Fuel injection nozzle

A fuel injection nozzle and fuel injection hole technology is applied in the field of fuel injection devices of internal combustion engine fuel systems, which can solve problems such as fast response time, achieve full and perfect combustion, promote uniform mixing, and reduce fuel injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

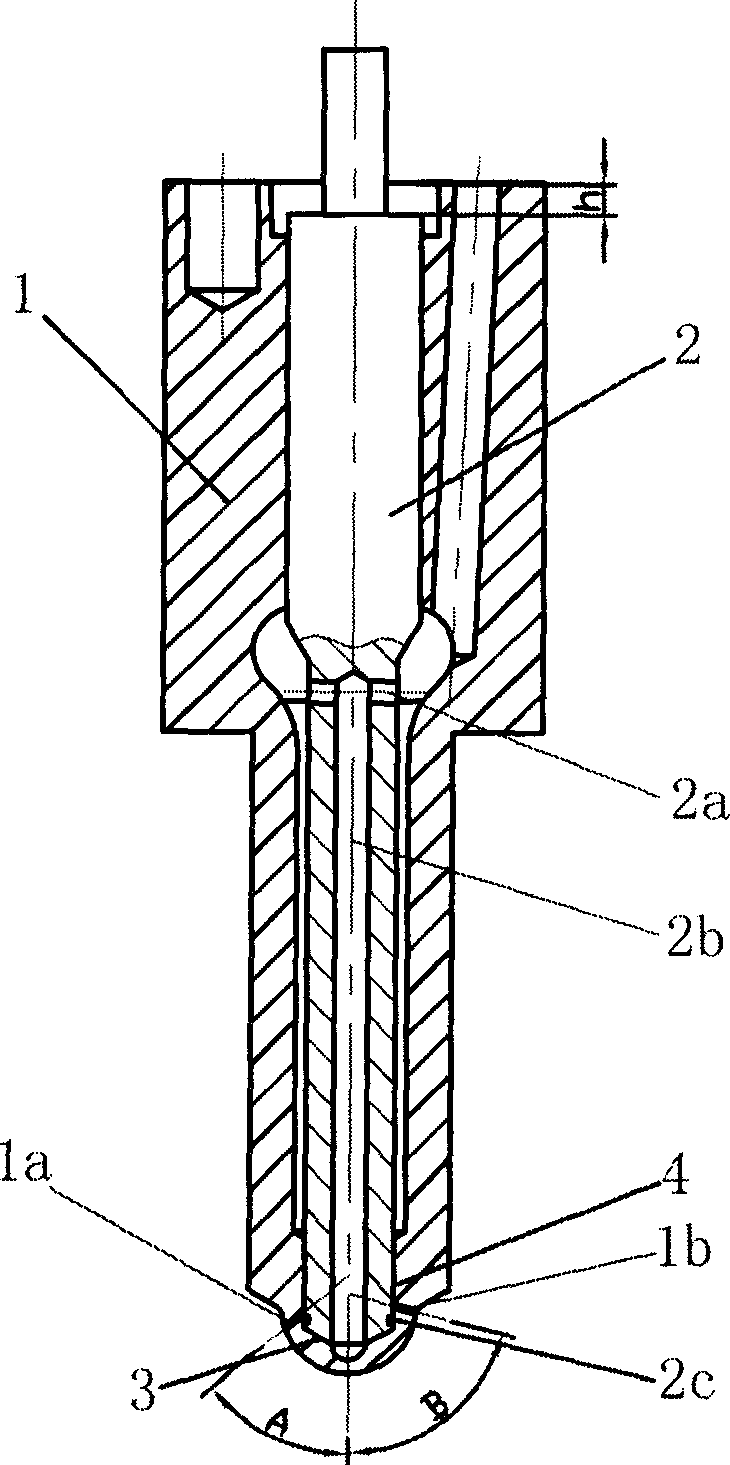

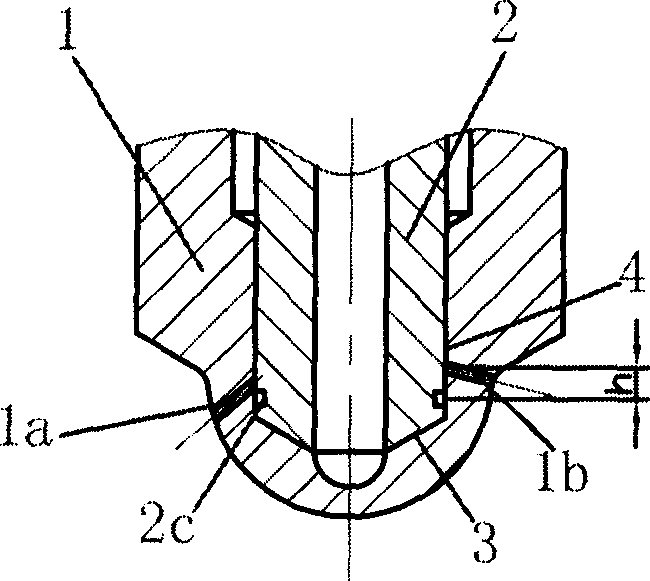

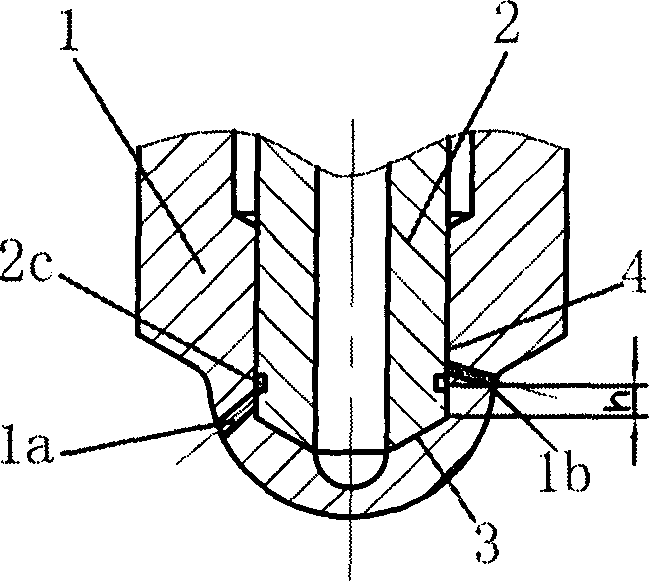

[0019] exist figure 1 , 2 , In the embodiment shown in 4 and 5, a fuel injection nozzle is composed of a needle valve body 1 and a needle valve 2, and the head of the needle valve body 1 is provided with two rows of oil injection holes 1a, 1b interlaced with each other. , the needle valve 2 is provided with a longitudinal hole 2b whose lower end is open, the middle part of the needle valve 2 is provided with a transverse hole 2a communicating with the longitudinal hole 2b, and a tapered sealing section is provided between the needle valve body 1 and the needle valve 2 3. There are four oil guide grooves 1c on the inner cylindrical surface 4 on the upper part of the conical sealing surface 3a of the needle valve body 1; The angle B between the hole 1b and the center line is 75 degrees; the position of the four lower row of oil injection holes 1a on the inner cylindrical surface 4 is lower than the position of the four upper row of oil injection holes 1b on the inner cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com