Protective gas on-line purging copper tube bright continuous annealing furnace

A technology of protective gas and continuous annealing furnace, which is applied in the direction of furnace, furnace type, lighting and heating equipment, etc., and can solve problems such as low efficiency, high price and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

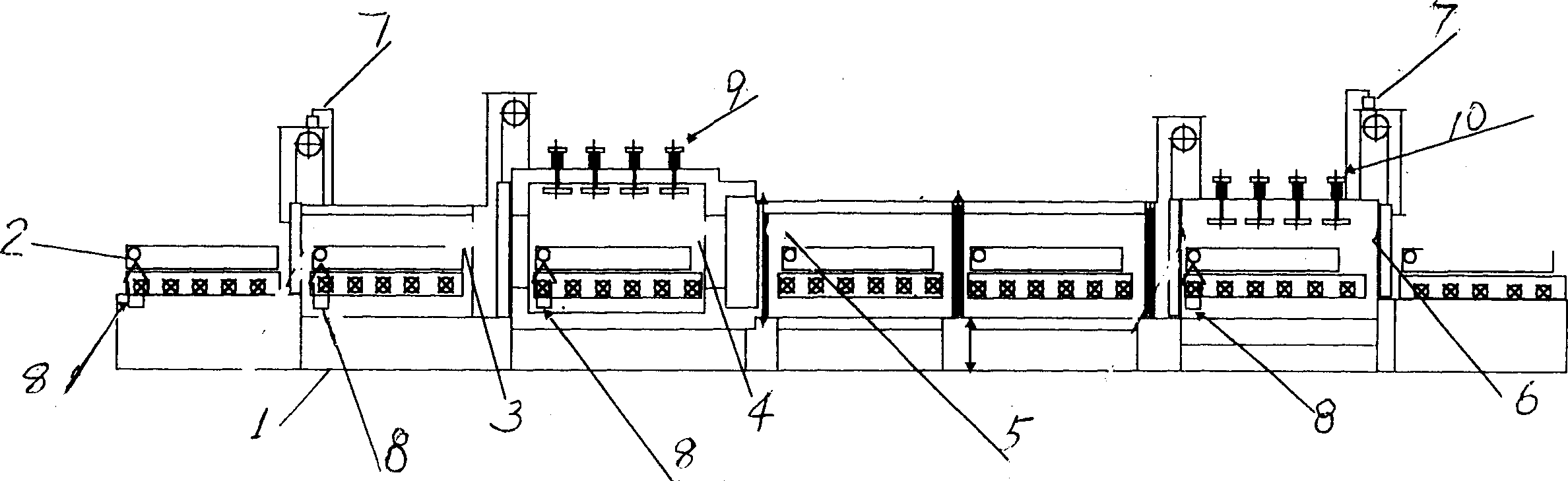

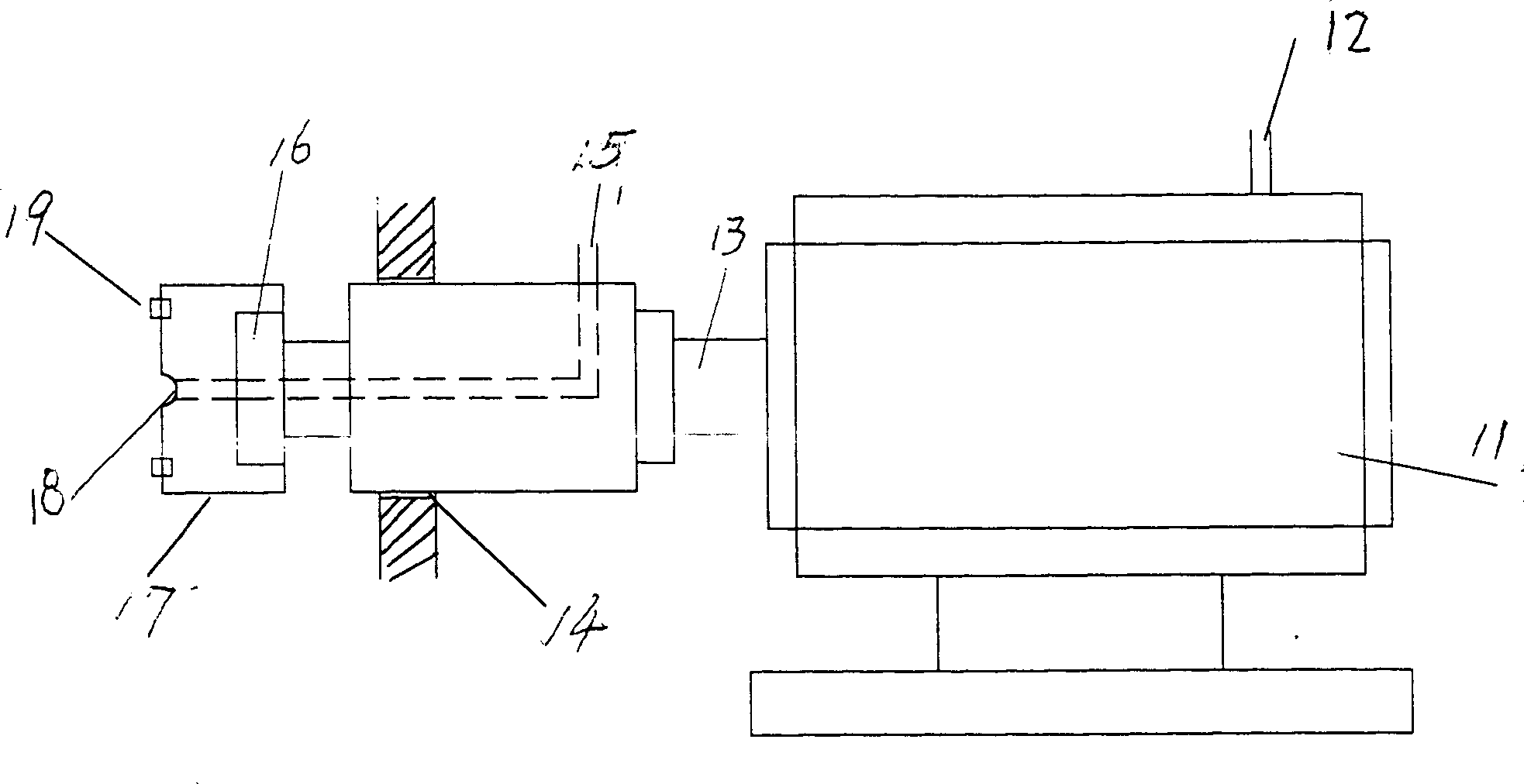

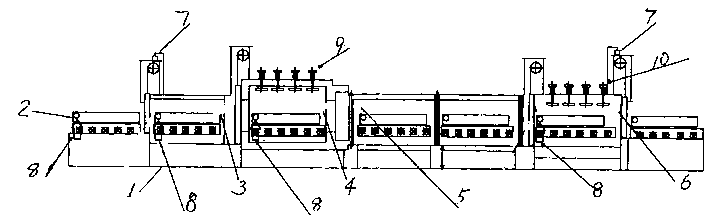

[0012] The present invention comprises furnace body 1, and this furnace body mainly comprises material rack 2, front chamber 3, heating chamber 4, water cooling chamber 5, forced cooling chamber 6 in turn, and it is different from prior art in that: material rack 2 is provided with air inlet pipe and The air outlet pipe is installed on both sides of the outer wall of the front chamber, the heating chamber, the water cooling chamber and the forced cooling chamber, and the copper pipe internal purging device 8 and the copper pipe internal exhaust device are installed, and the copper pipe internal purging device and the copper pipe internal exhaust device The structure is the same, except that the air inlet of the purging device in the copper pipe is the exhaust port of the exhaust device in the copper pipe, and the air inlet pipes in the air purging device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com