Roll caliber for rolling special-shaped wide steel strip

A roll and pass technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of uneven pressure distribution, inappropriate size, deviation, etc., to achieve satisfactory size and performance, no surface defects, Reasonable effect of metal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

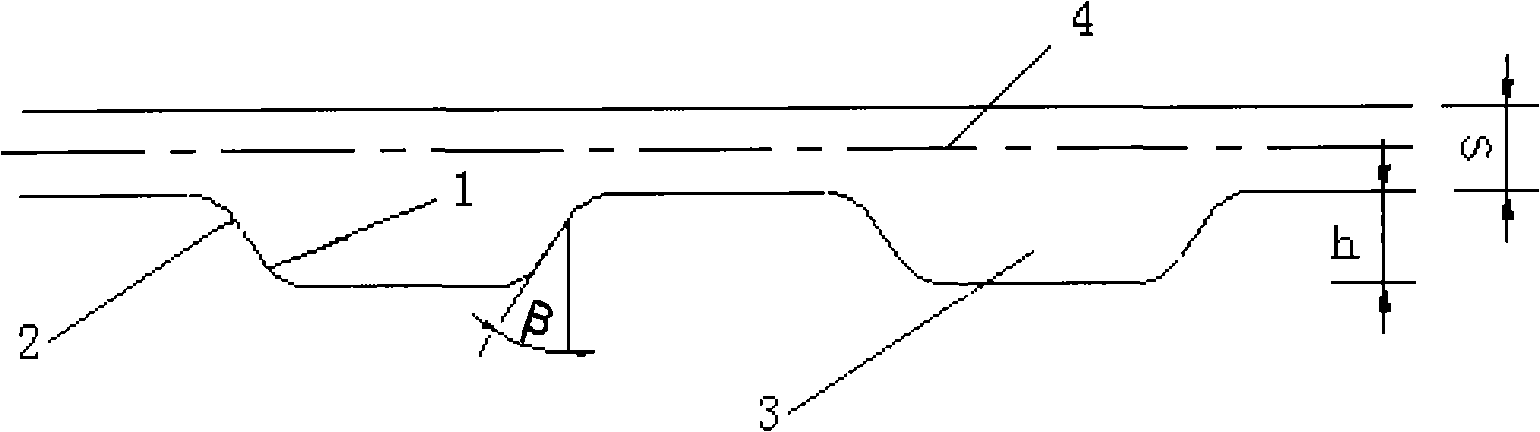

[0015] A roll pass used for rolling special-shaped wide steel strips is located between the upper and lower rolls of the last stand of the steel strip rolling mill. The chamfer 1 on the upper side of the boss 3 is a circular arc with a radius of 1 mm, and the chamfer 2 on the lower side of the boss 3 is a circular arc with a radius of 1 mm. The angle β between the side of the boss 3 and the vertical line 4 of the rolling centerline 4 is 30°, the height of the boss is h=2mm, and the width S of the rectangle is 10mm. Such as figure 1 shown.

[0016] According to the needs of the product, select a partially filled pass for rolling during rolling. The rest achieve the thickness dimension by changing the rolling force and the size of the roll gap.

[0017] In the embodiment, a billet with a cross-sectional size of 175×1150 mm is rolled into a special-shaped wide steel strip, and a finished steel strip with a specification size of 10 mm×1170 mm. According to the test of this emb...

Embodiment 2

[0019] A roll pass used for rolling special-shaped wide steel strips is located between the upper and lower rolls of the last stand of the steel strip rolling mill. The chamfer 1 on the upper side of the boss 3 is an arc with a radius of 3 mm, and the chamfer 2 at the bottom of the boss 3 is an arc with a radius of 3 mm. The angle β between the side of the roll boss 3 and the vertical line 4 of the rolling center line 4 is 30°, the height of the boss is h=2mm, and the width S of the rectangle is 8mm. Such as figure 1 shown.

[0020] According to the needs of the product, select a partially filled pass for rolling during rolling. The rest achieve the thickness dimension by changing the rolling force and the size of the roll gap.

[0021] In the embodiment, a billet with a cross-sectional specification size of 175×1150 mm is rolled into a special-shaped wide steel strip, and a finished steel strip with a specification size of 8 mm×1170 mm. According to the test of this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com