Compact work light with high illumination uniformity

a work light and uniform illumination technology, applied in the field of work lights, can solve the problems of large variation in light spilling out to a wide area, and high intensity of the circular spo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

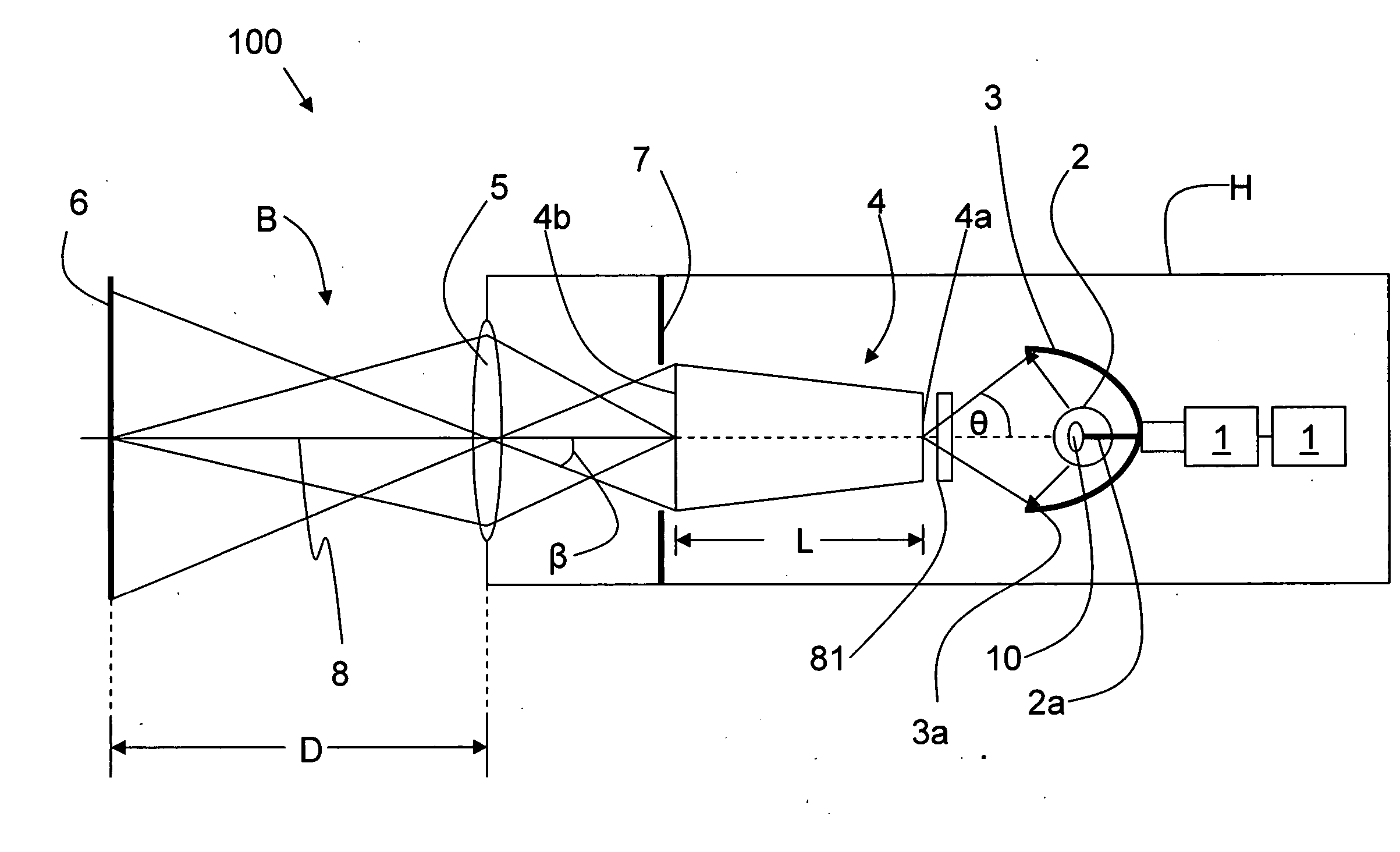

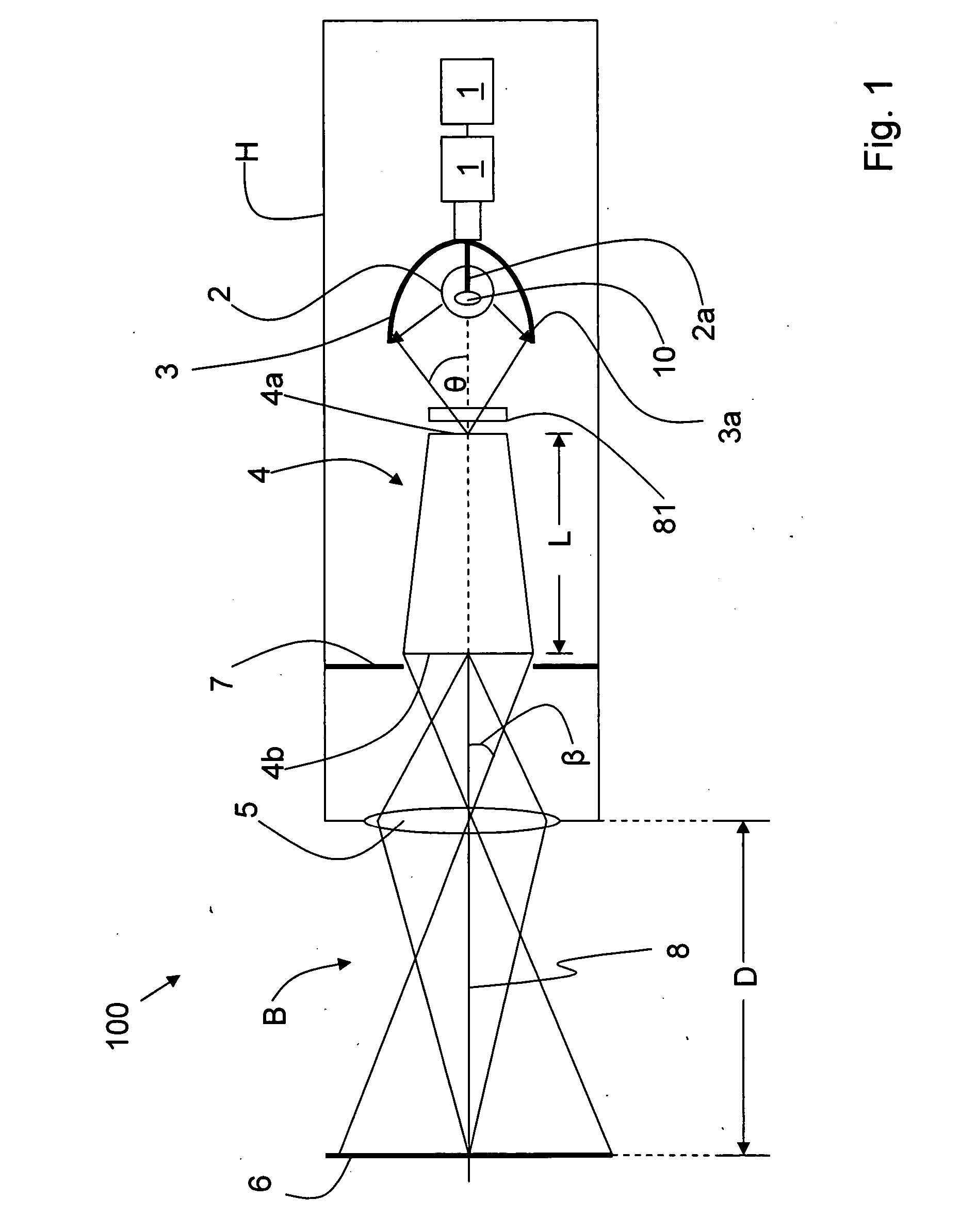

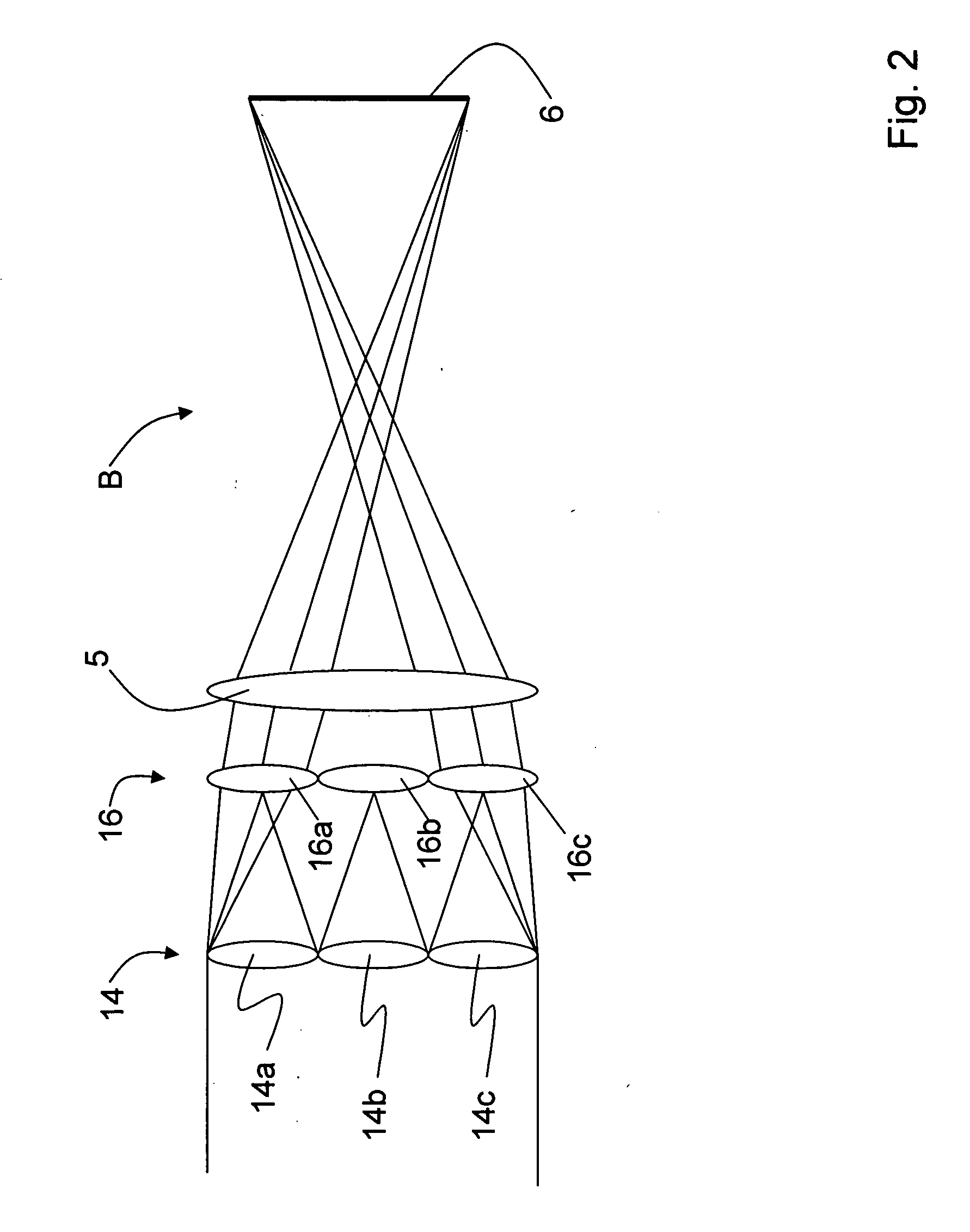

[0075] The present invention also includes a compact work light that provides bright, uniform illumination. The work light is adaptable for a variety of industrial, professional and personal applications, several examples of which are illustrated below.

[0076] Work Lamp

[0077] FIG. 9 is a schematic side view of an example embodiment of a work light according to the present invention in the form of a work light 500. Work light 500 includes flashlight 100 or a variation thereof, which is referred to hereinafter as just "light 100." Similarly, the beam generated by light 100 is referred to hereinafter as just "light beam B." Further, the image formed by light beam B at object 6 is also referred to as "beam spot BS."

[0078] In an example embodiment, light 100 is supported by a mount 502 attached to housing H. In an example embodiment, mount 502 is adjustable, and in an example embodiment includes an adjustable (e.g., a flexible) arm 504 having respective first and second ends 504A and 504B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com