Shift control method for an automatic gearbox

A technology of automatic transmission and transmission, applied in the direction of electrical control, control device, engine control, etc., can solve the problems of shifting duration, shifting comfort, unfavorable shifting changes, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

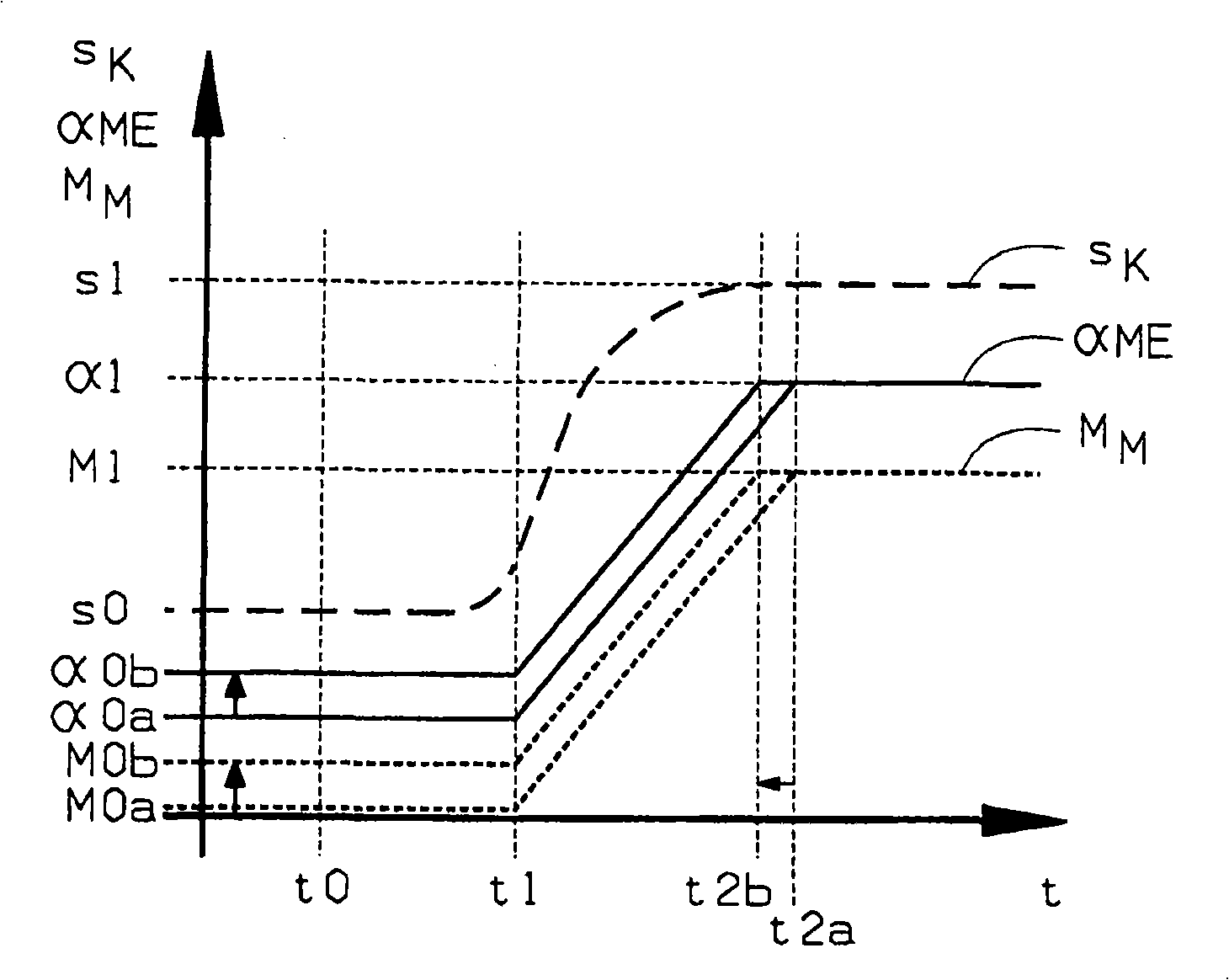

[0024] The time diagram shows, for example, the adjustment travel S of the motor clutch for the end of the shifting process with the opening of the motor clutch K , fuel injection quantity α M and the fuel injection quantity α of the transmission motor ME Control torque M M distribution over time t.

[0025] Engage the target gear and inject quantity α at time t0 ME In the normal case, it drops to the value α0a assigned to the idle torque M0a. Torque M of drive motor M Therefore, the value M0a is close to zero. The motor clutch is in position s0 when it is disengaged, that is to say fully disengaged. At time t1, the load composition of the drive motor begins to pass through the injection quantity α ME There is a ramp from the value α01 to the value α1 reached at time t2a. Torque M between t1 and t2a M Correspondingly, under the coordinated closing of the motor clutch at the same time (clutch stroke S K from position s0 to position s1), from value M0a to value M1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com