Pipe type continuously reacting apparatus

A chemical reaction and tube-type technology, applied in the field of tube-type continuous reaction devices, can solve problems such as large latent heat of gasification of liquefied gas raw materials, accelerated feeding, and poor control, so as to reduce side reactions, reduce production energy consumption, The effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

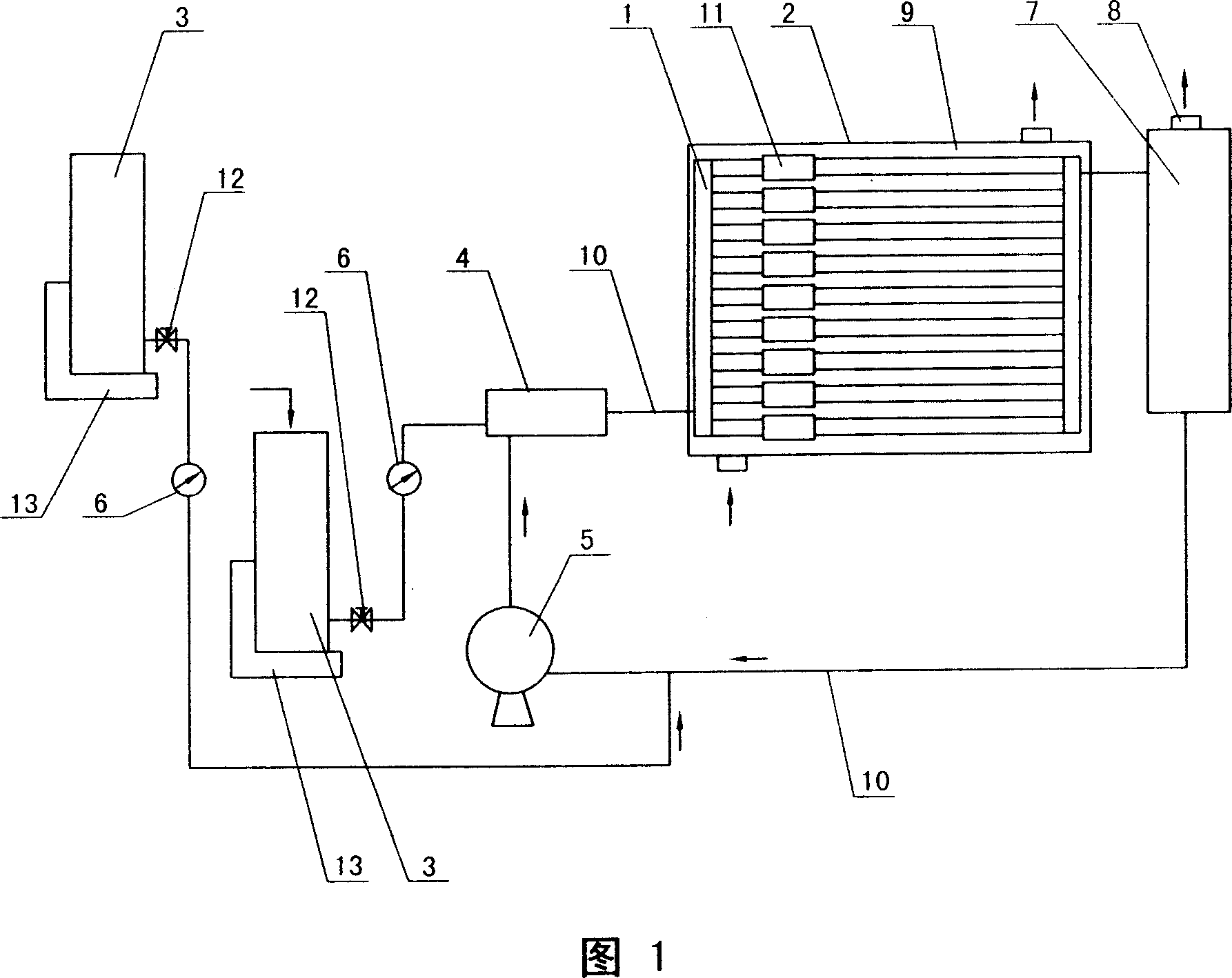

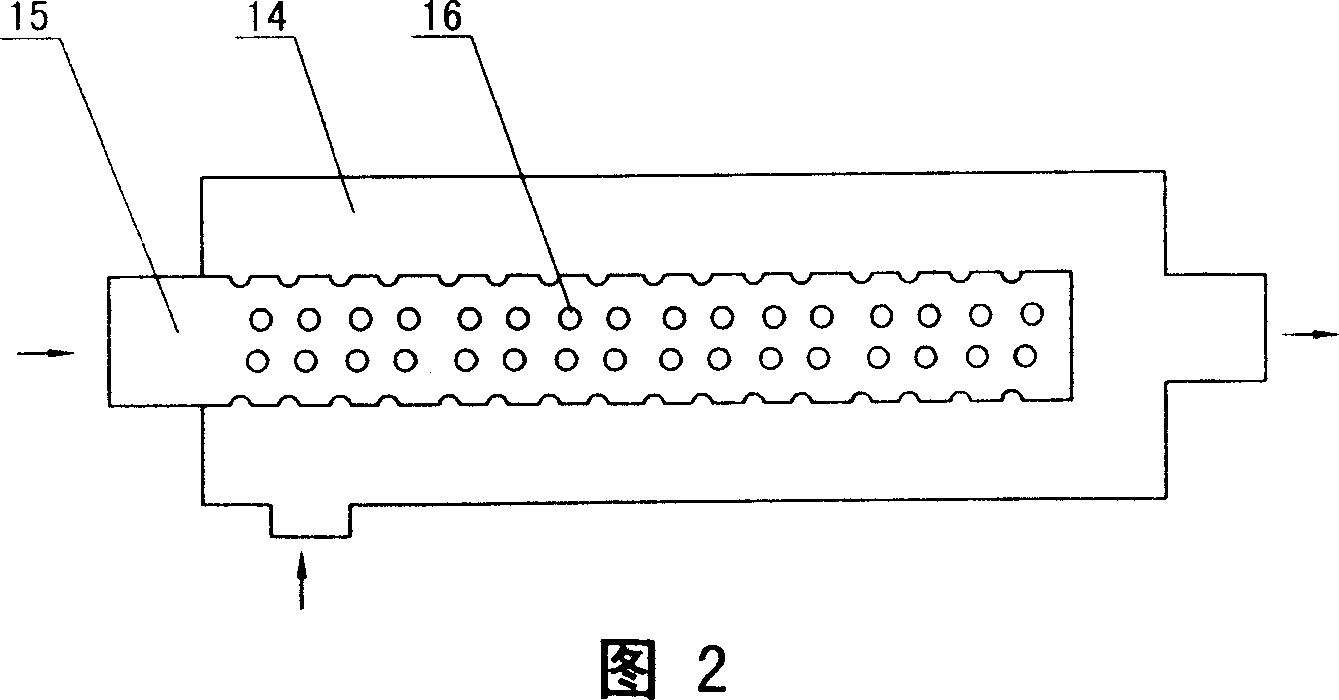

[0015] 1. Reactor 2, heat exchanger 3, raw material tank 4, pre-mixer 5, circulation pump 6, flow controller 7, buffer tank 8, outlet 9, cooling medium 10, pipeline 11, static mixer 12, valve 13 , measuring scale 14, round tube 15, thin tube 16, small hole

[0016] Fig. 1~2 is the embodiment that the present invention adopts the reaction of ethylene oxide and phosphorus trichloride to generate tris (2-chloroethyl) phosphite. The reactor 10 adopts a tubular reactor, the static mixer 11 is connected in series in the reaction tube, and placed in the heat exchanger 2 filled with the cooling medium 9, the pre-mixer 4 includes a circular tube 14 with both ends blocked and a set The narrow tube 15 fixed in the round tube 14, the end of the thin tube 15 is blocked, and the small holes 16 with a diameter of 0.5-1mm are evenly distributed on the tube wall, and the head end passes through the round tube 14, and passes through the flow controller 6 Connect the outlet of the ethylene oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com