Thread roll-forming process for large-specification bolt

A roll forming, large-scale technology, applied in the direction of threaded products, other household appliances, household appliances, etc., can solve the problem of large-scale screw thread and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

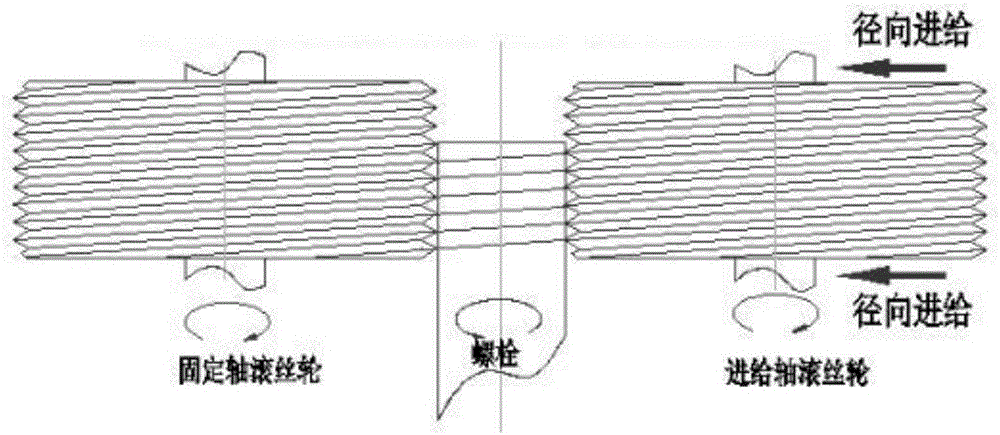

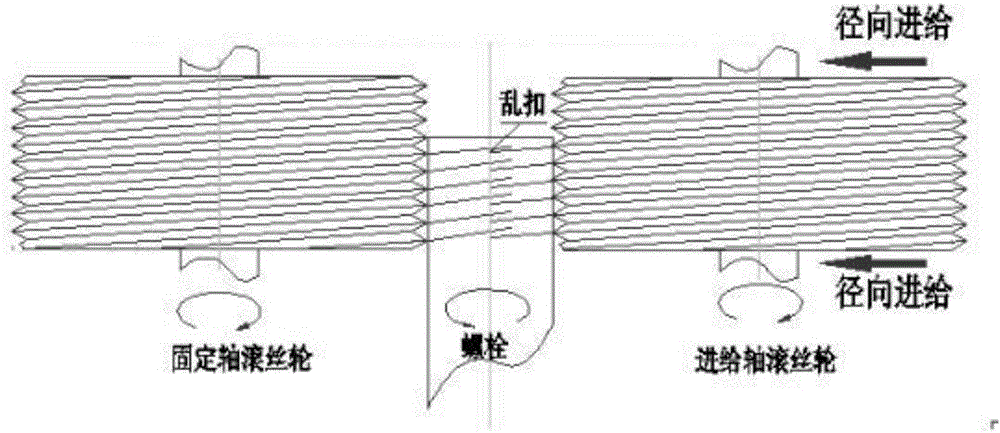

[0026] In order to overcome the problems that the existing methods are difficult to roll large-size threads and are prone to disorderly fastening, the present invention provides a method such as image 3 The thread rolling forming process of the large-size bolts shown in the present invention adopts a very shallow guide groove (the requirements for the tooth angle and half angle are not high) before the blank rolling, and then roll forming, guiding The groove is machined according to the pitch of the bolt (corresponding to the helix angle of the corresponding specification), so that in the subsequent rolling process, the cusp of the roller is always limited in the guide groove of the bolt, so that there will be no random buckling phenomenon, which solves the problem This problem, and this method is simple and feasible.

[0027] 3. The thread rolling forming process of large-size bolts, the specific steps are:

[0028] S1 blank preparation: carve a spiral guide groove on the s...

