Integrated structure clutch applied to gearbox

A technology for clutches and gearboxes, which is applied in the direction of fluid-driven clutches, clutches, and non-mechanical drive clutches. Reduced transmission efficiency and other issues, to achieve the effect of reducing weight, reducing shifting impact, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

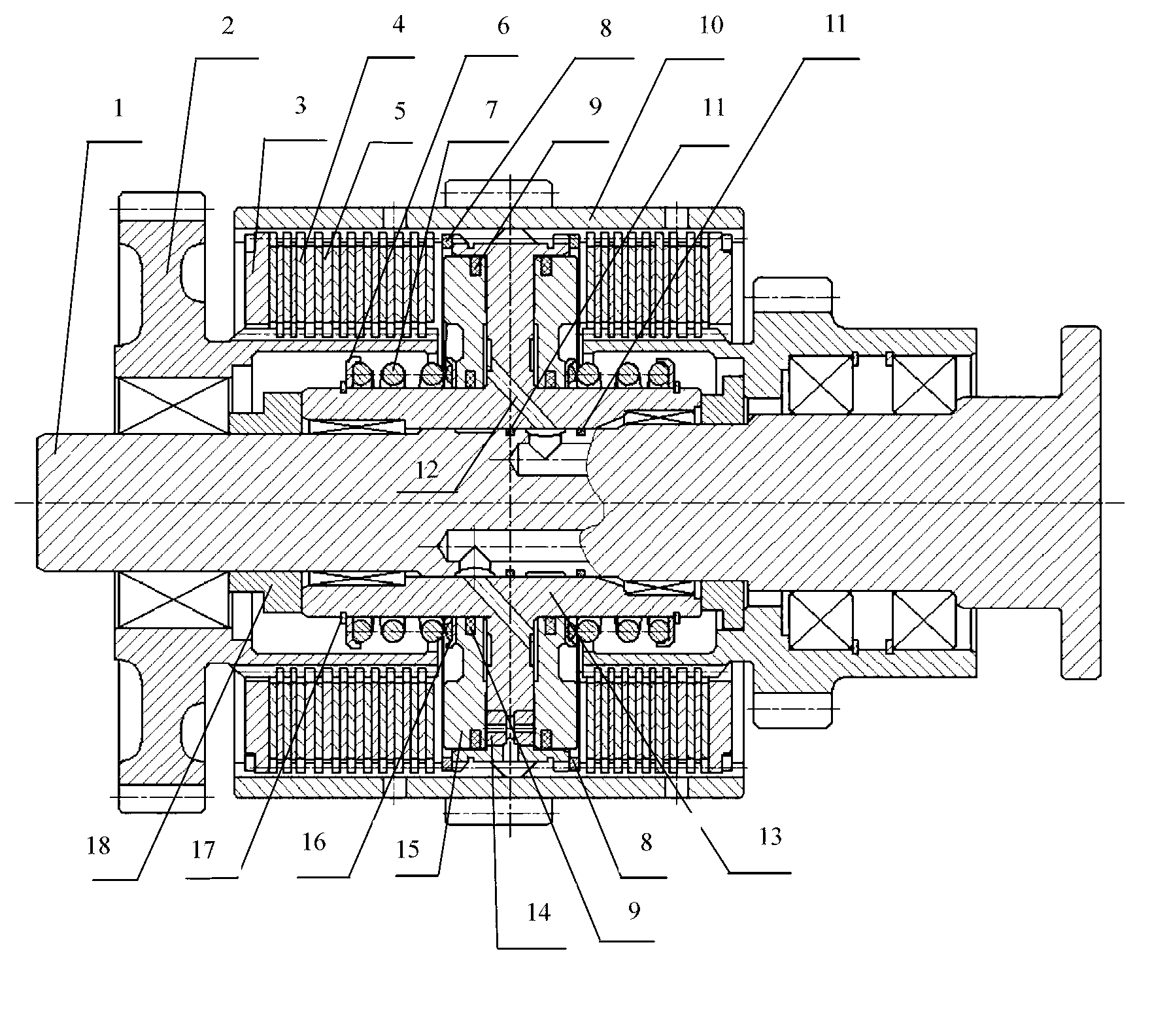

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] see figure 1 , the present invention includes a main shaft 1, a gear 2, a hydraulic system, a power transmission system, a return system and a housing 10, the main shaft 1 is fixed on the gearbox case, and the gear 2 is positioned on the main shaft 1 through a wear pad 18 Above, one end of the power transmission system is connected to the gear 2, the other end is connected to the housing 10, and at the same time, it is connected to the hydraulic system through the return system. The hydraulic system includes a piston 15, a piston seat 13 and an oil drain valve 14. The piston 15 is fixed on the piston seat 13 through a snap ring A8, and the seal between the piston 15 and the piston seat 13 is sealed by a sealing ring A9. The oil drain valve 14 is arranged at one end of the piston seat 13 . The piston seat 13 is fixed on the housing 10 through a snap ring A8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com