Electrically controlled electromechanical automatic shift system

An automatic shifting and mechanical technology, applied in the direction of mechanical equipment, transmission devices, friction transmission devices, etc., can solve the problems of high cost, low shift quality, complex structure, etc., achieve low cost, shorten shift time, Effects with simple control structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

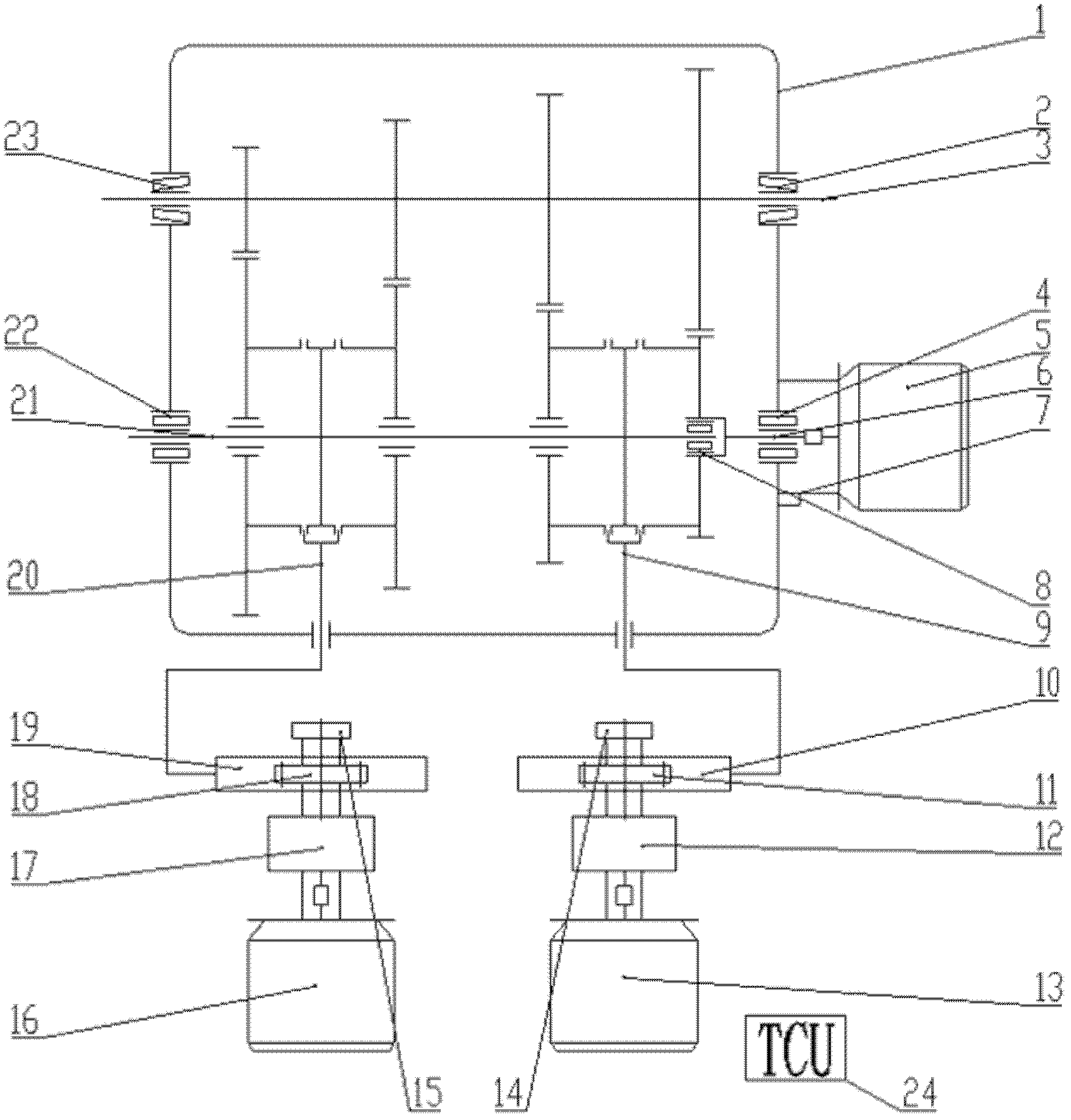

[0021] refer to figure 1 and figure 2 , The electronically controlled electromechanical automatic shifting system of the present invention consists of a parallel shaft gearbox 1, a No. 1 motor 5, a gear selection mechanism and an electronic control unit (TCU) 24.

