Screw and helical bevel gear combined three-dimensional parking garage achieving outside-garage vertical lifting

A technology of spiral bevel gears and three-dimensional parking garages, applied in the field of mechanical transmission, can solve the problems of chain drop and stripping, low stability and reliability, and loose combination, etc., and achieve uniform lifting and translation speeds, simple structure, and smooth process smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

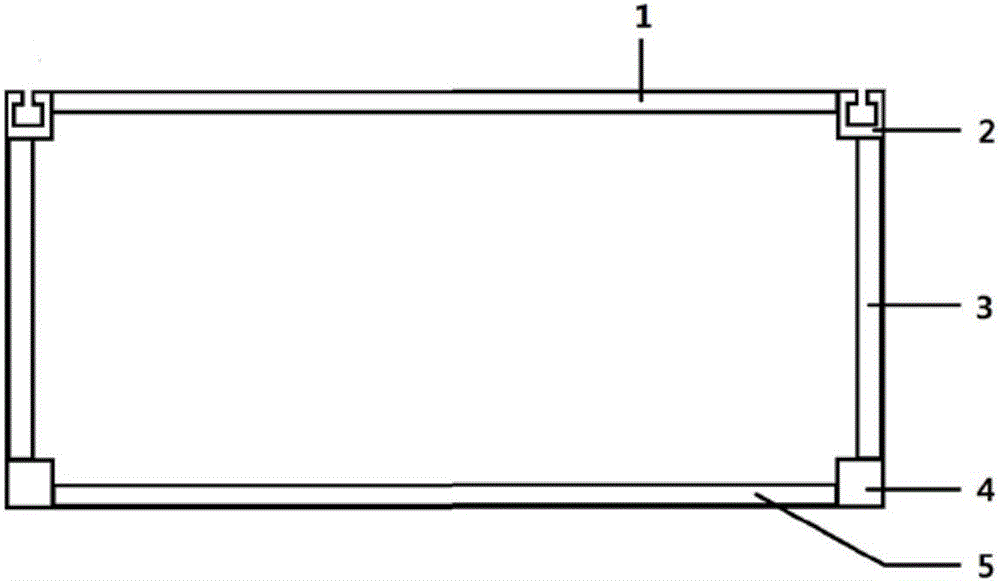

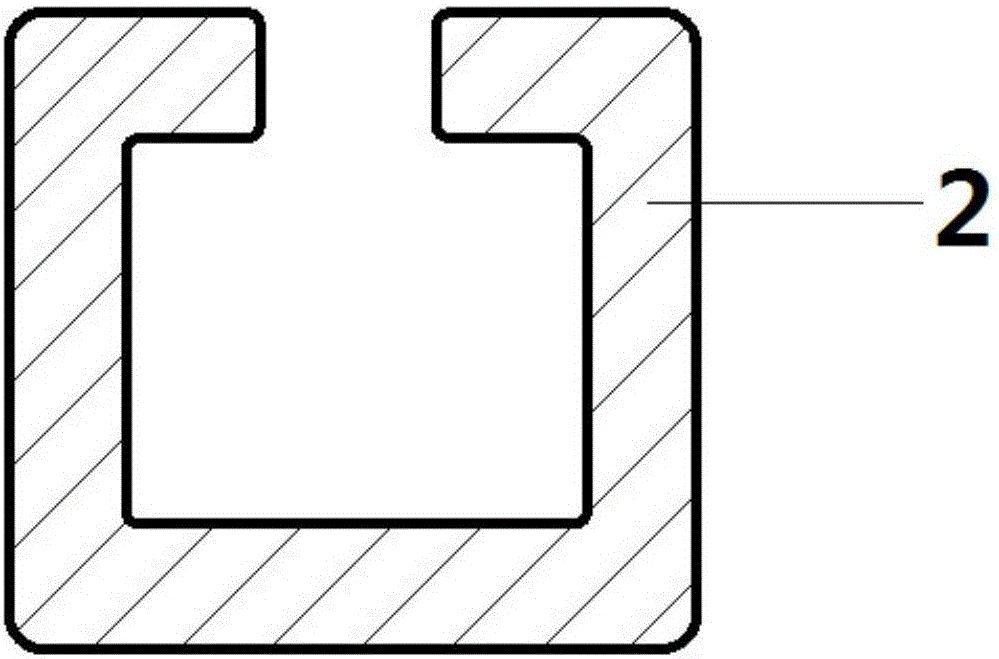

[0049] figure 1 It is a top view of the main body frame described in this embodiment. In the figure, 1 is the front beam, 2 is the front A-pillar, 3 is the side beam, 4 is the rear A-pillar, 5 is the rear beam; the front A-pillar (2) and the rear A-pillar (4) pass through the side beam (3 ) high rigid connection. The beam shown in the figure is the beam of the second parking floor.

