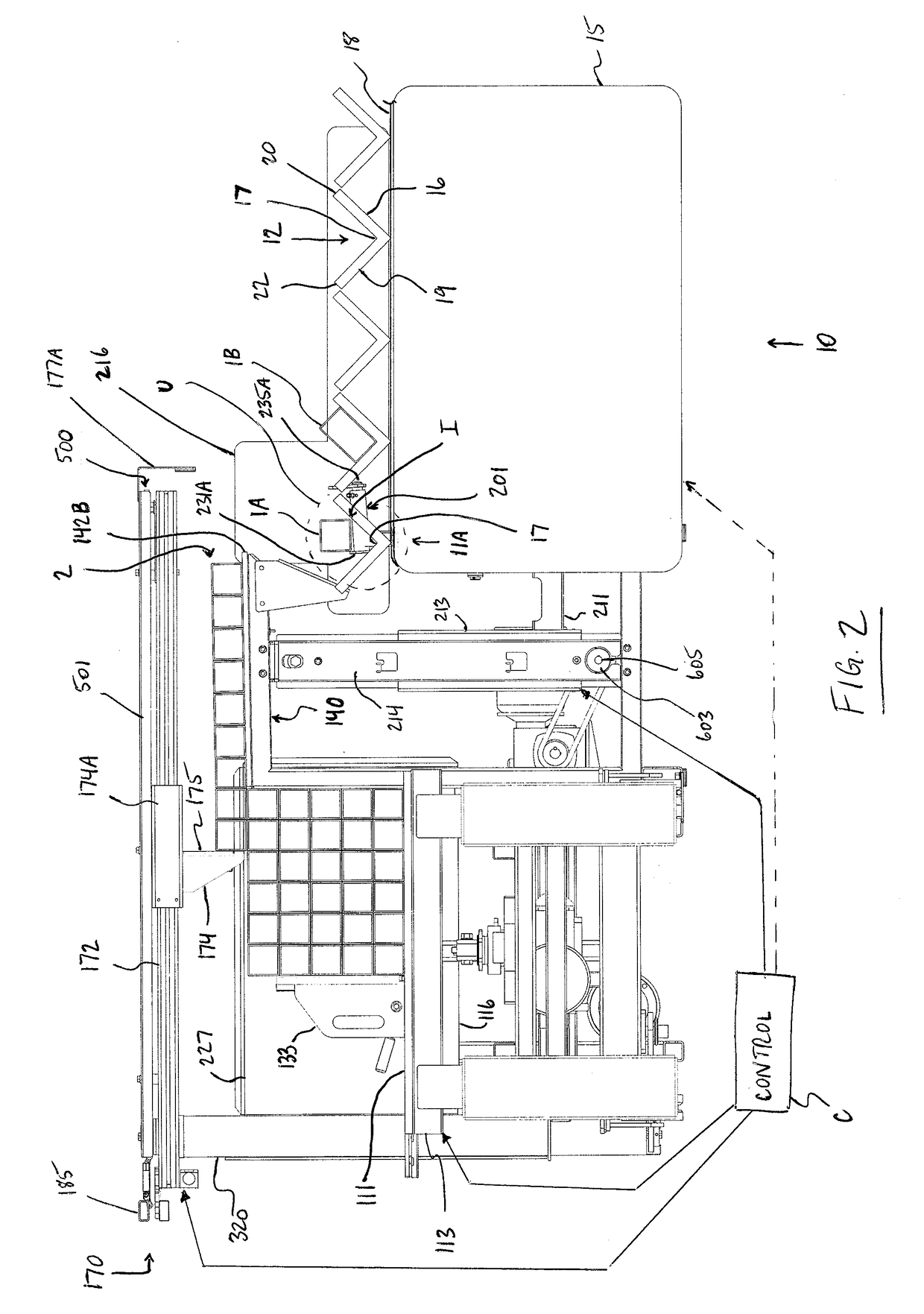

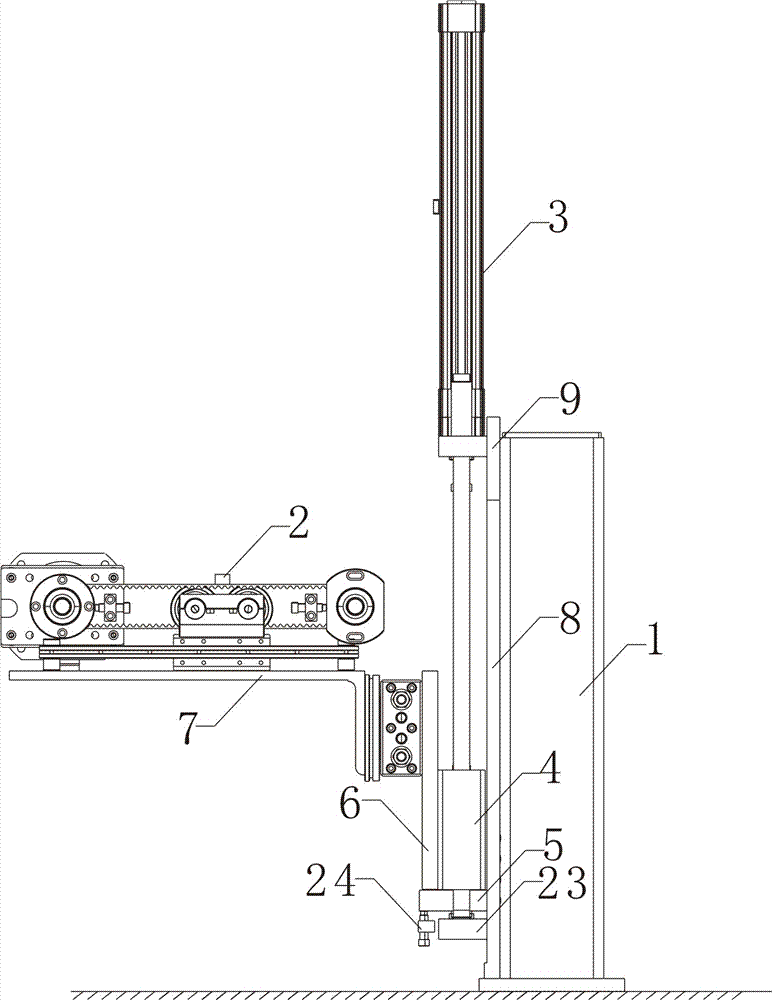

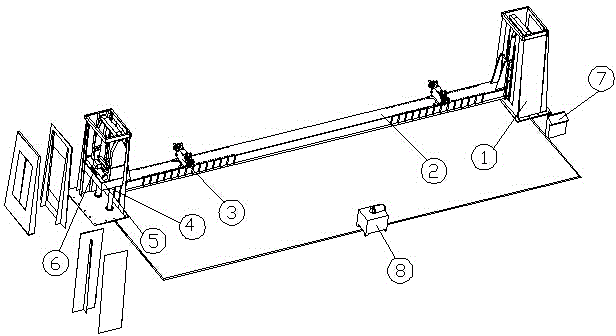

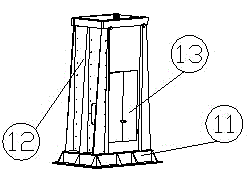

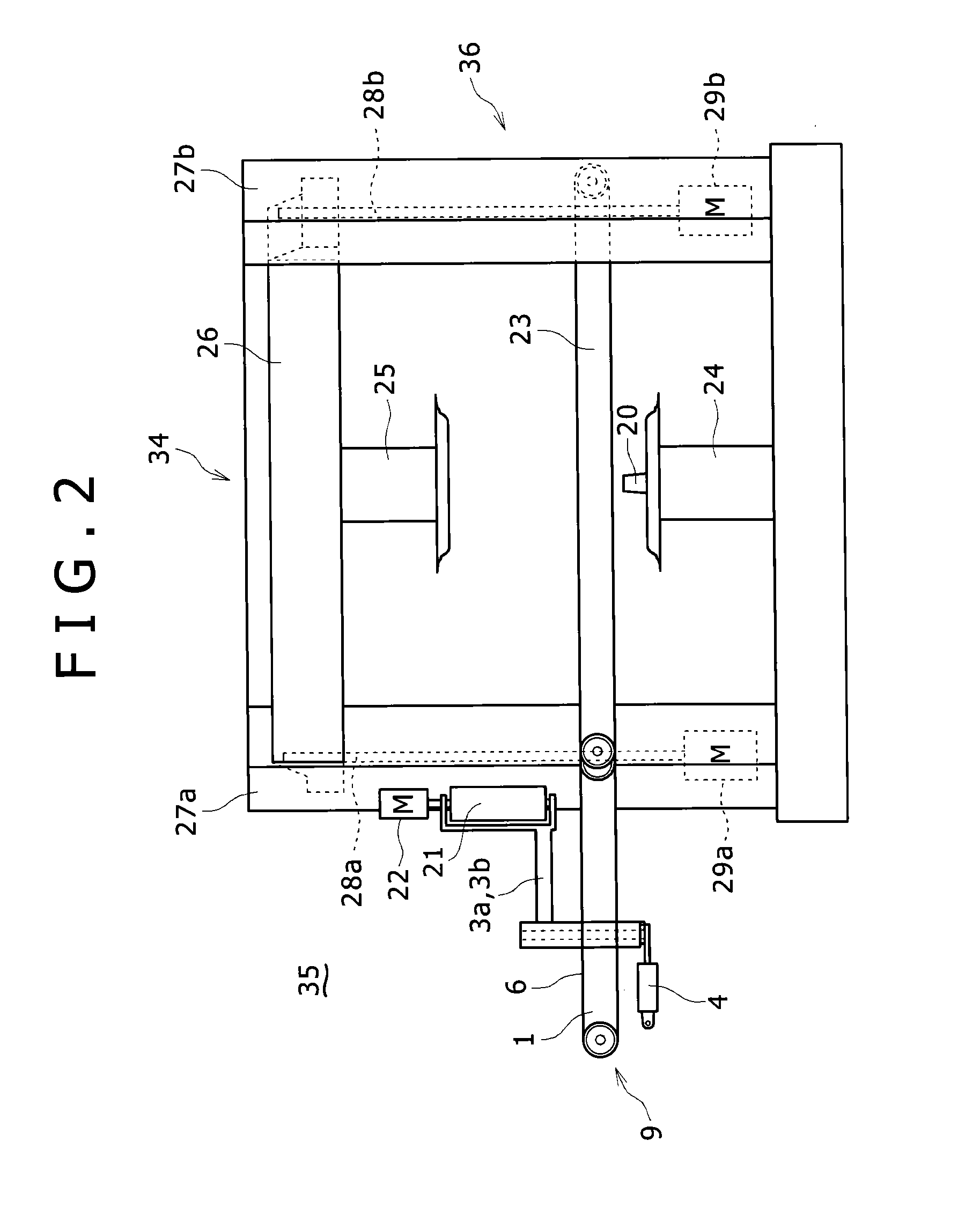

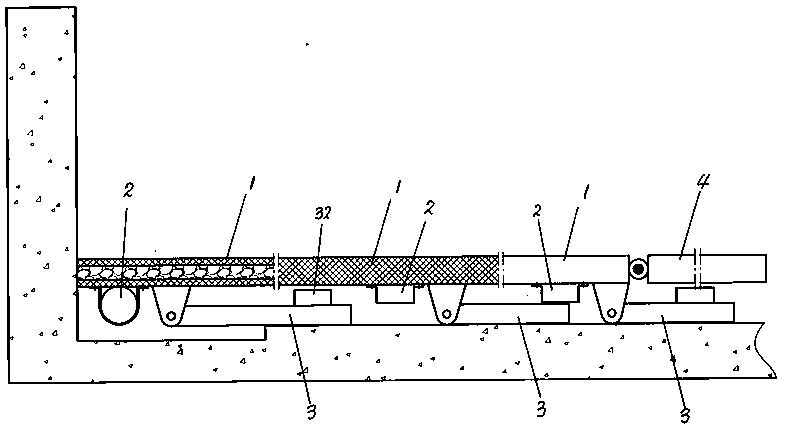

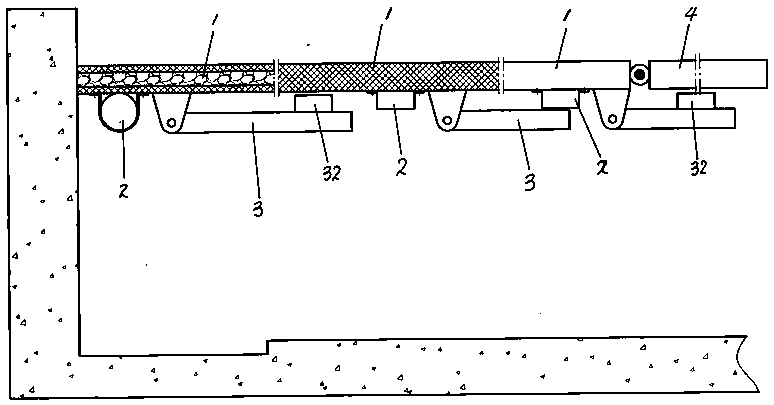

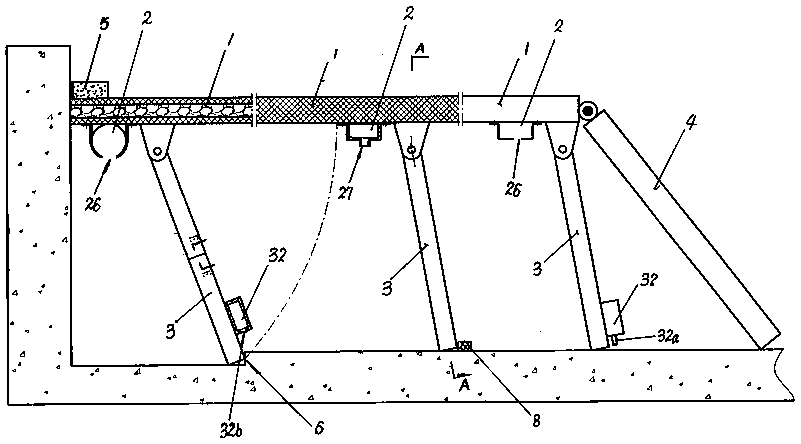

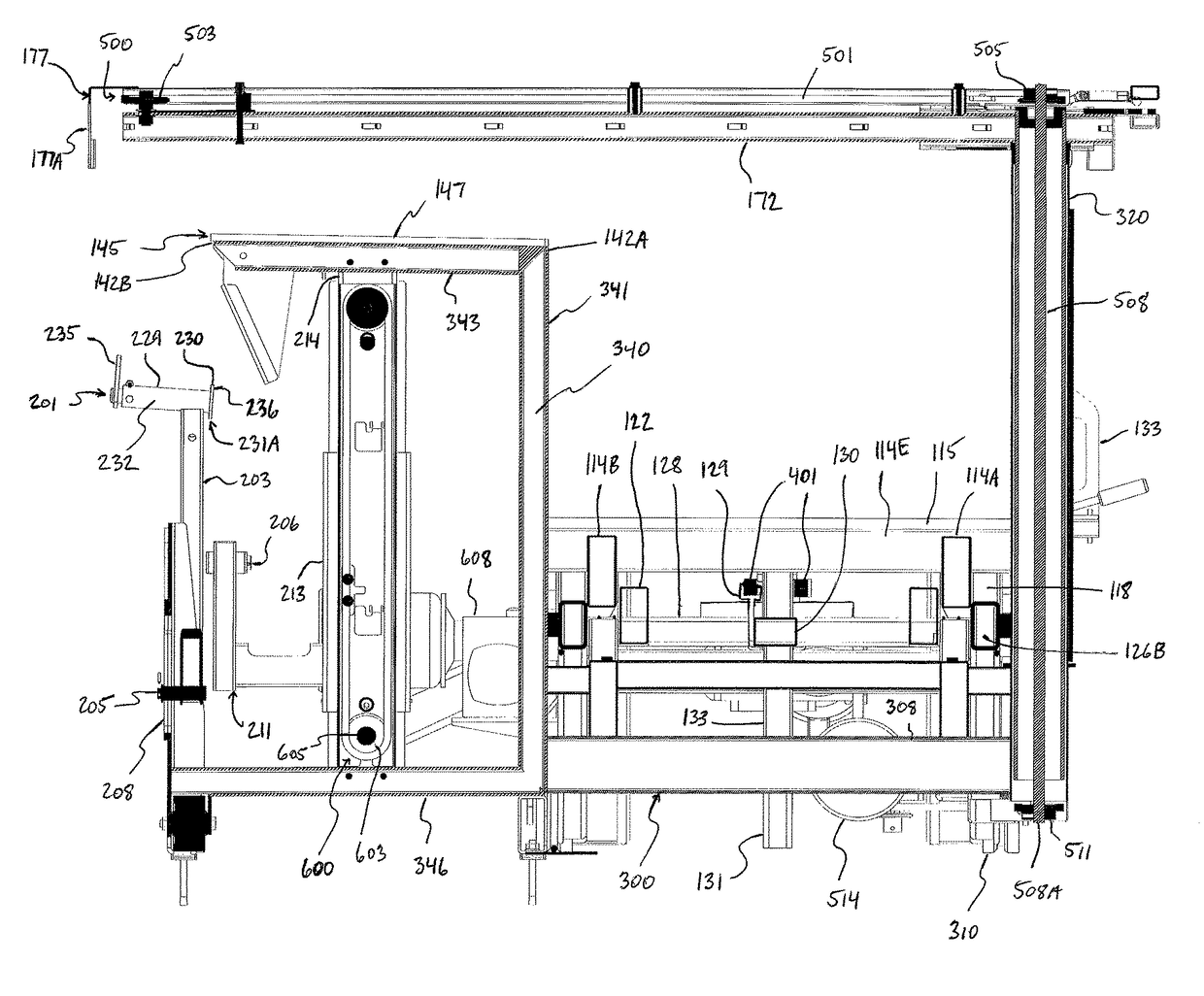

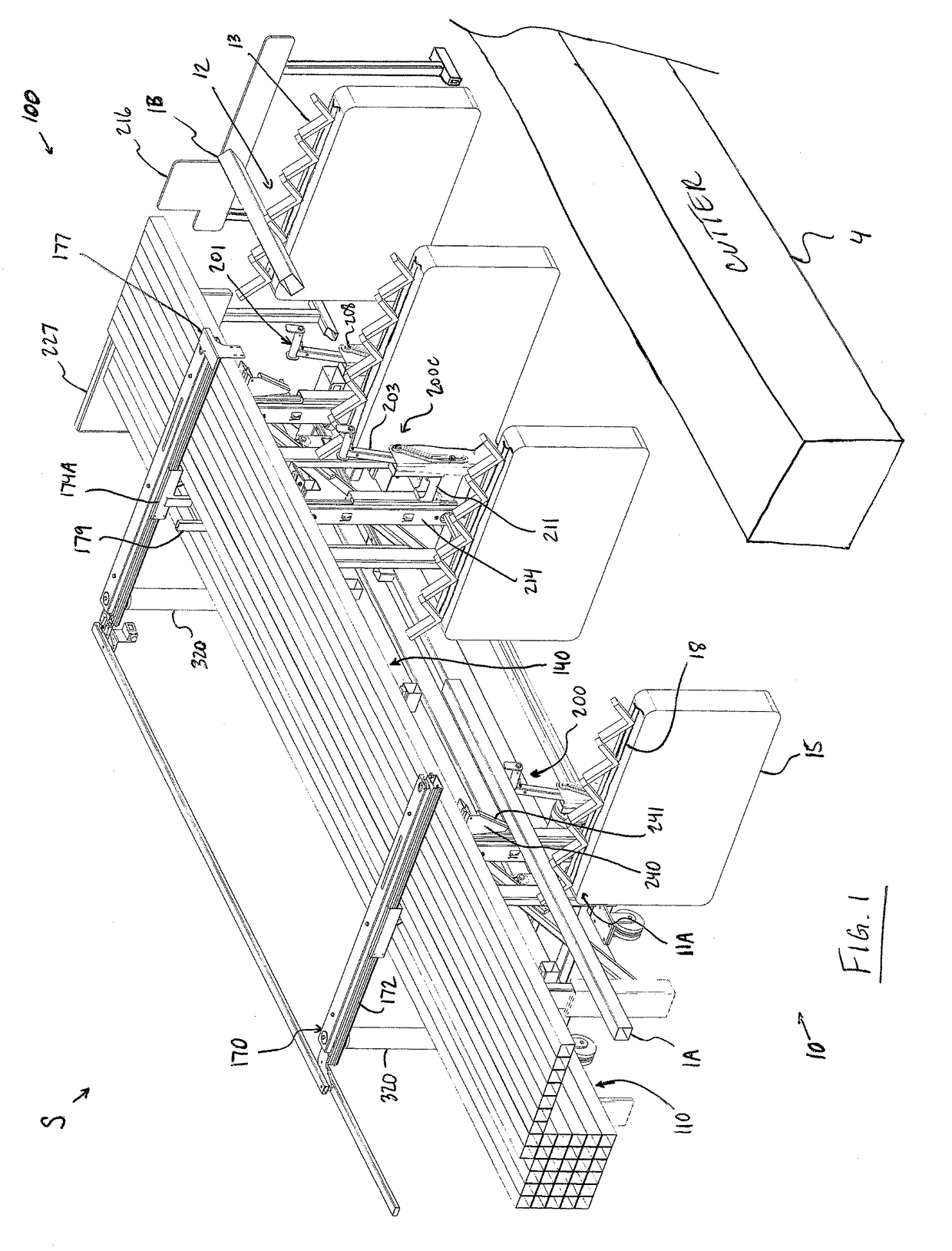

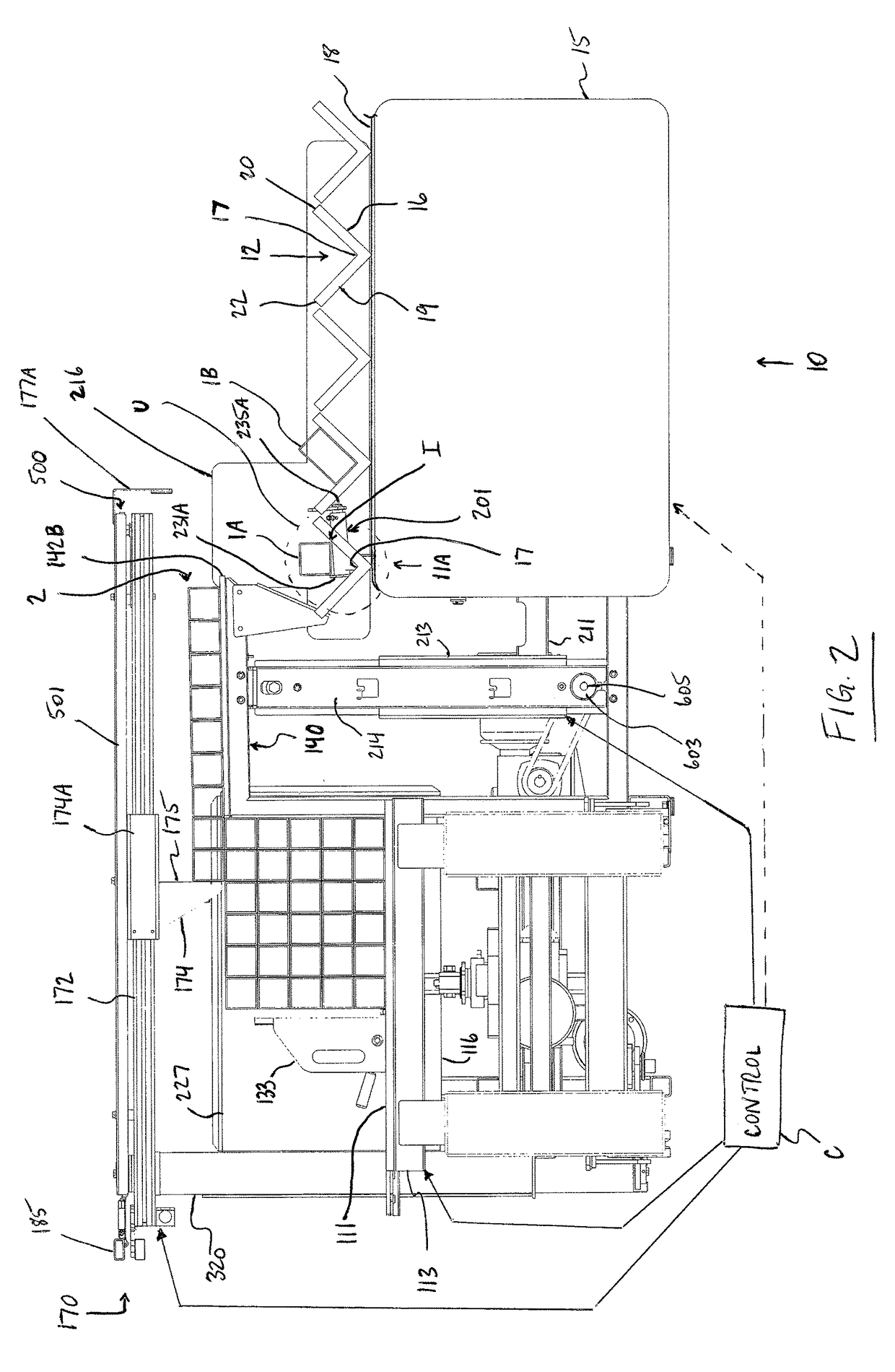

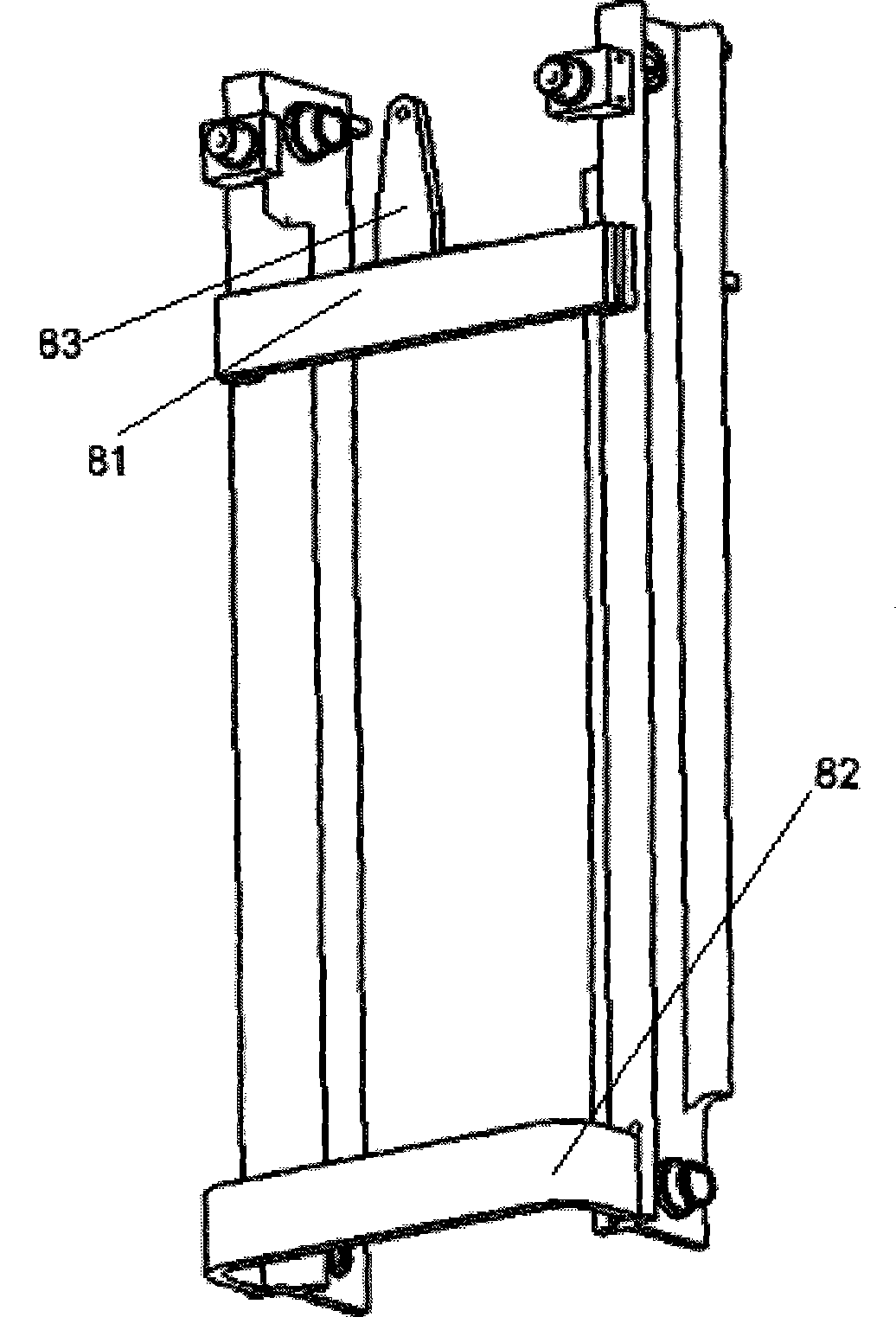

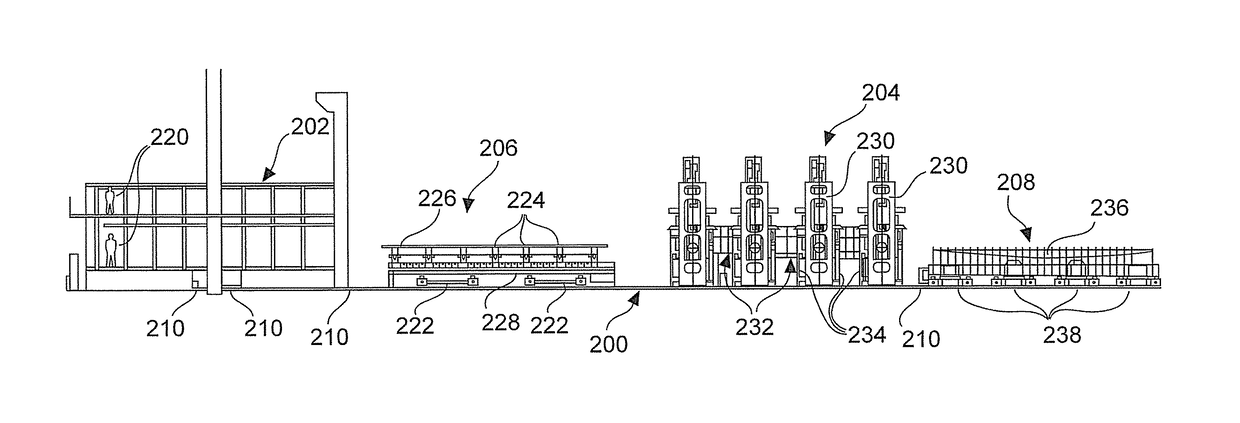

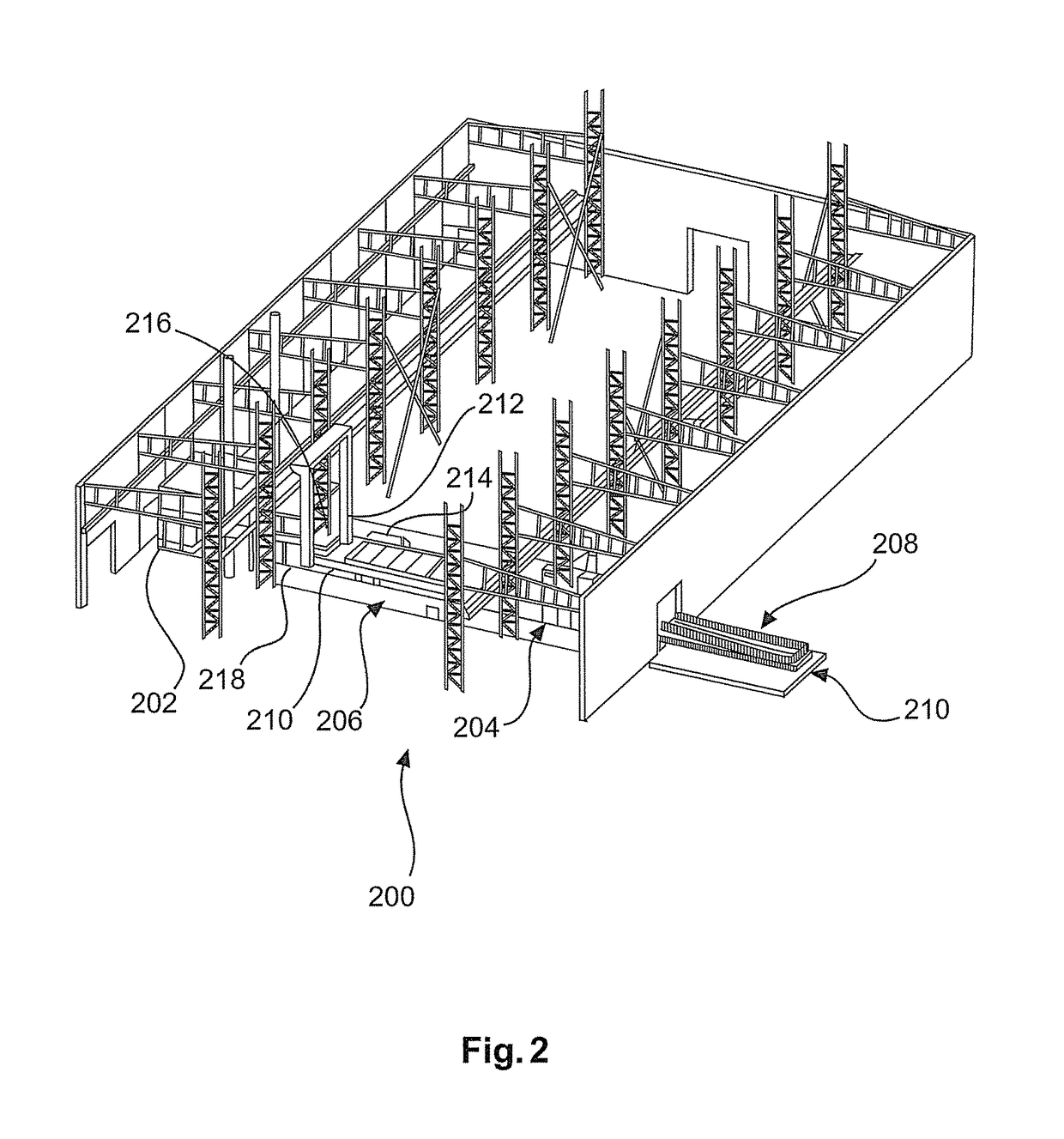

System for Loading Elongated Members Such as Tubes Onto a Conveyor for Later Processing

A system for loading elongated members, such as metal tubes and bars, onto a conveyor for later processing features an elevator, pusher arms, a support surface provided at a predetermined height, and gripper arms. The elevator acts to lift a topmost layer of the members, which are typically arranged in a stack thereon, to a predetermined height so that the pusher arms may transfer the members forming the