Wheel forging and pressing preforming die

A pre-forming, forging technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problem of difficulty in obtaining the inner hub face blank, affecting the quality of the wheel, and low thermal forming pass rate and other problems, to achieve the effect of facilitating process adjustment, improving wheel quality, and improving the qualification rate of hot forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

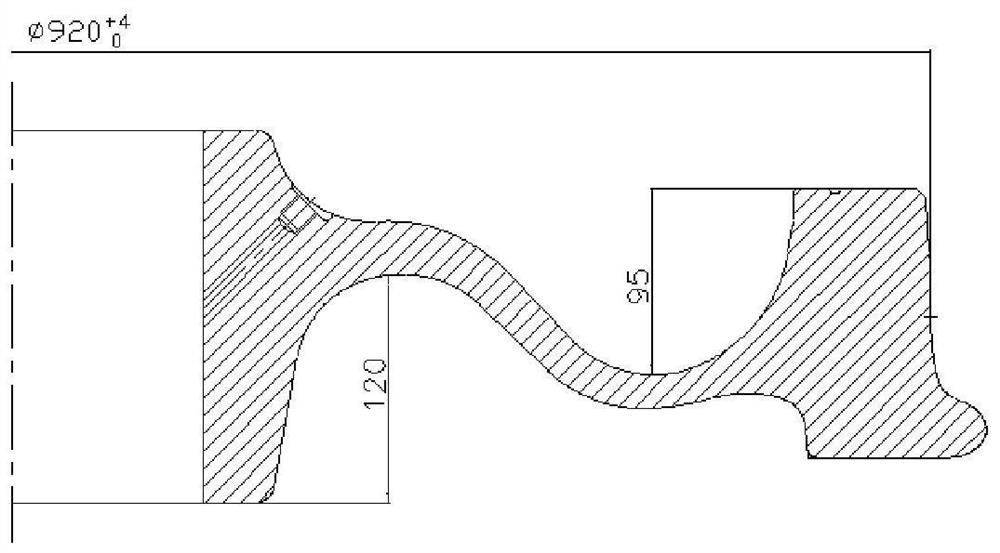

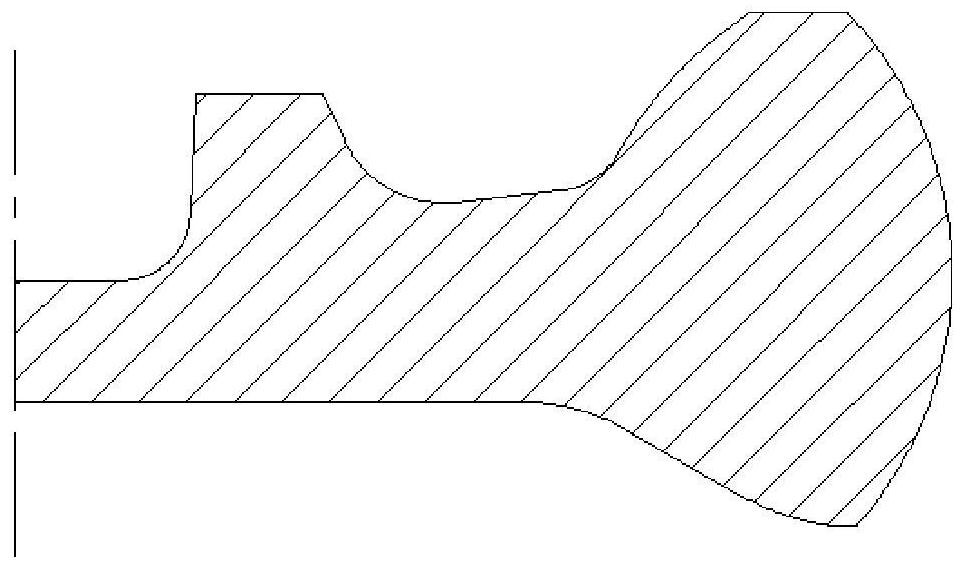

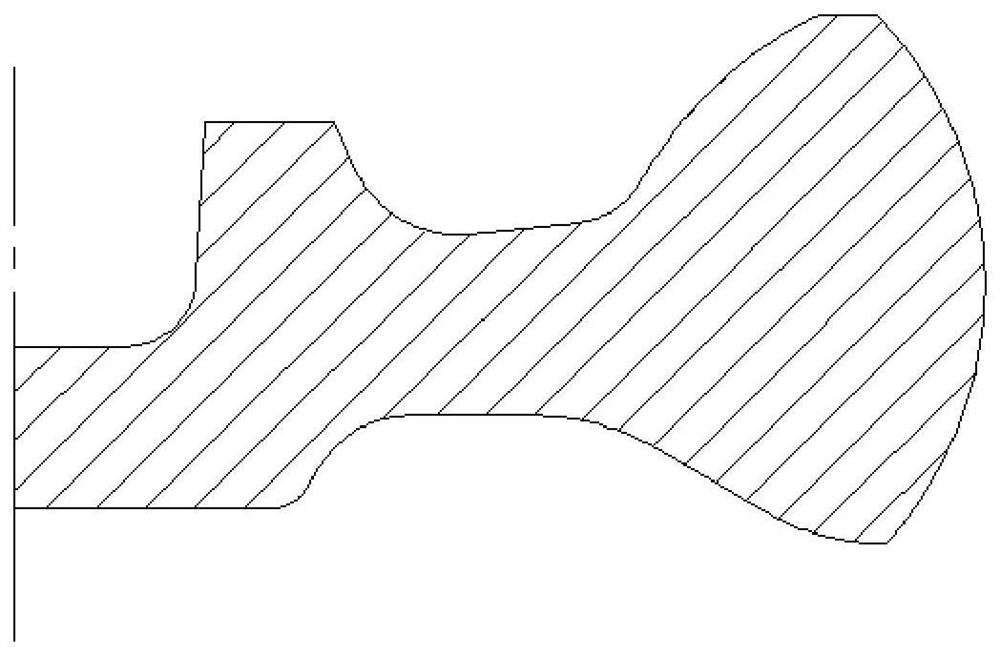

[0030] Such as Figure 1 to Figure 8 As shown, the wheel forging preforming mold includes an upper mold structure and a lower mold structure; the lower mold structure includes a lower mold base 6, a preforming mold pad 4, a preforming mold core 2 and a preforming mold 3, and the preforming mold core 2 And the preforming mold 3 is arranged on the lower mold base through the preforming mold pad 4, the preforming mold is an annular structure, the preforming mold core is located in the annular preforming mold, and the upper surface of the preforming mold is provided with an annular protrusion, which is set The raised preform mold and the preform core cooperate to form the mold cavity structure.

[0031] The protrusion on the preforming mold 3 is an arc-shaped protrusion, the top surface of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com