Regeneration method for waste lubricant and apparatus

A waste lubricating oil and process technology, applied in the directions of lubricating compositions, chemical instruments and methods, semi-permeable membrane separation, etc., can solve the problems of high energy consumption of high-frequency vibration, difficult backwashing, high equipment cost, and achieve high service temperature. , easy operation, high energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Using the waste oil regeneration equipment and regeneration method described in the embodiment of the present invention, the waste oil (the same below) taken from the automobile repair factory is subjected to coarse filtration, impurity removal and dehydration, and the high temperature resistance of 85 °C with an average pore size of 0.1 μm is used. Polyvinylidene fluoride (PVDF) hollow fiber membrane module, under the conditions of the pre-treatment temperature of 65 ° C and 85 ° C and the operating pressure of 0.1 MPa, membrane separation and purification of the waste oil after dehydration and impurity removal are carried out. A clear, transparent brown regenerated oil is obtained.

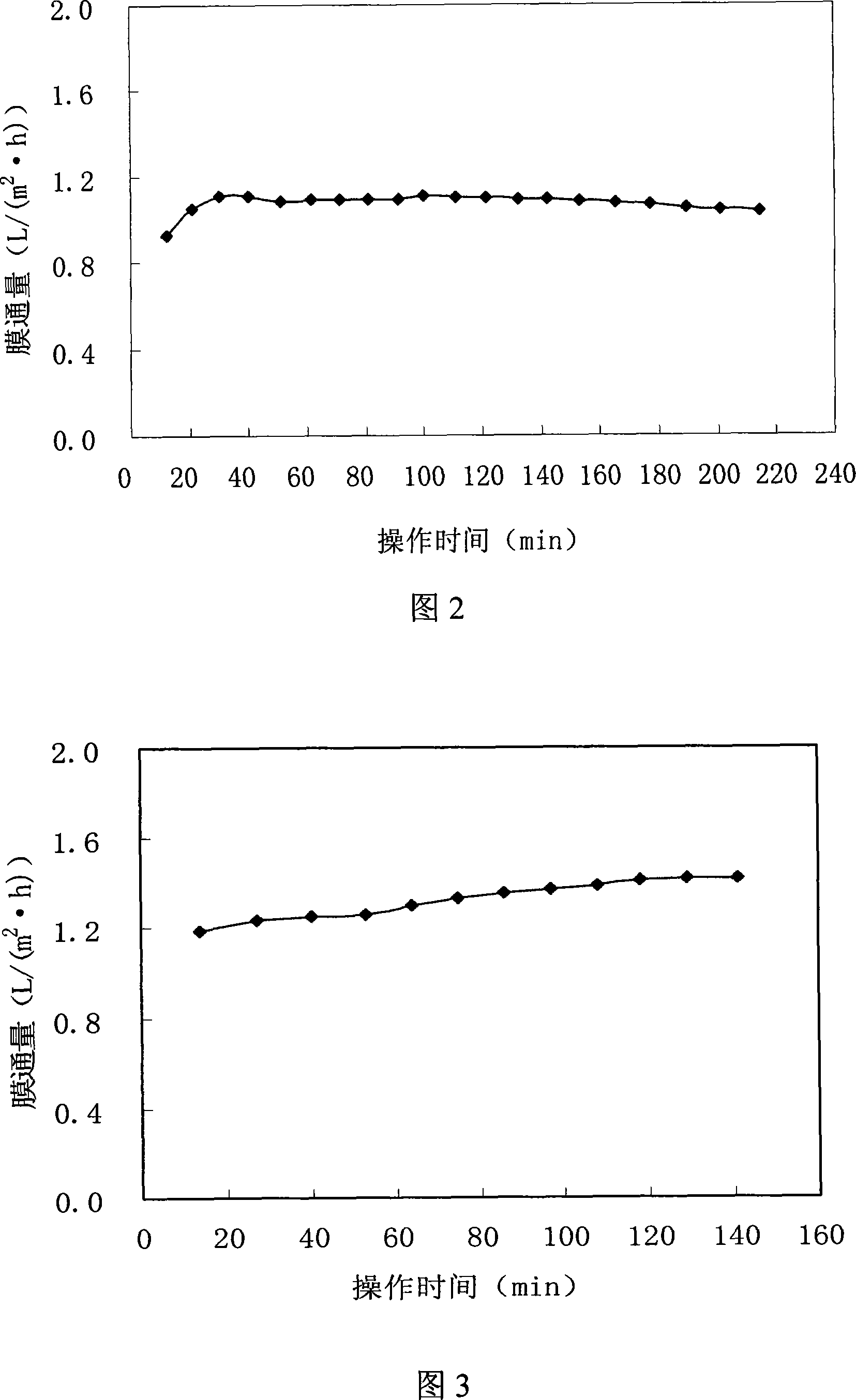

[0057] Fig. 2 is a graph showing the change of membrane flux with operating time during the separation process. It can be seen from Figure 2 that the membrane flux is relatively stable throughout the operation. Simple viscosity measurement of recycled oil: the viscosity of waste oil at 4...