[0050] The main frame of this embodiment is rigidly connected by 4 main columns and 4 beams, and is made of steel materials. The main column is fixed on the base of the column pile, and the front A column (2), the front B column, the rear A column (4) and the rear B column are in sequence according to the front, rear, left and right sides, and the 4 beams and the column are perpendicular to each other, etc. Rigid connections at high places constitute the planar frame of the square-shaped parking floor. In this embodiment, the net height between the lower bottom surface of the beam and the grou...

Embodiment 2

[0064] The three-dimensional parking garage described in this embodiment is structurally the same as that of Embodiment 1, except that the two three-dimensional parking garage units described in Embodiment 1 are laterally spliced into a three-dimensional parking garage with double-decker structure for two cars. Promptly take embodiment 1 as the three-dimensional parking garage unit, and install a three-dimensional parking garage unit identical to embodiment 1 side by side again, constitute the three-dimensional parking garage of two-car double-deck structure.

Embodiment 3

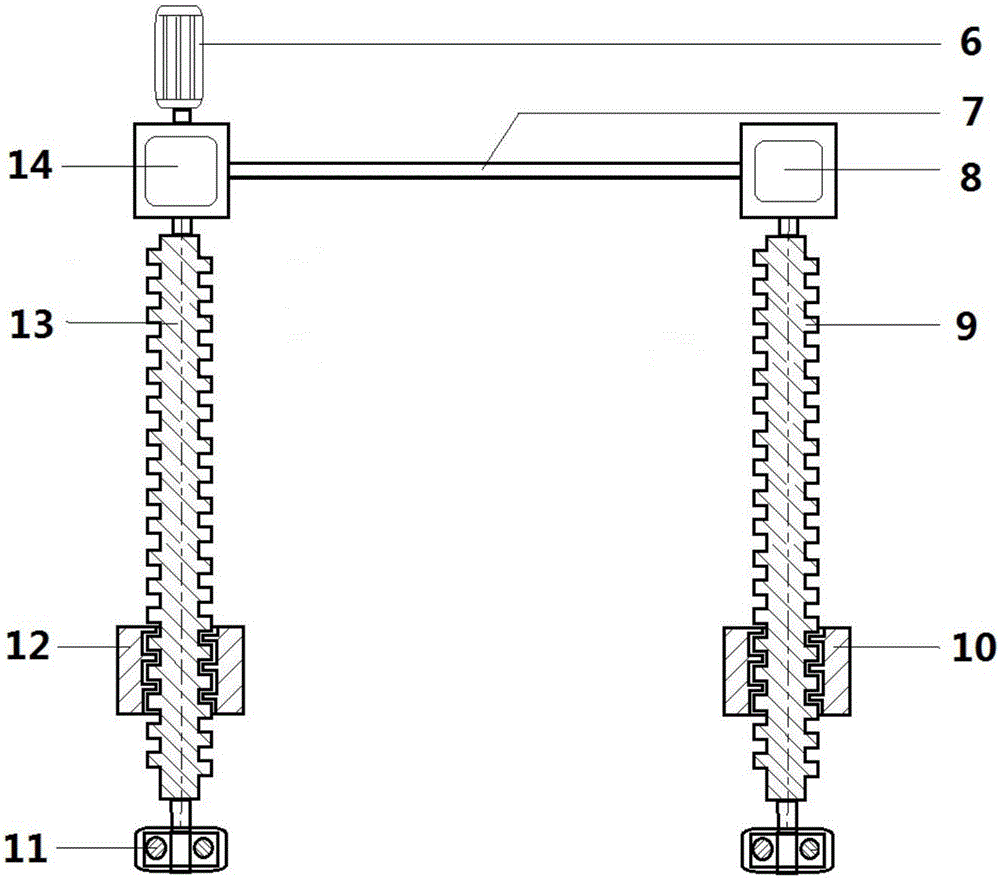

[0066] The three-dimensional parking garage described in this embodiment is structurally the same as that of embodiment 1, except that the two three-dimensional parking garages described in embodiment 1 continue to be superimposed upwards into a three-dimensional parking garage with a four-layer structure for single vehicles. That is, take embodiment 1 as the three-dimensional parking garage unit, and then install an independent three-dimensional parking garage identical with embodiment 1 to form a three-dimensional parking garage with a four-layer structure for bicycles. In the four-story structure of the bicycle, in order to ensure the stability of the lifting, the lifting screws in the front A-pillar, the front B-pillar, and the vertical lifting transmission system should be uninterrupted and smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com