topmost layer onto the support surface at this height. The pusher arms push these members across the support surface by engaging the member farthest from the support surface until the respective elongated member passes over a distal side of the support surface and onto the gripper arms arranged at a height of this side. The gripper arms lower that member to an unloading location below the support surface where an empty support cradle of the conveyor is arranged for receiving same.

Owner:VIDIR SOLUTIONS INC

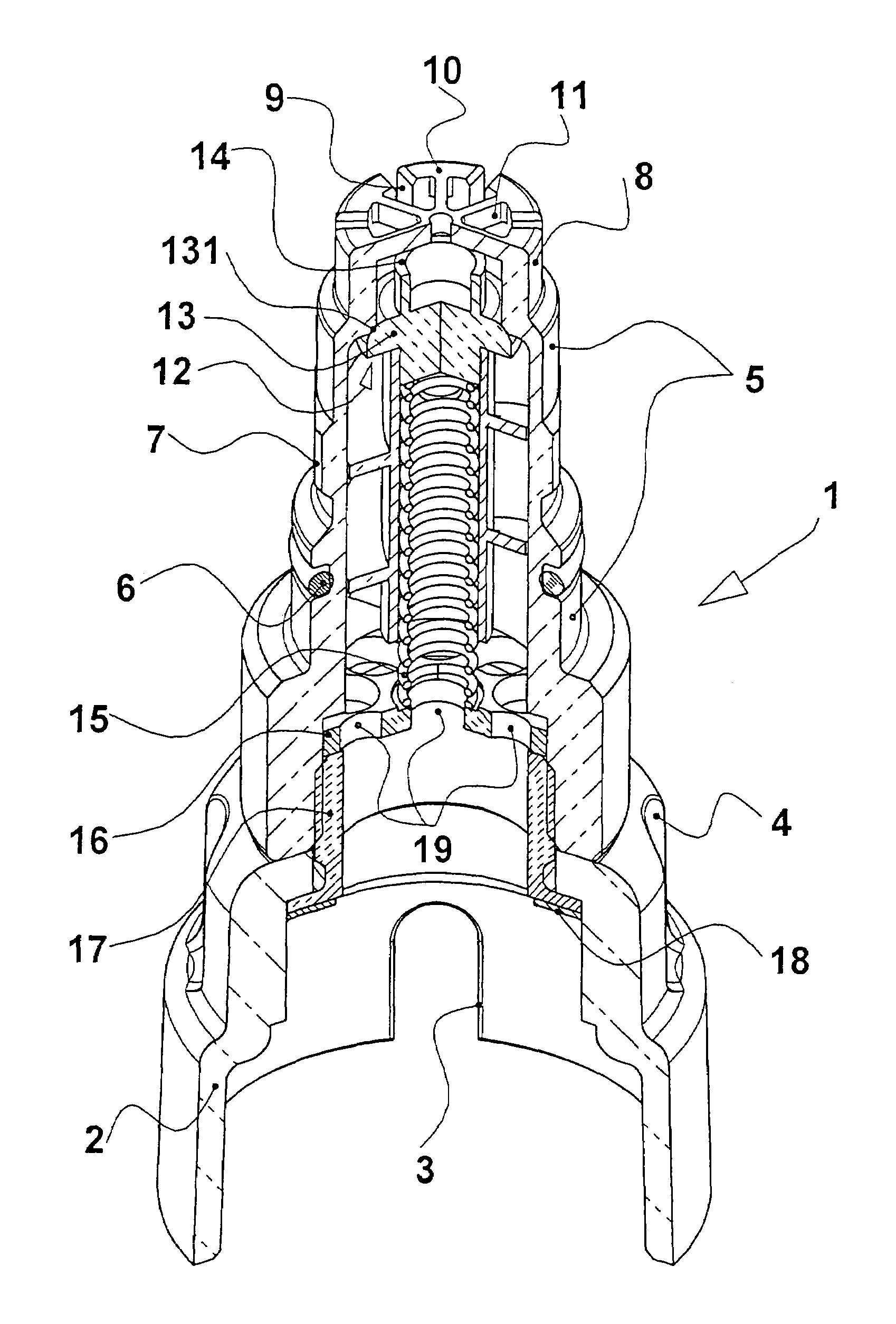

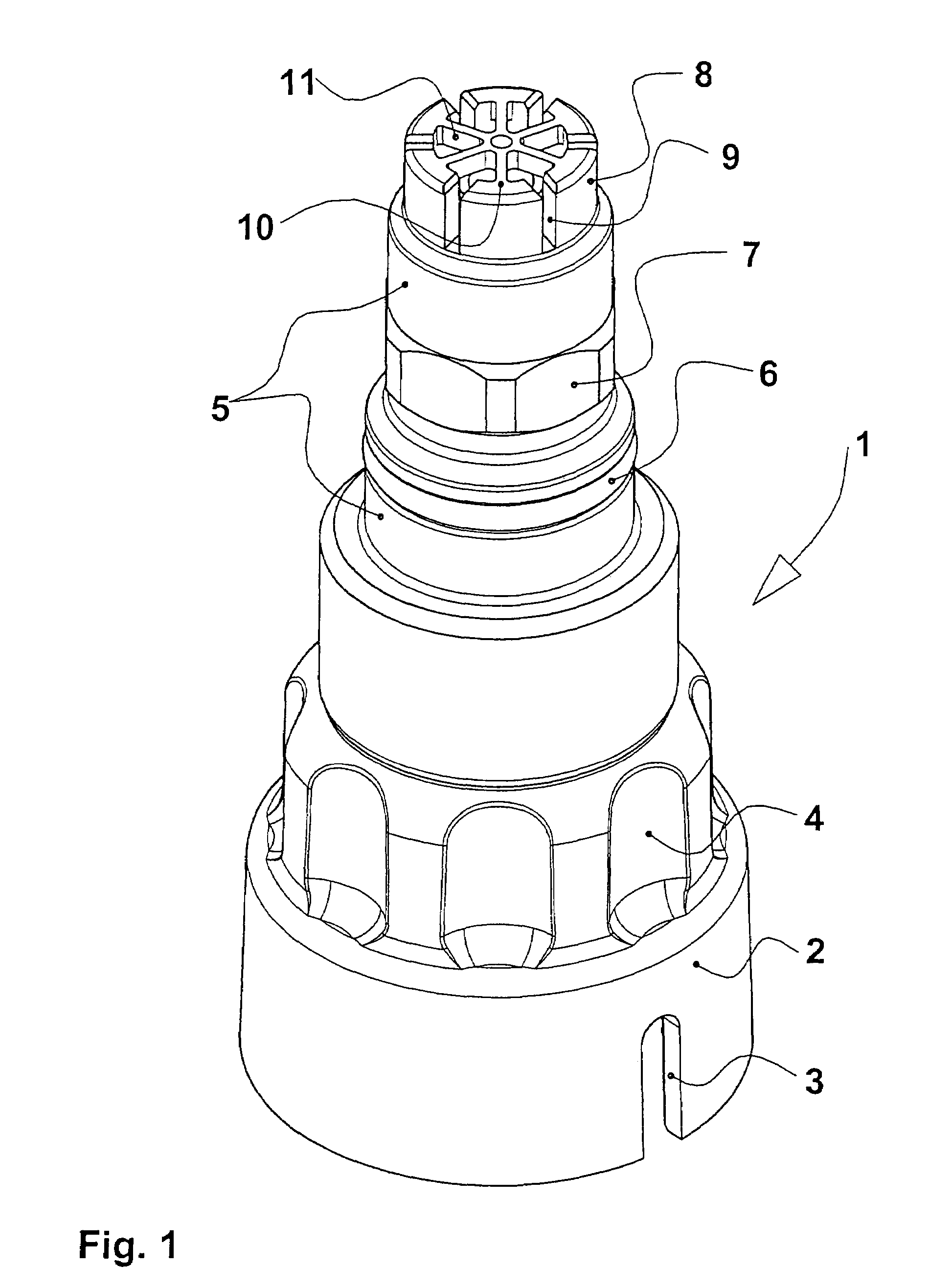

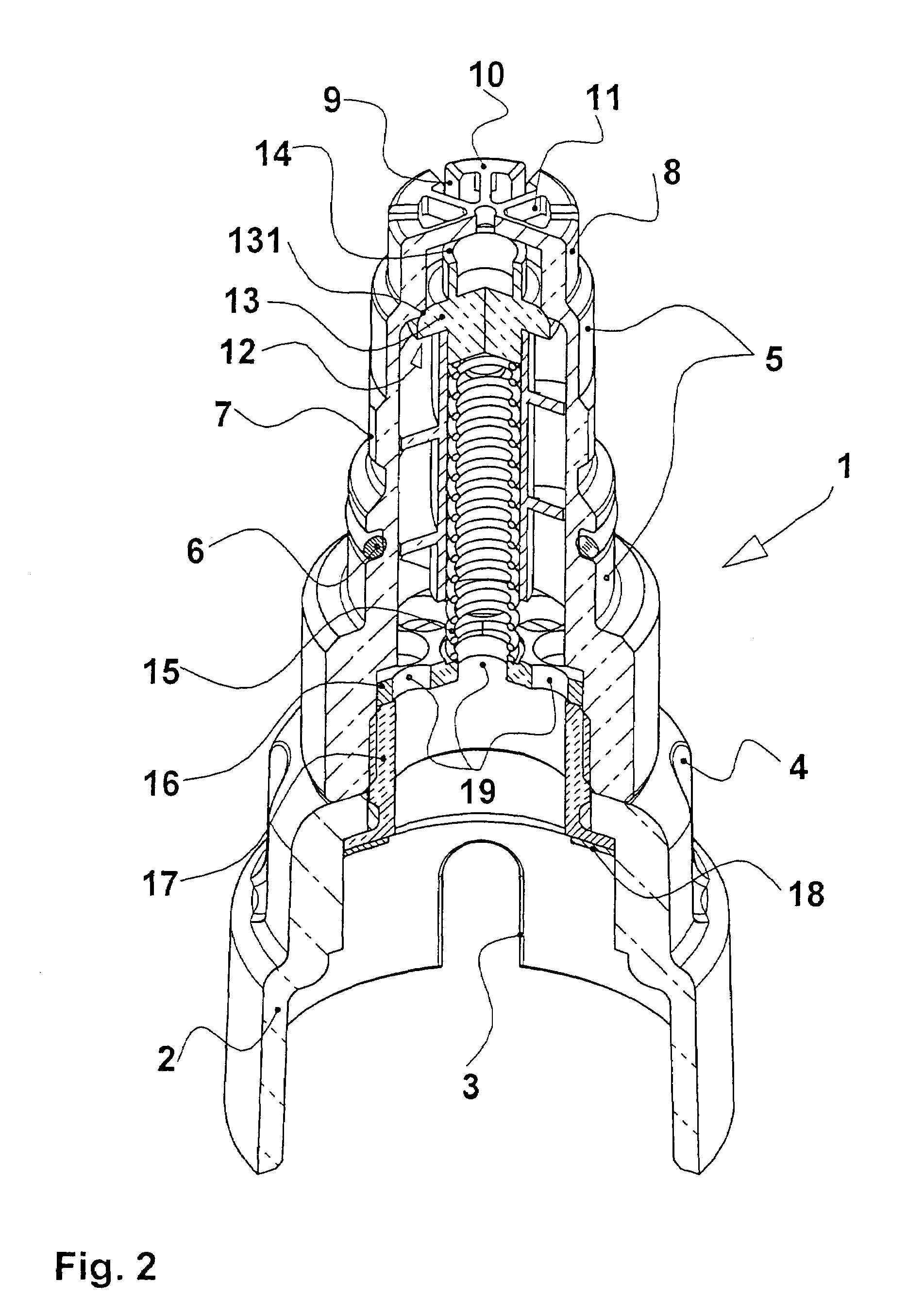

Filling system for an anesthetic evaporator

The interaction between a filling valve (28) on the filling device and an adapter valve on a bottle adapter has improved anesthetics filling features including radially inwardly directed bars (26), which engage (pass into) corresponding slots on the outlet pipe of the bottle adapter. The bars engaged in the slots actuate the adapter valve. The bars are provided on the inner wall of a filler neck (22).

