Air purifier capable of automatically cleaning ash

An air purifier and automatic dust removal technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of increasing power consumption, affecting the effect of dust removal, prolonging the cleaning time, etc., and achieve good practicability , Reduce use time and power consumption, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

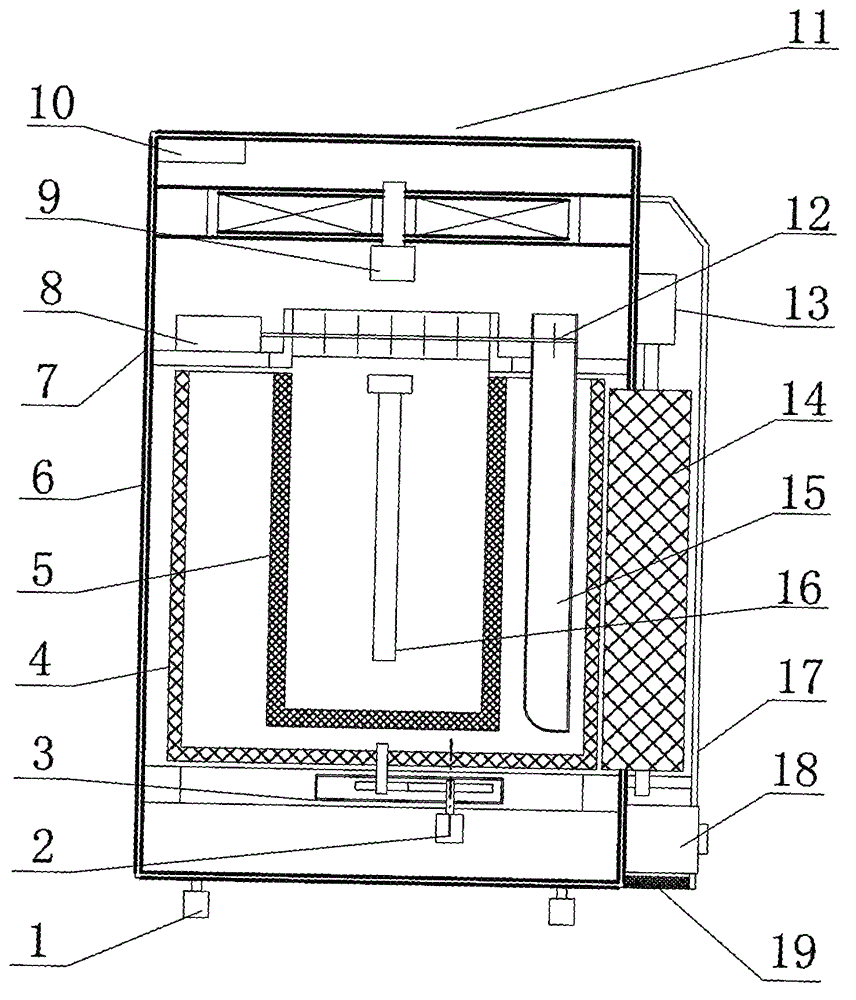

[0011] When the purifier is working, the exhaust fan (9) is turned on, the air enters from the air inlet (6), and the air enters from the four sides. After the air passes through the primary filter barrel (4) to filter particulate dust, it enters the secondary filter barrel (5 ), the second stage is made up of a variety of filter materials, which can filter toxic and harmful gases. After passing through the secondary filter barrel (5), the air moves toward the exhaust fan (9) and kills harmful bacteria through the ultraviolet lamp (16). At this time, the shutter In the conduction state, the air is discharged from the air outlet (11) through the exhaust fan (19). When entering the automatic dust cleaning state, the electromagnet (8) makes the louver (12) on the filter barrel close, and the louver (12) on the blowback pipe (15) changes from closed to open, and at the same time, the exhaust fan (9) reverses, turning the The air is pressed into the blowback pipe (15), and the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com