Method for preparing poly-alpha-olefin in continuous manner

An olefin and continuous technology, applied in chemical instruments and methods, processing hydrocarbon oil, production of liquid hydrocarbon mixtures, etc., can solve problems such as demanding control of process parameters, increasing process operation complexity, and long process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The following examples serve to illustrate the invention and to compare the products obtained in these examples with those obtained by methods known in the art. Those skilled in the art can make many modifications and changes to the following embodiments according to specific situations, and it should be understood that the present invention can be practiced in other ways than those specifically described herein without departing from the scope of the claims.

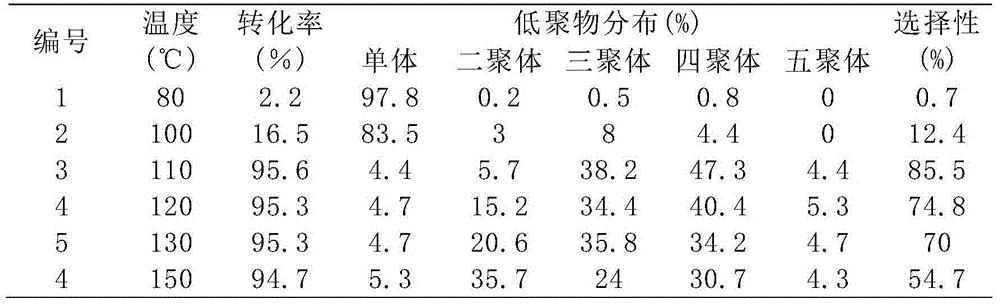

[0030] In the following examples, gas chromatography is used to conduct qualitative and quantitative analysis of the product reaction system. The adopted gas chromatograph includes a DB-1HT chromatographic column (30m×0.25mm) and a hydrogen ion flame detector, and the detection injection volume is 0.2 μL, wherein the injection is a mixture of the substance to be tested and dichloromethane in equal volume. The injector temperature was 300°C, the oven temperature was 50°C, and the detector temperature was 350°C. T...

Embodiment A

[0033] Embodiment A: the preparation of catalyst system A

[0034] In this example, catalyst system A for use in the present invention was prepared by the following steps. A motorized stirrer was fitted to a dry 1 liter four necked round bottom glass flask which was placed in a thermostatic heating mantle. Nitrogen was blown into the flask, 200 g of bromide-1-ethyl-3-methylimidazole white solid was placed in the flask, and AlCl was added in batches 3 Pale yellow powder, final bromide-1-ethyl-3-methylimidazole with AlCl 3 The molar ratio was 0.6, the reaction temperature was kept at 50-60°C, and stirred for 2 hours under nitrogen protection to obtain brown bromide-1-ethyl-3-methylimidazole / AlCl 3 solution, as the catalyst system A of the present invention.

Embodiment B

[0035] Example B: Preparation of Catalyst System B

[0036] In this example, Catalyst System B for use in the present invention was prepared by the following steps. A motorized stirrer was fitted to a dry 1 liter four necked round bottom glass flask which was placed in a thermostatic heating mantle. Nitrogen was passed through the flask, and 200ml of dichloromethane was first placed in the flask, and 1 mole of diethylaluminum chloride and 1 mole of TiCl were sequentially added to it. 4 , and finally diethylaluminum chloride with TiCl 4 The molar ratio was 1, the reaction temperature was kept at 30-40° C., and stirred for 1 hour under nitrogen protection conditions to obtain a light yellow solution, which was used as the catalyst system B of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com