Nano heat-insulation paint, preparation method of heat-insulation coating and heat-insulation glass

A nano-insulation and coating technology, which is used in the preparation of heat-insulating coatings, heat-insulating glass, and nano-heat-insulating coatings, can solve problems such as the inability to meet diverse needs, the high cost of coating preparation, and the large limitations of coatings. , to achieve the effect of improving thermal insulation performance, convenient operation and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

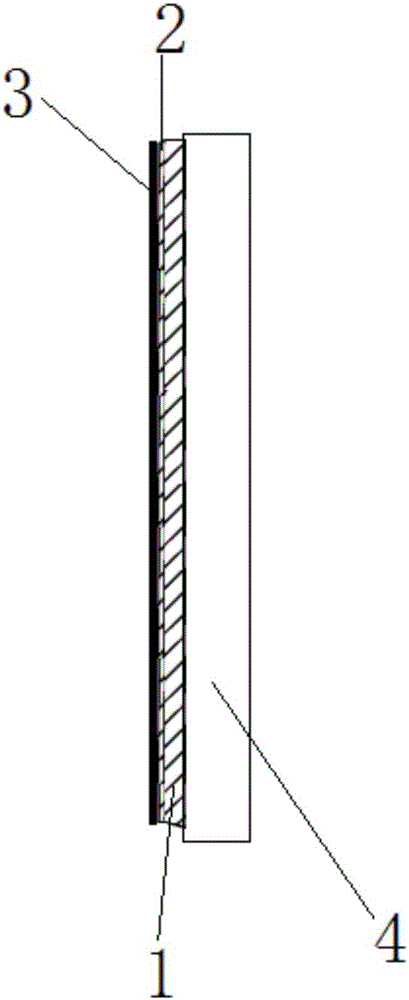

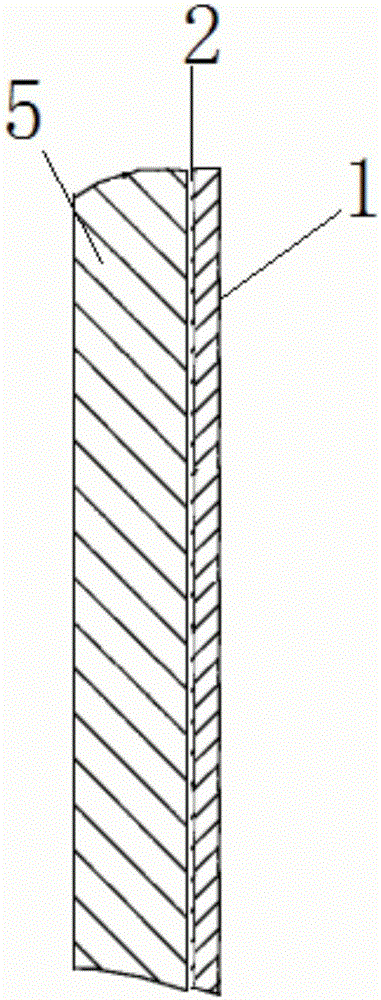

Image

Examples

Embodiment 1

[0019] Example 1, the nano-insulation coating includes nano-powder, polymer resin and coating additives, the nano-powder includes nano-silicon nitride and silver, and the raw material components of the nano-insulation material are in the following weight percentages Composition: 6.7% of nano powder, 78% of polymer resin and 15.3% of coating additives; polymer resin is water-based polyurethane, epoxy resin or polyvinyl butyral; coating additives include at least dispersant and leveling agent , a defoamer, a film-forming aid and a thickener; the weight percentages of nano-silicon nitride and silver in the nano-powder are respectively 33.5% and 66.5%; the average particle size of the nano-silicon nitride diameter of 60nm, and the average particle diameter of the silver is 15nm.

Embodiment 2

[0020] Example 2, the nano-insulation coating includes nano-powder, polymer resin and coating additives, the nano-powder includes nano-silicon nitride and silver, and the raw material components of the nano-insulation material are in the following percentages by weight Composition: 19.7% of nano powder, 60% of polymer resin and 20.3% of coating additives. The polymer resin is water-based polyurethane, epoxy resin or polyvinyl butyral; the paint additive includes at least one of dispersant, leveling agent, defoamer, film-forming aid and thickener.

[0021] The weight percentages of nano-silicon nitride and silver in the nano-powder are 70% and 30% respectively; the average particle diameter of the nano-silicon nitride is 100nm, and the average particle diameter of the silver is 12nm.

Embodiment 3

[0022] Example 3, the nano heat-insulating coating includes nano-powder, polymer resin and coating additives, the nano-powder includes nano-silicon nitride and silver, and the raw material components of the nano-heat-insulating material are in the following weight percentages Composition: 30% of nano powder, 55% of polymer resin and 15% of coating additives; polymer resin is water-based polyurethane, epoxy resin or polyvinyl butyral; coating additives include at least dispersant and leveling agent , defoamer, film-forming aid and thickener.

[0023] The weight percentages of nano-silicon nitride and silver in the nano-powder are 63% and 37% respectively; the average particle diameter of the nano-silicon nitride is 120nm, and the average particle diameter of the silver is 23nm.

[0024] In the above-mentioned embodiments, with the increase of nano-powders, the heat-insulating and UV-reducing properties of the nano-heat-insulating coatings are continuously strengthened, and with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com