Fuel cell stack for jointly applying intraplate counter-flow flow field and interpolate counter-flow flow field

A fuel cell stack and countercurrent technology, applied in fuel cells, fuel cell grouping, fuel cell additives, etc., can solve the problems of insufficient countercurrent, large parasitic power, mutual cooperation and mutual support of coolant flow fields, etc. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

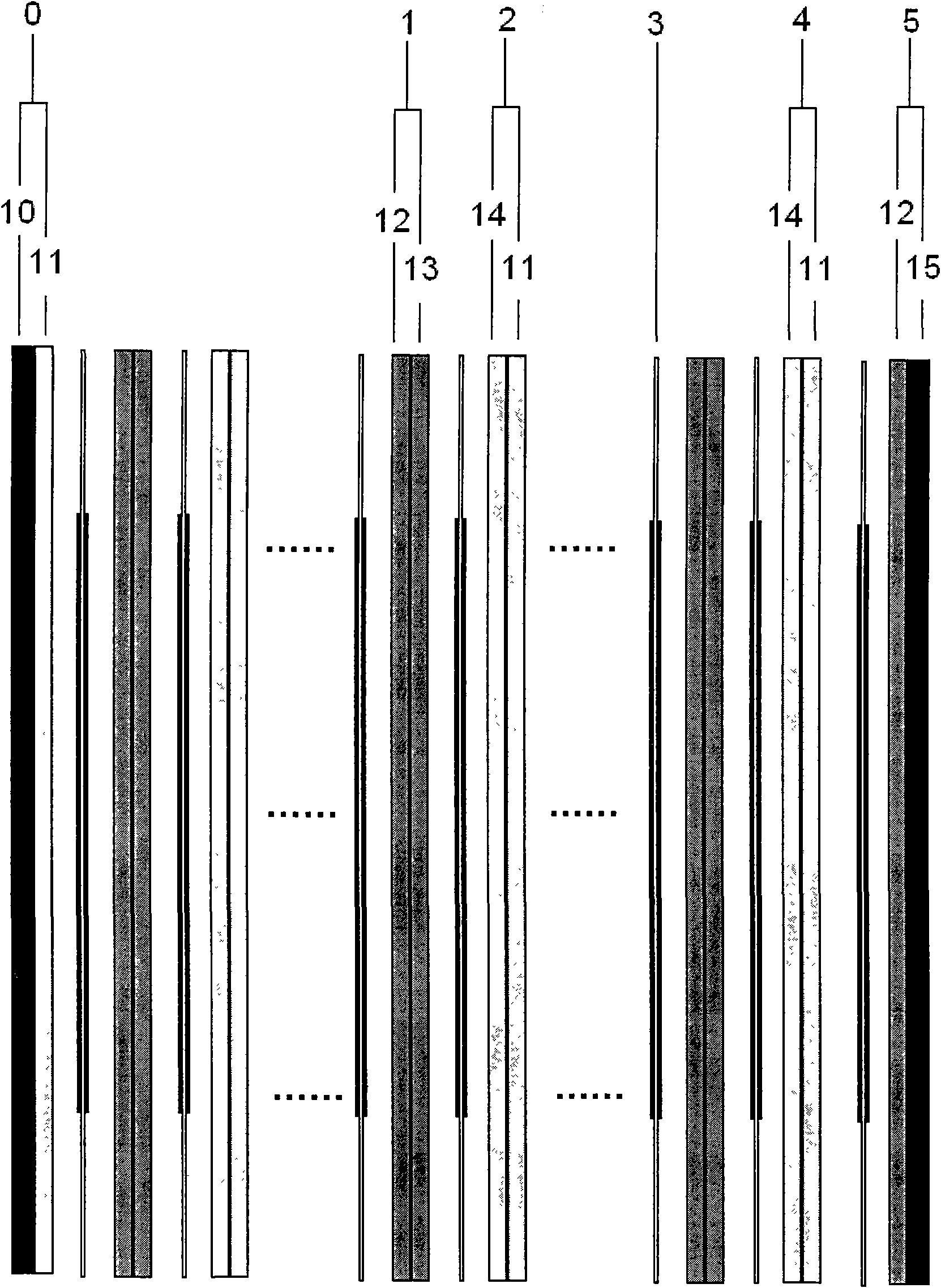

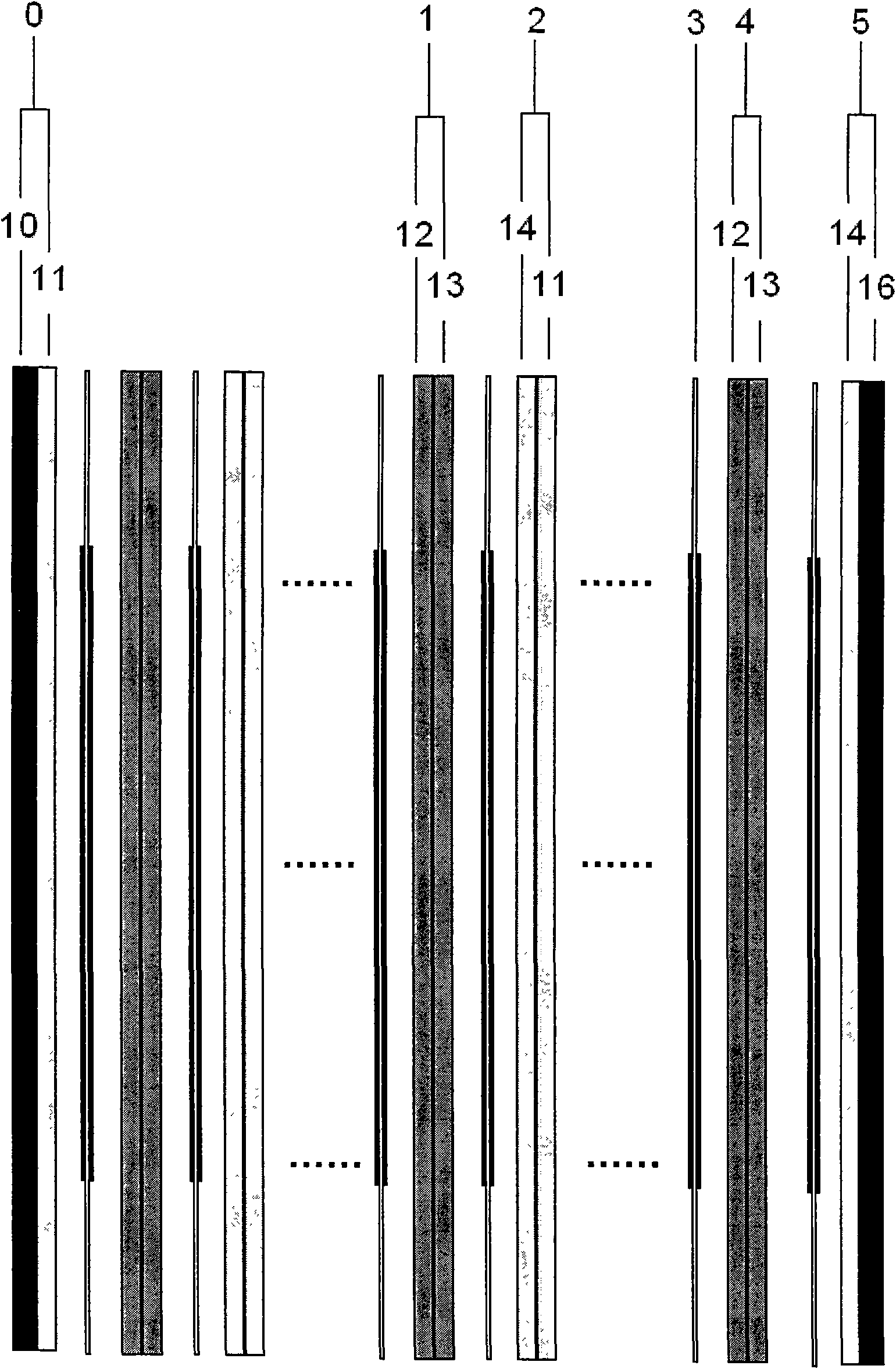