Owner:DRAGERWERK AG

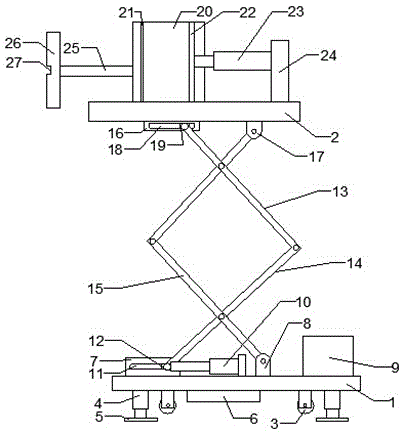

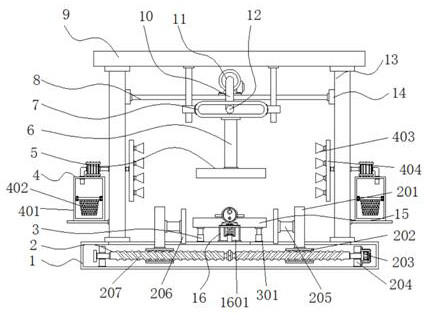

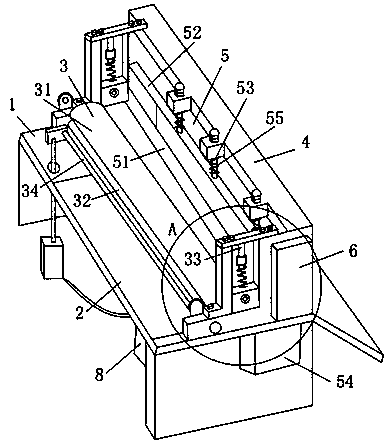

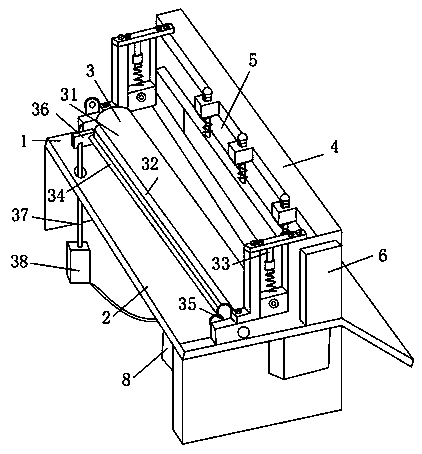

Scissors plastering machine

InactiveCN105155824AImprove plastering effectSimple structureBuilding constructionsAir compressorScissors mechanism

The invention relates to a scissors plastering machine, comprising a base and a working platform. The base is provided with a first fixing block, a first fixing bar, an air compressor and a first telescopic bar. The first fixing block is provided with a first slide slot. The first telescopic bar is hinged to a first slide block in the first slide slot. A scissors mechanism is disposed above the base. Lower ends of the scissors mechanism are hinged to the first slide block and the first telescopic bar, respectively. A second fixing block, a second slide slot, a second slide block and a second fixing bar are disposed below the working platform. Upper ends of the scissors mechanism are hinged to the second slide block and the second fixing bar, respectively. A plaster box is disposed on the working platform, a moving retaining plate is disposed in the plaster box, and a second telescopic bar is disposed on the back of the moving retaining plate. The plaster box is connected with a plastering plate which is provided with an outlet. The scissors plastering machine is simple in structure and practical; through the moving retaining plate discharging material by squeezing and the scissors mechanism lifting, plaster is evenly discharged, lifting is stable, and wall plastering effect is good; the scissors plastering machine is applicable to operation in an area which is inaccessible for a large-sized plastering machine.

Owner:王永志

Reciprocation water spraying device applied to road greening conservation

InactiveCN107135907AAchieve fixationSimple structureWatering devicesCultivating equipmentsReciprocating motionGreening

The invention discloses a reciprocation water spraying device applied to road greening conservation. A spraying head assembly is driven by a spraying-head vertical lifting mechanism and a spraying-head horizontal reciprocating movement mechanism to achieve vertical lifting and horizontal reciprocating movement, the conservation range of the spraying head assembly can be widened through heightening of the position; water can be sprayed in a reciprocation mode in the range through the horizontal reciprocating movement, and the aim that water is evenly sprayed is achieved. The reciprocation water spraying device is simple in whole structure, operation is convenient and rapid, the height of sprayed water can be flexibly adjusted, barriers can also be avoided, and green belts in the range can be thoroughly and fully conserved, and the urban environment is beautified.

