Air-conditioner defroster

A technology for air conditioners and evaporators, applied in instruments, simulators, high-efficiency regulation technologies, etc., can solve the problems of compressor input power attenuation, exhaust temperature not defrosting, exhaust temperature attenuation, etc., to reduce power loss , The effect of avoiding excessive exhaust temperature attenuation and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will be described in conjunction with the accompanying drawings and specific embodiments.

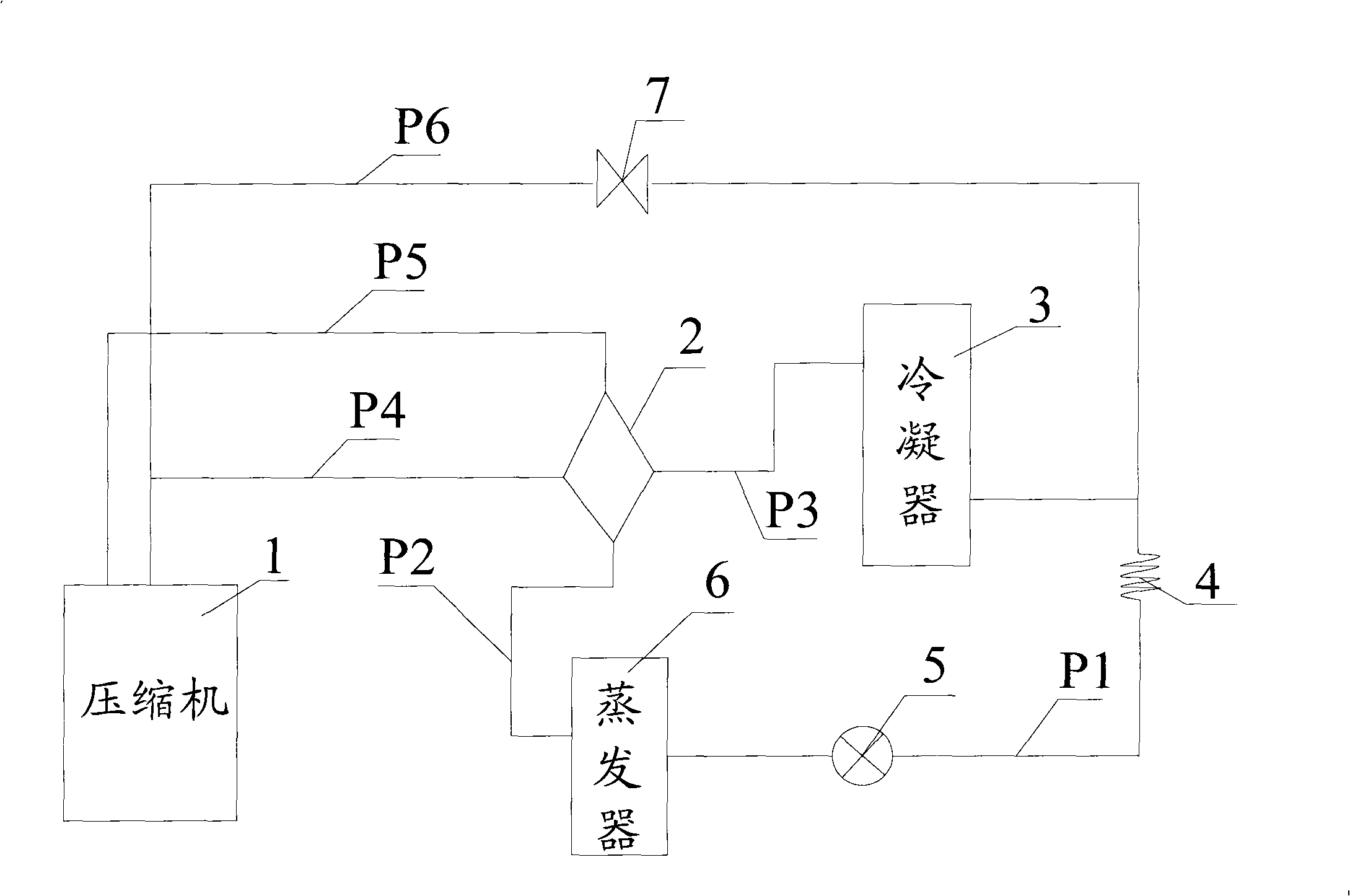

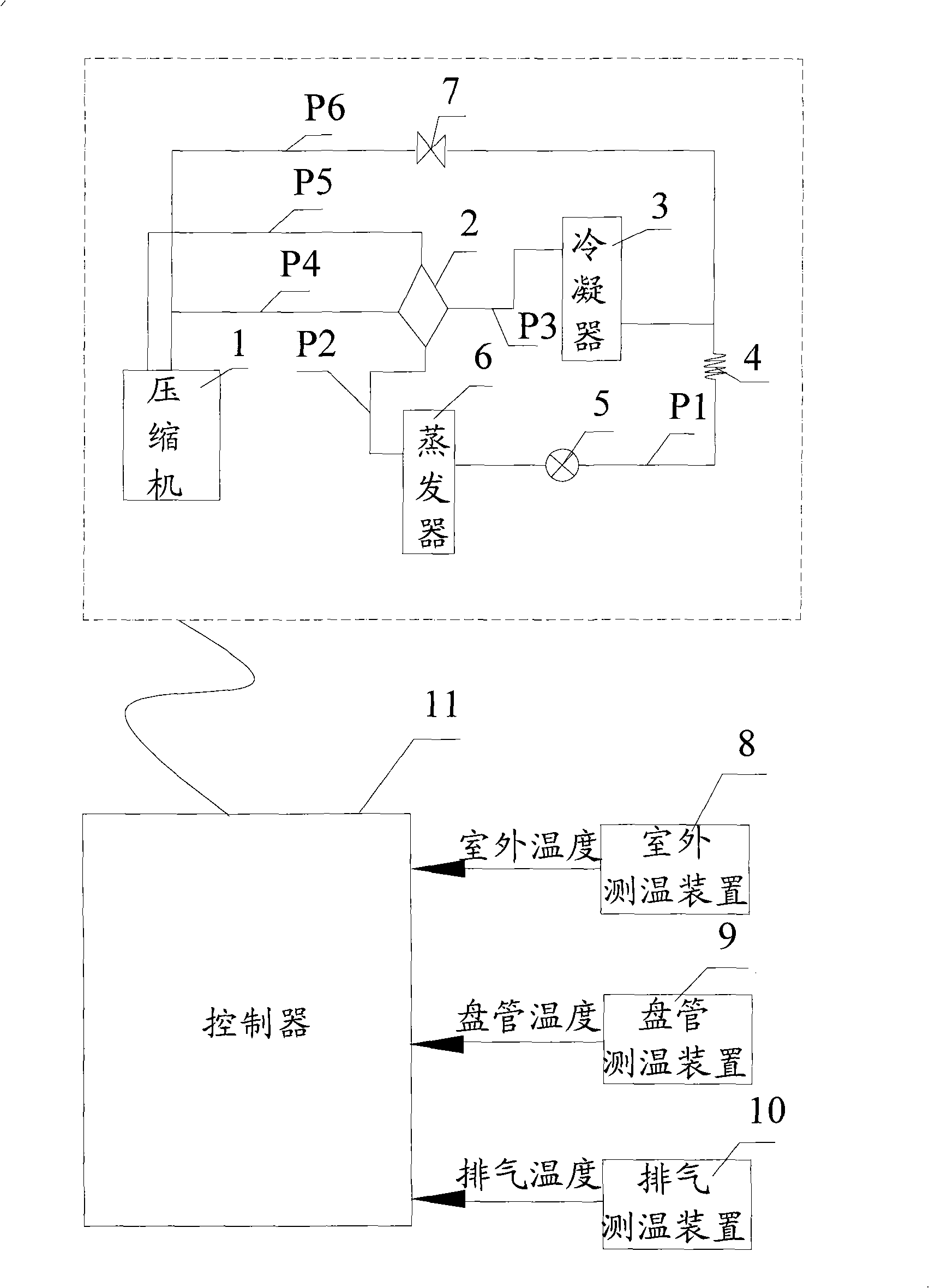

[0039] See figure 1 , which is a schematic structural view of the first embodiment of the air conditioner defrosting device of the present invention. The figure shows the defrosting device of the air conditioner, including:

[0040] Compressor 1, used to compress refrigerant;

[0041] Four-way valve 2, used to switch the forward and reverse flow directions of the refrigerant;

[0042] The evaporator 6 and the condenser 3 are respectively used to exchange heat with the outside;

[0043] The compressor 1, the four-way valve 2, the evaporator 6, and the condenser 3 are connected by pipelines, and each pipeline is specifically:

[0044] The first pipeline P1 is connected to the liquid inlet of the evaporator 6 and the liquid outlet of the condenser 3;

[0045] The second pipeline P2 connects the air return port of the evaporator 6 with the first port of the four-wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com