Vehicle body hydraulic turnover machine

A hydraulic flipping and vehicle body technology, applied in fluid pressure actuating devices, hoisting devices, hoisting devices, etc., can solve the problems of difficult flipping, low efficiency, poor versatility, etc., and achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

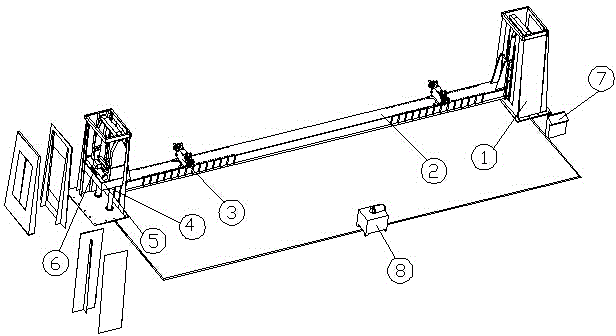

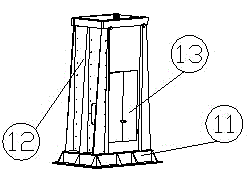

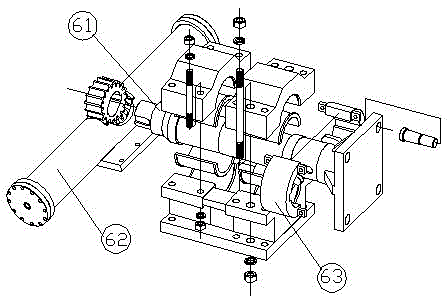

[0015] Such as figure 1 , 2 , 3 and 4 show a hydraulic turning machine for car body, including frame 1, main beam 2, turning clamping device 3, electrical control cabinet 7 and hydraulic station 8. The main beam 2 is connected to the frame 1 at the left and right ends, Two ends of the main beam 2 are close to the frame 1 with flipping clamping devices 3, one side of the main beam 2 is provided with a hydraulic station 8, and one side of the frame 1 is provided with an electrical control cabinet 7, the main beam 2 is a welding box Beam structure, the frame 1 is a door box structure. The frame 1 includes a base 11, a box body 12 and an assembly door 13. The assembly door 13 is located in the middle of the box body 12, and two lifting cylinders 4 are fixed on the base 11. Anchor bolts are uniformly distributed on the base 11, and a supporting lifting platform 5 is provided inside the box body 12. The supporting lifting platform 5 moves up and down along the guide rails on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com