Device and method for simulating volume fracturing of horizontal well on shale reservoir stratum

A technology for simulating reservoirs and shale reservoirs, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of large construction scale, lack of simulation devices and methods, and lack of experimental devices, and achieve reliable device principles and practical methods. Feasible, the effect of optimizing the construction parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

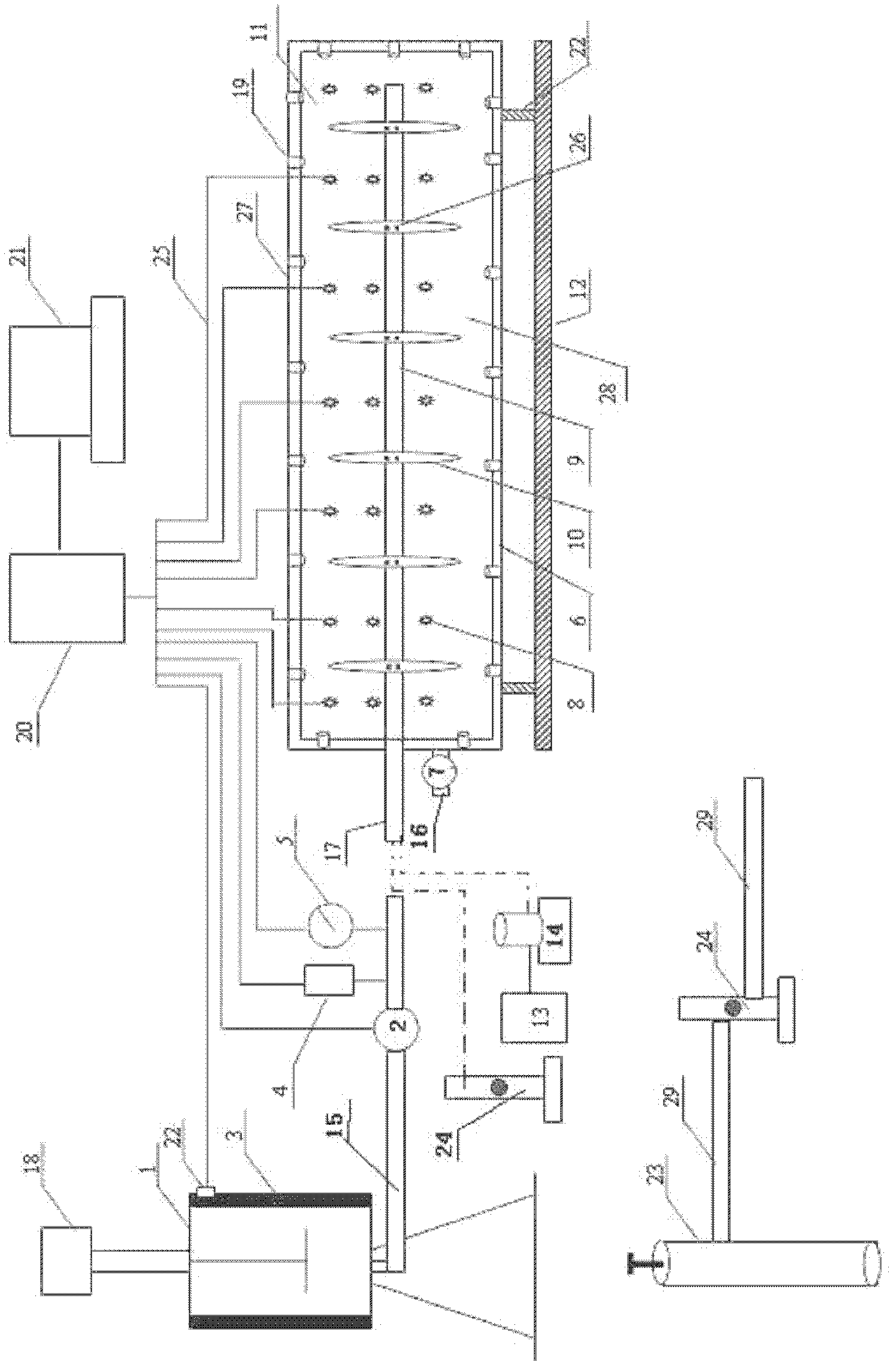

[0056] Embodiment 1 is the device used for simulating the shale reservoir pressure fracture expansion process; embodiment 3 is the device used for simulating the production process of shale oil reservoir; embodiment 5 is the device used for simulating the production process of shale gas storage reservoir .

[0057] Embodiment 1,

[0058] A device for simulating volume fracturing of a horizontal well in a shale reservoir, comprising a simulated reservoir cavity, a data acquisition control panel 20, a computer 21, a horizontal wellbore 9 set in the simulated reservoir cavity, the data acquisition control panel 20 is connected to the computer 21; the simulated reservoir chamber includes an upper cover 27 and a rectangular cavity 28, and the upper cover 27 is sealed on the rectangular cavity 28 by bolts;

[0059] The simulated reservoir cavity is installed on the universal support 12, which is composed of four height-adjustable pillars. By adjusting the height of each pillar, th...

Embodiment 2

[0066] Utilize the device described in embodiment 1 to simulate the shale reservoir pressure fracture expansion process, carry out according to the following steps,

[0067] (1) According to the similarity criterion, select a horizontal wellbore 9 with a certain length and steel grade, and select the perforation hole 26 of the horizontal wellbore 9 according to the perforation requirements, perforation density and shot Hole phase angle; the valve 7 at the liquid inlet of the supply source is closed and set, and the liquid storage tank 1 is communicated with the liquid inlet 17 of the horizontal wellbore through the pipeline 15;

[0068] (2) Add the sand-carrying liquid in the liquid storage tank 1, and the sand-carrying liquid in the liquid storage tank 1 is passed into the horizontal wellbore 9 at a low speed along the pipeline 15 and the horizontal wellbore liquid inlet 17, and check the pipeline 15 and the cavity of the simulated reservoir tightness;

[0069] (3) connect f...

Embodiment 3

[0075] The device for simulating volume fracturing of horizontal wells in shale reservoirs as described in Example 1, the difference lies in:

[0076]According to this embodiment, when simulating the production process of the shale oil reservoir, the liquid storage tank is connected to the liquid inlet 16 of the supply source through the pipeline 15, and the liquid inlet 17 of the horizontal wellbore is connected to the atmosphere; An artificial fracture model 10 is set at the perforation hole 26, so that the artificial fracture model 10 communicates with the perforation hole 26; the artificial fracture model is a horizontal well transverse fracture model, a longitudinal fracture model, an oblique fracture model or a distorted fracture model. The size (radius, width) of the artificial fracture model is determined according to the needs of the experiment, and the number of artificial fractures ranges from a few to dozens. The simulated reservoir cavity is installed on the unive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com