Owner:河北安贞市政工程有限公司

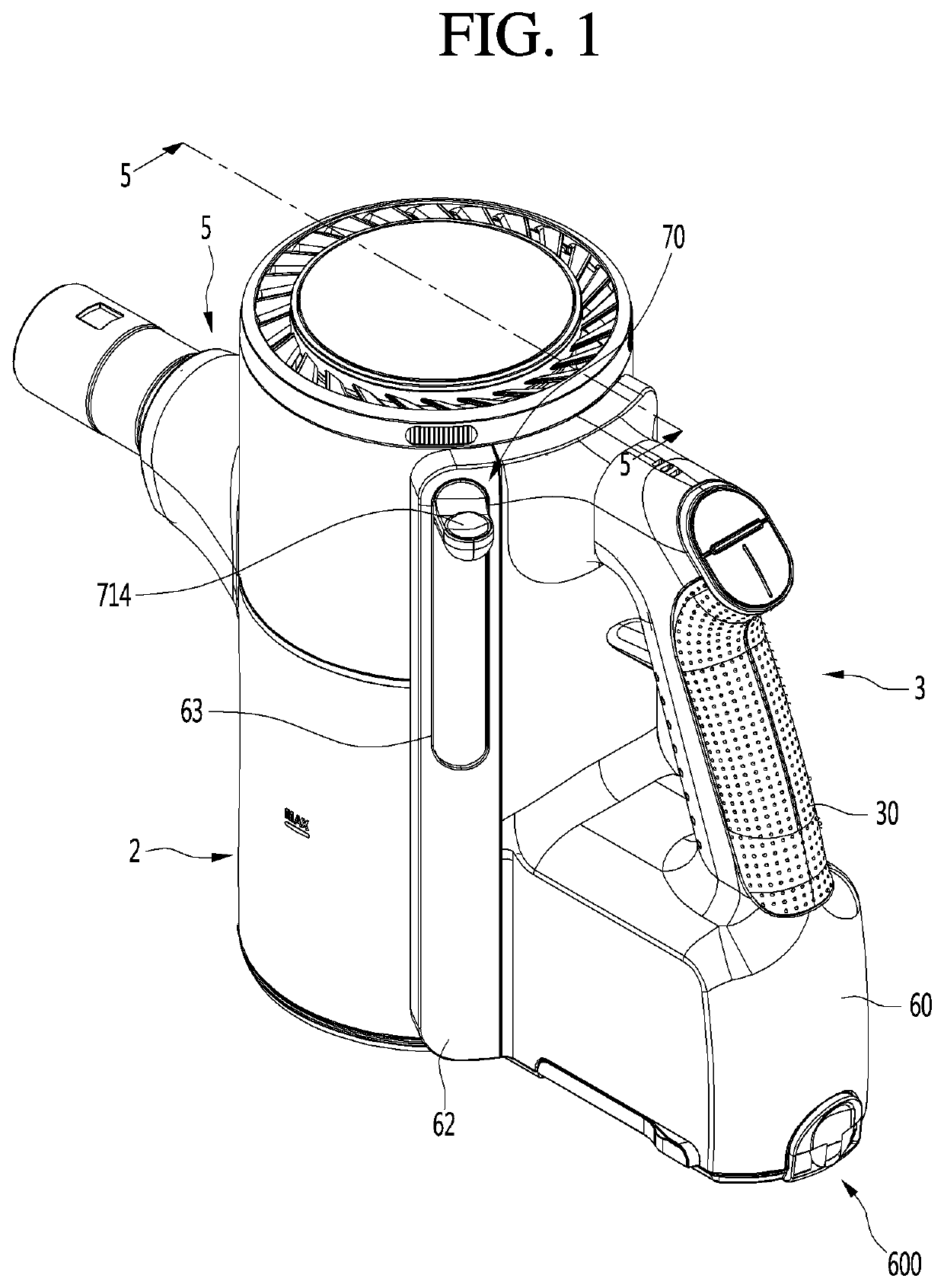

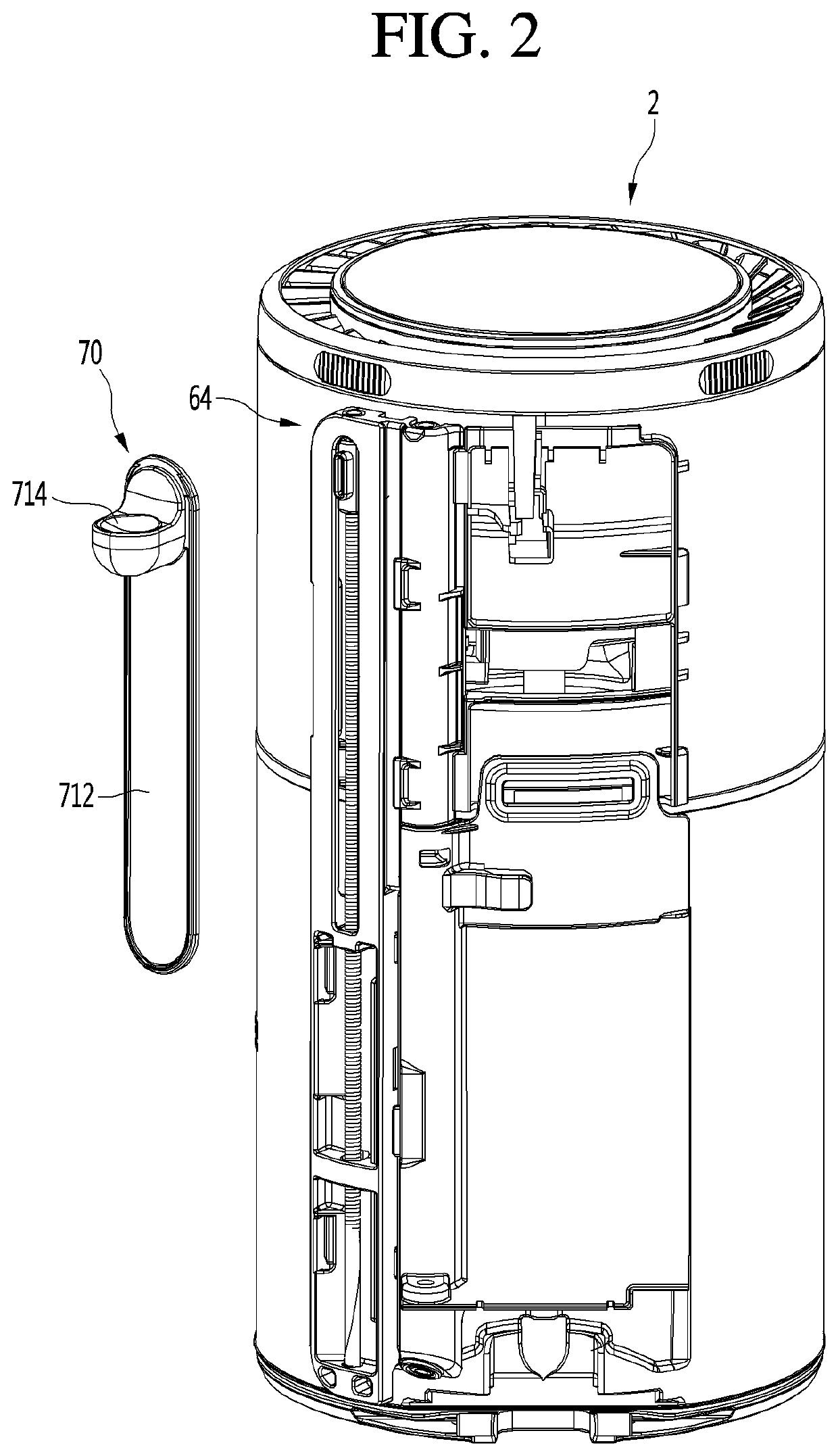

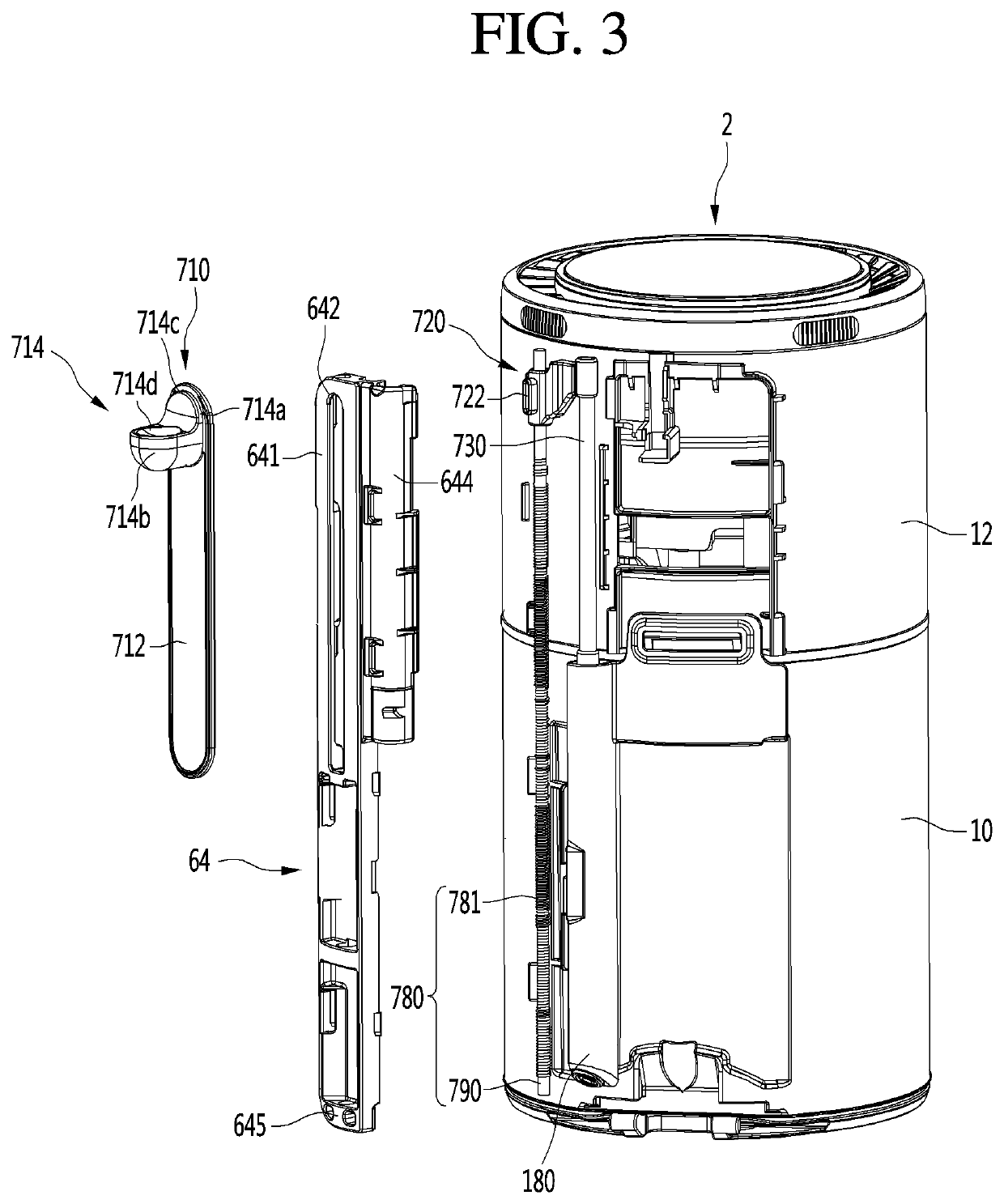

Cleaner

Owner:LG ELECTRONICS INC

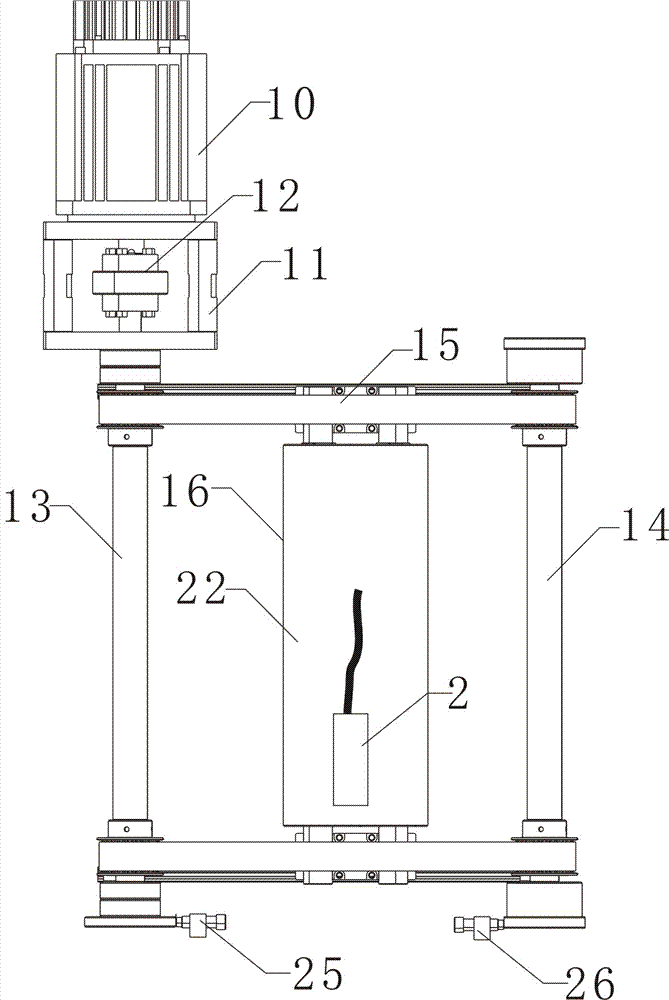

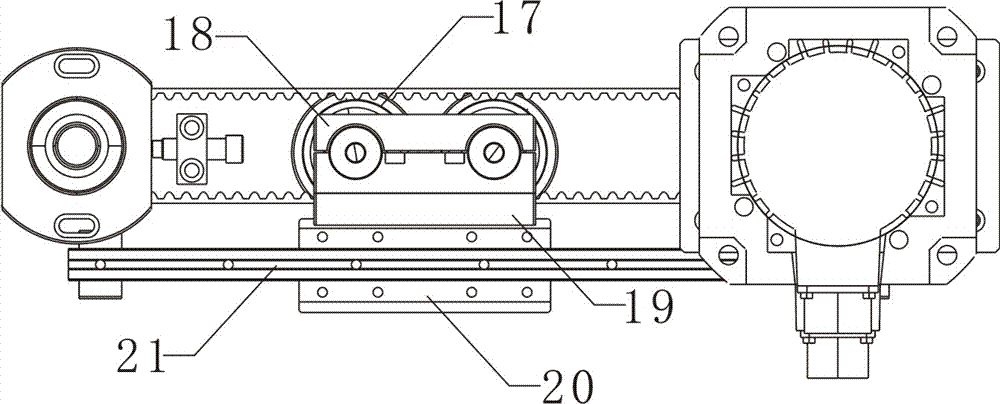

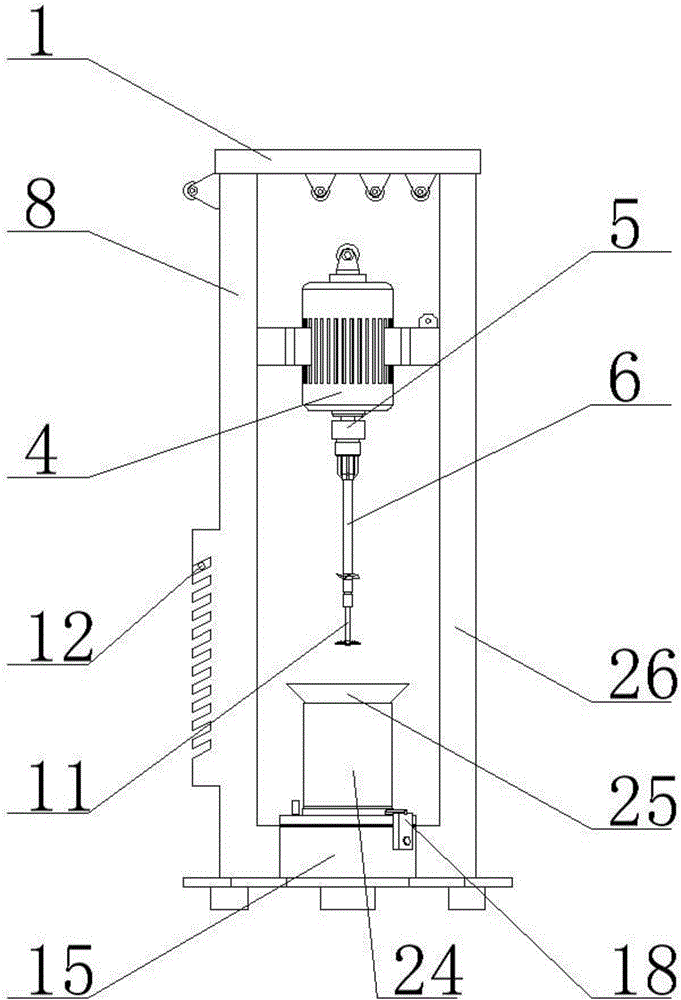

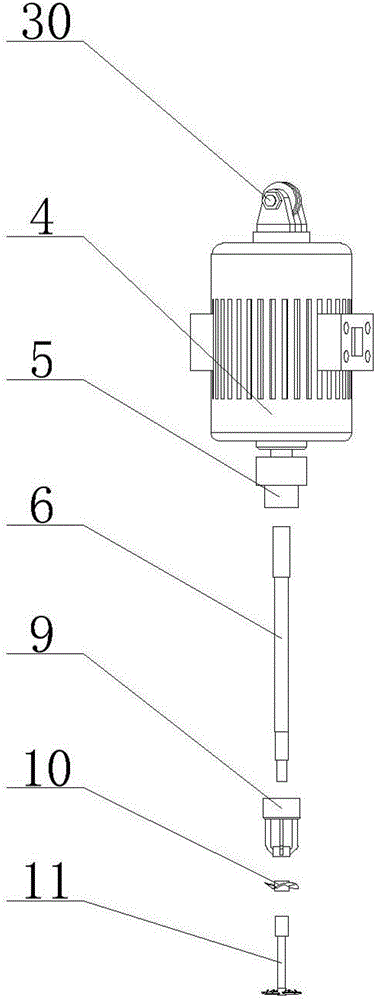

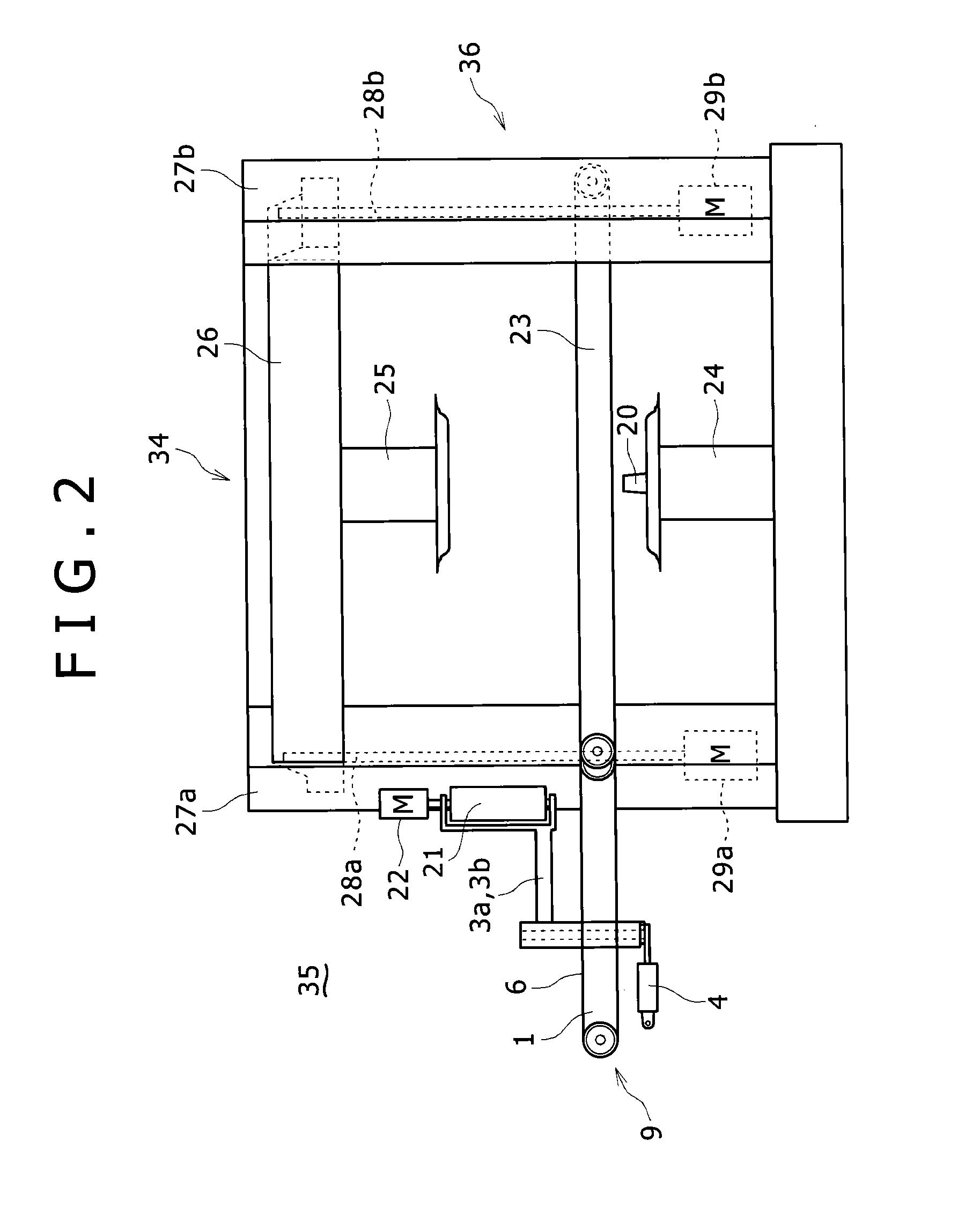

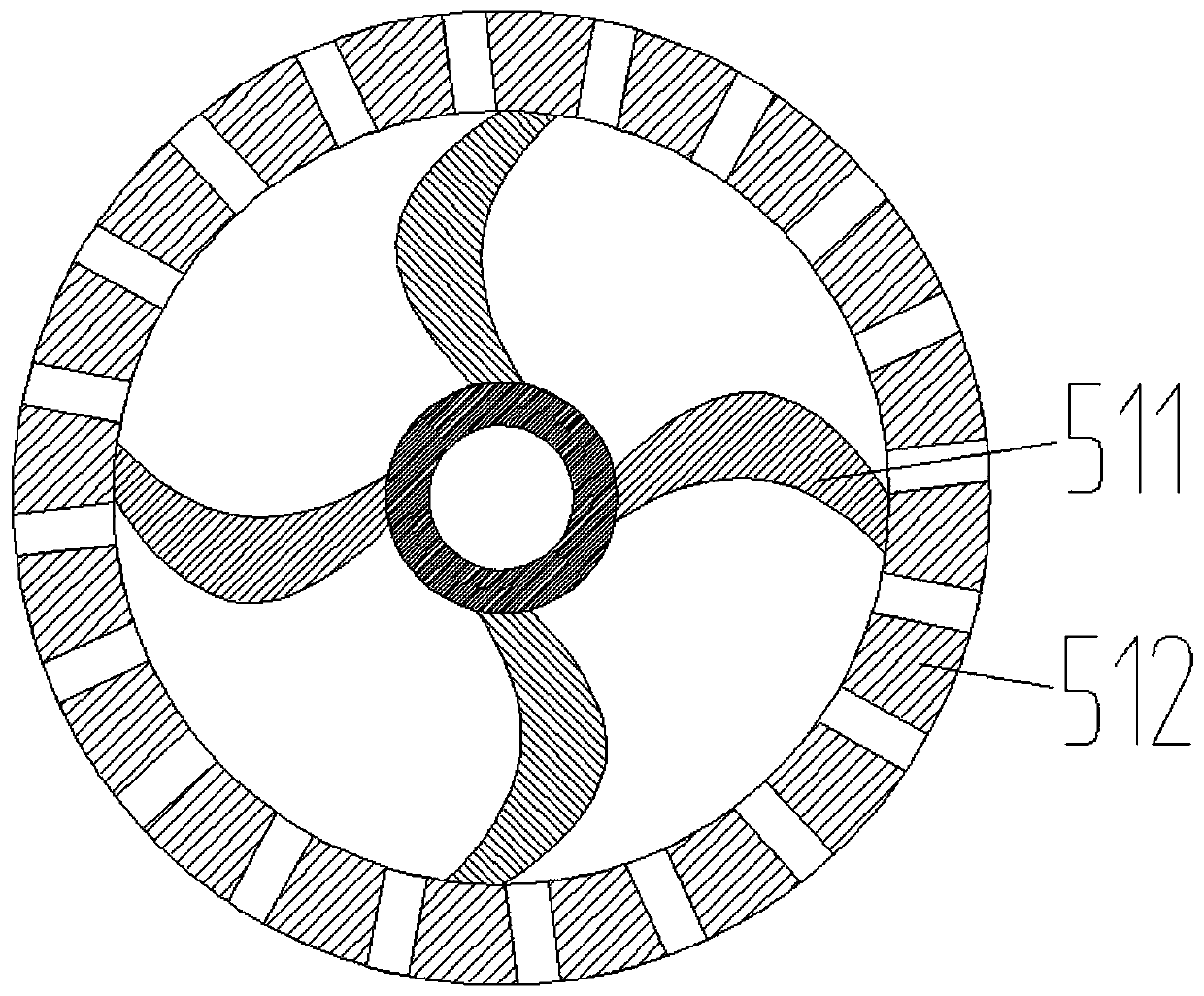

Sliding rail type mechanical stirrer

InactiveCN105709668AEasy to liftImprove stabilityTransportation and packagingRotary stirring mixersImpellerGas liquid reaction

The invention discloses a sliding rail type mechanical stirrer which comprises a motor adjustment component, a stirring component, a base component and a stirring container component, wherein the motor adjustment component is fixed on the base component; the stirring container component is adsorbed on the base component; and the upper end of the motor adjustment component is connected with the stirring component through a steel wire rope, and two ends are matched with the stirring component in a separate tightening manner. According to the sliding rail type mechanical stirrer, by the adoption of symmetric sliding rail motor adjustment, the problems of inconvenience in motor adjustment and working vibration are solved; by the adoption of a shaft reinforcement piece, the problems of shaft vibration, noise, and deflection are solved; by the adoption of a magnet adsorption type base, the problem that a stirring trough clamps a bracket is solved; by the adoption of a lifting type base, the problem of poor stirring due to a fixed position of a stirring impeller is solved; by the adoption of the stirring impeller, the problems of poor stirring and small circulating amount are solved; by the additional arrangement of a fan wheel, the problem of long stirring time in gas-liquid reaction is solved; and by the adoption of a simple anti-splashing cover, the problem that a stirred liquid is splashed to a user in a liquid stirring process is solved.

Owner:JILIN UNIV

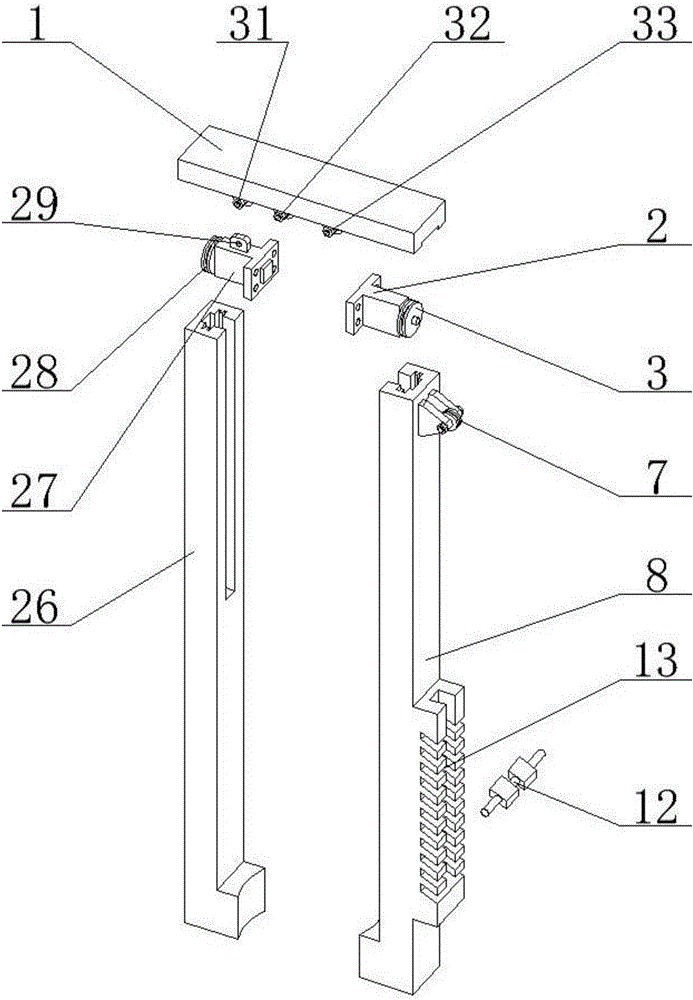

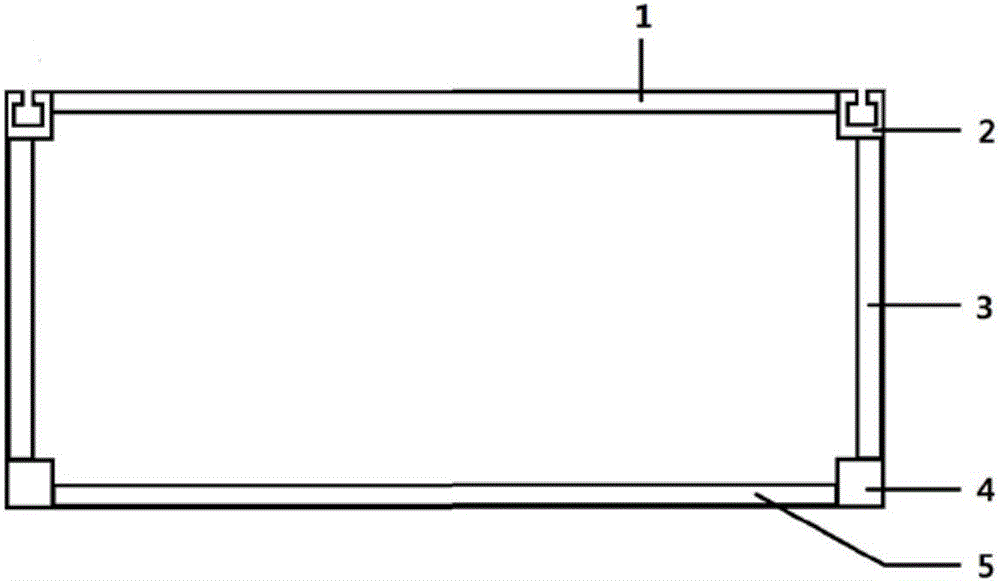

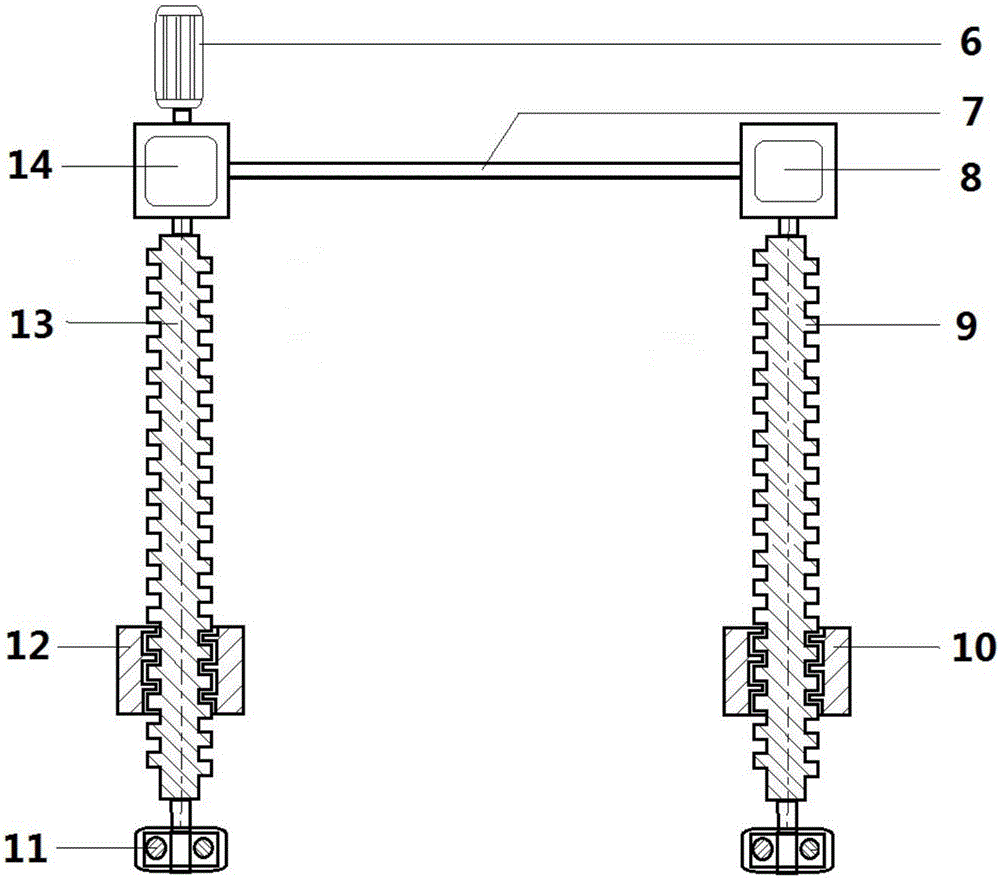

Screw and helical bevel gear combined three-dimensional parking garage achieving outside-garage vertical lifting

The invention relates to a screw and helical bevel gear combined three-dimensional parking garage achieving outside-garage vertical lifting. The three-dimensional parking garage is formed by a main body frame, a vertical lifting drive system, a transverse moving system and a vehicle body support plate; the vertical lifting drive system is located on the front side portion of the main body frame and connected with the stand columns, the transverse moving system is located on an interlayer plane formed by cross beams of the main body frame, and the vehicle body support plate is in dynamic connection with the vertical lifting drive system and the transverse moving system through arranged rolling wheels. The vertical lifting system is formed by a lifting servo motor, lifting screws, lifting helical bevel gear commutators and a connecting rod; the transverse moving system is formed by a transverse translation servo motor, a first transverse translation drive device, a second transverse translation drive device, a first transverse translation guide rail and a second transverse translation guide rail; the rolling wheels are arranged on the lower bottom face of the vehicle body support plate, and meanwhile dovetail hook slots are formed. According to the screw and helical bevel gear combined three-dimensional parking garage achieving outside-garage vertical lifting, a single-vehicle multi-layer three-dimensional parking garage can be erected on the only parking area, and vehicle parking and obtaining can be achieved by means of roads; due to the fact that the screw mode is adopted, the process is smooth and steady and free of drag feeling.

Owner:福建天成新能源科技有限公司

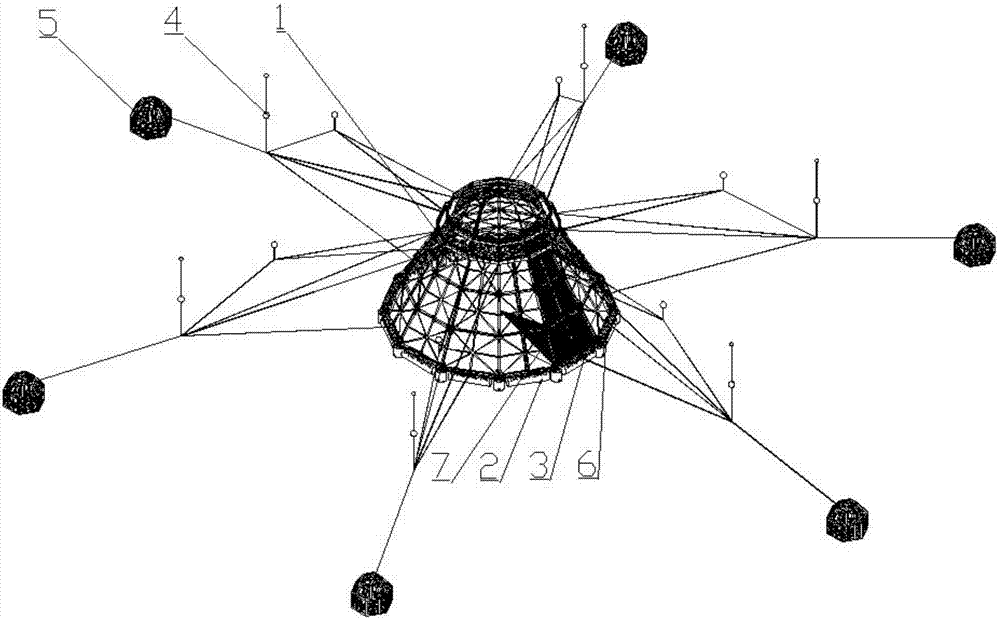

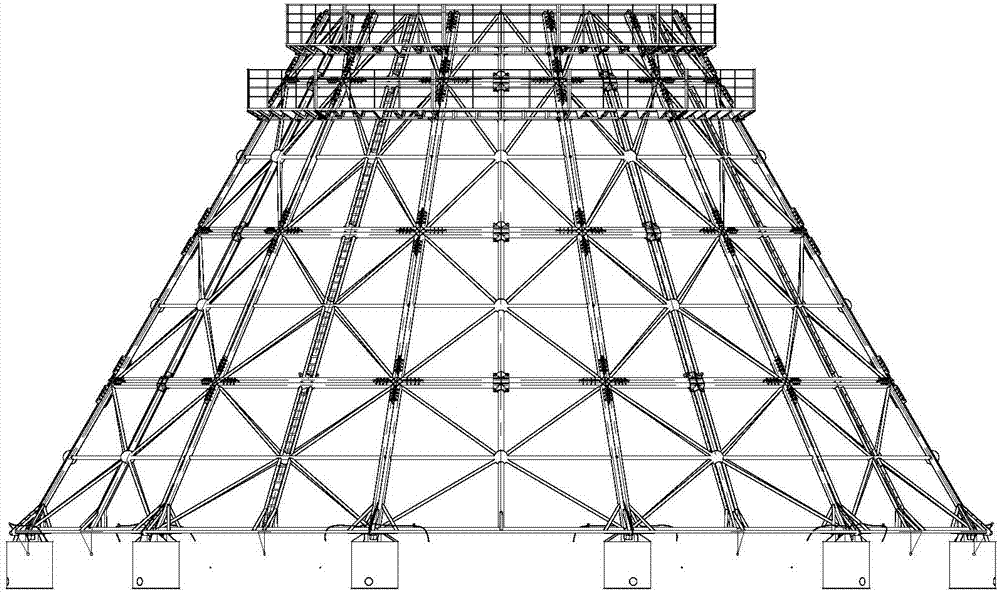

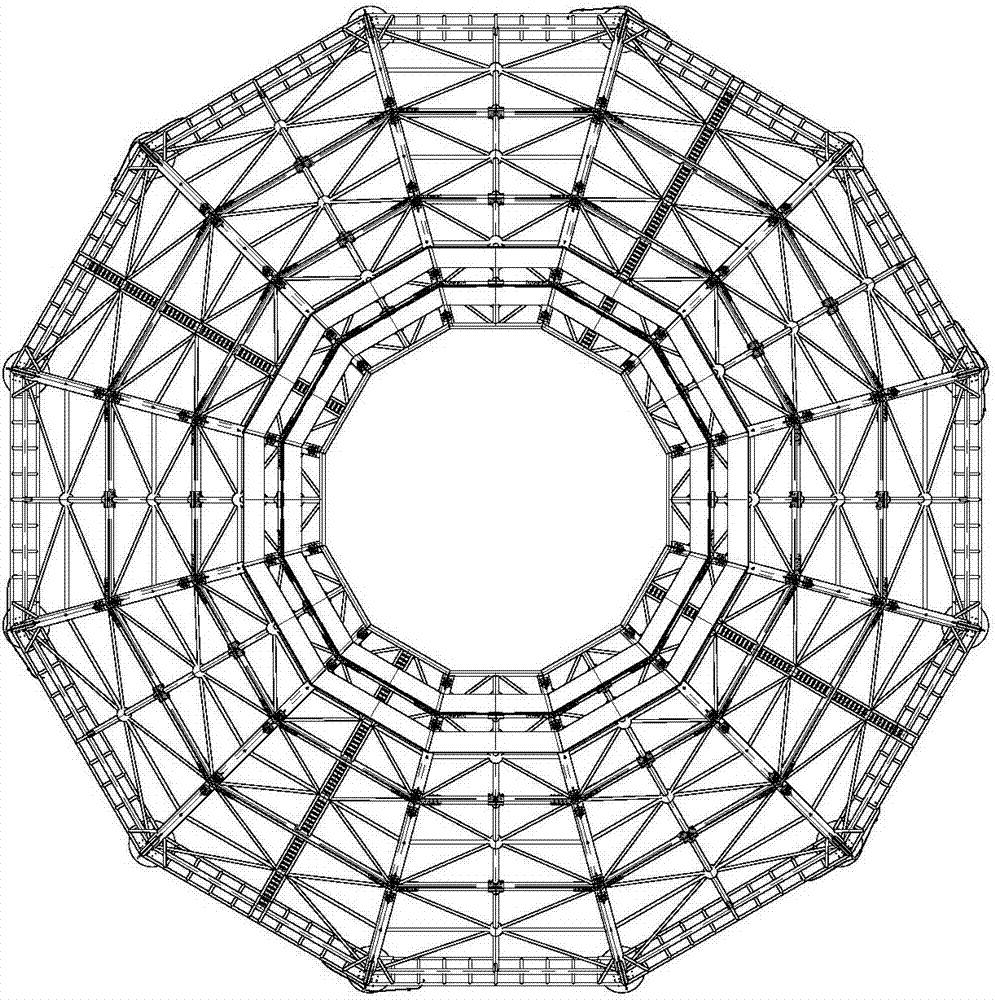

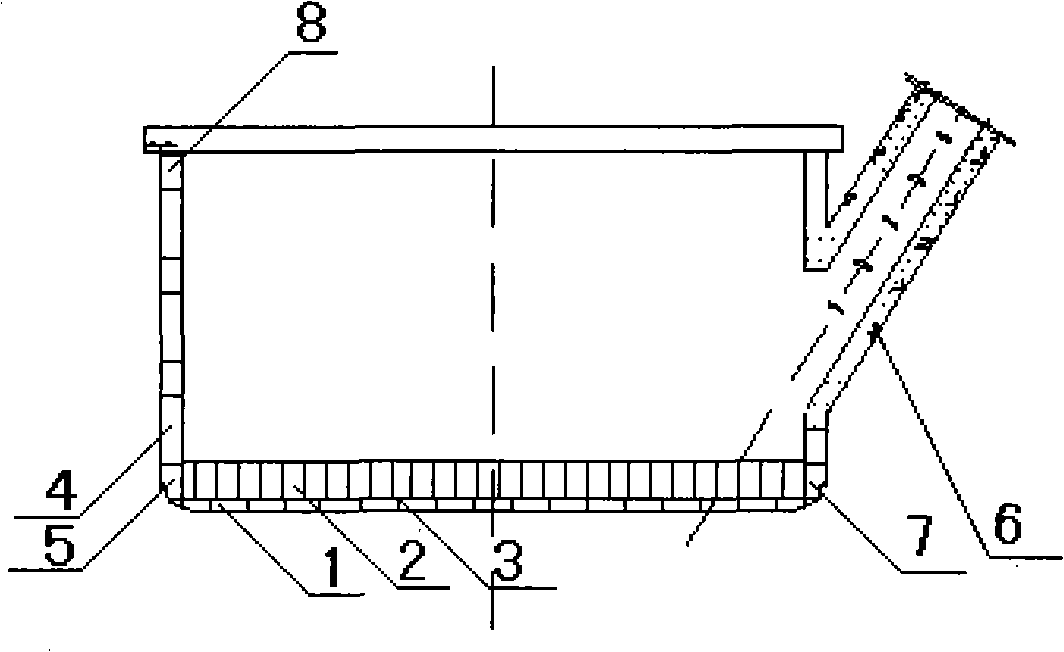

Splicing and lifting type sea-area cultivation net cage

ActiveCN107223619AReduce volumeLow costClimate change adaptationPisciculture and aquariaFisheryEdge structure

