Cleaning and drying device and method and harvester

A drying device and cleaning technology, which is applied to harvesters, circuit devices, battery circuit devices, etc., can solve the problems of incapable of applying pressure energy recovery and utilization, so as to improve utilization and conversion efficiency, reduce energy consumption, and improve battery life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

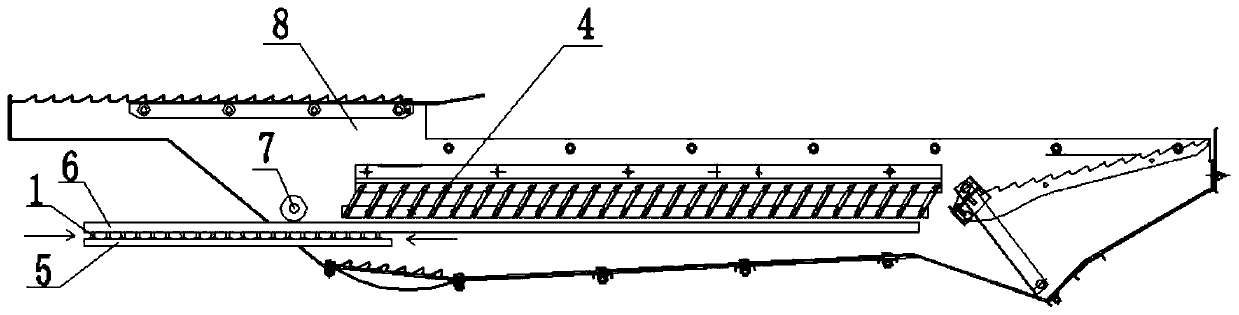

[0051] figure 1 Shown is a preferred embodiment of the cleaning and drying device of the present invention. The cleaning and drying device includes an energy conversion device 1, an electric energy collection and processing system 2, an electric energy flow control system 3, a storage battery 302, and a vibrating screen heating Device 4, supporting device 5 and vibrating screen bearing rolling guide 6.

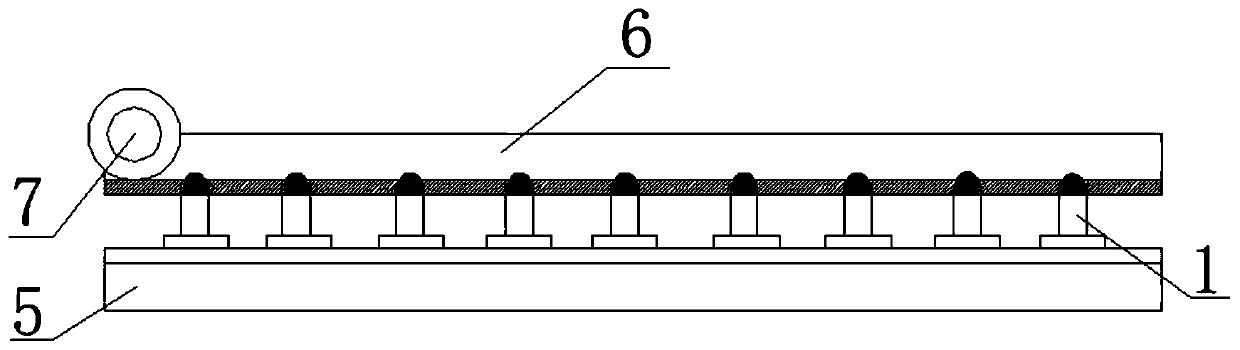

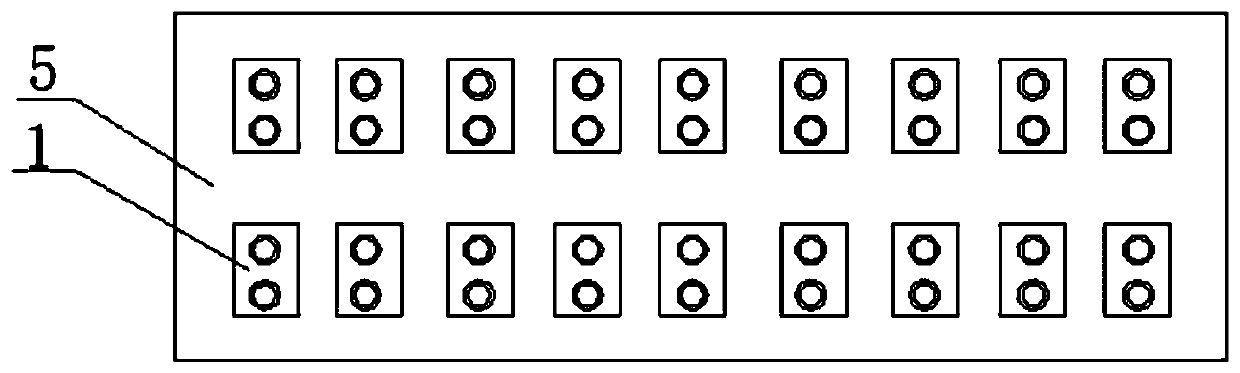

[0052] Such as figure 2 and 3 As shown, the support device 5 is provided with a plurality of energy conversion devices 1, the upper part of the energy conversion device 1 is connected with the vibrating screen bearing rolling guide 6, and the energy conversion device 1 is used to reciprocate the vibrating screen body 8. The generated pressure energy is converted into electric energy; the electric energy collection and processing system 2 is respectively connected with the energy conversion device 1, the electric energy flow control system 3, the storage battery 302 and the ...

Embodiment 2

[0065] A harvester, the harvester includes the cleaning and drying device described in Embodiment 1, so it has the beneficial effects of Embodiment 1, and will not be repeated here.

Embodiment 3

[0067]A method for controlling the cleaning and drying device according to embodiment 1, comprising the following steps:

[0068] The energy conversion device 1 converts the pressure energy generated by the reciprocating motion of the vibrating screen body 8 into electrical energy; the electrical energy collection and processing system 2 collects the generated electrical energy; the electrical energy flow control system 3 is based on the SOC value of the battery 302 Based on the actual working current of the vibrating screen heating device 4, it is judged whether the electric energy is used for charging the battery 302 or for the vibrating screen heating device 4 to heat the vibrating screen body 8, and whether to use the battery 302 to provide electric energy for the vibrating screen heating device 4.

[0069] The judgment process of the electric energy flow to the control system 3 is specifically:

[0070] When the SOC monitoring device 303 of the electric energy flows to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com