Gas pipeline leakage detecting and positioning device and method thereof

A gas pipeline and leakage detection technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as noise interference, influence on detection results, and missed reports of leakage accidents, so as to reduce false alarms rate, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose and technical solution of the present invention clearer, the present invention will be described in further detail with reference to the accompanying drawings.

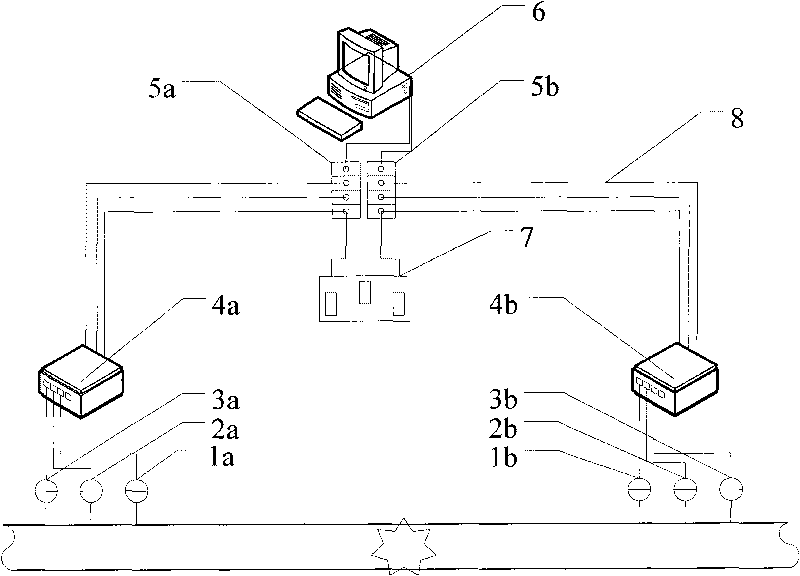

[0032] as attached figure 1 As shown, a device for gas pipeline leak detection and leak point location based on transient model, including sensor group, signal pre-processing equipment 4, I / V board 5, working condition machine 6 with internal acquisition card, stable Piezoelectric source 7 and shielded wire 8. The sensor group consists of two pressure transmitters 1a and 1b, two flow transmitters 2a and 2b, and two temperature transmitters 3a and 3b, which are respectively connected to the beginning and end of the pipeline section to be leak tested, and directly connected to the pipeline The gas contact inside, two signal pre-processing devices 4a and 4b are located near the signal source, two I / V boards 5a and 5b are located near the working machine, and are connected to the acqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com