Preparation device and method of low-concentration gas of certain humidity

A technology of gas preparation and low concentration, which is applied in the direction of mixing methods, chemical instruments and methods, gas and gas/steam mixing, etc. It can solve the problems of limited applicable gas types, complicated and cumbersome operation, and large gas consumption to achieve gas dilution ratio The effect of wide range, overcoming the influence of adsorption factors, and low concentration of gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

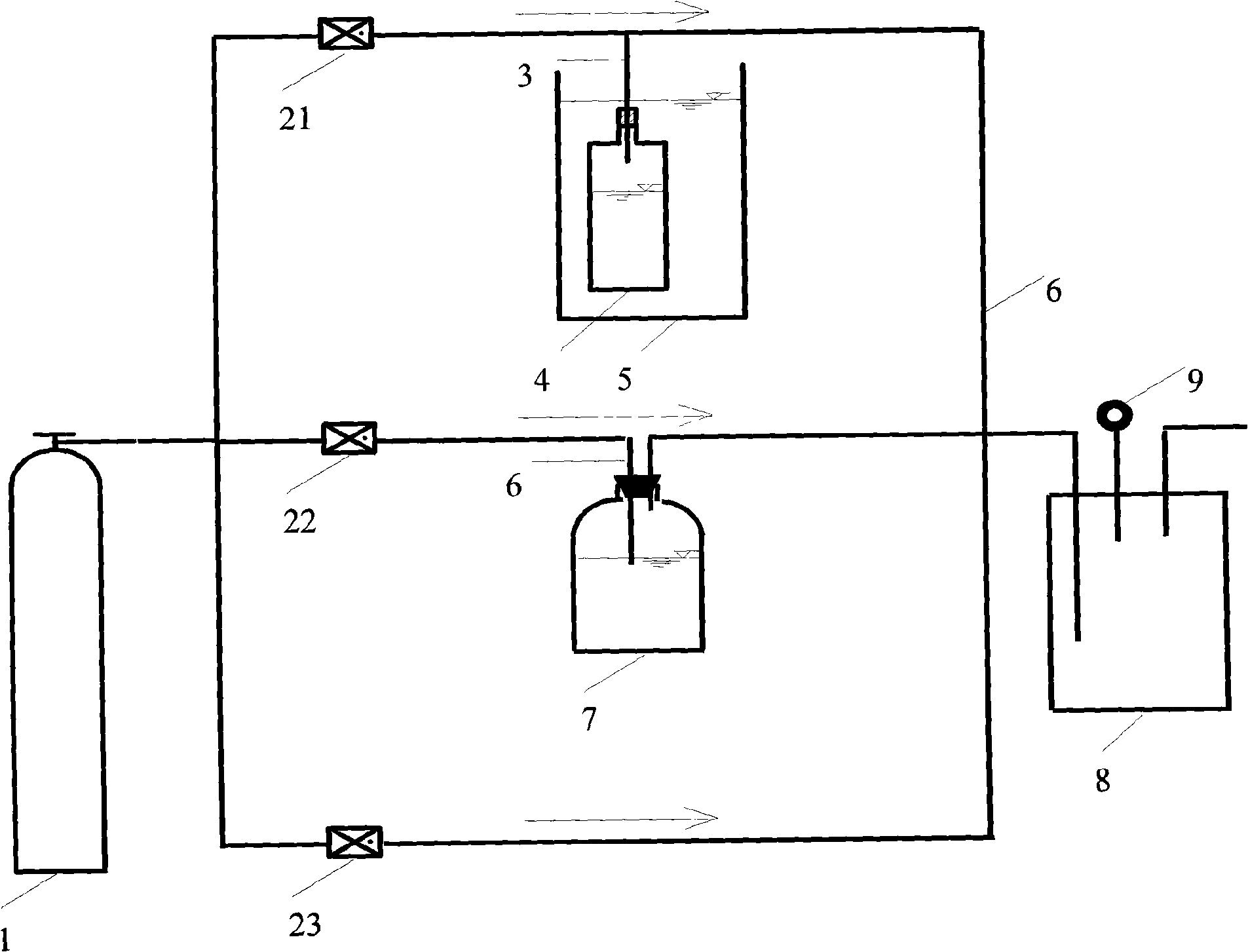

[0036] application figure 1 The device for preparing low-concentration toluene with a certain humidity:

[0037] The materials and parameters of each part of the low-concentration toluene preparation device in this example are as follows: 1- The carrier gas cylinder is an air cylinder; 21, 22- The range of the mass flow controller is 0-1.5L / min; 23- The mass flow controller 3- The length of the capillary tube is 5-8cm, and the inner diameter is 0.2-0.3mm; 4- The heating diffusion bottle is made of quartz material, and the volume is 200-250ml; 5- The heater is a multi-function constant temperature Water bath, the temperature range of water bath is 30~65℃; 6-capillary is made of stainless steel, polytetrafluoroethylene in the order of carrier gas control part, diffusion gas control part, dry air gas path part, humidity generating part and gas concentration mixing and stabilizing part. Made of ethylene, aluminum and PTFE, the capillaries of each gas path are connected by two-way...

