Evanescent mode casting technology method for lightweight balance shaft beam

A technology of lost foam casting and process method, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as poor impact resistance, and achieve the effects of improving impact resistance, saving metal, and rational flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

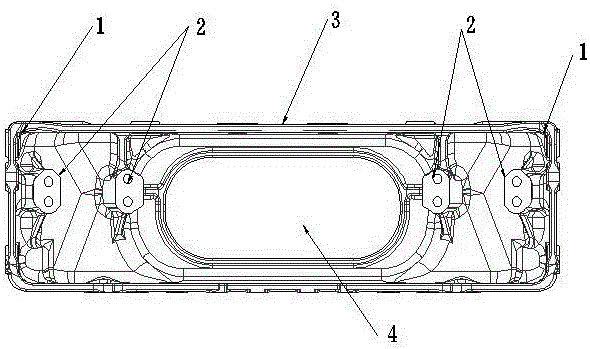

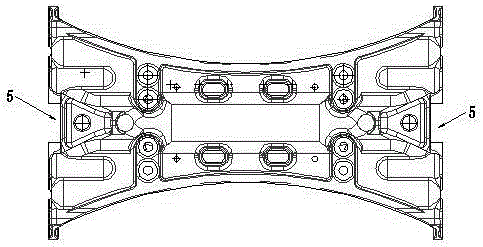

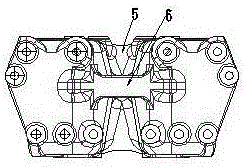

[0020] combine Figure 1-Figure 5 As shown, the present invention is further described as follows:

[0021] The process method of lost foam casting of light weight balance shaft crossbeam is characterized in that:

[0022] (1) Structural design of the lightweight balance shaft crossbeam: connecting bracket 1, thrust rod support 2, and crossbeam 3 are integral structures formed by one-time casting, with an elliptical weight-reducing cavity 4 in the middle of the crossbeam, and the connecting brackets at both ends are symmetrical structures , the middle position of the connecting bracket is provided with a weight-reducing groove 5, and the mouth of the weight-reducing groove is connected 6 through reinforcing ribs;

[0023] (2) Design of gating system: 3 ingates 11, 1 runner 9, 4 slag collection bags 10, 1 sprue 8, runner 9 is connected with sprue 8, sprue There is a sprue cup 7 on the top, 3 ingates 11 are connected under the runner 9, 3 ingates 11 are directly connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com