The invention provides a splicing and lifting type sea-area cultivation net cage. The splicing and lifting type sea-area cultivation net cage is characterized in that the whole outer frame of the cultivation net cage is of a cone frustum shape, and the bottom surface diameter of the outer frame of the cultivation net cage is larger than the top surface diameter of the outer frame of the cultivation net cage; the outer frame of the cultivation net cage is assembled by a plurality of trapezoid frames with narrow upper portions and wide lower portions, a net rack is mounted on the bottom surface of the cultivation net cage, adjacent trapezoid frames are mounted together through flanges and connectors, a float is arranged at the bottom of each trapezoid frame, each float is provided with an air inlet pipe and a draining outlet, and the floats are used for controlling the floating of the cultivation net cage; fish shelter anchors are hung to the cultivation net cage through anchor cables, and the middles of the anchor cables are connected with floater components suspended above through inhaul cables. Compared with a traditional deep-sea rigid net cage, the splicing and lifting type sea-area cultivation net cage has the advantages that the cone-frustum-shaped splicing structure of the net cage adopts a cone-frustum-shaped multi-edge structure, net cage strength is enhanced while modularized, standardized and miniaturized batch factory production is achieved, manufacturing precision is guaranteed, transportation is facilitated, and on-site assembling and net cage putting are achieved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

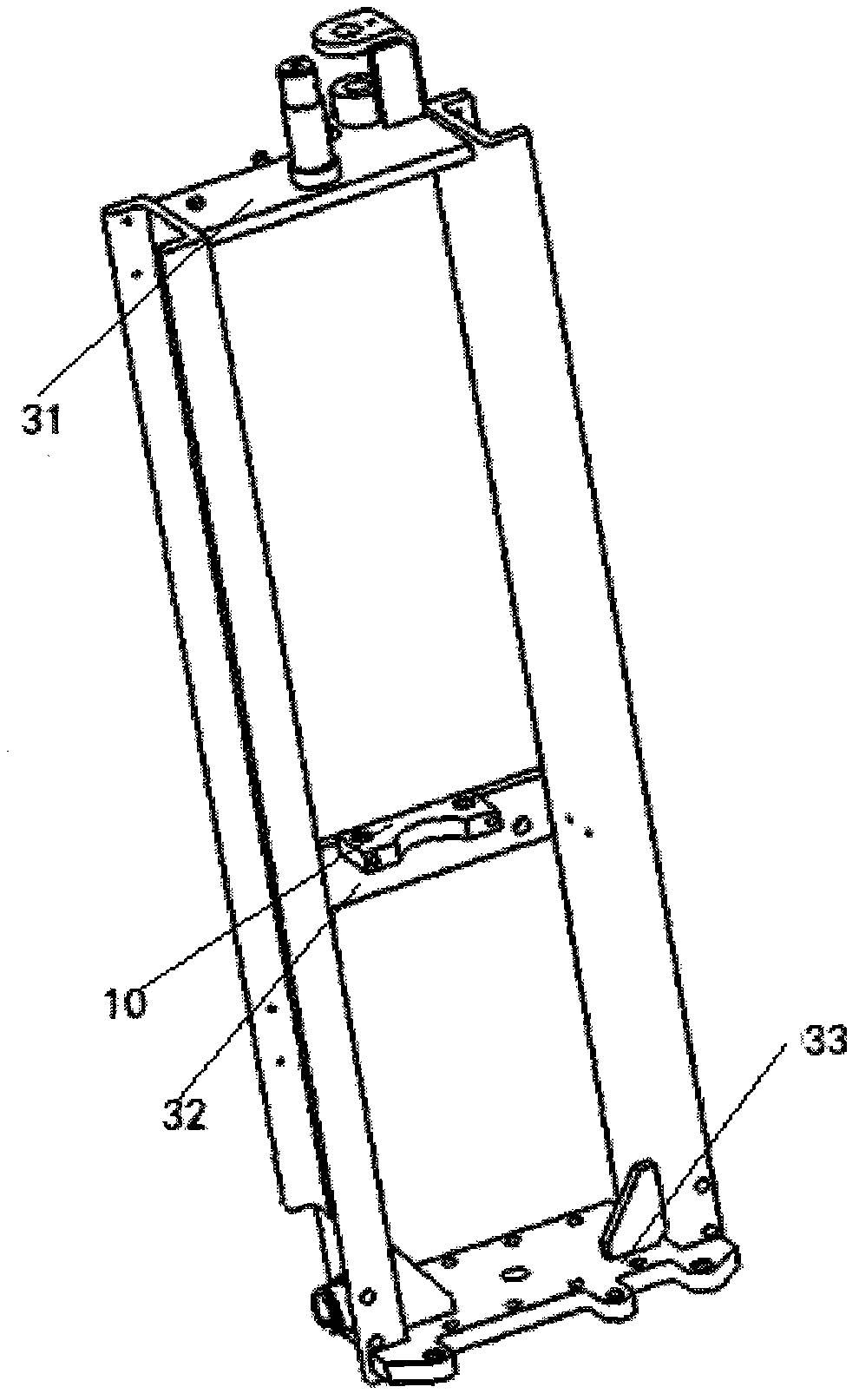

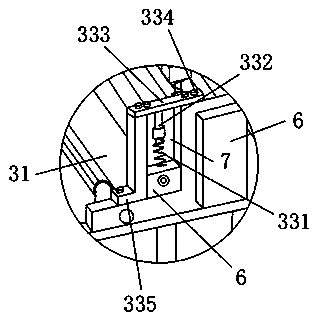

Vehicle body hydraulic turnover machine

InactiveCN104477834AReduce mistakesElevate evenlyLifting devicesFluid-pressure actuatorsSelf lockingElectric control

The invention relates to the technical field of vehicle body production or repair equipment, in particular to a vehicle body hydraulic turnover machine. The vehicle body hydraulic turnover machine comprises a rack, a main beam, a turnover clamping device, an electric control cabinet and a hydraulic station, wherein the main beam is of a welded box beam structure; the rack is of a door type box structure; a supporting lifting platform is arranged in the box body and moves up and down along guide rails on the two sides of the box body through a lifting oil cylinder; the supporting lifting platform is provided with a hydraulic swing rotating mechanism; the lifting oil cylinder and a swing oil cylinder are both provided with a synchronous valve and double locks; the turnover clamping device is a lead screw clamping device with self-locking capacity; clamping interlock control devices are arranged on the two sides of the lead screw clamping devices. When hydraulic pressure is adopted for transmission by the improved vehicle body hydraulic turnover machine, synchronous coordination is performed by using a hydraulic control system to reduce the error probably produced during operation between two groups of transmission mechanisms, so the relatively balanced, stable, safe and reliable operation of equipment lifting and turnover action is realized.

Owner:CRRC QISHUYAN CO LTD

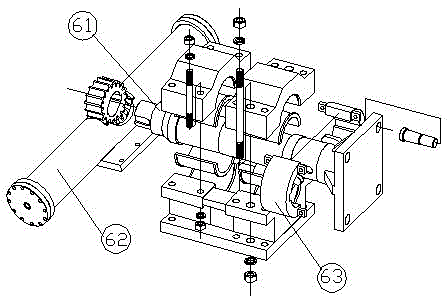

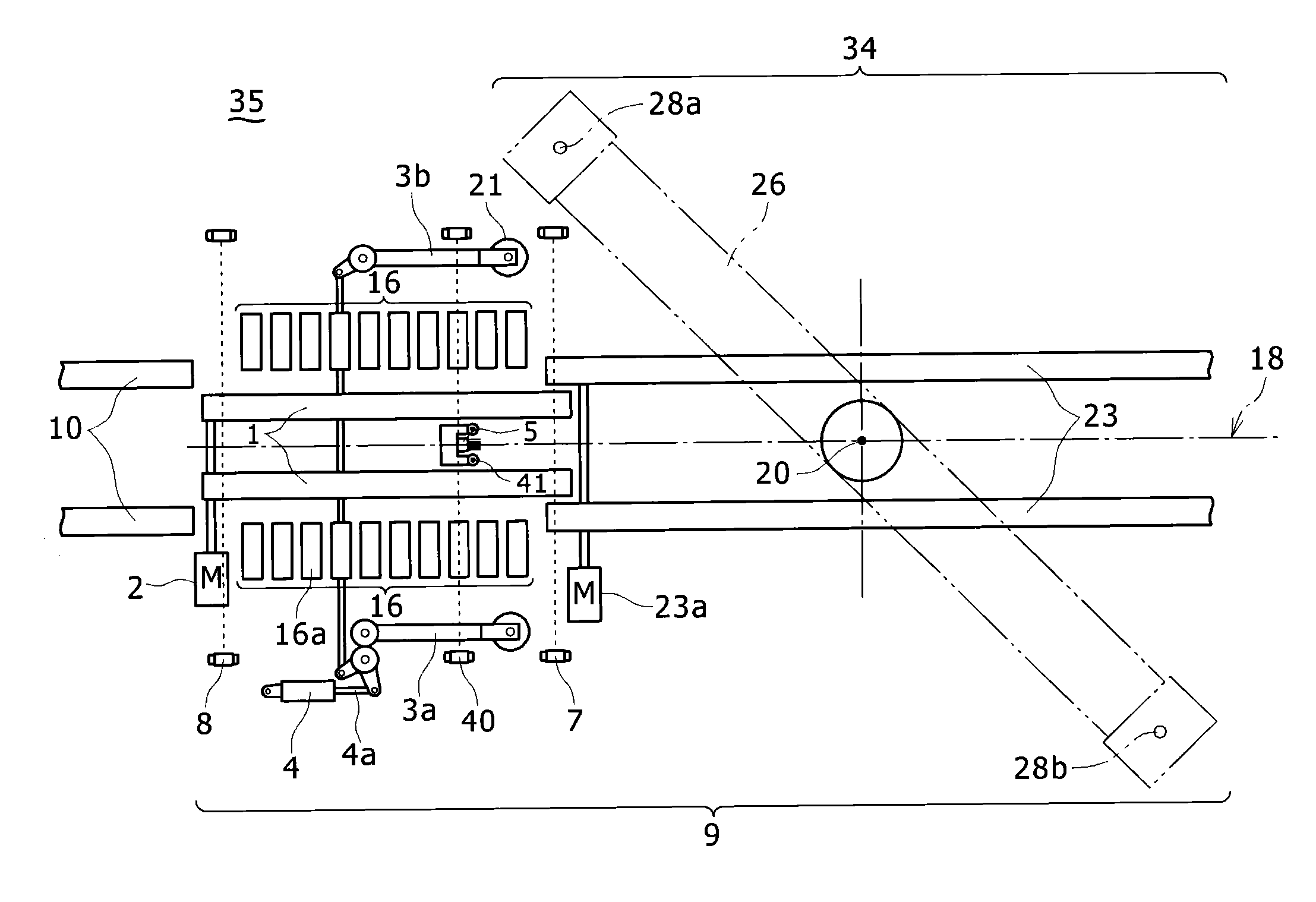

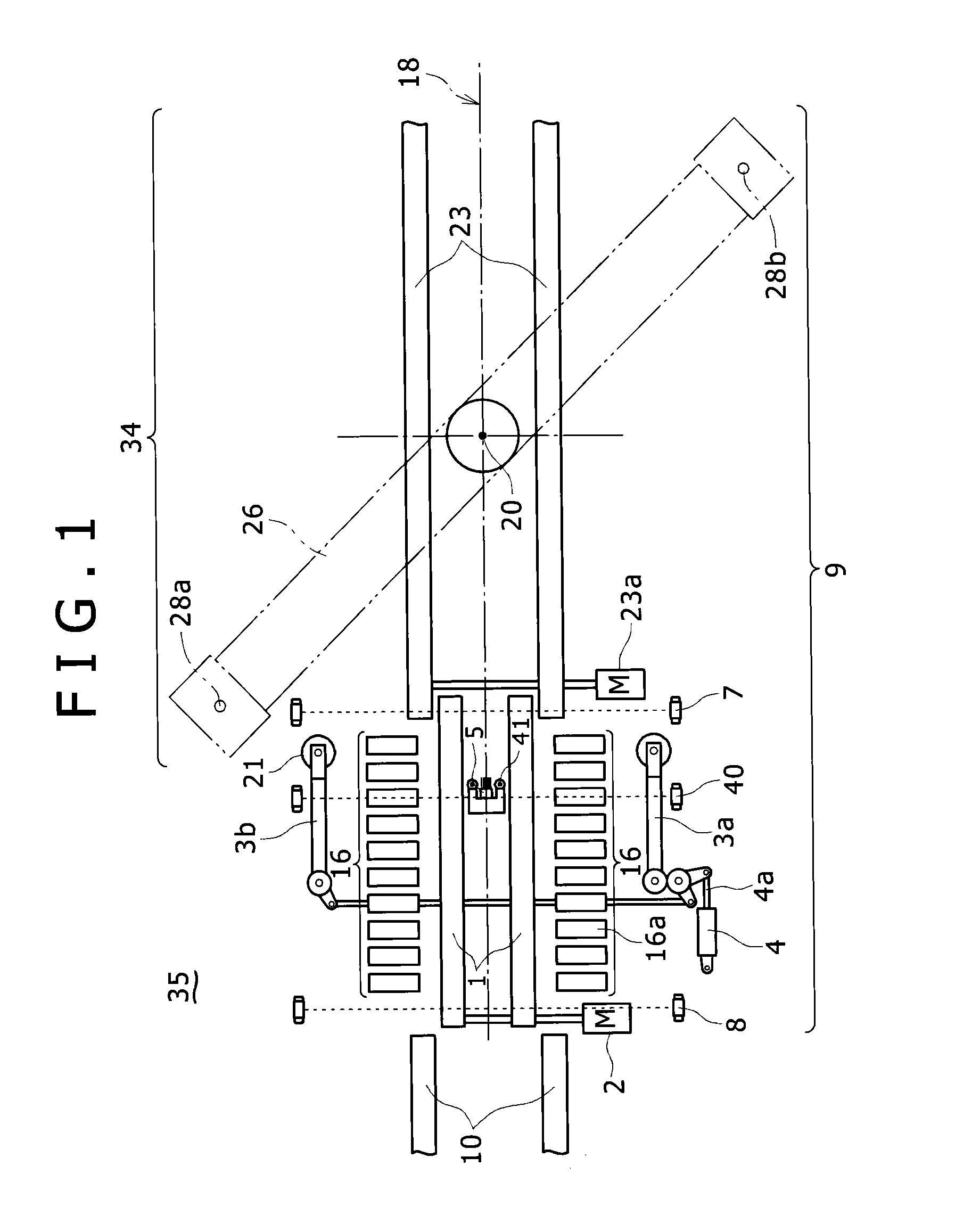

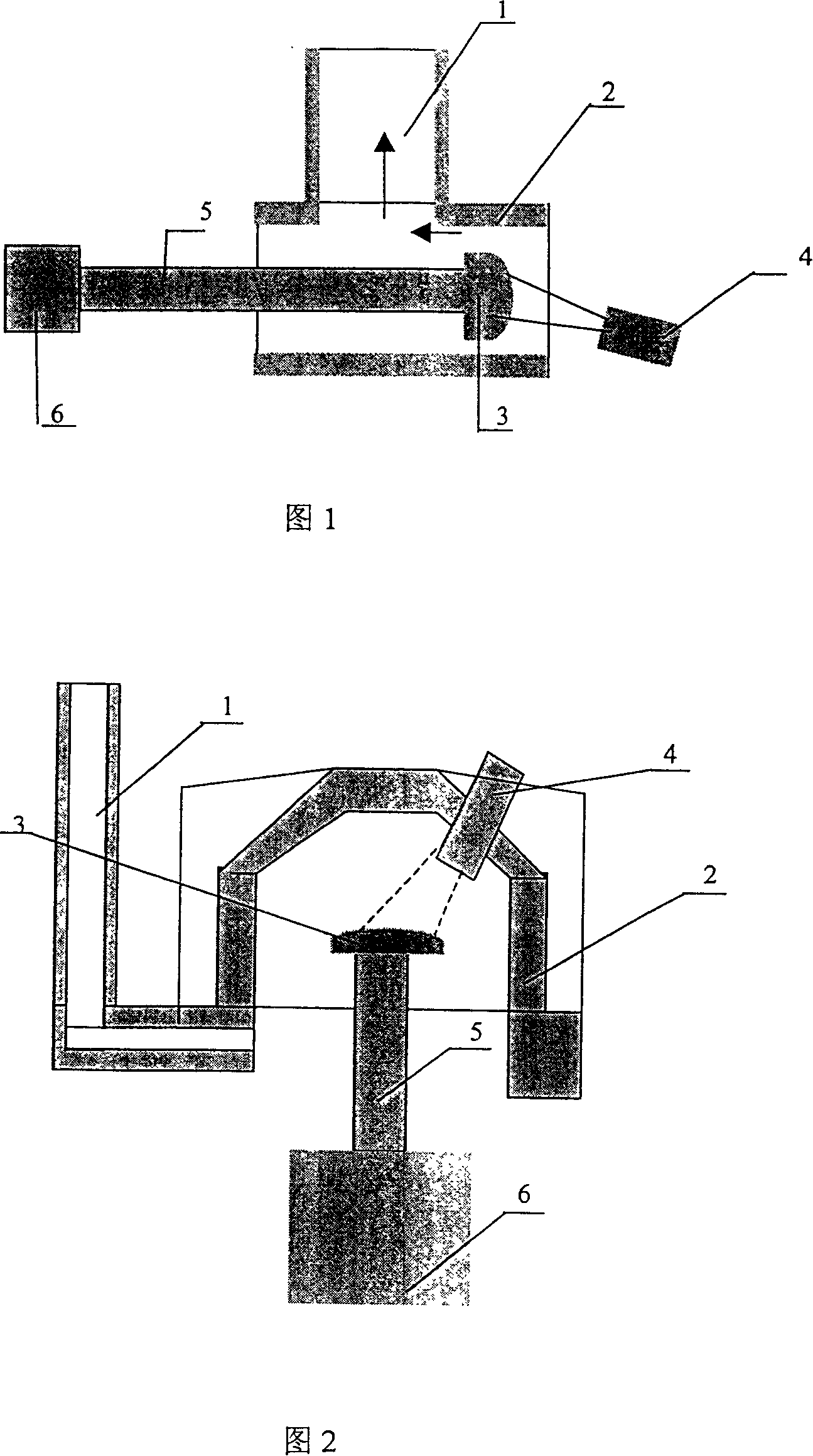

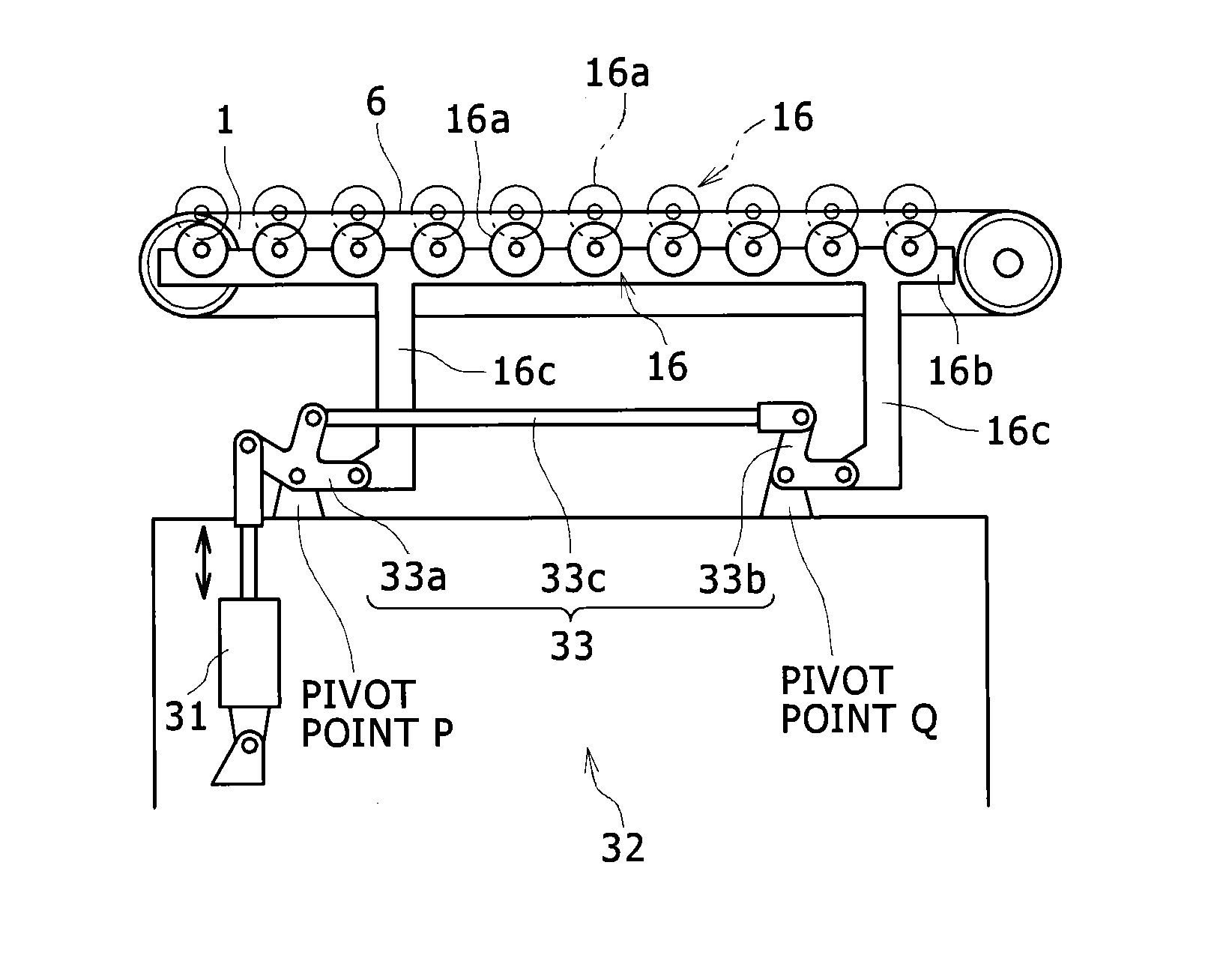

Tire conveyor for a tire testing machine

In order to stably transfer a tire between a roller portion and a conveyor for a tire testing machine, the tire conveyor of the present invention includes: a roller portion that is provided at a position without a conveying surface of the conveyor in the width direction perpendicular to the conveying direction of the conveyor in the conveying surface of the conveyor so as to be parallel to the conveying surface of the conveyor and is provided with a plurality of placement rollers forming a placement surface on which the tire is rotatably placed; and an elevation mechanism that includes an actuator and a link mechanism connecting the roller portion or the conveyor to the actuator in a supported state and moves the placement surface of the roller portion upward and downward relative to the conveying surface of the conveyor or moves the conveying surface of the conveyor upward and downward relative to the placement surface of the roller portion by the driving of the actuator.

