Side sucking type range hood and oil path structure thereof

A range hood and side-suction technology, applied in the field of side-suction range hoods and their oil circuit structure, can solve problems such as drooping and poor user experience, and achieve lower requirements, avoid drooping, and provide a better experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

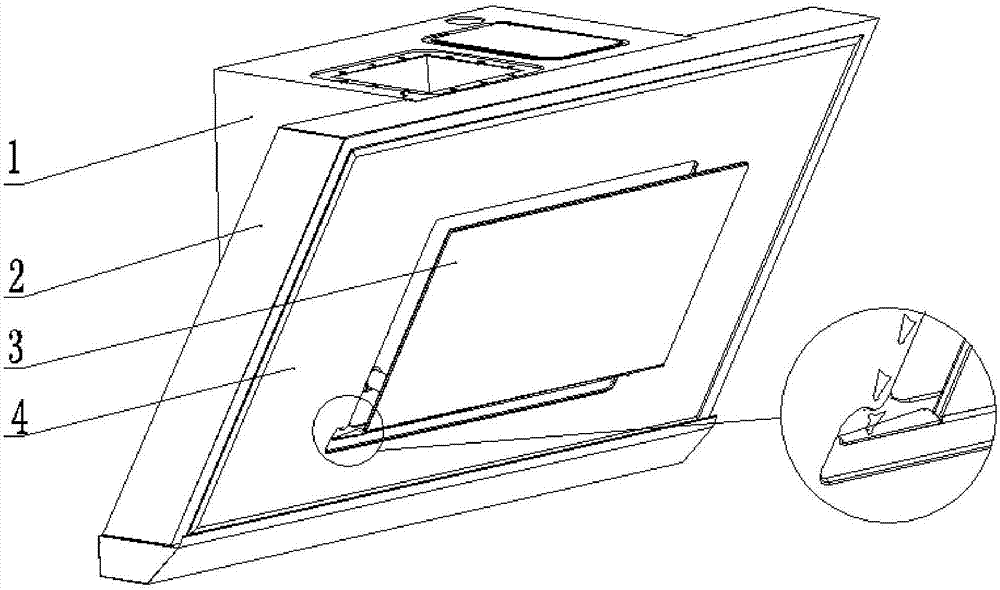

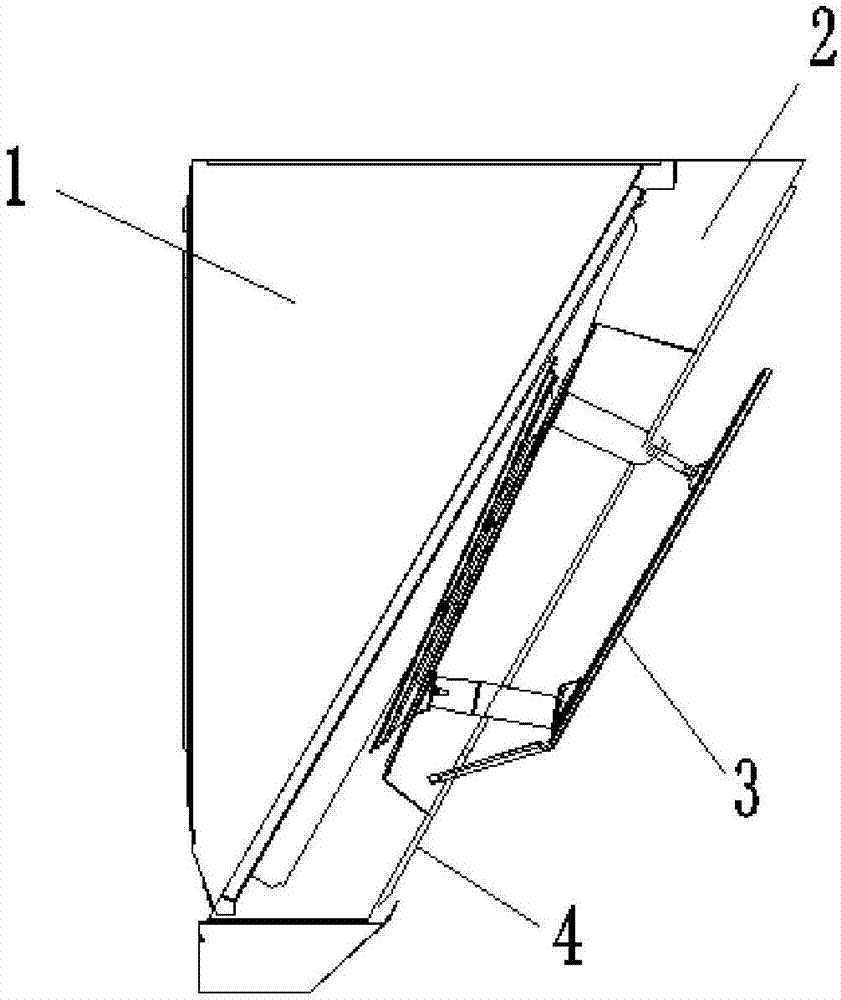

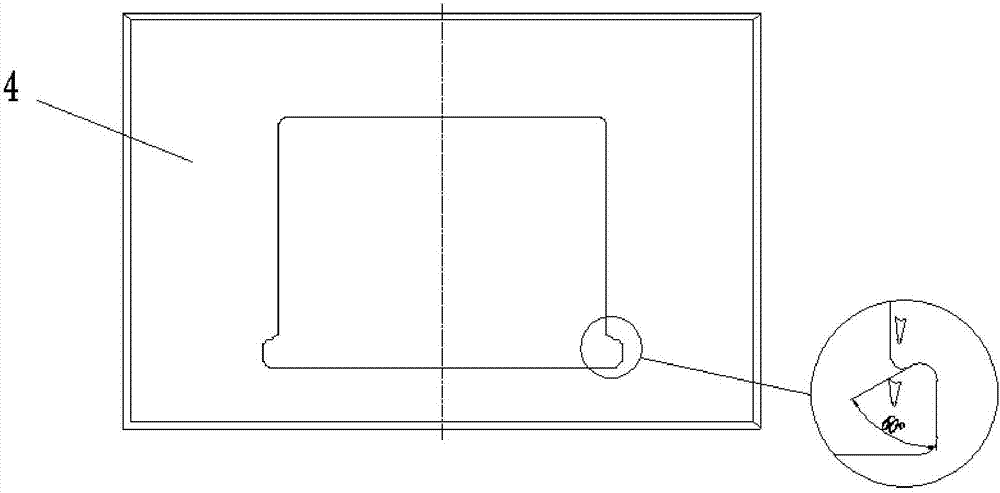

[0026] Embodiment 1: The oil circuit structure of this side-suction range hood mainly includes a range hood body and a panel 4. The range hood body is provided with a panel 4, and the lower end of the inner edge of the panel 4 is a special-shaped structure, and the special-shaped structure It is a notch structure, the middle part of the panel is provided with an air deflector assembly 3, and the lower part of the air deflector assembly is provided with an extension part from the outside of the panel to the inside of the panel, and the left and right sides of the extension part are located at the lower part of the notch structure, the notch structure, the air deflector assembly The extension part of the lower side to the body and the inside of the body form an oil channel. The notch structure is horizontally arranged on the panel, and the upper side of the notch structure is provided with a protrusion protruding downward. A slope is provided on the notch structure, and the angl...

Embodiment 2

[0028] Embodiment 2: On the basis of Embodiment 1, the central part of the panel 4 is provided with the wind deflector assembly 3 , and the rear part of the panel 4 is provided with the smoke collecting hood assembly 2 and the shell assembly 1 in sequence. The shell assembly 1 and the fume collecting hood assembly 2 are fixed by screws. The panel 4 is fixed with the fume collecting hood assembly 2 through silica gel. The wind deflector assembly 4 is fixed with the smoke collection hood assembly 2 through hooks. The lower edge of the wind deflector assembly 4 is bent inwardly to form an inward slope, which corresponds to the profiled structure of the panel 4, and the lower end of the wind deflector assembly 4 extends to the inside of the panel, allowing oil droplets to drip When the air deflector assembly 4 is used, the oil droplets will directly enter the inside of the fume collecting hood.

[0029] The panel 4 , the smoke collecting hood assembly 2 and the wind deflector as...

Embodiment 3

[0030] Embodiment 3, this side suction range hood includes the oil circuit structure of the side suction range hood described in the above embodiment, which avoids the phenomenon of sagging, has a neater and more beautiful appearance, and better user experience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com