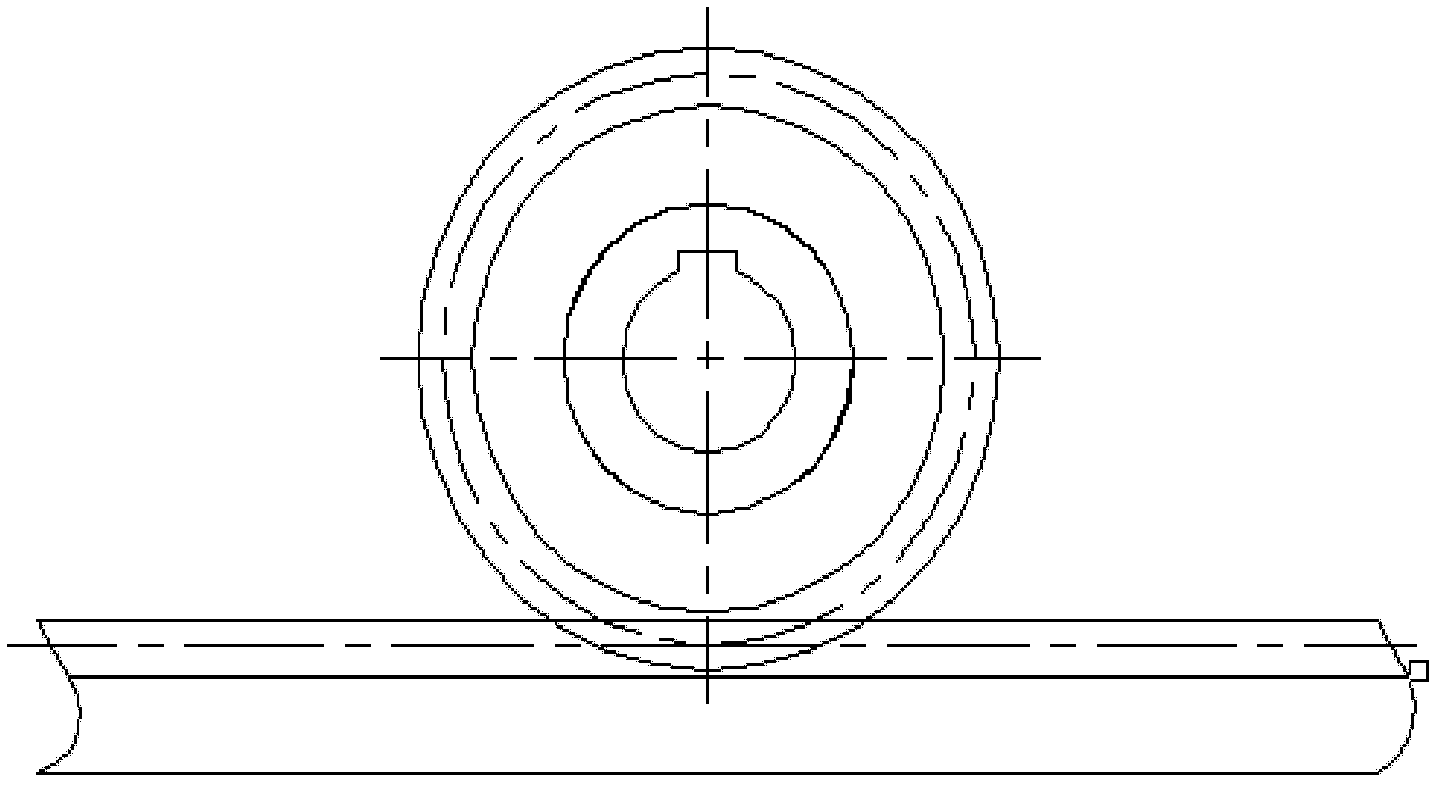

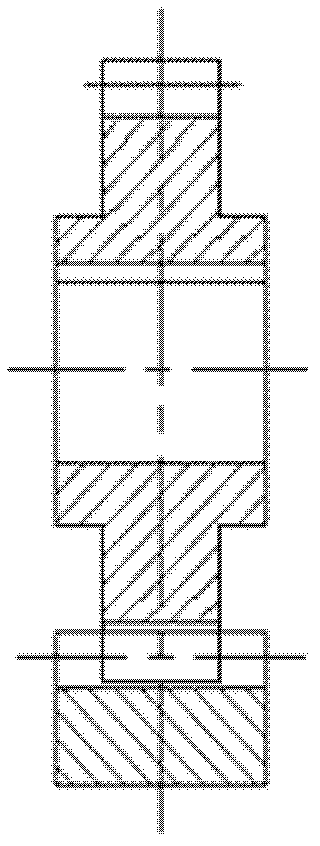

[0022] The parallel shaft gearbox belongs to the prior art. The motor 5 is fixedly connected to the right end face of the box of the parallel-shaft gearbox 1 by bolts through the end flange, and the input shaft 6 of the parallel-shaft gearbox 1 is directly connected to the output end of the motor 5 through a spline pair, and the parallel shaft The right end of the input shaft 6 of the gearbox 1 is installed on the right box wall of the gearbox 1 through the No. 1 cylindrical roller bearing 4 to form a rotational connection, and the right end of the output shaft 21 of the gearbox 1 is connected by the No. 2 cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com