Energy-saving cooker frame with combustion gas range residual heat utilizing function

A gas stove and waste heat technology, which is applied to the bracket of the cooker and other directions, can solve the problems of energy waste and the inability to effectively improve the utilization rate of heat energy, and achieve the effects of improving the utilization rate of heat energy and convenient connection and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Further details will be described below in conjunction with the accompanying drawings and embodiments.

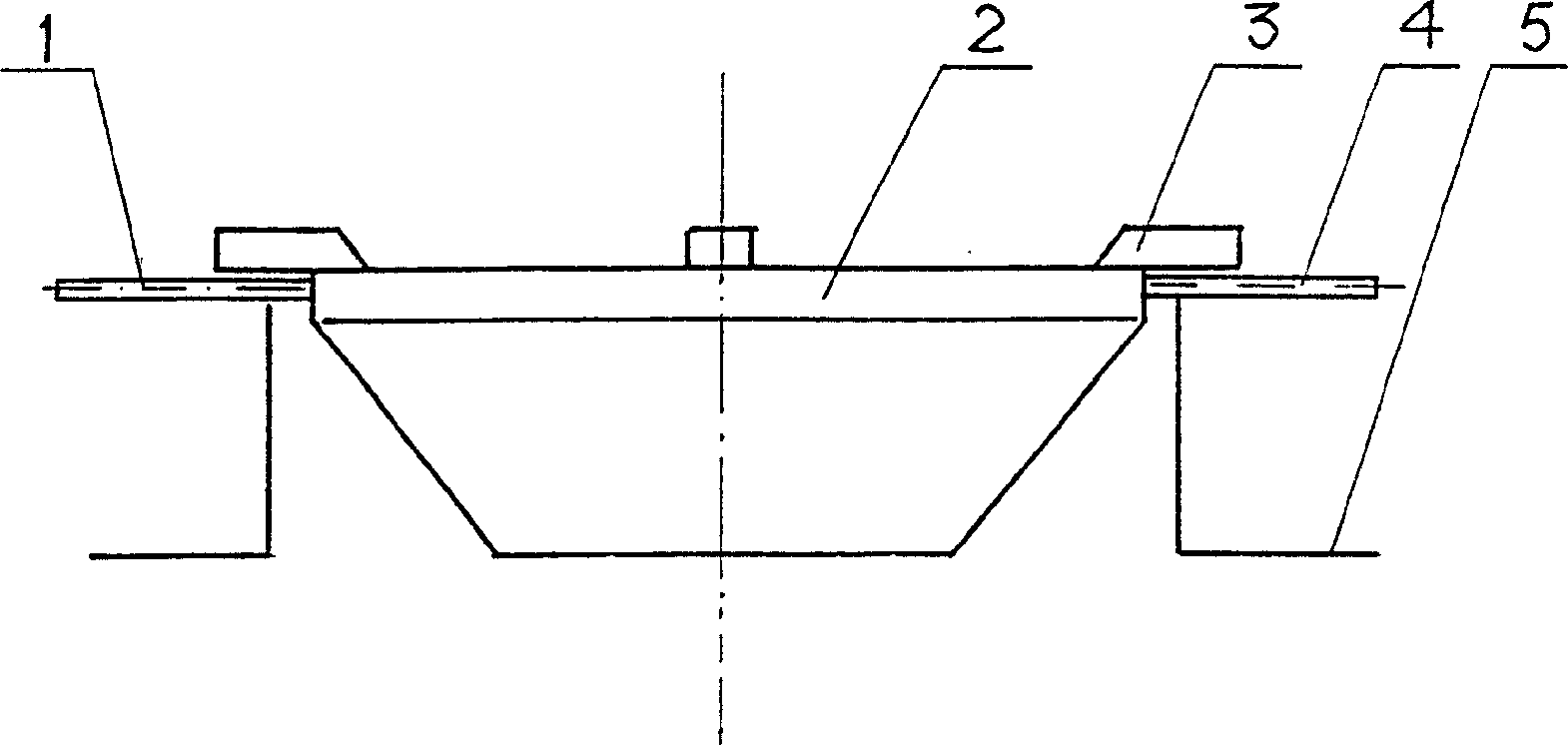

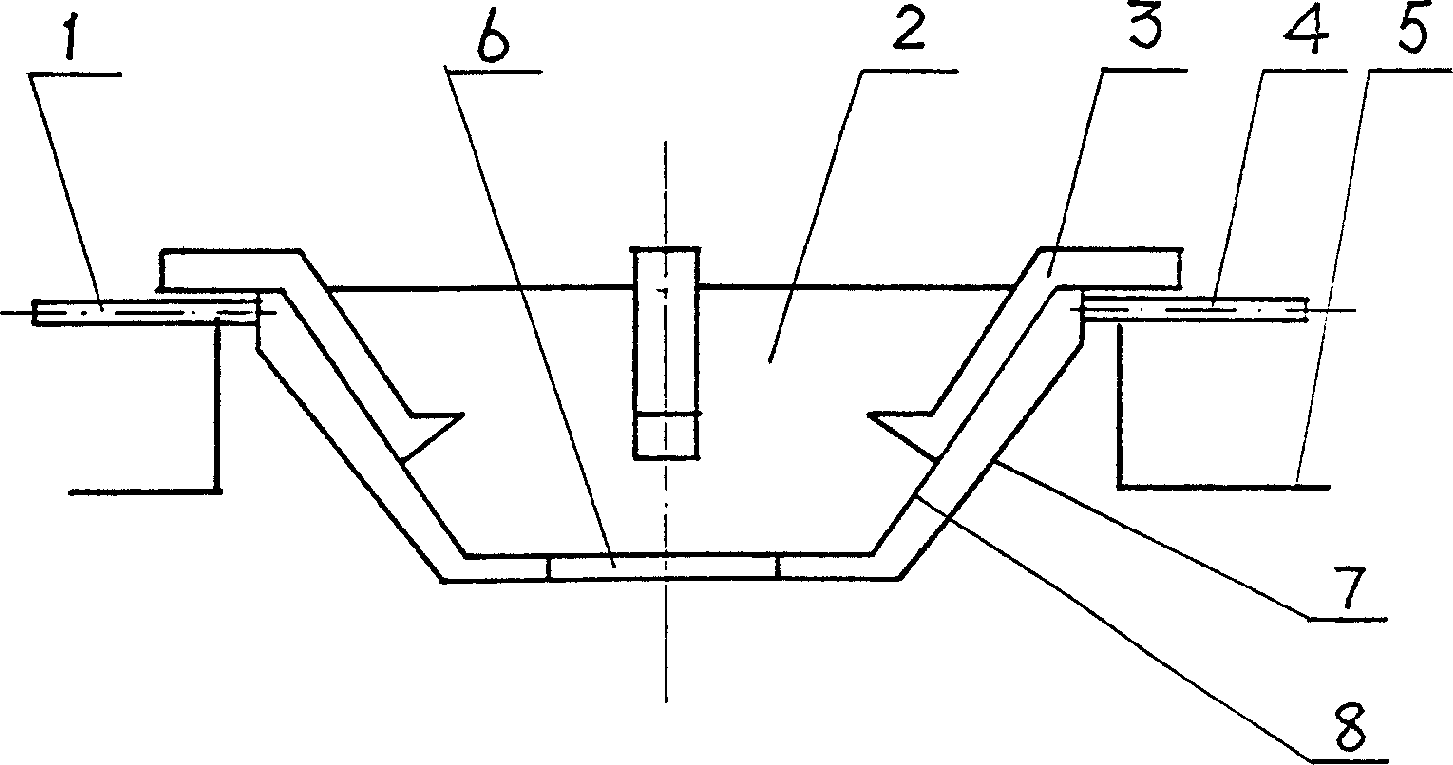

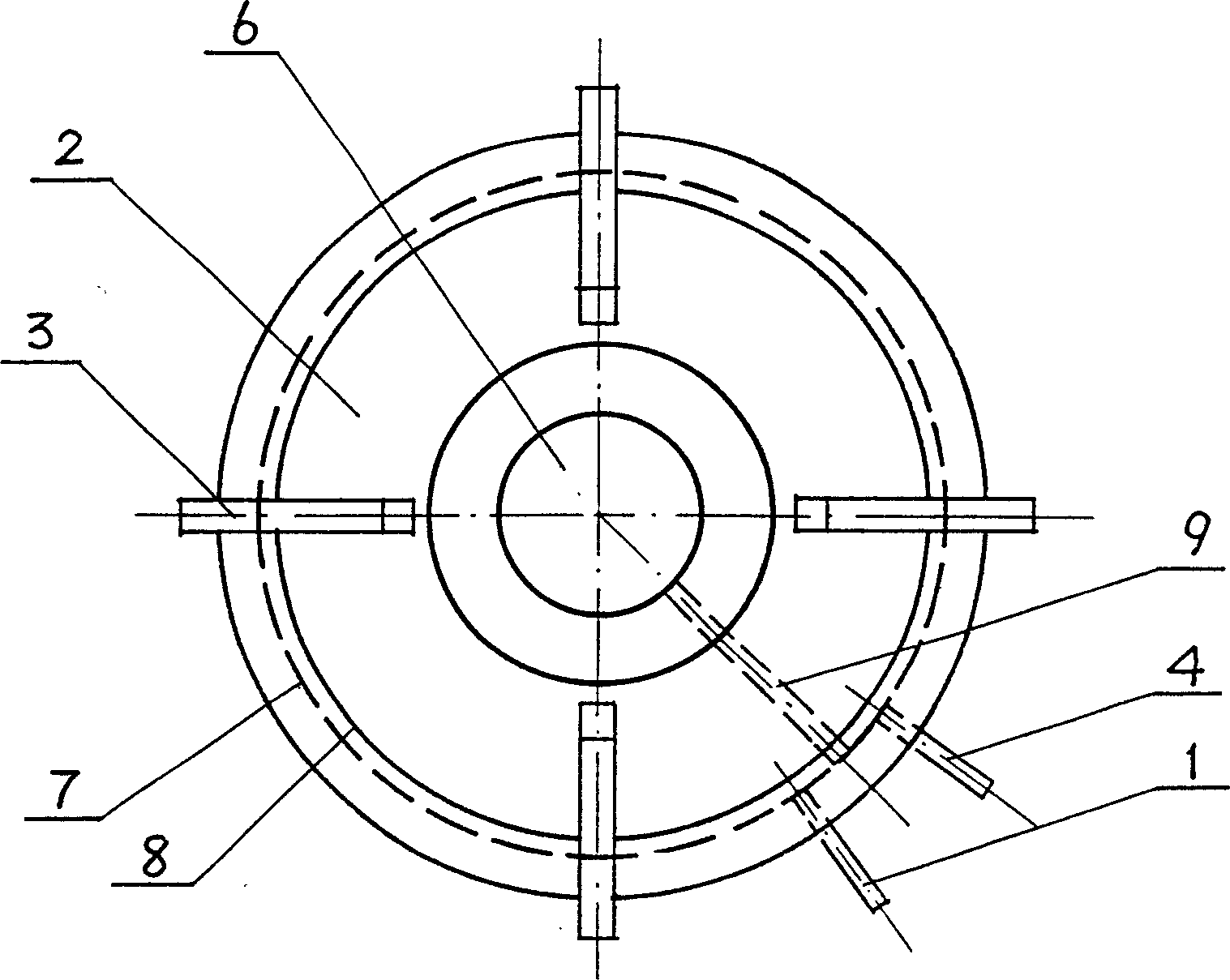

[0031] like figure 1 , figure 2 As shown, the gas stove waste heat utilization energy-saving pot support includes 3 to 5 supporting claws 3, and also includes a basin-shaped inner wall 8. The supporting claws 3 are evenly distributed and radially arranged on the circumference of the garden, and are fixed on the basin-shaped inner wall 8 by welding or riveting. On the outer side of the basin-shaped inner wall 8, there is an outer wall 7 corresponding to the shape of the basin-shaped inner wall to jointly form the basin-shaped interlayer water jacket 2, and in the middle of the bottom surface of the basin-shaped interlayer water jacket 2, there is a port 6 suitable for the burner , used to pass through and accommodate the burner, the upper part of the outer wall 7 of the basin-shaped interlayer water jacket 2 is correspondingly provided with a water inlet pipe 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com