Precursor of lithium ion battery cathode material, preparation method thereof, cathode active material, lithium ion battery, and continuous reactor

A lithium-ion battery and cathode material technology, applied in the field of new energy materials, can solve the problems of unstable particle growth rate and nucleation rate, affecting the electrochemical performance of materials, and disordered particle growth, so as to achieve long-term stability of process parameters, Excellent cycle life, high temperature rate performance, and uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

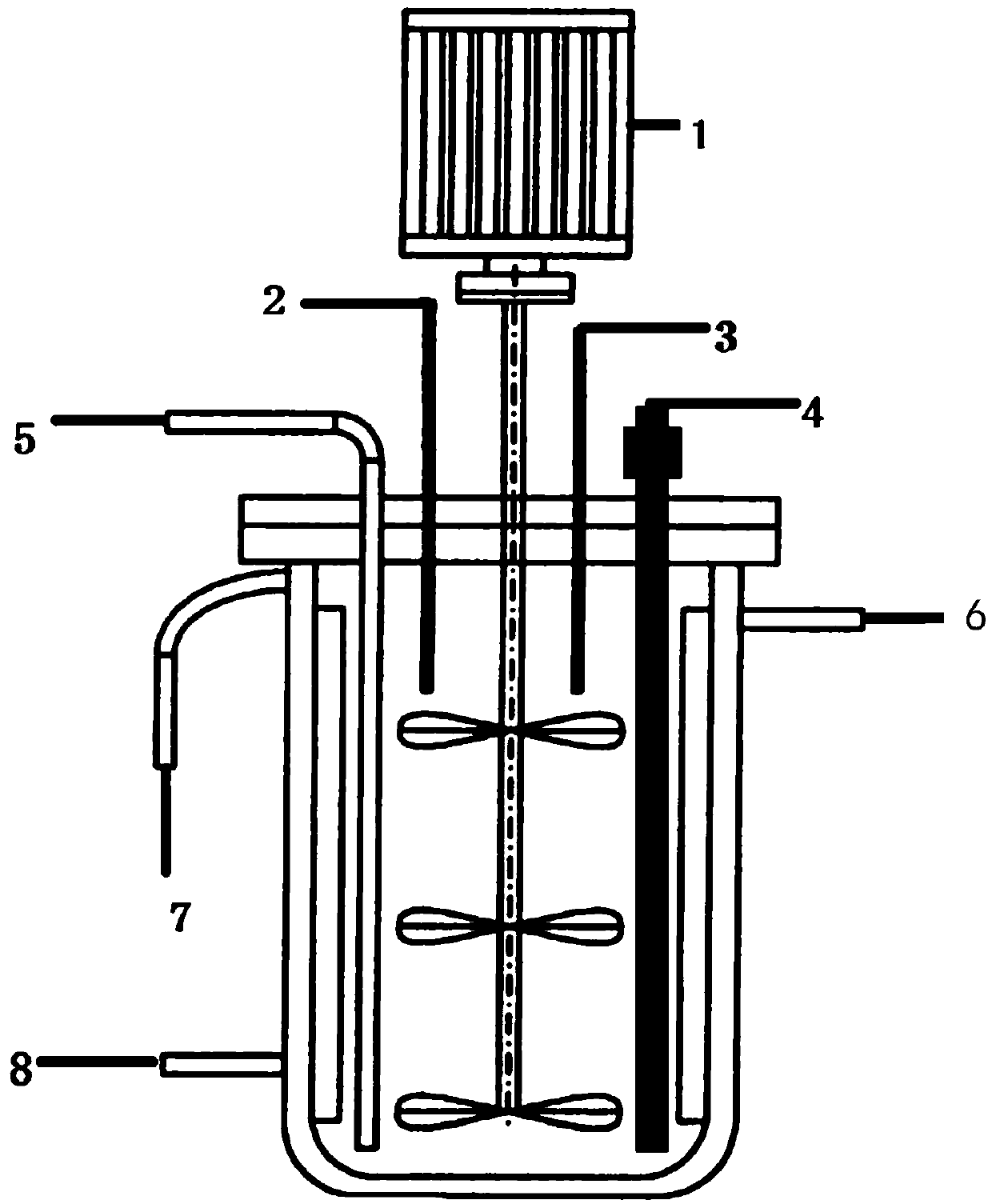

[0054] The continuous reactor of this embodiment is a reactor, and the structure of the reactor is shown as figure 1 As shown (1 is the motor, 2 is the pH meter, 3 is the thermometer, 4 is the ultrasonic generator, 5 is the feed pipe, 6 is the circulating water outlet, 7 is the overflow discharge pipe, 8 is the circulating water inlet).

[0055] Specifically, the reaction kettle includes a reaction vessel and a top cover matched with the reaction vessel. The upper end of the reaction vessel is provided with an overflow port, and an overflow discharge pipe 7 is connected to the overflow port. The reaction kettle also includes a feed pipe 5 for feeding into the reaction vessel. The feed pipe 5 is fixedly arranged on the top cover of the reaction kettle, and one end extends into the inside of the reaction vessel until the bottom of the reaction vessel. The outlet of the feed pipe is set at the bottom of the reaction vessel. The reaction kettle also includes a stirrer for stirri...

Embodiment 2

[0068] The preparation method of the lithium-ion battery cathode material precursor of the present embodiment comprises the following steps:

[0069] 1) Nickel sulfate, cobalt sulfate, and manganese sulfate are dissolved in a molar ratio of Ni:Co:Mn=8:1:1 to prepare a nickel-cobalt-manganese mixed salt solution. The concentration of total metal ions in the mixed salt solution is 2.6mol / L; preparation mass fraction is 32% sodium hydroxide solution; preparation mass fraction is 17% ammoniacal liquor, standby;

[0070] 2) Use a metering pump to pump the nickel-cobalt-manganese mixed salt solution, sodium hydroxide solution, and ammonia water into the 50L reaction kettle at the same time, and stir the synthesis reaction while pumping the materials, wherein the pumping speed of the mixed salt solution is 100mL / min , the pumping speed of sodium hydroxide solution is 20mL / min, and the pumping speed of ammoniacal liquor is 30mL / min; 15L ultrapure water is added in advance in the abov...

Embodiment 3

[0076] The preparation method of the lithium-ion battery cathode material precursor of the present embodiment comprises the following steps:

[0077] 1) Nickel sulfate, cobalt sulfate, manganese sulfate and zirconium sulfate are dissolved in a molar ratio of Ni:Co:Mn:Zr=0.6:0.15:0.2:0.05 to prepare a nickel-cobalt-manganese-zirconium mixed salt solution. In the mixed salt solution, the total The concentration of metal ions is 2.6mol / L; the preparation mass fraction is 32% sodium hydroxide solution; the preparation mass fraction is 17% ammonia solution, for subsequent use;

[0078]2) Use a metering pump to pump nickel-cobalt-manganese-zirconium mixed salt solution, sodium hydroxide solution, and ammonia water into the 50L reaction kettle at the same time, and stir the synthesis reaction while pumping the materials, wherein the pumping speed of the mixed salt solution is 80mL / min, the pumping speed of sodium hydroxide solution is 15mL / min, and the pumping speed of ammonia water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com