Embodiment 2

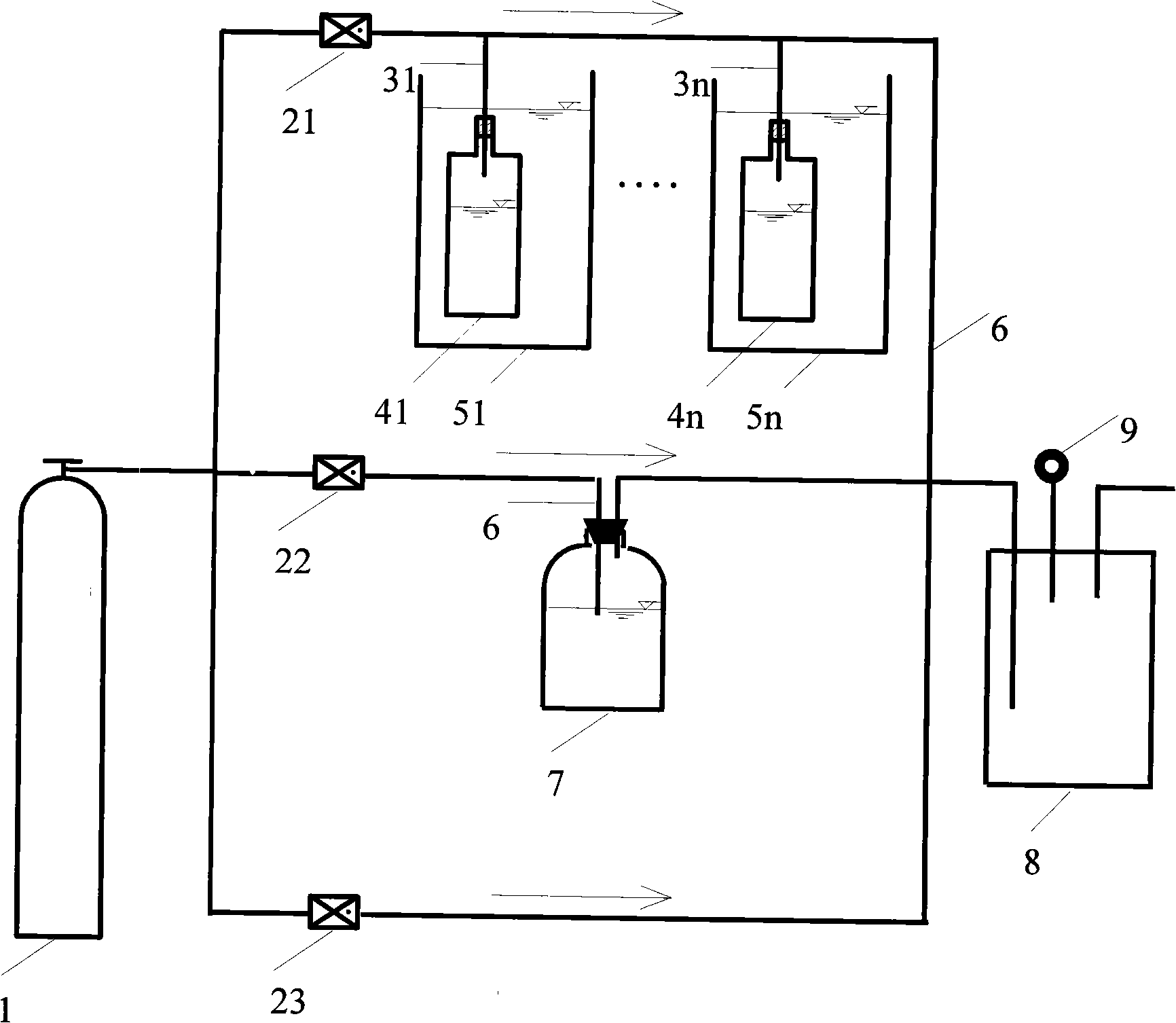

[0044] To prepare a mixed gas of low concentration benzene and toluene with a certain humidity:

[0045] Use the attached figure 2 A gas preparation device system containing n kinds of components (n is between 1 and 10) with a certain humidity, the number of diffusion gas control parts in the device is 2, the volume of 2 heating diffusion bottles is 200-250ml; The length of the needle tube is 8~12cm, and the inner diameter is 0.2~0.3mm; the capillary tube is mixed according to the carrier gas control part, the diffusion gas control part benzene gas path, the diffusion gas control part toluene gas path, the dry air gas path, the humidity generating part and the gas concentration. The order of the stable part is made of PTFE, brass, stainless steel, stainless steel, PTFE and PTFE in sequence, and each section of capillary is connected by a two-way air-tight stainless steel joint, and the inner diameter of the stainless steel capillary is 0.4~0.8. mm, brass capillary 0.2-1.0 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com