Embodiment 2

[0059] The regeneration method and equipment are the same as in Example 1, but the process conditions are: the pre- and post-treatment temperatures are 75°C and 80°C respectively, and the operating pressure is 0.1Mpa. Polysulfone hollow fiber membranes are used to carry out membrane separation and purification of waste oil after dehydration and impurity removal. A clear and transparent brown regenerated oil is obtained.

[0060] Fig. 3 is a graph showing the change of membrane flux with operating time during the separation process. It can be seen from Figure 3 that the membrane flux is relatively stable throughout the operation process.

Embodiment 3

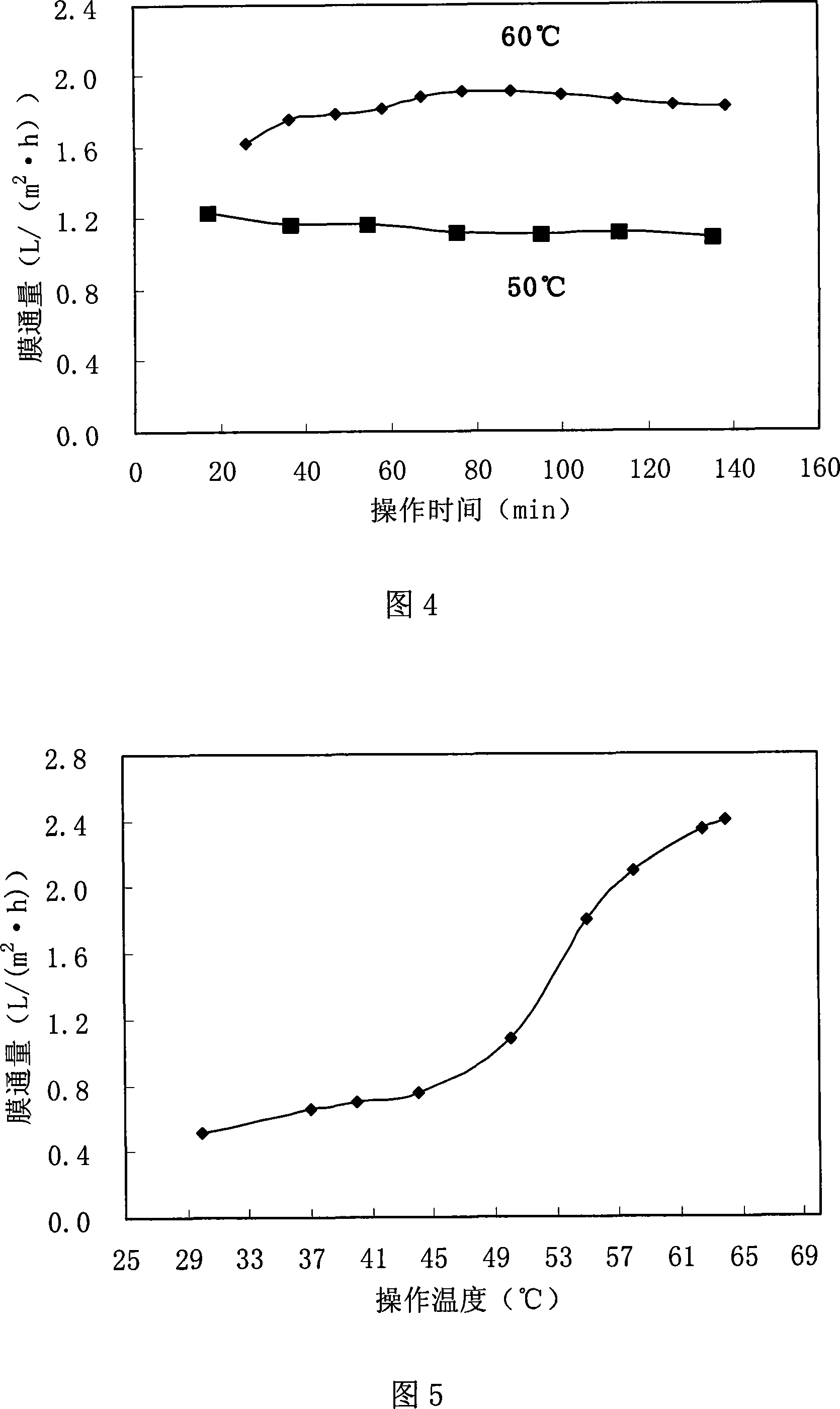

[0062] Using the same PES membrane module and the same operation method as in Example 2, at the treatment temperature of 50°C and 60°C, the change of membrane flux with time was studied, and the results are shown in Figure 4.

[0063] It can be seen from Fig. 4 that when the treatment temperature is 60°C, the membrane flux of the whole purification process is increased by about 64% compared with that at 50°C. This shows that the treatment temperature has a direct impact on the waste oil regenerated by the hollow fiber membrane: higher temperature is beneficial to reduce the viscosity of the waste oil and increase the flow velocity of the fluid on the surface of the membrane, so that the waste oil can easily pass through the membrane pores, and the performance increase in membrane flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com