Embodiment 2

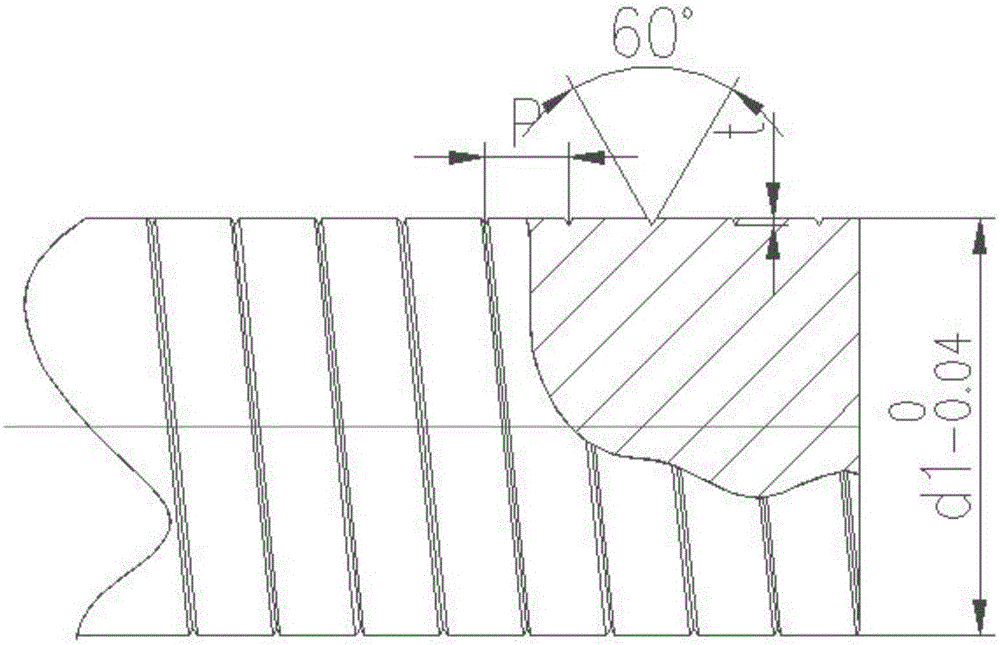

[0035] Based on Embodiment 1, in this embodiment, in the step S1, a spiral guide groove is formed on the surface of the large-size bolt to be rolled, and the guide groove is a triangular guide groove, and the guide groove is according to The thread pitch of the bolt is machined.

[0036] The included angle of the triangular guide groove is 60°.

[0037] The thread rolling machine selected in the step S2 is a Z28-60 thread rolling machine.

[0038] The maximum thread rolling diameter of the Z28-60 thread rolling machine is M68.

[0039] In the step S2, the positions of the two thread rolling wheels are adjusted before the bolt rolling, so that the cusps of the two thread rolling wheels are just in the triangular guide groove of the bolt blank, and the position of the two thread rolling wheels is adjusted to extend the axis locked to a fixed position.

[0040] For equipment adjustment, choose Z28-60 thread rolling machine, install a thread rolling wheel on the fixed shaft and...

Embodiment 3

[0044] Based on the above two embodiments, in this embodiment, M76-M125 bolts are used for experiments.

[0045] The above simple, economical and efficient method is used to roll large-size threads, which solves the problem of large-size bolt thread roll forming. At present, this method has been applied to the trial production of M76-M125 bolts. From the perspective of effect, this method is simple and easy to implement, meets the quality requirements, and has high production efficiency.

[0046] The thread rolling forming process of the large-size bolt provided by the present invention can roll out the large-size screw thread with the above method, but in ensuring the accuracy of the thread, there are two problems to be discussed and tested (see image 3 , d1 in the figure is the diameter of the front billet of the triangular guide groove of the bolt car, p is the pitch of the bolt, and t is the depth of the triangular guide groove):

[0047] (1) Reasonable triangular guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com