Automatic green date pitting machine and automatic green date slotting and pitting machine

An automatic technology for jujubes, which is applied in the fields of fruit de-pitting device, food science, application, etc., can solve the problems of poor de-pitting effect and difficult to be practical, and achieves the effect of avoiding the problem of mildew in the rainy season, high processing efficiency, and easy handling and movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

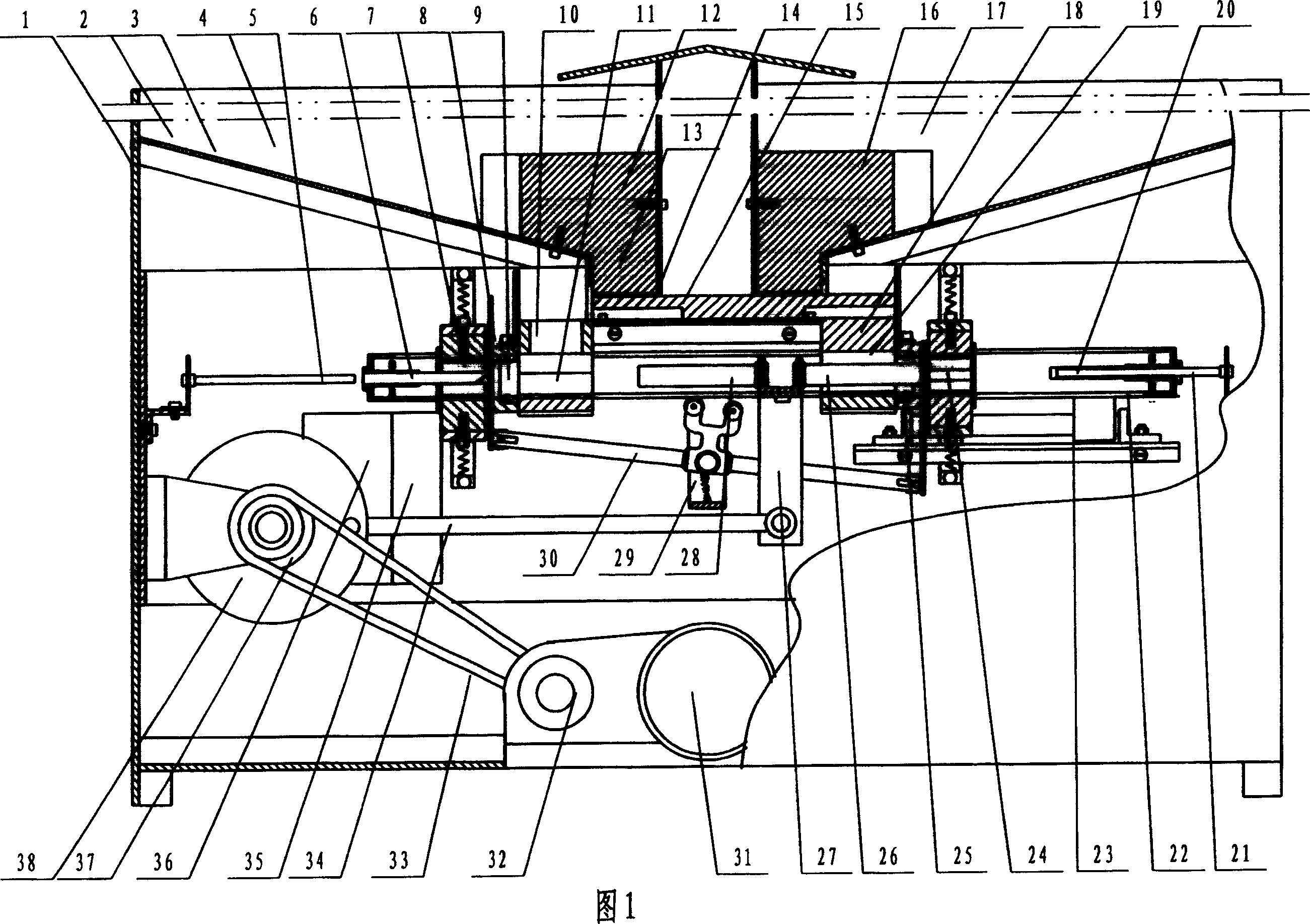

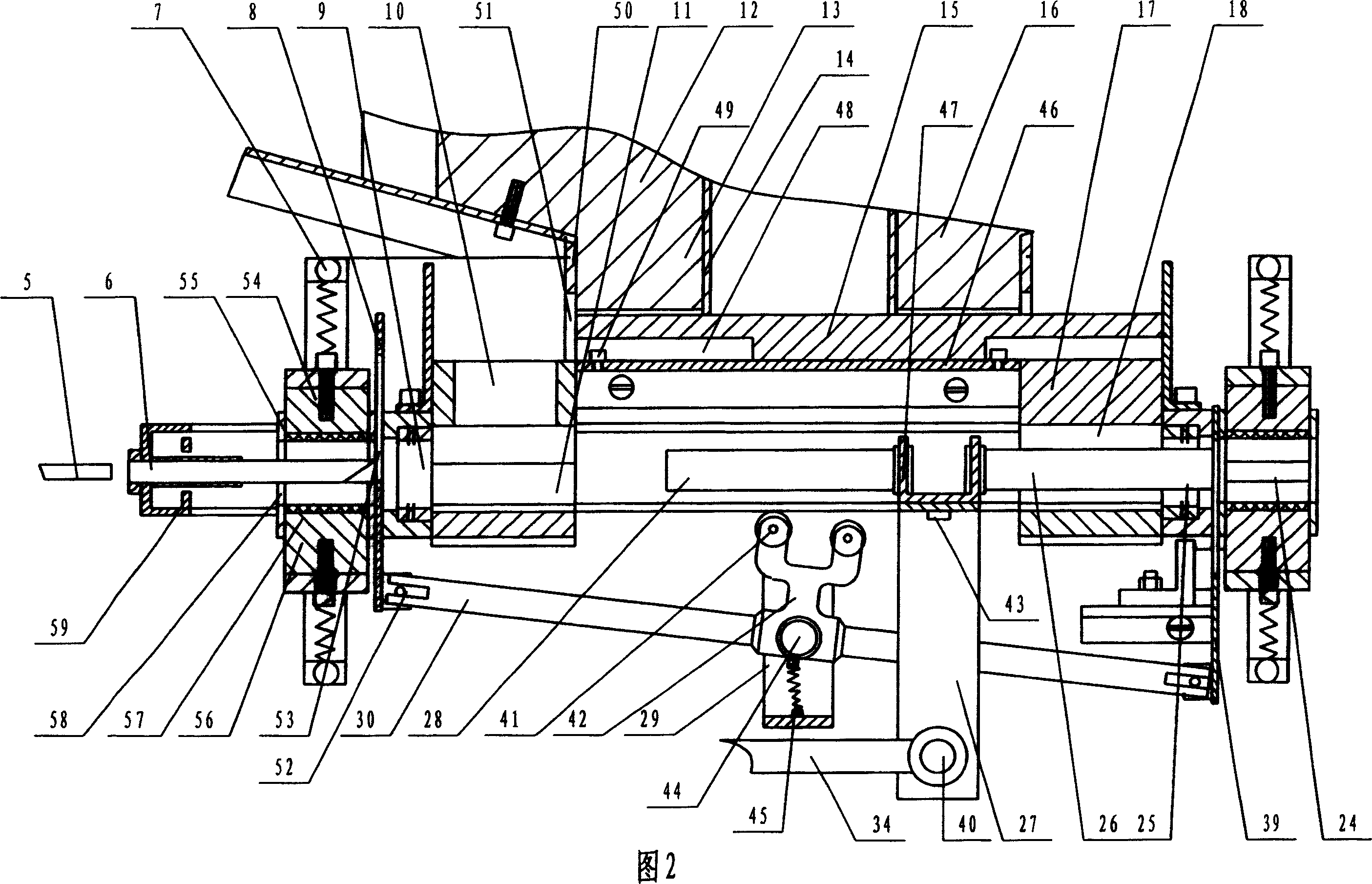

