Conjugated diene polymer, conjugated diene polymer composition, and method for producing conjugated diene polymer

A technology of conjugated diene and manufacturing method, which is applied in the direction of rolling resistance optimization, road transportation emission reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

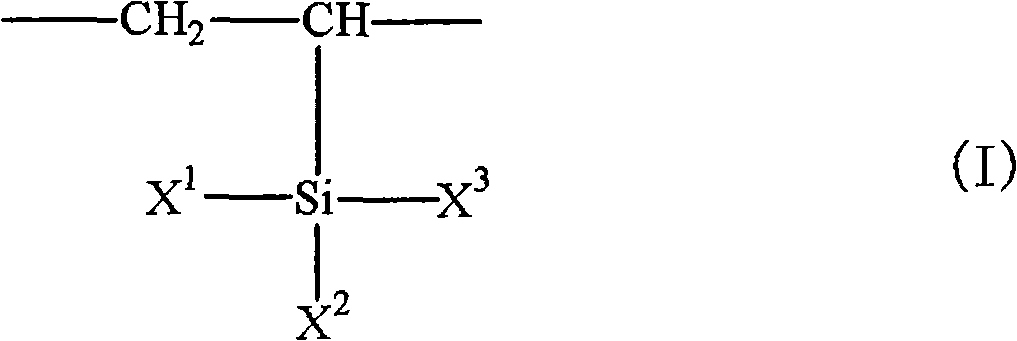

[0324] Washing and drying In the stainless steel polymerization reactor with an internal volume of 20 liters, replace with dry nitrogen, and drop hexane (specific gravity 0.68g / cm2) into the polymerization reaction vessel 3 ) 10.2kg, 1,3-butadiene 547g, styrene 173g, tetrahydrofuran 6.1ml, ethylene glycol diethyl ether 5.0ml. Next, 16.0 mmol of bis(diethylamino)methylvinylsilane and 18.5 mmol of n-butyllithium were added as a cyclohexane solution and a n-hexane solution, respectively, to start polymerization.

[0325] The stirring speed was set at 130 rpm, the temperature in the polymerization reactor was set at 65° C., and the copolymerization of 1,3-butadiene and styrene was carried out for 3 hours while continuously supplying monomers into the polymerization reactor. The supplied amount of 1,3-butadiene under total polymerization was 821 g, and the supplied amount of styrene was 259 g.

[0326] Next, the obtained polymer solution was stirred at a stirring rate of 130 rpm, ...

Embodiment 2

[0330] Washing and drying In the stainless steel polymerization reactor with an internal volume of 20 liters, replace with dry nitrogen, and hexane (specific gravity 0.68g / cm 3 ) 10.2kg, 547g of 1,3-butadiene, 173g of styrene, 6.1ml of tetrahydrofuran, and 5.0ml of ethylene glycol diethyl ether were put into the polymerization reaction container. Next, 17.3 mmol of n-butyllithium was charged into the n-hexane solution, and copolymerization of 1,3-butadiene and styrene was performed for 1 time. During the polymerization, the stirring speed was set to 130 rpm, and the temperature in the polymerization reactor was set to 65° C., and the mixture was continuously supplied into the polymerization reaction vessel.

[0331] After this 1-hour polymerization, 14.4 mmol of bis(diethylamino)methylvinylsilane was used as a cyclohexane solution, and under the condition that the stirring speed was 130 rpm and the temperature in the polymerization reactor was 65° C. input into the device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com