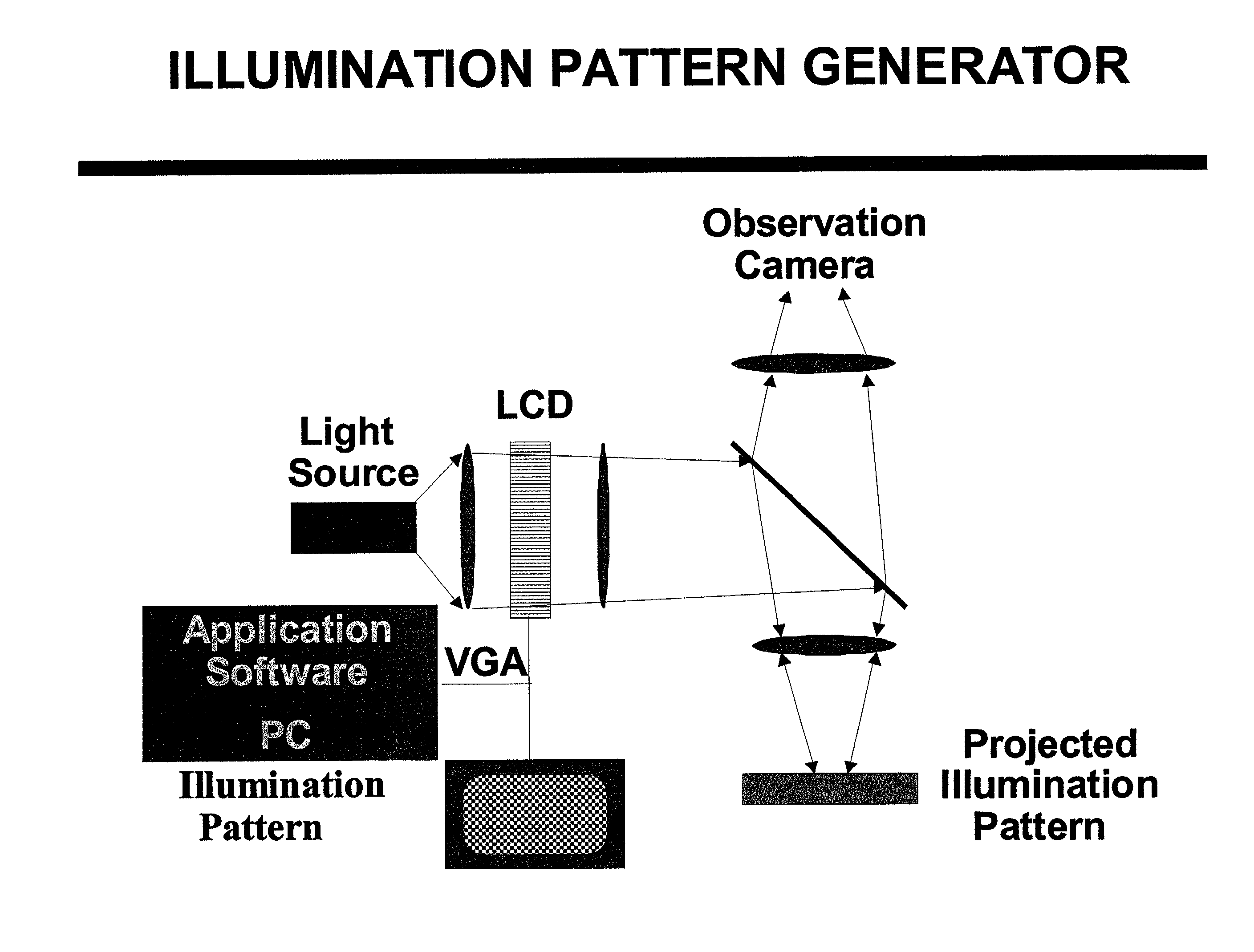

System and method for programmable illumination pattern generation

a programmable illumination and pattern technology, applied in the field of material science and analytical chemistry, can solve the problems of not being used to form a complete system, and placing rather severe requirements on the overall system layout, and achieve the effects of reducing steric constraints, facilitating disassembly, and minimizing faradaic processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

Fabrication of Surfaces and Coatings with Designed Properties

[0093]The present invention may be used to fabricate planar surfaces and coatings with designed properties. Specifically, the functional elements of the present invention enable the formation of arrays composed of particles of a wide range of sizes (approximately 100 Angstrom to 10 microns) and chemical composition or surface functionality in response to AC or DC electric fields. These arrays may be placed and delineated in designated areas of the substrate, and the interparticle spacing and internal state of order within the array may be controlled by adjusting the applied field prior to anchoring the array to the substrate. The newly formed surfaces display pre-designed mechanical, optical and chemical characteristics, and they may be subjected to further modification by subsequent treatment such as chemical cross-linking.

[0094]The mechanical and / or chemical modification of surfaces and coatings principally determines th...

example ii

Assembly of Lens Arrays and Optical Diffraction Elements

[0102]The present invention can be used to fabricate lens arrays and other surface-mounted optical elements such as diffraction gratings. The functional elements of the present invention enable the placement and delineation of these elements on ITO, facilitating integration with existing planar display technology, and on Si / SiOx, facilitating integration with existing silicon-based device technology.

[0103]Silica or other oxide particles, polymer latex beads or other objects of high refractive index suspended in an aqueous solution, will refract light. Ordered planar arrays of beads also diffract visible light, generating a characteristic diffraction pattern of sharp spots. This effect forms the basis of holographic techniques in optical information processing applications.

[0104]A.—The present invention provides for the use of arrays of refractive colloidal beads as light collection elements in planar array formats in conjunctio...

example iii

A Novel Mechanism for the Realization of a Particle-Based Display

[0109]The present invention provides the elements to implement lateral particle motion as a novel approach to the realization of a particle-based display. The elements of the present invention provide for the control of the lateral motion of small particles in the presence of a pre-formed lens array composed of large, refractive particles.

[0110]Colloidal particulates have been previously employed in flat-panel display technology. The operating principle of these designs is based on electrophoretic motion of pigments in a colored fluid confined between two planar electrodes. In the OFF (dark) state, pigments are suspended in the fluid, and the color of the fluid defines the appearance of the display in that state. To attain the ON (bright) state, particles are assembled near the front (transparent) electrode under the action of an electric field. In this latter state, incident light is reflected by the layer of particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com