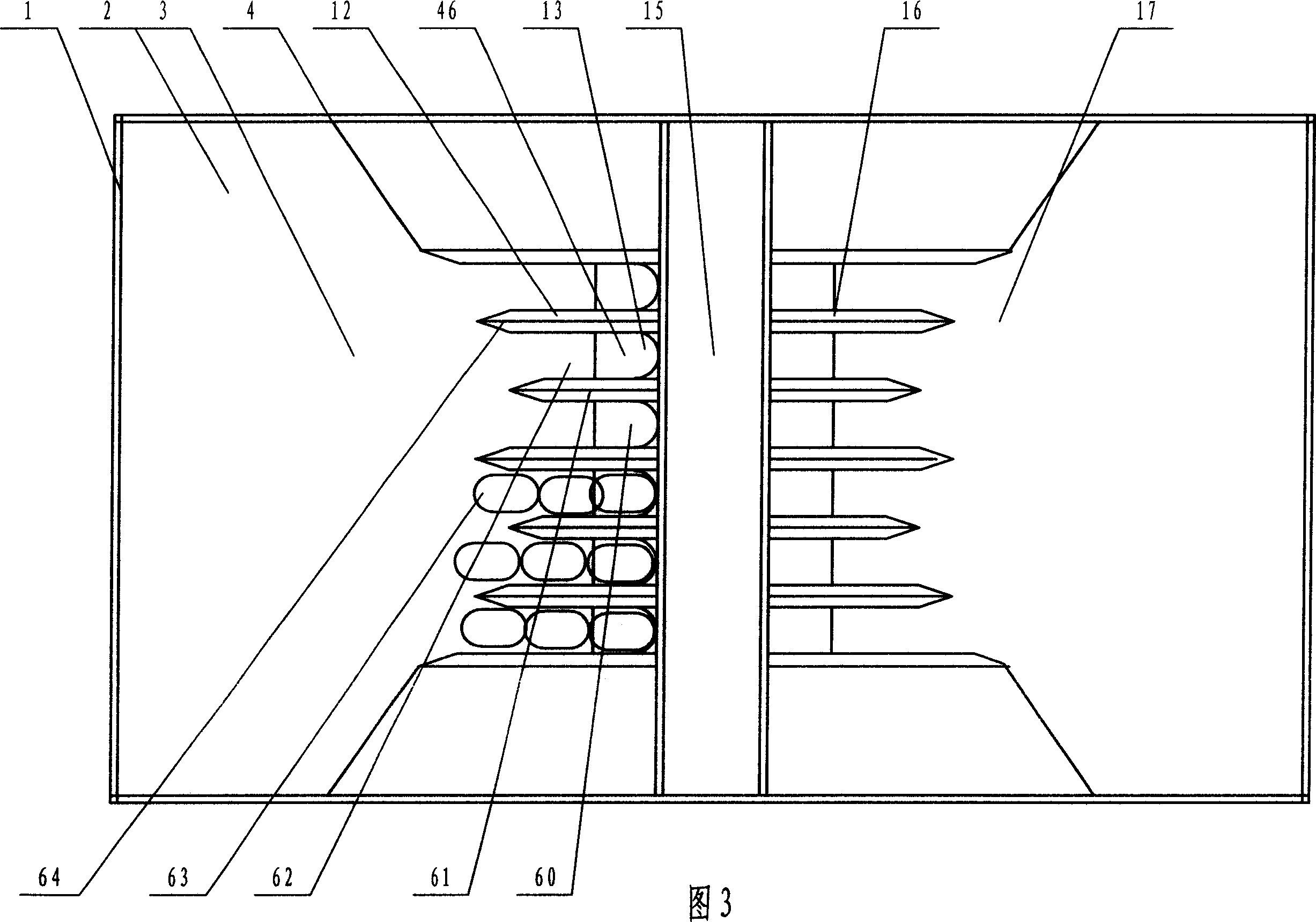

[0062] The specific embodiment of the present invention is provided by following embodiment and accompanying drawing thereof, but jujube pitting machine of the present invention is not limited to following embodiment.

[0063] Fig. 1, Fig. 2, the jujube pitting machine described in Fig. 3 comprise frame 1, power input device, hopper, jujube dispensing device, jujube centering device, get nuclear knife, and hopper is installed on frame 1 as hopper 3, Hopper 3 has four side plates, and it is characterized in that: present embodiment has two hoppers, that is, symmetrical hopper 3 and hopper 17 and two sets of matching denucleating ditching devices. Mounting plates 29 are welded on the longitudinal both sides of the frame 1, and a lever position converter is also installed on the frame 1. The lever position converter has a helical compression spring 45 and a vertical horizontal lever 30 and a vertical horizontal lever 30 fixed as one. Fork bar 42, the front end of fork bar 42 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com