Method for treating sewage by Fenton process

A Fenton method and sewage technology, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of increased investment and operating costs, poor technical economy, restrictions on promotion and application, etc., to reduce treatment costs, reduce sludge volume, The effect of dosage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

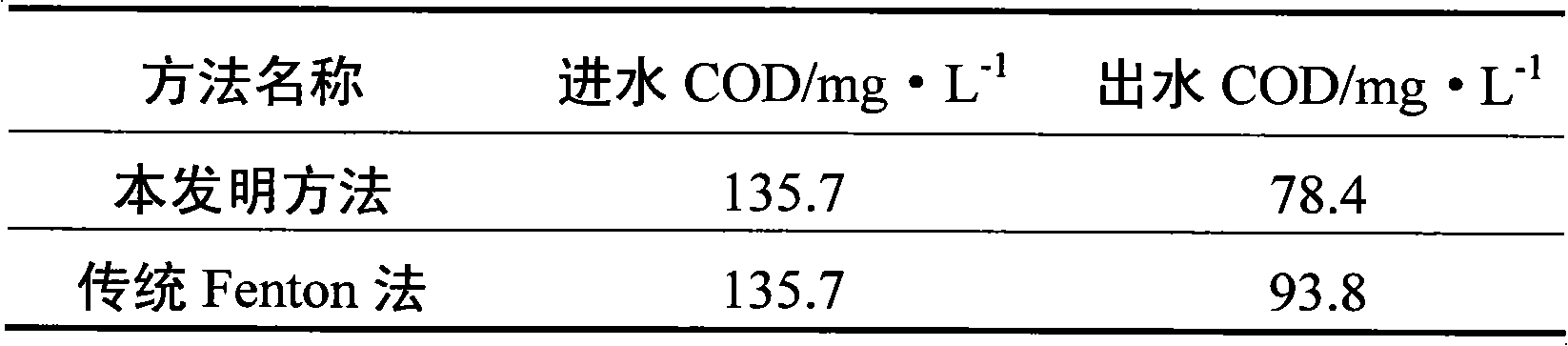

[0023] To treat the high-concentration sewage of an oil refinery that still does not meet the standard after the secondary biochemical treatment, the Fenton reaction is carried out by using two-stage series fully mixed flow reactors, and the dosage of each stage is 50mg / L H 2 o 2 , the total dosage is 100mg / L, and the catalyst is FeSO 4 , and make n(Fe 2+ ) / n(H 2 o 2 )[Fe 2+ Ions and H 2 o 2 The molar ratio] reached 0.7, with H 2 SO 4 Control the pH of the treated sewage at about 3.0, and the hydraulic retention time is 1h. Compared with the traditional Fenton process, 100mg / L H 2 o 2 , other conditions are the same as the method of the present invention. The results of the two methods are shown in Table 1. The results in Table 1 show that the influent COD is 135.7mg / L, and the H 2 o 2 When the dosage is the same, the effluent COD of the method of the present invention is 78.4mg / L, and the effluent COD of the traditional Fenton method is 93.8mg / L.

[0024] Table...