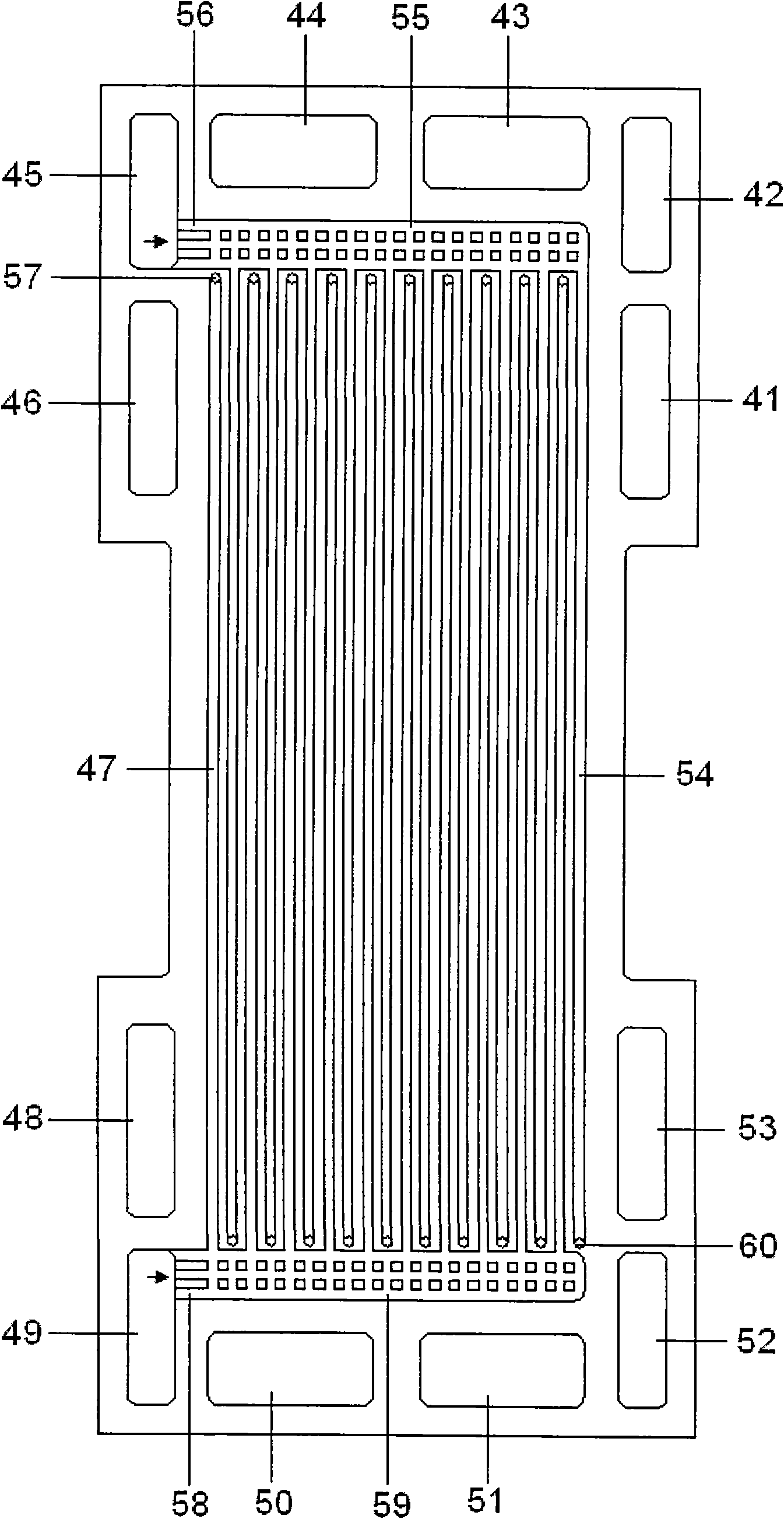

[0031] The present invention proposes a fuel cell stack that combines the countercurrent reactant flow field in the plate and the countercurrent coolant flow field between the plates, such as figure 1 and figure 2As shown, it includes a compound cathode unipolar plate 0 , a plurality of odd bipolar plates 1 , a plurality of even bipolar plates 2 , a plurality of membrane electrodes 3 and a compound anode unipolar plate 5 . The plurality of membrane electrodes 3, the plurality of odd-type bipolar plates 1 and the plurality of even-type bipolar plates 2 are placed between the composite cathode unipolar plate 0 and the composite anode unipolar plate 5, and the two bipolar plates repeat They are arranged alternately, and the composite cathode unipolar plates, multiple odd-shaped bipolar plates, multiple even-shaped bipolar plates and anode composite unipolar plates are connected one by one by membrane electrodes. For two bipolar plates arranged alternately, it is specified that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com