Owner:KOBE STEEL LTD

Lifting device capable of adjusting water depth of swimming pool by using air pressure

InactiveCN107090991AImprove versatilityIncrease usageGymnasiumSwimming poolsMarine engineeringAtmospheric pressure

The invention is a lifting device for adjusting the water depth of a swimming pool by using air pressure, which includes a lifting device and a support mechanism arranged below the lifting device, and is characterized in that the lifting device adopts a bottom-opening floating warehouse with inlet and exhaust pipe ports Or the air bag; the air intake port of the bottom open floating storehouse or the air bag is connected with the inflatable device through the communication pipeline; Support the legs. The lifting device solves the problems of complex structure of the swimming pool lifting mechanism in the prior art, high manufacturing and installation costs, inconvenient use and maintenance, poor stability, uneven lifting and potential safety hazards, and has the advantages of simple and practical structure, low manufacturing and installation costs , easy to use and maintain, uniform lifting, stable support and other advantages.

Owner:郭学忠 +1

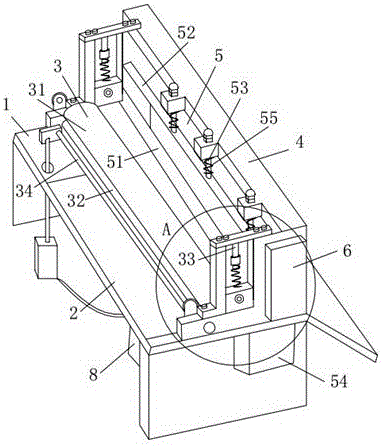

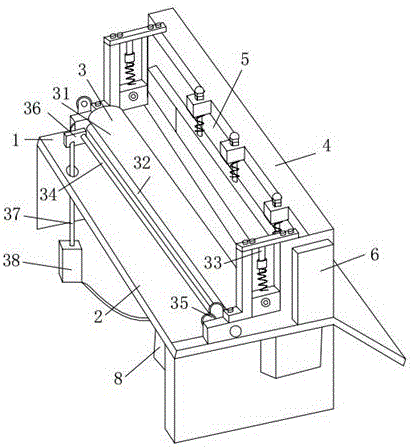

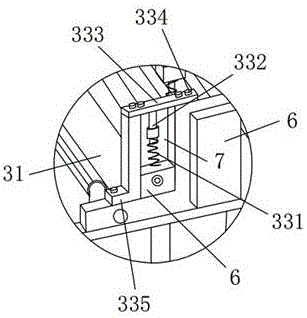

Rubber plastic numerical control hydraulic bar cutter

ActiveCN106313152AElevate evenlyImprove uniformityMetal working apparatusNumerical controlProgrammable logic controller

The invention discloses a rubber plastic numerical control hydraulic bar cutter, comprising a workbench, a conveyor belt, a pressing device, a cutter stand, a cutter mechanism and a PLC (programmable logic controller) control device; the conveyor belt is arranged on the workbench and used for conveying materials to be cut to the pressing device and the cutter mechanism; the cutter mechanism comprises a cutter, lifting cross beams, several fixing rods and a lifting oil cylinder; the cutter is fixed on the lifting cross beams, and the lifting oil cylinder is fixed on the lifting cross beam to push the lifting of the lifting cross beams; the lifting cross beams are fixed on the cutter stand through at least two lifting cross beams; every fixing rod is externally sleeved with one buffer spring, and every buffer spring is situated between the lifting cross beams and the cutter stand; the conveyor belt, the pressing device and the cutter mechanism are connected with the PLC control device. The numerical control bar cutter of the invention can stably cut rubber and plastic products; meanwhile, the rubber strips and plastic strips after cutting have uniform openings; thus the quality of the rubber and plastic products after cutting can be improved.

Owner:NANTONG HAILITE RUBBER & PLASTIC MACHINERY

System for loading elongated members such as tubes onto a conveyor for later processing

Owner:VIDIR SOLUTIONS INC

Inside lining building method for aluminium electrolysis two-man ladle

The invention relates to a technology to heavily repair the ladle lining of 5t in an aluminum electrolytic industry, in particular to an aluminum electrolytic ladle lining building method which can effectively improve the service life of the aluminum electrolytic ladle lining. The building method disclosed by the invention includes the following steps: 1) eliminating the inside of the ladle shell; 2) building the inner side of the cylinder part of the ladle shell alternatively according to wide type high aluminum special shape bricks and narrow type high aluminum special shape bricks; 3) building the bottom surface of the ladle shell by high aluminum bricks longitudinally and alternatively; 4) adopting high intensity bonding to bond the gaps of the special shape bricks at the cylinder and the bottom part of the ladle shell; 5) welding a hook nail first on the cover and the mouth parts of the ladle; 6) pouring the cover and the mouth of the ladle by high-aluminum low-cement fire-resistant castable material; 7) drying the ladle lining. The invention improves the service life of the ladle lining of 5t, meets the manufacture requirements, simultaneously saves a plurality of repairing cost and reduces the environment pollution. The invention is suitable for the building of the ladle lining in the aluminum electrolytic industry and the building of the linings of any other furnace type.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

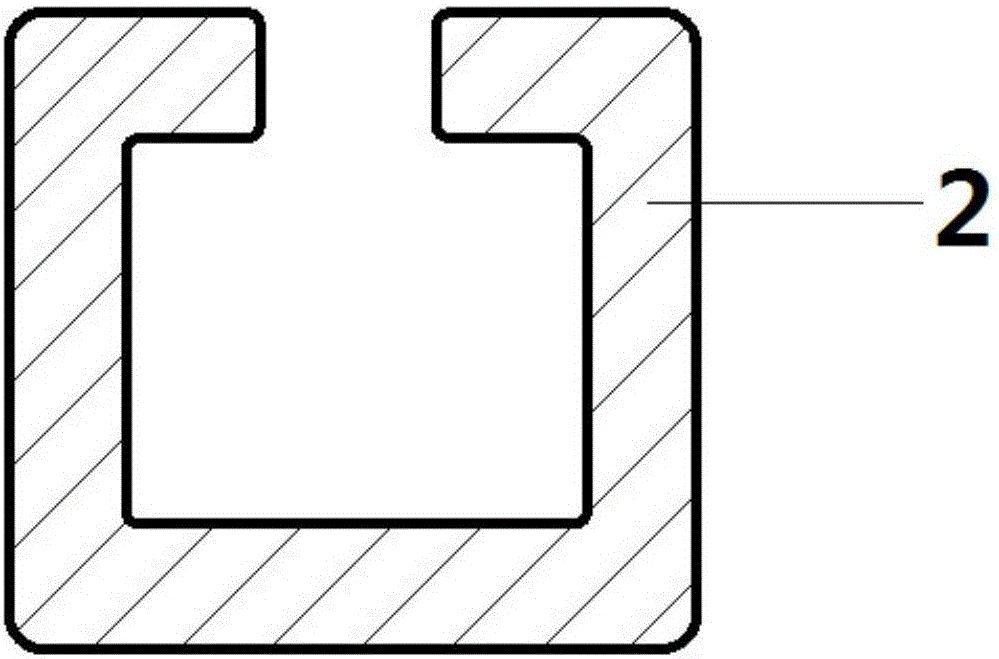

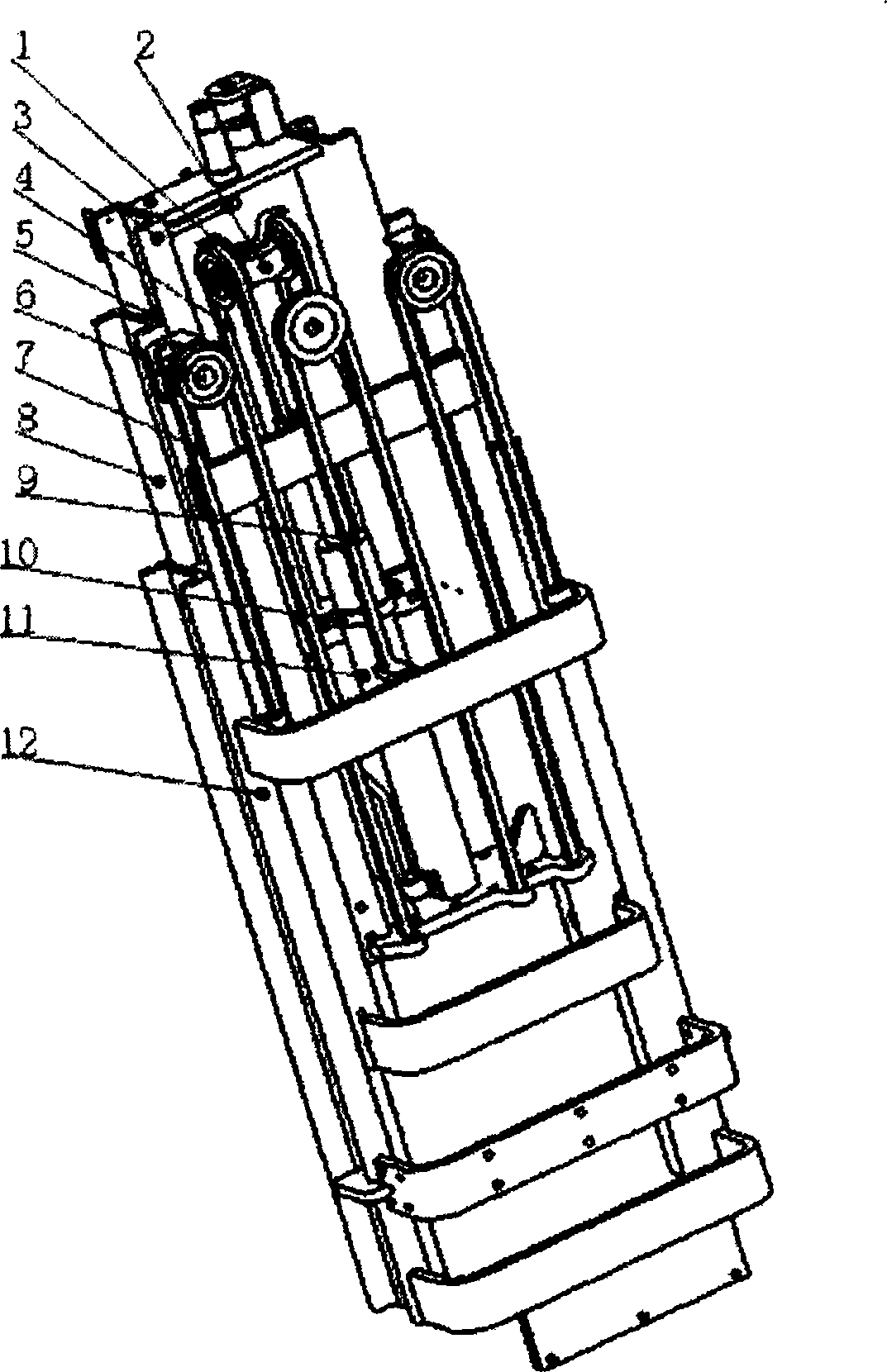

Hoisting device in three-section hoisting pattern

The invention discloses a hoisting device in a three-section hoisting pattern. The hoisting device comprises a hoisting inner rail assembly, a hoisting middle rail assembly, a hoisting outer rail assembly, a hoisting oil cylinder, a first hoisting chain, a second hoisting chain and a third hoisting chain, wherein both ends of the hoisting inner rail assembly, the hoisting middle rail assembly and the hoisting outer rail assembly are all in square-groove shape; the hoisting middle rail assembly moves up and down in the square groove of the hoisting inner rail assembly by use of a composite roller and the hoisting outer rail assembly moves up and down in the square groove of the hoisting middle rail assembly by use of a composite roller. The hoisting device in the three-section hoisting pattern has the advantages that the three-section hoisting pattern mechanism is adopted and three groups of associated guide rails work cooperatively, and therefore, the top space is saved, the transmission ratio of a chain wheel-chain transmission mechanism is accurate so that the rise-and-fall speeds of motion at different hoisting points are kept consistent, smooth and steady rise and fall and stress balance of a vehicle carrying plate are realized, the synchronism of rising of the vehicle carrying plate is good, and the synchronization mechanism is simple in structure, convenient to operate and control, high in reliability and low in requirement on the interior mounting space.

Owner:ANHUI LOCKU INTELLIGENT PARKING EQUIP

Assembling device for producing semiconductor light-emitting element

InactiveCN112701069AImprove work efficiencyRealize limitSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringMechanical engineering

The invention discloses an assembling device for producing semiconductor light-emitting element and particularly relates to the technical field of semiconductor production equipment; the assembling device comprises a bottom plate and supporting plates, the two sides of the top end of the bottom plate are fixedly connected with the supporting plates, the top ends of the supporting plates are provided with a top plate, and one side of each supporting plate is provided with a dust removal mechanism; and a limiting mechanism is arranged in the bottom plate. By arranging supporting blocks, a hydraulic air cylinder, a telescopic rod, a rubber pad and a push plate, after a semiconductor at the top end of the workbench is assembled, the hydraulic air cylinder at the top end of the supporting block is started, the hydraulic air cylinder drives the push plate through the telescopic rod to push out the semiconductor assembled at the top end of the workbench, and the rubber pad is bonded to one end of the push plate; the rubber pad has elasticity and can protect the semiconductor, the semiconductor is prevented from being damaged when the push plate pushes the semiconductor out of the top end of the workbench; the structure is simple, the assembled semiconductor can be pushed out conveniently, and the assembling efficiency of the device can be improved.

Owner:李丽蓉

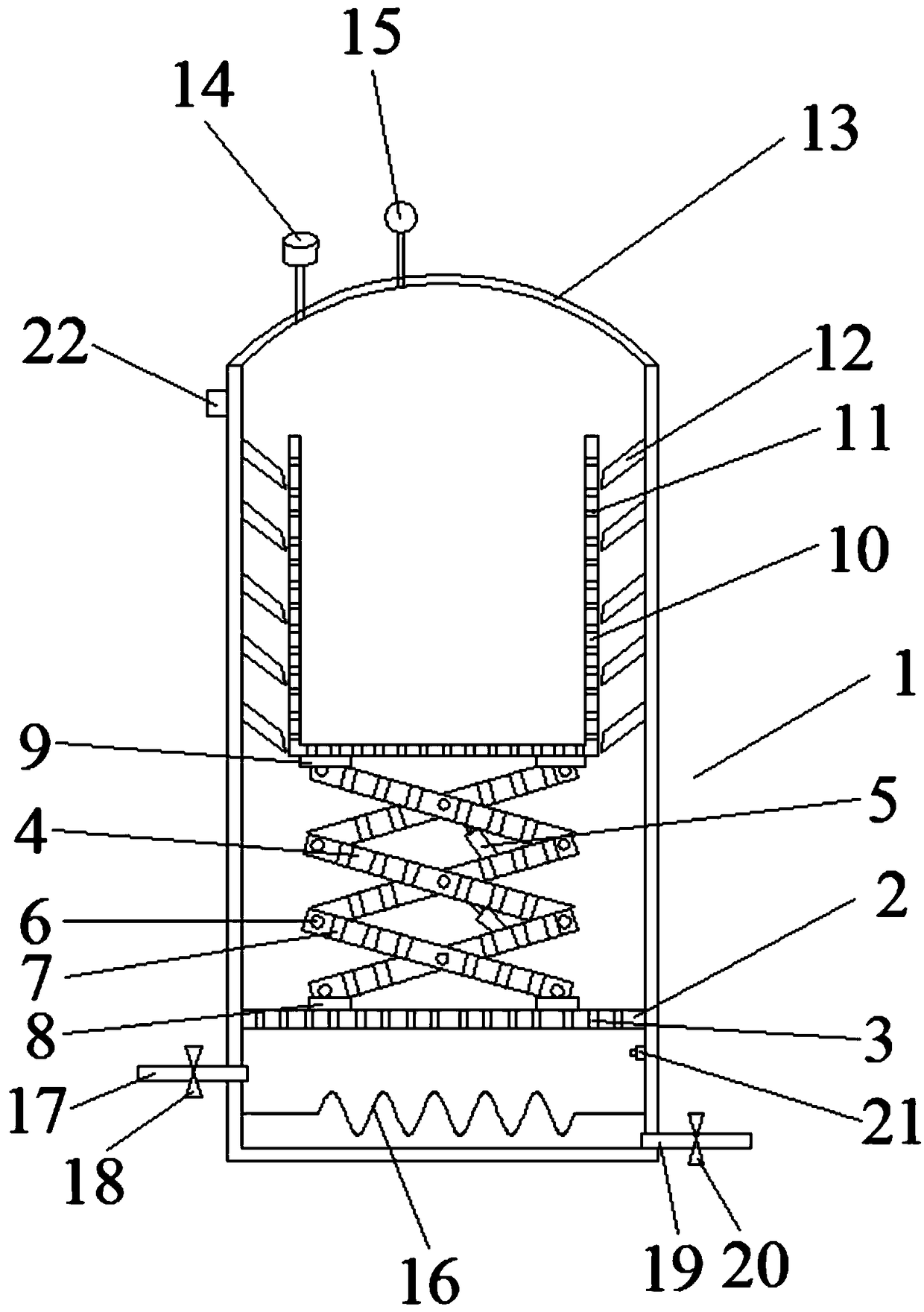

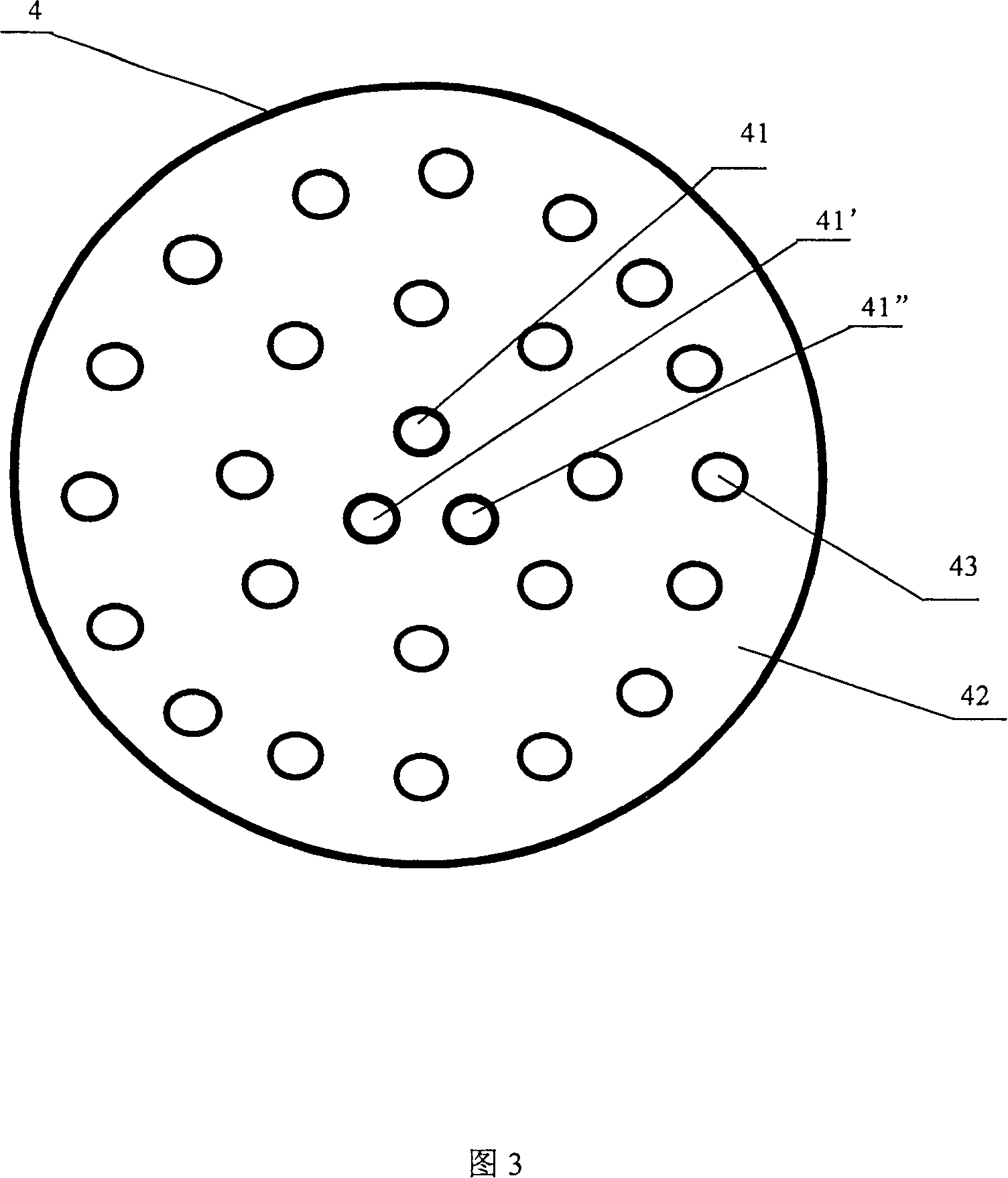

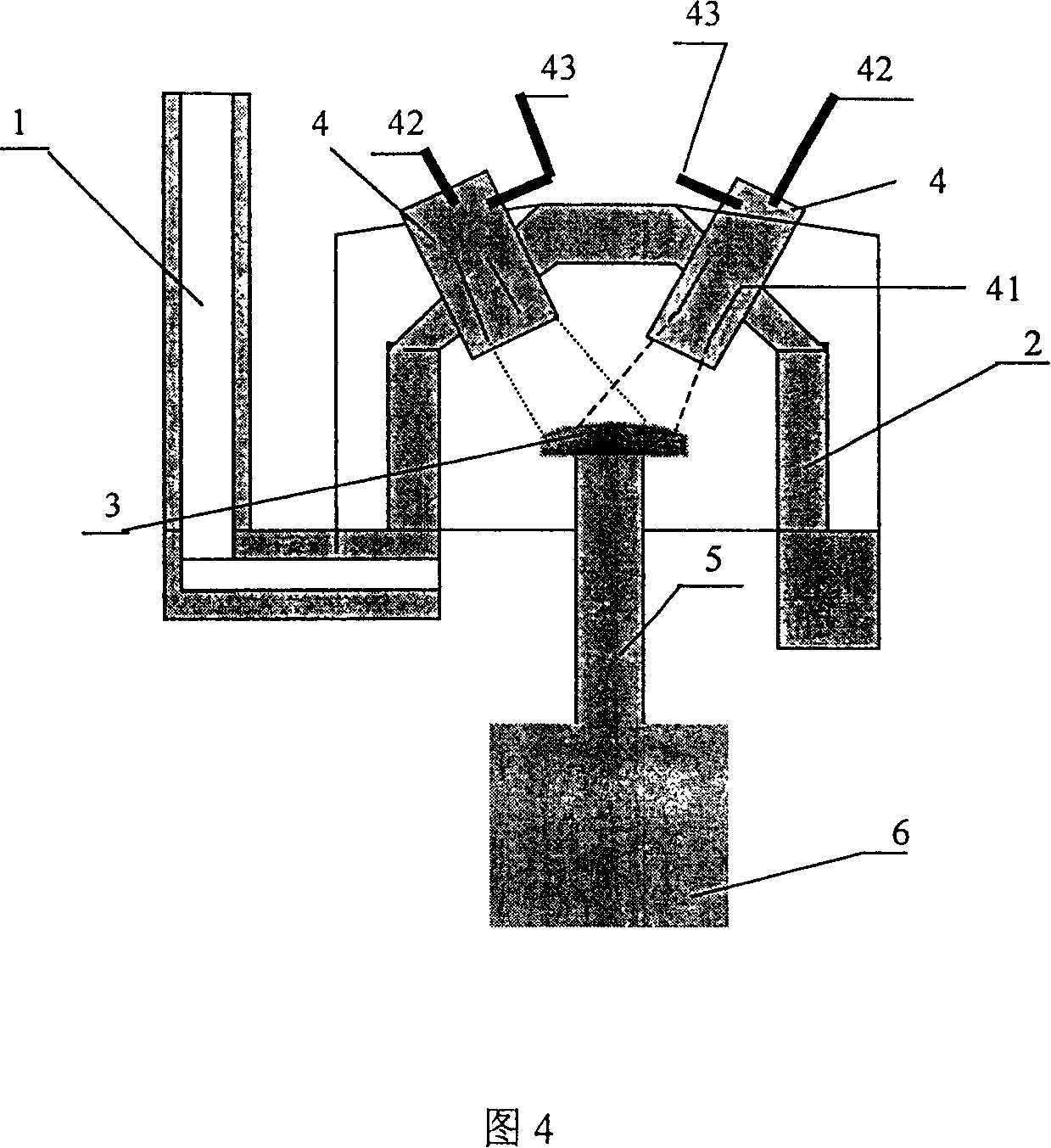

Novel medical sterilization apparatus

InactiveCN109078205APrevent bevelingImprove sterilization effectLavatory sanitoryHeatExhaust valveBiochemical engineering

The invention discloses a novel medical sterilization apparatus and belongs to the technical field of medical equipment. The novel medical sterilization apparatus comprises a tank; a supporting plateprovided with a plurality of first through holes is arranged in the middle lower portion of the tank and divides the tank into an upper sterilization chamber and a lower steam generator chamber; a lifting drive mechanism is arranged on the upper side of the supporting plate, a sterilization basket is arranged on the lifting drive mechanism, and the body of the sterilization basket is provided witha plurality of third through holes; a cover for opening the tank is arranged at the top of the tank and is provided with a safety valve and an exhaust valve. With the arrangement of the steam generator chamber, the lifting drive mechanism and the sterilization basket, sterilized vessels can be picked conveniently, and work staff is protected against scalds; since the sterilization basket has suitable height, taking and placing of the vessels are facilitated, breakage of the vessels is avoided, and thus, time is saved for the work staff and work efficiency is improved.