Embodiment 2

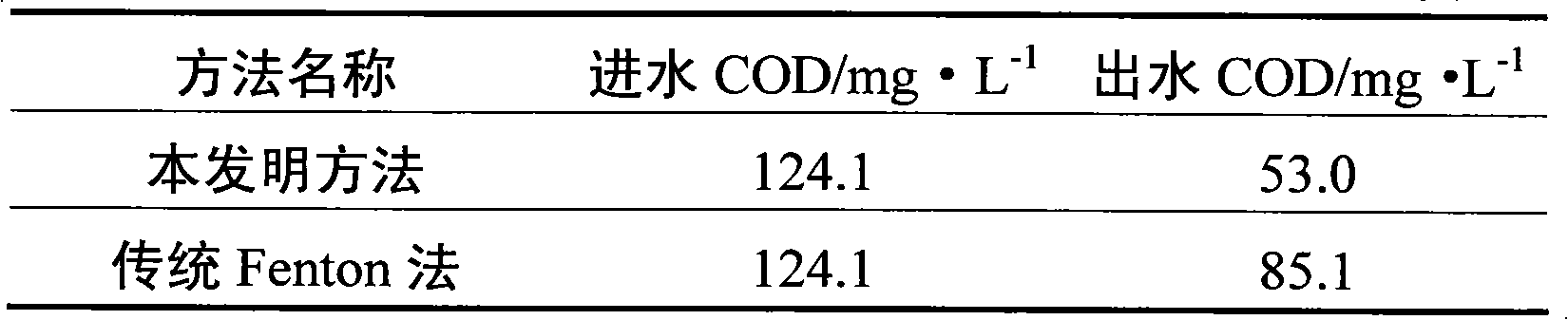

[0027] To treat the difficult-to-biochemical sewage of a chemical company that still does not meet the standard after three-stage BAF treatment, four-stage fully mixed-flow reactors in series are used for Fenton reaction, and the dosage of each stage is 25mg / L H 2 o 2 , the total dosage is 100mg / L, and the catalyst is Fe(NO 3 ) 2 , and make n(Fe 2+ ) / n(H 2 o 2 ) to 1.0, use dilute HNO 3The pH is controlled at about 4.0, and the hydraulic retention time is 1h. Compared with the traditional Fenton process, 100mg / L H 2 o 2 , other conditions are the same as the method of the present invention. The results of the two methods are shown in Table 2. The results in Table 2 show that the influent COD is 124.1 mg / L, the effluent COD of the method of the present invention is 53.0 mg / L, and the effluent COD of the traditional Fenton method is 85.1 mg / L.

[0028] Table 2 Comparison of the effects of two Fenton methods in treating substandard sewage in oil refineries

[0029] ...

Embodiment 3

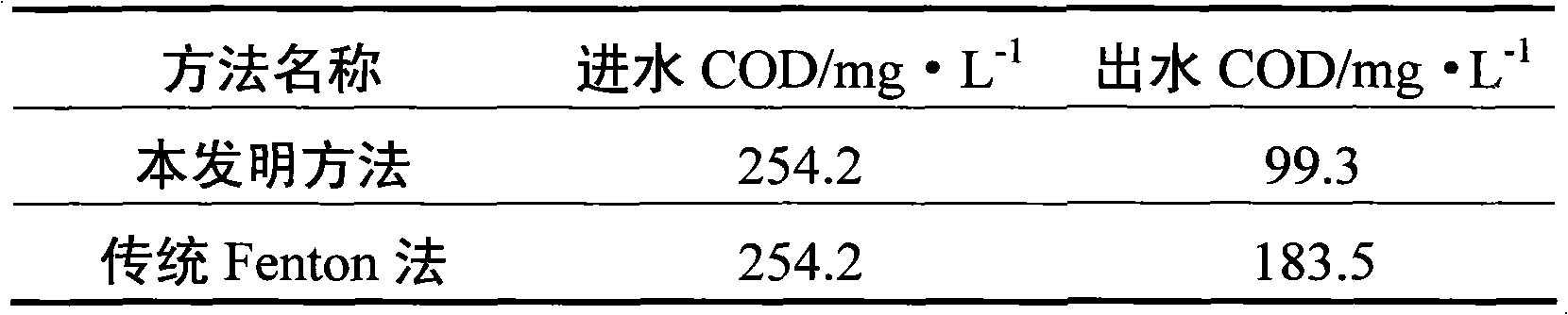

[0031] To treat the high-concentration sewage of an oil refinery that still does not meet the standard after secondary biochemical treatment, six-stage fully mixed-flow reactors in series are used, each stage of H 2 o 2 The dosage is 1 / 10 of the current COD value, the total dosage is 105mg / L, and the catalyst is Fe(NO 3 ) 2 , and make n(Fe 2+ ) / n(H 2 o 2 ) to 0.8, use dilute HNO 3 The pH is controlled at about 2.0, and the hydraulic retention time is 1.5h. Compared with the traditional Fenton process, 105mg / L H 2 o 2 , other conditions are the same as the method of the present invention. The results of the two methods are shown in Table 3. The results in Table 3 show that the influent COD is 254.2 mg / L, the effluent COD of the method of the present invention is 99.3 mg / L, and the effluent COD of the traditional Fenton method is 183.5 mg / L.

[0032] Table 3 Comparison of the effects of two Fenton methods in treating substandard sewage in petrochemical enterprises

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com