Owner:自贡德西玛医疗设备有限公司

Process for synthesizing guartz glass by vertical silicon tetrachloride vapor deposition

InactiveCN1323043CImprove deposition environmentUniform depositionGlass shaping apparatusCombustorIngot

The present invention discloses the vertical silicon tetrachloride vapor deposition process of synthesizing quartz glass. One vertical deposition furnace is designed, which includes chimney, closed furnace body, burner in the top of the furnace body, base rod standing inside the furnace body, deposition plane on the base rod and opposite to the burner, and lathe clamped to the lower part of the base rod. There may be several burners with several material feeding tubes each. The present invention makes it possible to produce quartz glass ingot with weight of 30-50 Kg and diameter of 250-500 mm in the deposition rate of 200-500 g / hr, 1-5 times higher than that of horizontal deposition furnace.

Owner:CHINA BUILDING MATERIALS ACAD

Tire conveyor for a tire testing machine

A tire conveyor includes a roller portion provided at a position, in the width direction perpendicular to the conveying direction, without a conveying surface. The roller portion extends parallel to the conveying surface and is provided with a plurality of placement rollers forming a placement surface on which the tire is rotatably placed. An elevation mechanism includes a single actuator and a link mechanism connecting the roller portion or the conveyor to the actuator in a supported state and moves the placement surface of the roller portion upward and downward relative to the conveying surface by driving the actuator.

Owner:KOBE STEEL LTD

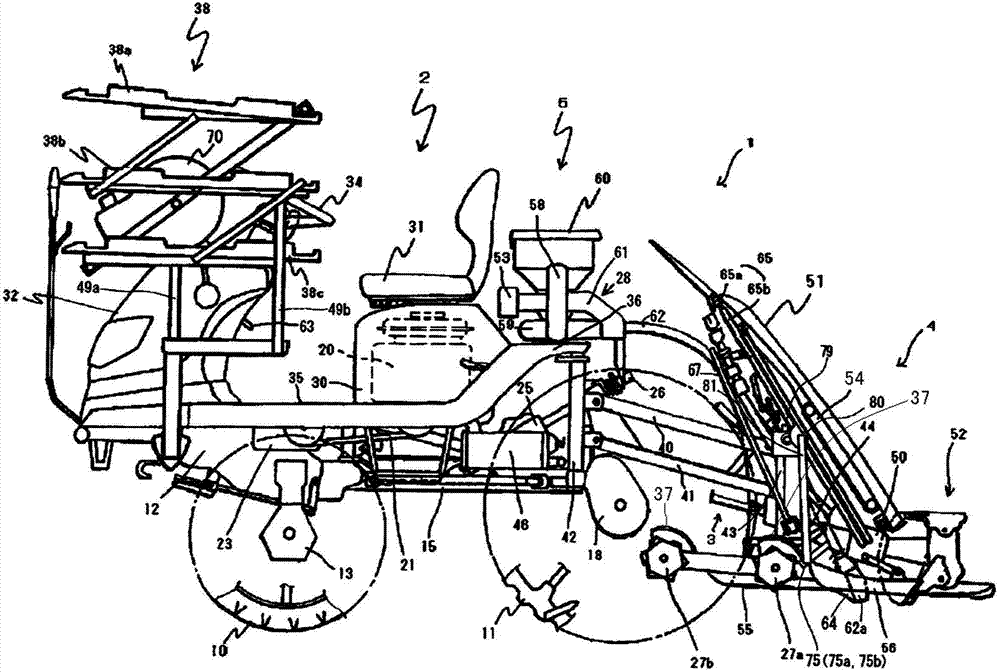

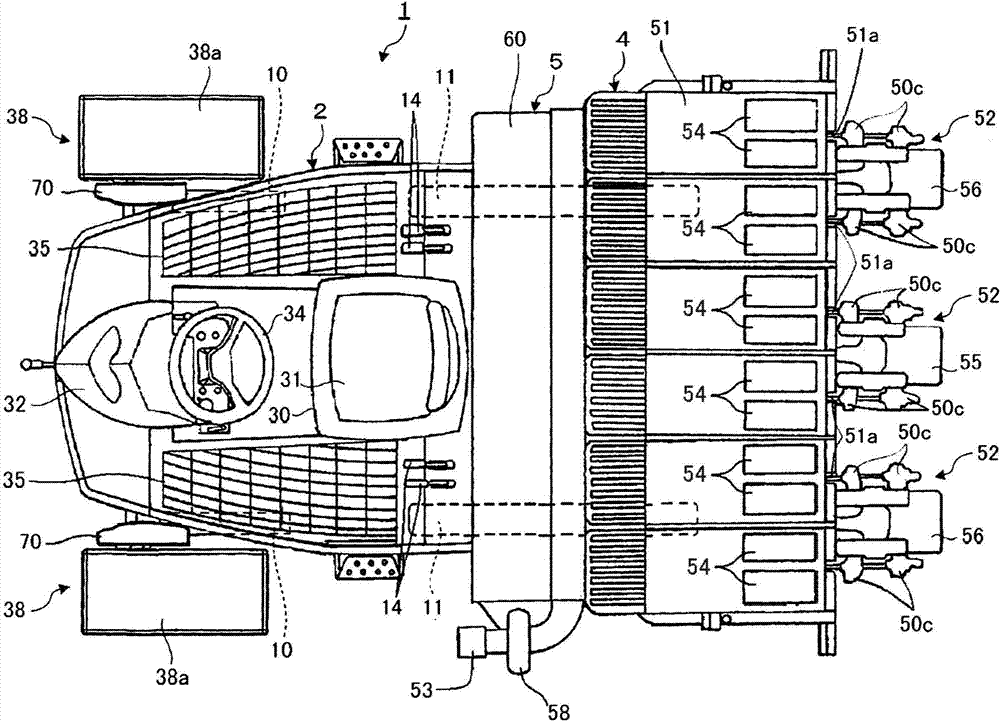

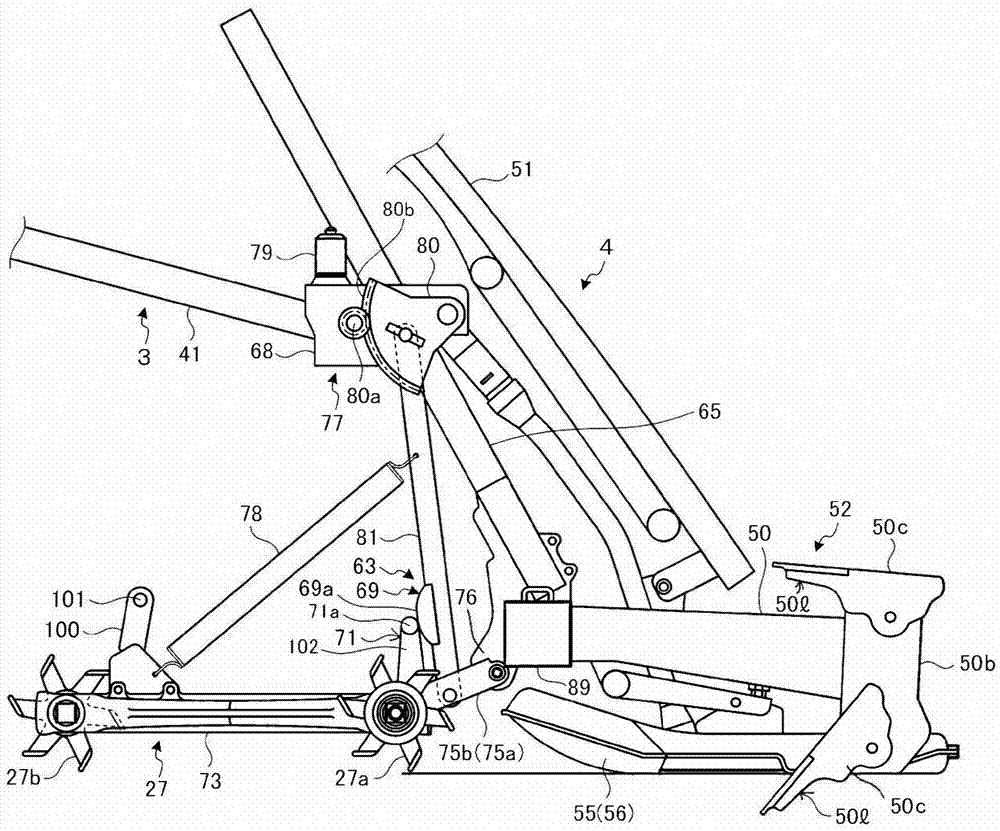

Seedling transplanter

ActiveCN104206082AImproving implant accuracyImprove soil preparationSpadesPloughsEngineeringActuator

The invention provides a seeding transplanter capable of preventing the damage of a soil preparation device and reliably smoothing the surface of a field. The rear part of a walking vehicle body is provided with a seedling planting portion (4) elevating by means of an elevating connecting mechanism (3), the seeding transplanter of the soil preparation device (27) for smoothing the surface of the field is provided with a soil preparation support bracket (76) for supporting the soil preparation device (27), the soil preparation device is configured to a position closer to the front side of the transplanter body than the soil preparation support bracket (76), a first soil preparation rotating arm (75a) for connecting the left side and the right side of the soil preparation device and the soil preparation supporting bracket is provided, a second soil preparation rotating arm (75b) is arranged between the left side and the right side of the first soil preparation rotating arm, the second soil preparation rotating arm is provided with a soil preparation elevating device (77) for elevating the soil preparation device, the soil preparation device is formed by an elevating actuator (79) and an elevating part (80) configured at the seedling planting portion (4), and the elevating part (80) and the second soil preparation rotating arm (75b) is connected via a suspension arm (81).

Owner:ISEKI & CO LTD

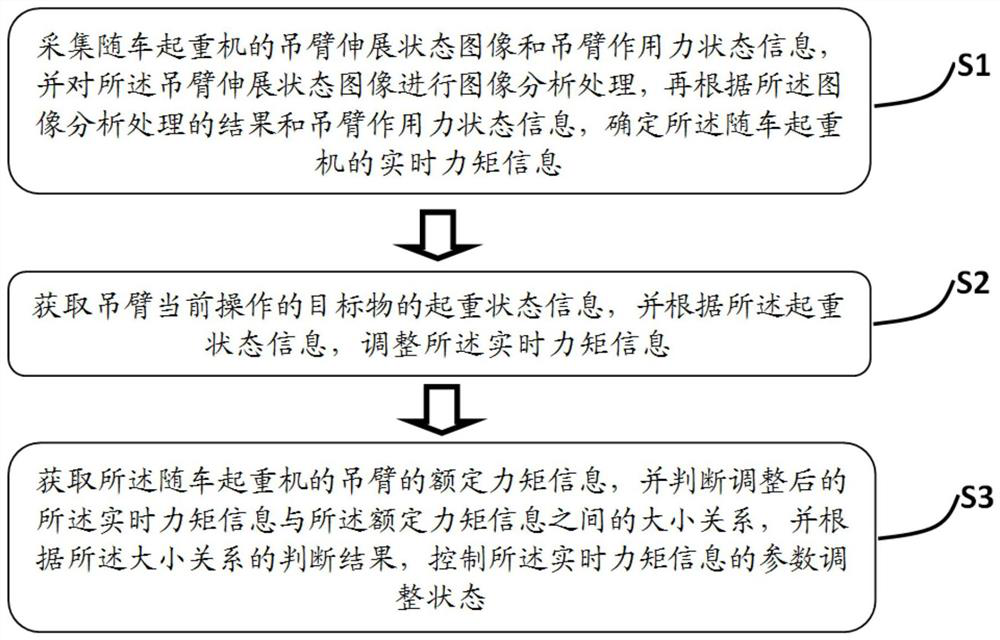

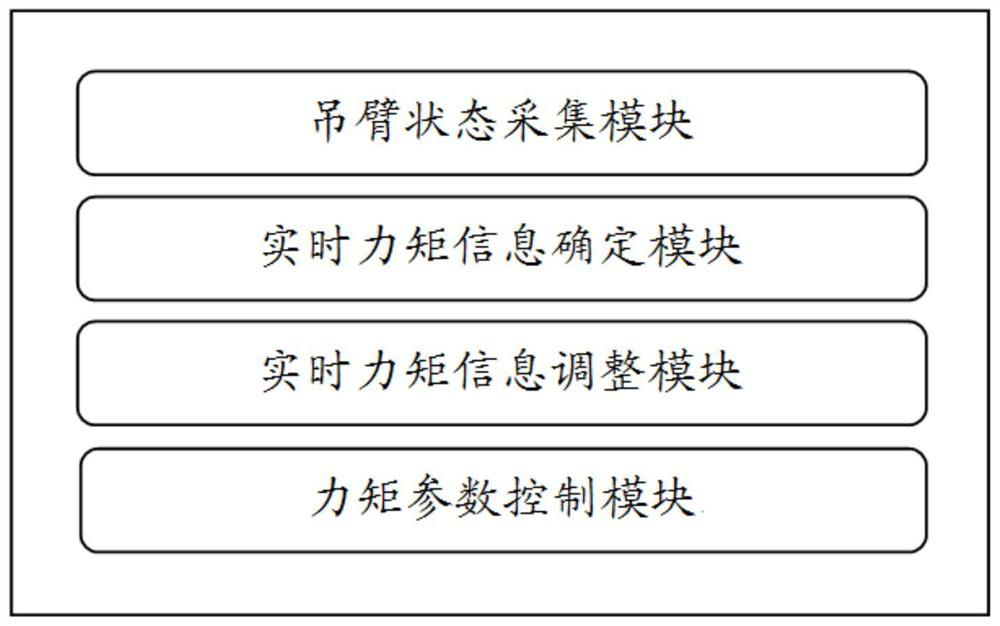

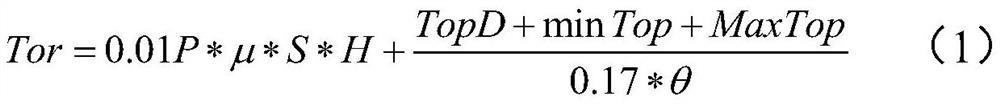

Moment control system and method of lorry-mounted crane

InactiveCN112265909AControl adjustment statusElevate evenlyLoad-engaging elementsControl systemControl engineering

The invention provides a moment control system and method for a lorry-mounted crane. According to the method, the real-time moment information of a lazy arm is determined through obtaining the stretching state and the acting force state of the lazy arm of the lorry-mounted crane, and the hoisting state information of a target object and the rated moment information of the lazy arm serve as the basis; and the actual magnitude of the real-time moment or different parameters of the real-time moment are adjusted so that the target object can be lifted uniformly and stably in the lifting operationprocess of the target object, and the lifting efficiency and the lifting stability of the target object are improved.

Owner:湖南鼎荣智能装备有限公司

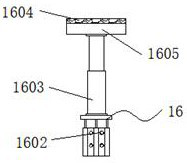

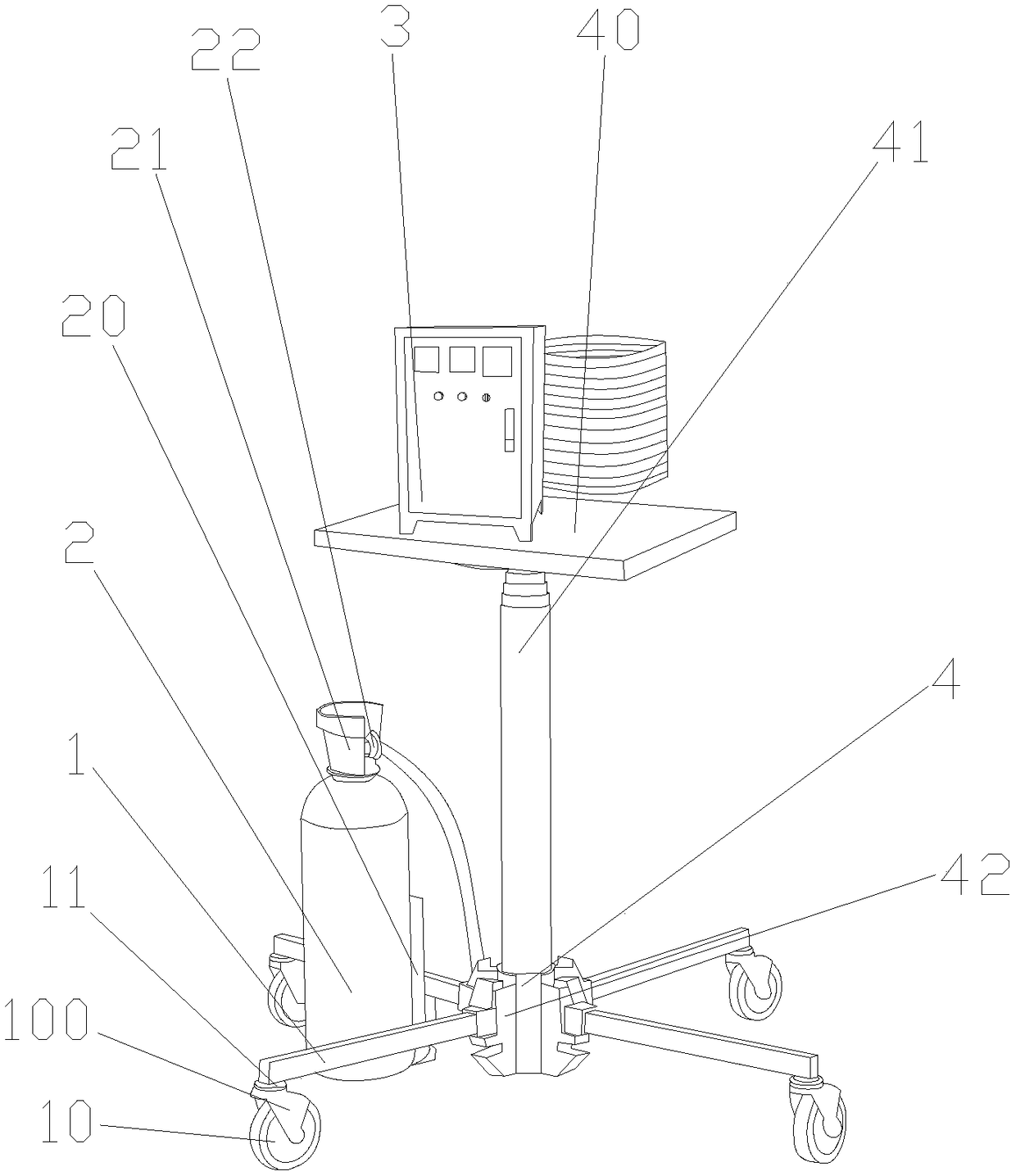

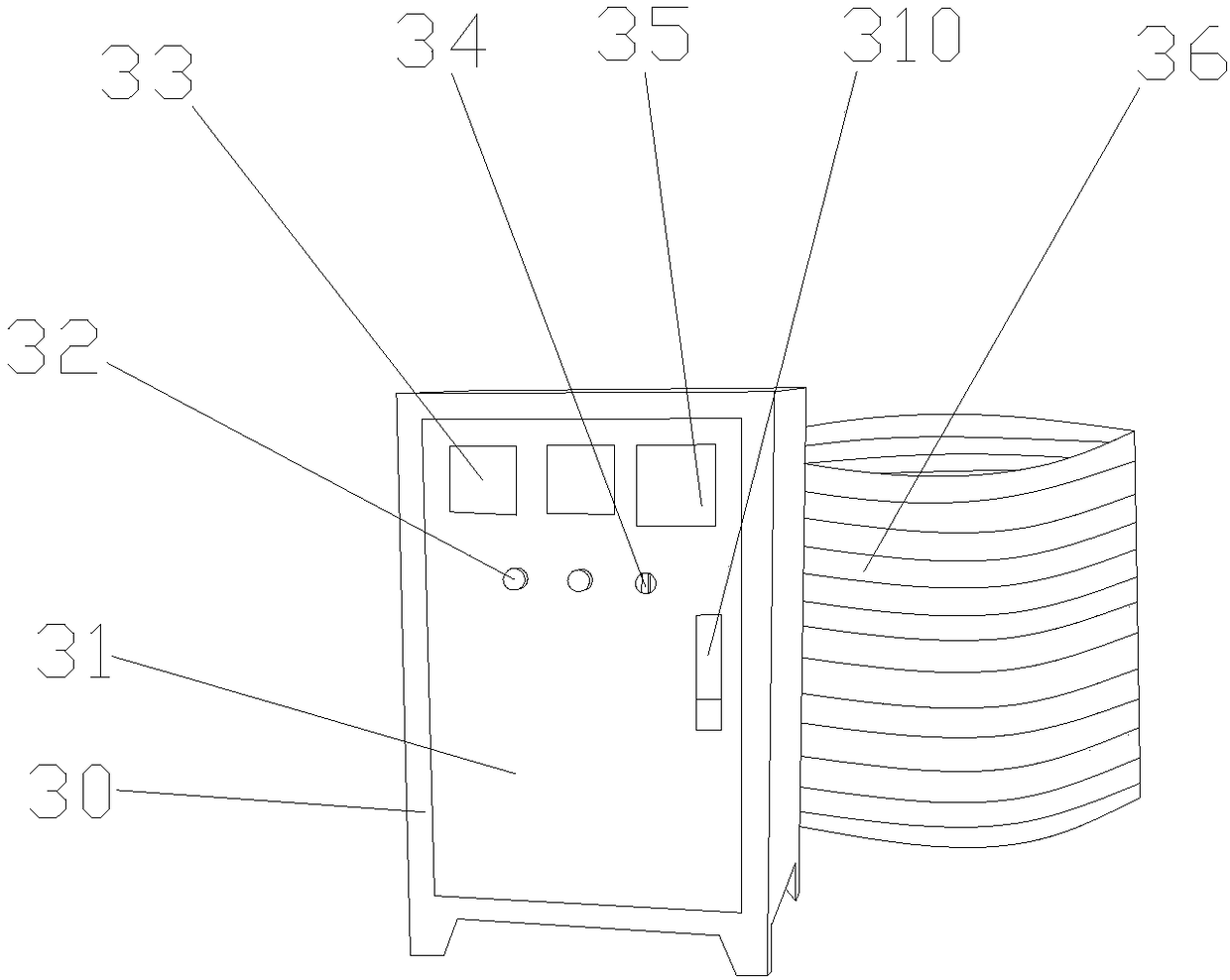

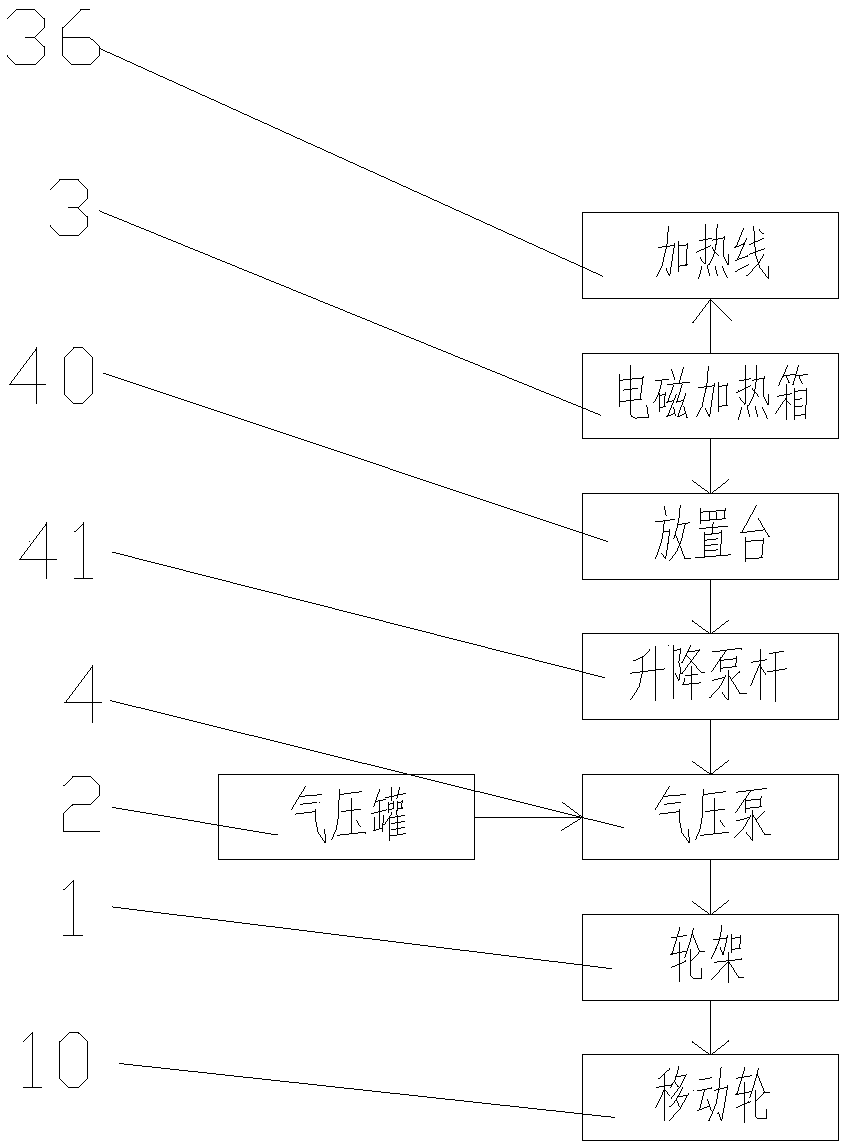

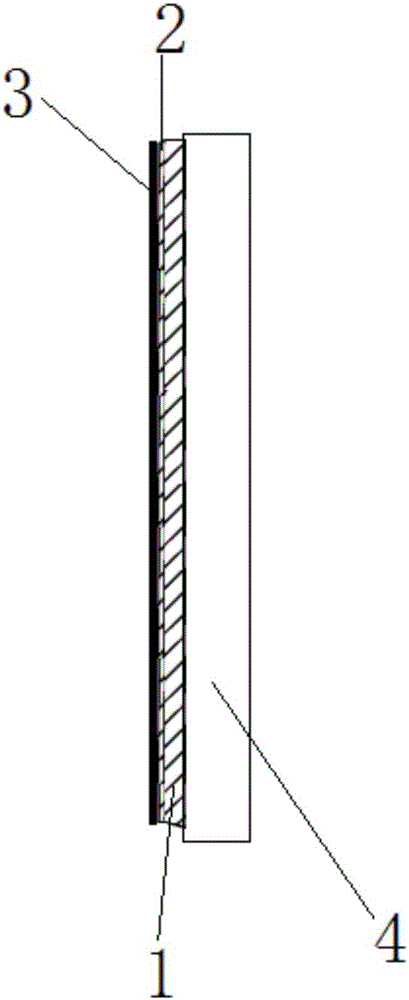

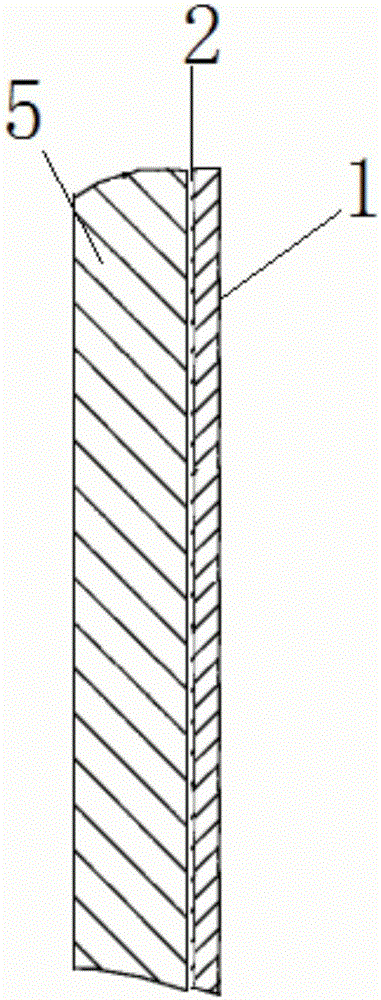

Preheating device for coking tower

InactiveCN108148613AConvenience and uniform preheatingWarm up evenlyThermal non-catalytic crackingCoking carbonaceous materialsEngineeringElectromagnetic heating

The invention provides a preheating device for a coking tower. The preheating device structurally comprises a wheel carrier, an air pressure tank, an electromagnetic heating box and an air pressure pump, wherein the wheel carrier is movably connected with the air pressure pump; the air pressure tank is connected with the air pressure pump; the electromagnetic heating box is arranged on the air pressure pump; the wheel carrier comprises movable wheels and rotary tables; the movable wheels are movably connected with the wheel carrier by the rotary tables; the air pressure tank comprises a controller, a retainer ring and an interface. According to the preheating device for the coking tower, lifting and uniform heating of equipment are realized by arranging the wheel carrier, the air pressuretank, the electromagnetic heating box, the air pressure pump, heating wires and a lifting pump rod; the equipment is provided with the air pressure tank for supplying pressure to the air pressure pump, and the lifting pump rod is controlled to lift the electromagnetic heating box, so that the electromagnetic heating box can switch at different heights for work; the electromagnetic heating box is provided with the electromagnetic heating wires for uniformly heating the coking tower; in addition, the equipment is also provided with the wheel carrier for moving the equipment more conveniently andfacilitating uniform heating of the coking tower.

Owner:天津藤井科技有限公司

Nano heat-insulation paint, preparation method of heat-insulation coating and heat-insulation glass

InactiveCN106280956AEffective isolationGood light transmissionPolyurea/polyurethane coatingsEpoxy resin coatingsNano siliconUltraviolet lights

The invention provides nano heat-insulation paint, a preparation method of a heat-insulation coating and heat-insulation glass. The nano heat-insulation paint is prepared from, by weight, 6.7-30% of nano powder, 55-78% of high-polymer resin and 15-20.3% of paint auxiliaries. The nano powder comprises, by weight, 33.5-70% of nano silicon nitride and 30-66.5% of silver. The preparation method of the heat-insulation coating includes the step that on the basis of a processing technology of the nano heat-insulation paint, after a curing agent is added and evenly stirred, the mixture is quickly coated on a substrate, heating and curing are conducted, and the nano heat-insulation coating is obtained. The heat-insulation glass comprises a glass substrate and the nano heat-insulation coating attached to the glass substrate. Photo-thermal radiometry and ultraviolet light can be effectively isolated. Compared with traditional heat-insulation glass, the heat insulation performance of the glass can be obviously improved, the application range is wide, the hardness and flexibility of the coating can be adjusted according to the ratio of the paint, and operation is convenient.

Owner:斯卡特(北京)铝业集团有限公司

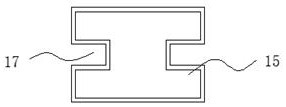

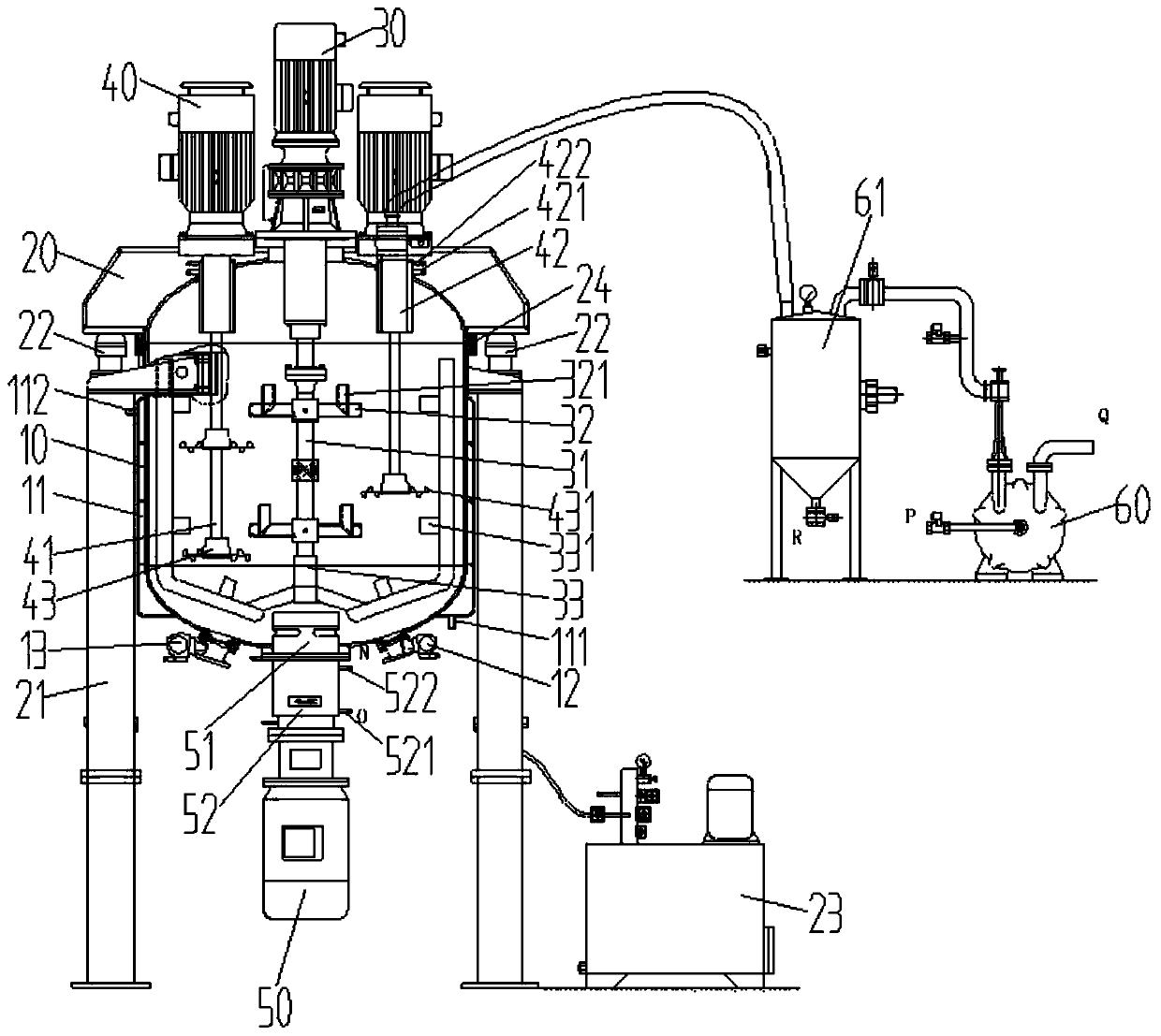

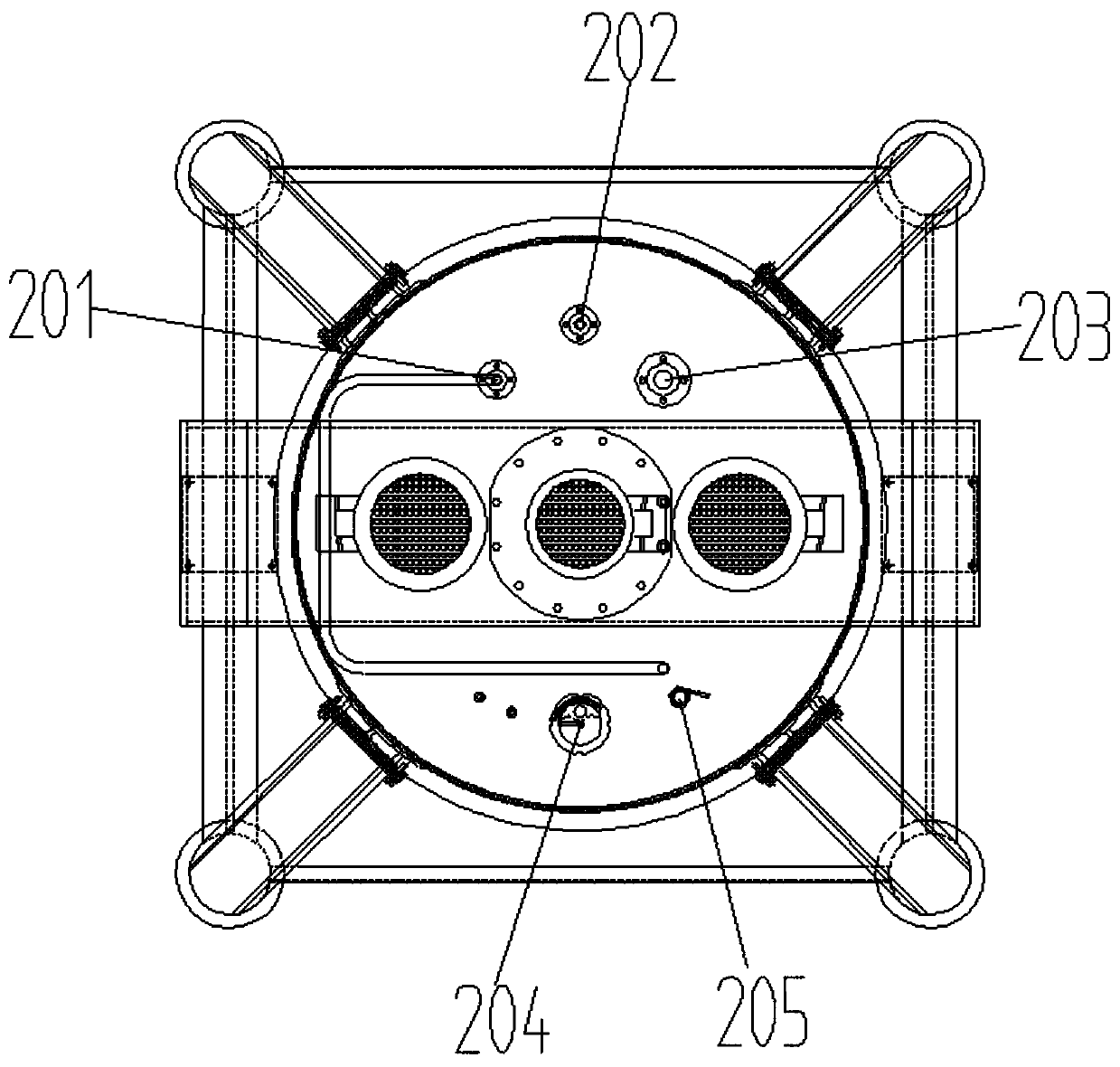

Double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine

PendingCN109745899AVersatileUniform emulsification reactionRotary stirring mixersTransportation and packagingHydraulic cylinderVacuum pumping

The invention provides a double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine, the double-oil-cylinder double-high-speed dispersing bottom homogenizer vacuum emulsifying paste making machine comprises a pot body and a pot cover arranged at the upper part of the pot body, hydraulic cylinders are arranged on the left side and the right side of the pot cover, the hydraulic cylinder is fixedly arranged on a cross beam connected with two uprights; a discharge valve and a feed valve are arranged at the bottom part of the pot body; a stirring mechanism is arranged on the pot cover and is located on the center position of the pot cover, dispersing mechanisms are respectively arranged on the left side and the right side of the stirring mechanism; a homogenizing mechanism is arranged on the middle position of the bottom part of the pot body and comprises a third motor, a drive end of the third motor is in transmission connection with a homogenizer, the homogenizer is arranged in the pot body; and a vacuum pumping system is connected on the pot cover, and comprises a vacuum pump. The double-oil-cylinder double-high-speed dispersing bottomhomogenizer vacuum emulsifying paste making machine has rich functions, so that the emulsifying reaction of a paste body is evener, less bubble is produced, the particle is thinner, and the paste body is more transparent and smoother.

Owner:江阴绿源环保科技有限公司

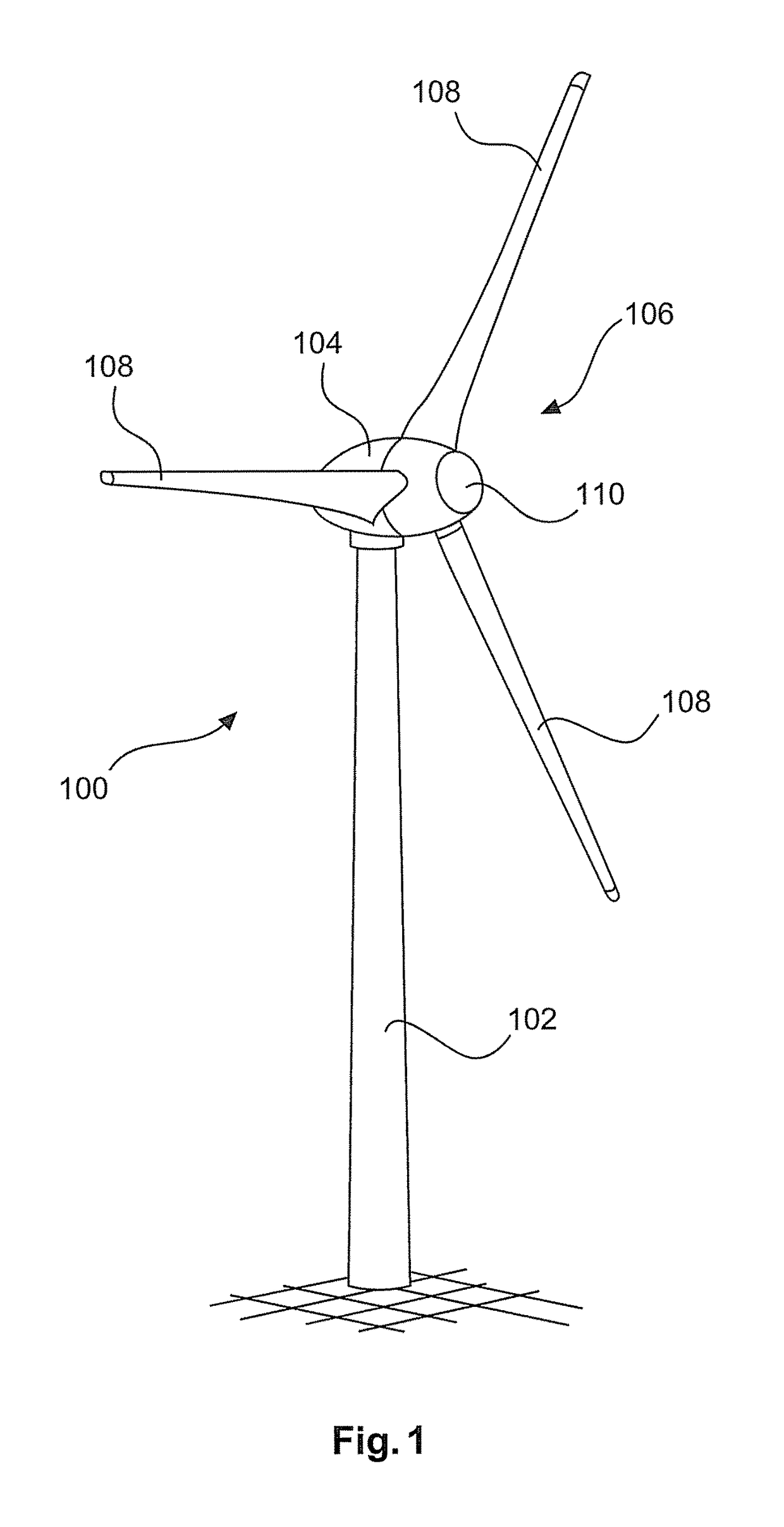

Forming process for hot forming a steel sheet of a rotor blade to be produced for a wind energy plant

ActiveUS9925626B2Easy to operateEfficient changeFinal product manufactureWelding/cutting auxillary devicesBogieSheet steel

The present invention concerns a forming process for hot forming of a steel sheet of a rotor blade to be produced of a wind power installation, including the steps heating the steel sheet in a furnace while the steel sheet is lying on a hearth bogie, displacing the heated steel sheet with the hearth bogie from the furnace into a pressing apparatus for the hot forming operation, transloading the heated steel sheet in the pressing apparatus from the hearth bogie on to a form bogie having a counterpart form, and pressing the steel sheet by at least one pressing punch which presses on the steel sheet in such a way that it is formed between the pressing punch and the counterpart form and in particular assumes the shape of the pressing punch and the counterpart form.

Owner:WOBBEN PROPERTIES GMBH

Rubber plastic CNC hydraulic cutting machine

ActiveCN106313152BElevate evenlyImprove uniformityMetal working apparatusNumerical controlProgrammable logic controller

The invention discloses a rubber plastic numerical control hydraulic bar cutter, comprising a workbench, a conveyor belt, a pressing device, a cutter stand, a cutter mechanism and a PLC (programmable logic controller) control device; the conveyor belt is arranged on the workbench and used for conveying materials to be cut to the pressing device and the cutter mechanism; the cutter mechanism comprises a cutter, lifting cross beams, several fixing rods and a lifting oil cylinder; the cutter is fixed on the lifting cross beams, and the lifting oil cylinder is fixed on the lifting cross beam to push the lifting of the lifting cross beams; the lifting cross beams are fixed on the cutter stand through at least two lifting cross beams; every fixing rod is externally sleeved with one buffer spring, and every buffer spring is situated between the lifting cross beams and the cutter stand; the conveyor belt, the pressing device and the cutter mechanism are connected with the PLC control device. The numerical control bar cutter of the invention can stably cut rubber and plastic products; meanwhile, the rubber strips and plastic strips after cutting have uniform openings; thus the quality of the rubber and plastic products after cutting can be improved.

Owner:NANTONG HAILITE RUBBER & PLASTIC MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com